Companies around the world, from major manufacturers down to your local grocery store, all share a common struggle: efficiently managing the movement of products and people. The business may slow down because storage isn’t organized, or forklift drivers aren’t sure which way to go. Every company could benefit from better organization, workflow, and safety. Enter floor marking.

Floor marking uses visual signals, such as lines, applied directly on the floor to provide information about a given area. Often, floor marking is used to identify aisles, walkways, or other spaces in warehouses and other industrial workplaces. Using specialized floor tape, paint, or even lighting systems, effective floor marking can enhance safety, streamline logistics, and improve organizational efficiency.

The photo of the day will outline the following :

- Floor Marking Requirements

- Applications for Floor Marking

- Floor Marking Tape Benefits

- How to Apply Floor Marking Tape

- Placement And Color Guide to Floor Marking

Floor Marking Requirements

OSHA’s general standard for workplace floors is 29 CFR 1910.22, titled “Walking and Working Surfaces.” The regulation requires these surfaces to be inspected periodically and kept clean, safe, and accessible. Additionally, where mechanical equipment such as forklifts are used, OSHA’s regulations for materials handling (in 1910.176) come into play. These rules require that safe clearances must be maintained, and permanent aisles and passageways must be appropriately marked.

These regulations don’t specifically require floor tape, painted lines, or other forms of floor marking; the rules are written to focus on the goal, rather than the method used to achieve it. However, floor marking can be an excellent way to move toward each of the goals laid out in the OSHA regulations. High-quality floor marking tape is cost-effective, highly visible, and withstands the abuse of warehouse traffic.

Applications for Floor Marking

While safety is a clear goal for floor marking, the same process can also be used to meet other important business needs. It can help facilities:

- Indicate where inventory should be stored

- Define loading and unloading areas for inventory

- Mark aisles, pathways, and hazardous areas

- Help visitors find their way around unfamiliar areas

- Direct the flow of traffic within the facility

Choose Floor Marking Tape for Your Facility

Companies are increasingly viewing floor marking as a component of the 5S lean manufacturing methodology. Essentially, it helps the Set in Order step. Everything is organized and has its place, from heavy machinery to garbage cans. Floor marking can cordon off these areas, or show employees where to find them.

While large companies may have more warehouse traffic, even small companies may have complex and confusing warehouse layouts. Both can benefit from floor marking to alleviate potential bottlenecks. For example, floor marking tape can clearly mark areas for pallets. If you can’t tell where to put the pallets, you’re wasting time, taking up valuable space, and compromising safety. With floor marking, you can organize the pallets based on their content or shipping destination.

Floor Marking Tape Benefits

Applying floor marking tape is quick and cost-effective, compared to painting floors. Stenciling or painting on a floor is messy. Basic paints wear off quickly under foot traffic, and tougher epoxy or enamel paints release fumes during application and curing that can require temporary closure of part of a facility. Preparation for painting, and waiting for paint to dry, can also impact productivity. Floor marking, by contrast, produces no fumes and needs no time to dry or cure.

All floor marking tape is not created equal. For heavy-duty facility traffic, Graphic Products has introduced a family of floor marking supplies that can take daily punishment from vehicles, enhance safety communication, and direct people to exits and entrances.

How to Apply Floor Marking Tape

It’s easy to apply floor marking tape, whether in a small facility or a large one. Follow this simple process:

- Prepare the floor surface by cleaning with soap and water

- Determine areas to be sectioned off including aisles, electrical boxes, storage areas, eyewash stations, fire extinguishers, garbage cans, recycling stations

- Measure area widths

- Determine floor marking tape colors and other supplies based on inventory, traffic flow patterns, areas needing specific boundaries for safety, height, available light in the facility, and corporate logos

- Load up applicator with floor marking tape

- Apply tape

- Clean with a damp mop

Floor Marking Placement

Floor marking should be used if there are two or more types of traffic, or as a way to make users aware of safety hazards. Floor marking is used to separate people from hazards, mark aisles and passageways, and establish safe zones and other specific traffic uses.

