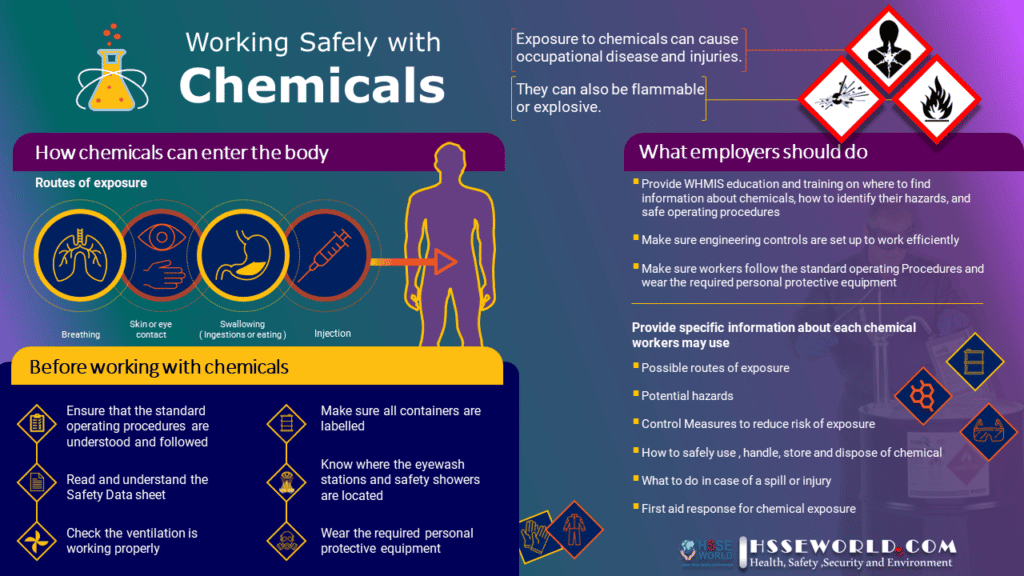

Photo of the day: Working Safely with chemicals and chemical Management

19 min readchemicals come in various forms and can affect those exposed in different ways. A chemical can take the form of a mist, vapor, liquid, dust, fume, or gas. The type of chemical, the way it is used, and the form that it takes determine its effect and what should be done to avoid harmful exposure. a comprehensive Chemical Management program allows all sites to be fully compliant with all applicable Environment, Health, and Safety (EHS) and Chemical Management requirements. this article and photo of today specify how information is provided to employees who work with chemicals ensuring that they are informed about hazardous materials in their workplace and the information they need to protect their health and safety. after reading you will be familiar with:

- General Requirements.

- Labeling

- Chemical Sweep

- Chemical Inventory and Approved/Prohibited Chemical Lists.

- Safety Data Sheets (SDS).

- Contractor Use of Chemicals.

- General Chemical Handling.

- General Chemical Storage.

- Flammable & Combustible Liquids, Gases, and Explosive Mixtures.

- Control and Handling of Corrosive Liquids.

- Compressed Gas Cylinders Handling and Storage.

- Control and Handling of Cryogenic Liquids.

- Records.

- Training.

- Auditing

Also Read: Photo of the day: WHMIS 2015 – Pictograms

Chemical Management is the process by which those materials designated as hazardous (based on regulations) are controlled at the site level.

General Requirements

- Each site must designate a Chemical Management Lead to implement this program. The name of this person is listed in SITE-SPECIFIC CHEMICAL MANAGEMENT INFORMATION LIST. ( Download )

- In addition, sites shall be familiar with and adhere to local regulations (including fire regulations). In cases of discrepancies, the most stringent requirement shall be followed.

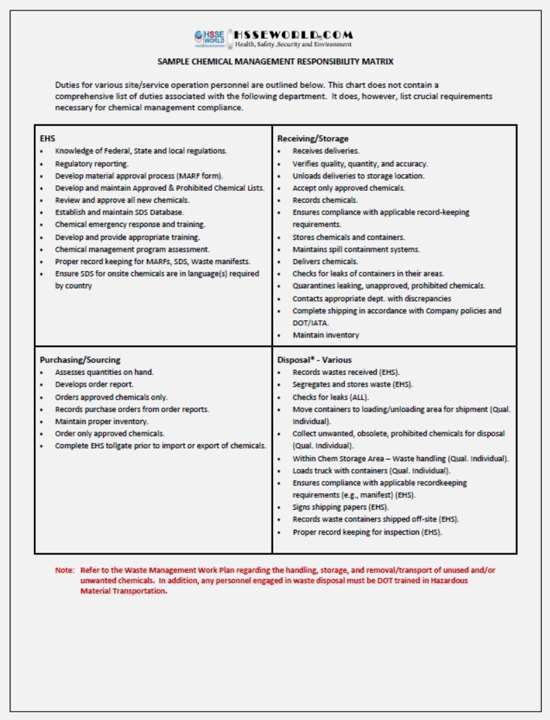

- Sites should clearly define responsibilities under the Chemical Management program. A sample Responsibility Matrix is provided HERE of this procedure, which sites should modify to reflect which personnel or departments are responsible for various Chemical Management activities at the site.

- When working with chemicals, the following general safety precautions shall be followed:

- Keep the work area clean and orderly; proper housekeeping

- Conduct regular reviews to limit the volume and toxicity of chemicals to the minimum needed, especially volatile, flammable, toxic, or carcinogenic chemicals.