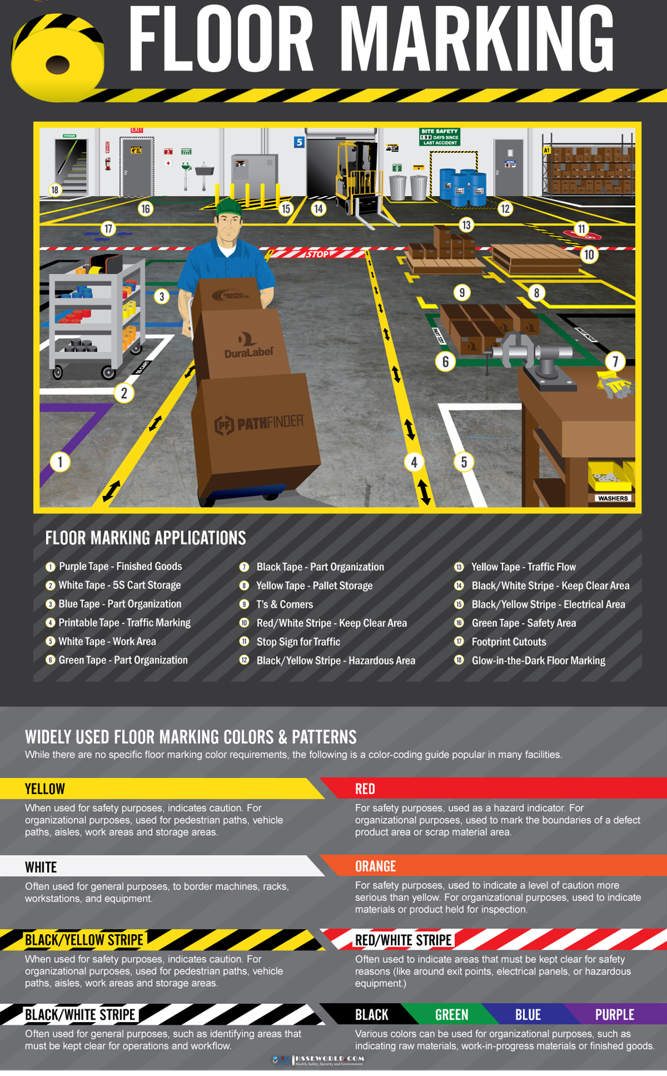

The following is a transcript of the Floor Marking Placement

Placement And Color Guide to Floor Marking

Floor Marking Applications:

- Purple Tape – Finished Goods

- White Tape – 5S Cart Storage

- Blue Tape – Part Organization

- Printable Tape – Traffic Marking

- White Tape – Work Area

- Green Tape – Part Organization

- Black Tape – Part Organization

- Yellow Tape – Pallet Storage

- T’s & Corners

- Red/White Stripe – Keep Clear Area

- Stop Sign for Traffic

- Black/Yellow Stripe – Hazardous Area

- Yellow Tape – Traffic Flow

- Black/White Stripe – Keep Clear Area

- Black/Yellow Stripe – Electrical Area

- Green Tape – Safety Area

- Footprint Cutouts

- Glow-in-the-Dark Floor Marking

Label Applications

- Fire Safety Label

- Door Safety Sign

- Emergency Eye Wash Label

- Dock Identification Label

- Forklift Safety Sign

- Rack & Shelf Labels

- Labeled Inventory Locations

- Shelf & Bin Labels

Widely Used Floor Marking COLORS & PATTERNS

While there is no specific floor marking color requirements, the following is a color-coding guide popular in many facilities.

YELLOW

When used for safety purposes, indicates caution. For organization purposes, used for pedestrian paths, vehicle paths, aisles, work areas and storage areas.

WHITE

Often used for general purposes, such as outlines around equipment or storage racks.

RED

For safety purposes, used as a hazard indicator. For organizational purposes, used to mark the boundaries of a defective product area or scrap material area.

ORANGE

For safety purposes, used to indicate a level of caution more serious than yellow. For organizational purposes, used to indicate materials or products held for inspection.

BLACK/GREEN/BLUE/PURPLE

Various colors can be used for organizational purposes, such as indicating raw materials, work-in-progress materials, or finished goods.

BLACK/YELLOW STRIPE

When used for safety purposes, indicates caution. For organizational purposes, used for pedestrian paths, vehicle paths, aisles, work areas, and storage areas.

BLACK/WHITE STRIPE

Often used for general purposes, such as outlines around equipment or storage racks.

RED/WHITE STRIPE

Often used to indicate areas that must be kept clear for safety reasons (like around exit points, electrical panels, or hazardous equipment).

Download the photo

Now you can download the Infographic ” Floor Marking” and post it at the workplace and communicate with everyone to be familiar with the types of Floor marking and how to place it at the workplace.

Photo of the day: Floor Marking

More photos:

- What are the Best Practices for Managing Subcontractor Risk

- Photo of the day: 10 Essential Safety Tips for Driving in Hot Weather Conditions

- Photo of the day: best workplace safety tips

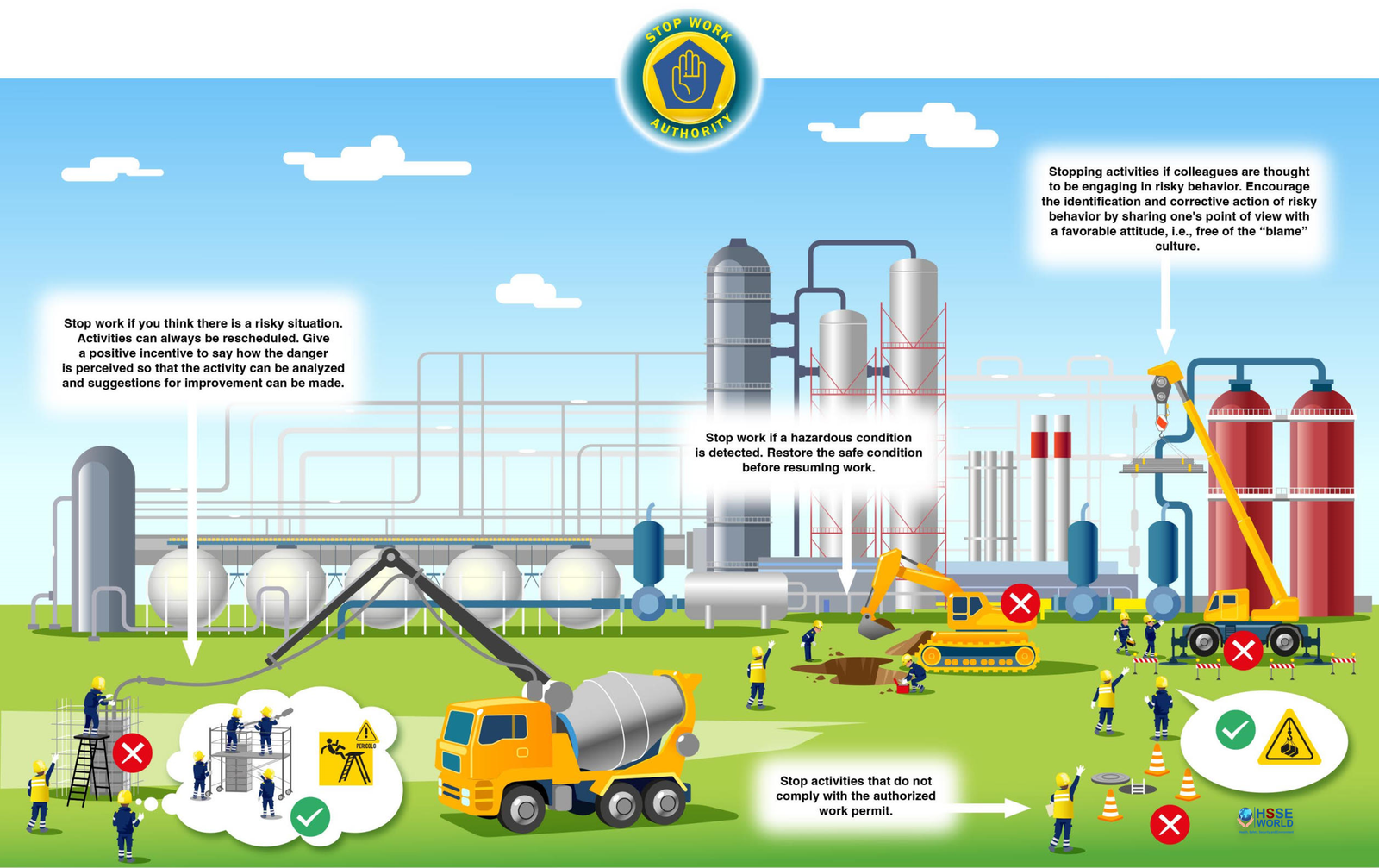

- Photo of the day: The Importance of Stop Work Authority in Maintaining Workplace Safety

- Photo of the day: Tomorrow’s Reward for Working Safely Today: Cultivating a Culture of Safety

- Photo of the day: Preventing slips and trips at work

- Photo of the day: Learn the DRSABCD action Plan

- Working with Electricity Electrical Accidents Guide for Electrical Workers

- Photo of the day: Hearing Protection Device Selection

- Photo of the day: If An Earthquake Shakes You-Infographic free

- Fire Safety Posters Free Download

- Photo of the day: First Aid for Electrical Burns-Infographic free

- Infographic: First Aid for Cuts and Scrapes free download

- Photo of The day: Work Safe with Lasers-Laser Safety free

- Photo of the day: Working Safely with chemicals and chemical Management

- Photo of the day: Safe work practices when using MEWPs ( updated)

- Photo of the day: Preventing Common Kitchen Hazards

- Photo of the day: Safe handling of Gas Cylinders and lecture bottles

- Photo of the day: Forklift Stability Triangle

- Photo of the day: Defective Tools Safe Work Practice

- Photo of the day: Lift With Your Legs Not With Your Back

- Photo of the day: First Aid for burns

- Photo of the day: The 7 Principles of HACCP

- Photo of the day: Working Safely with Suspended Loads

- Photo of the day: Heat Stroke First Aid and safety posters

- Photo of the day: Near-Miss Reporting and Posters

- Photo of the day: Ergonomic chair and office chair safety tips

- Photo of the day: Whole Body Vibration

- Photo of the day: Substation Safety Equipment

- Photo of the day: Bypassing Safety Controls Rules

- Photo of the day: Lightning Safety Tips

- Photo of the day: Overhead Power lines Clearance

- Photo of the day: Floor Marking

- Photo of the day: Types of Foot Protection

- Photo of the day: Types of Hand Protection

- Photo of the day: Lockout and Tagout Safety

- Photo of the day: Fall Protection Plans

- Photo of the day: Flood Safety Tips

- Photo of the day: Read All Labels Work safe

- Photo of the day: Run Project safely with Crane Hand Signals

- Photo of the day: Flagman and Traffic control

- Photo of the day: Managing Risks of Exposure to Solvents in the workplace

- Photo of the day: Scissor Lift Safety

- Photo of the day: HSE Bulletin Board

- Photo of the day: Arc-Fault Circuit Interrupters (AFCI)

- Photo of the day: Safe use of ladders and step ladders

- Photo of the day: Concrete Truck Driver Hand Signals

- Photo of the day: Extension Cord Safety Tips

- Photo of the day: Protect your Head

- Photo of the day: choosing the right Anchorage

- Photo of the day: Work-Related Asthma

- Photo of the day: Top FIVE Heavy Equipment Construction Site Safety Tips

- Photo of the day: sun safety in the workplace

- Photo of the day: Cannabis and Impairment in the Workplace

- Photo of the day: Position for safety and comfort-Safety Tips

- Photo of the day: Generator Safety

- Photo of the day: Controlling COVID-19 in the Workplace-Physical Barriers

- Photo of the day: Manual Material handling

- Photo of the day: Personal Protective Equipment last resort

- Photo of the day: WHMIS 2015 – Pictograms

- Photo of the day: Indoor Air Quality

- Photo of the day: Noise in the affected workplace

- Photo of the day: Fatigue at Work

- Photo of the day: Don’t be Driven to Distraction

- Photo of the day: working in heat and Humidex Rating

- How to use Plate Clamps Safely: Safety Moment#34

- Photo of the day: Sitting at work

- Photo of the day: 5 ways to reduce the risk of Slipping and Tripping

- Photo of the day: Preventing the spread of contagious illness

- Photo of the day: Incident Investigations

- Photo of the day: 10 Scaffold Safety Essentials

- Photo of the day: Effective Health and Safety Committees

- Photo of the day: New worker Orientation & Safety Orientation checklist

- Photo of the day: Workplace Inspection

- Photo of the day: musculoskeletal disorders

- Photo of the day: Emergency preparedness in the workplace

- Photo of the day: Mental health in the workplace

- Photo of the day: Trenching Safety Tips That Can Save a Life

- Photo of the day: Dangerous Goods Classes

- Photo of the day: Safety Equipment for Confined Spaces

- Photo of the day: Tips to reduce Heat stress in the workplace

- Photo of the day: hierarchy of controls

- Your steps to chemical safety

- H2S Gas and how to handle its Emergency

- Photo of the day: Importance of Mock drill and Fire Action Emergency Procedure

- Photo of the day: Choosing the Right Face Mask and the difference between a respirator and face mask

- Photo of the day: Confined space safety Precautions

- Breath Safely: The Proper Use of Respiratory Protection

- Photo of the day: Electric shock survival

- Photo of the day: Chemical Spill Emergency Response

- Photo of the day: Construction Site fire Safety

- Photo of the day: Confined Space rescue

- Photo of the day: Conveyors Safety Tips