- Have spill response equipment nearby in case the container leaks or is accidentally spilled; (refer to Emergency Response Planning for Hazardous Material )(Tips for Chemical spills Preparation and Incident Response)

- Each work site is required to have a copy of the current regulations with respect to Hazard Communication and Chemical Management, either in hard copy or electronically.

- Evaluation of certain chemicals at the site may require an Industrial Hygiene assessment.

- Each site must maintain an inventory list of the hazardous chemicals that are present at the site, as required by Hazard Communication regulations.

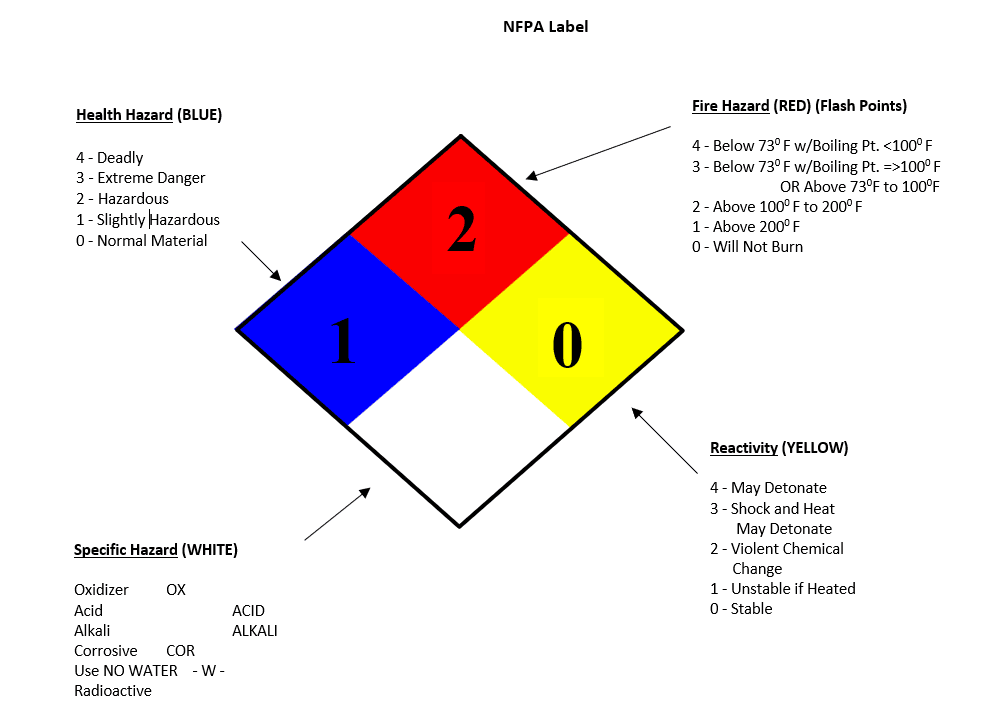

Labeling

- All chemical containers (primary and secondary) must be labeled appropriately in accordance with all regulations (e.g. HAZCOM, COSHH, WHIMIS). Examples of the labels used for this site can be found in Appendix A ( Download )

- Additional labeling may be required, including, but not limited to, hazardous waste in satellite and long-term storage, PCB waste, equipment containing Class I ozone-depleting substances, etc.

- (China only) Non-dangerous chemicals have separate labeling requirements. Ensure labeling for hazardous chemicals is distinct from non-dangerous chemicals.

- Labels shall not be removed unless the container is unless the container is empty and has been decontaminated. Defaced or illegible labels shall be replaced and properly filled out according to regulatory requirements.

- All labels will be legible, in the local language, and prominently displayed on the container.

- Employees with questions concerning the appropriate label to use must contact the Site Chemical Management Lead or EHS Representative.

- The Site EHS Representative and employees must ensure that label information on the chemical containers is consistent with a chemical documents such as an SDS and site-approved chemical list

- Piping systems that contain chemicals shall be labeled in accordance with local, country, or accepted industry standards (i.e. ANSI/ASME A13.1).

- All chemical piping shall be labeled so that it can be seen from every valve, union, hose connection, and joint. Specify the labeling system that is applicable to your site in Appendix A.

- Piping labeling shall be performed for all new installations or when modifications are made to existing piping systems.

Also Read:Photo of the day: Read All Labels Work safe

Chemical Sweep

- A chemical sweep shall be conducted annually at each work site. This task shall be tracked using Compliance Calendar.

- The focus of the chemical sweep will be to:

- Ensure that the site-approved chemical list is complete and accurate,

- Remove chemicals from the list that are no longer at the site and no longer used at customer sites by the site personnel,

- Evaluate the need to keep chemicals on the list whose Purchasing Approval is expired. If needed, update Purchasing Approval Date,

- Identify chemicals that are not listed on the approved chemical list but should be added and take action to get them listed,

- Remove and quarantine materials that are not listed on the approved chemical list and should not be added,

- Ensure that materials are labeled properly and stored correctly including proper segregation of incompatible chemicals,

- Identify opportunities to reduce chemical exposure to employees,

- Identify opportunities to substitute chemicals used with less-hazardous or less toxic alternatives or more sustainable alternatives, and

- Properly dispose of materials that are over-stocked, expired, off-spec, contaminated, or otherwise considered unusable.

- Unresolved issues identified during a chemical sweep will be addressed with a corrective action plan and tracked to closure using the Audit Tracking System.

- In addition to the annual chemical sweep, regular housekeeping inspections, should identify and remove un-labeled or incorrectly containerized and stored chemicals.

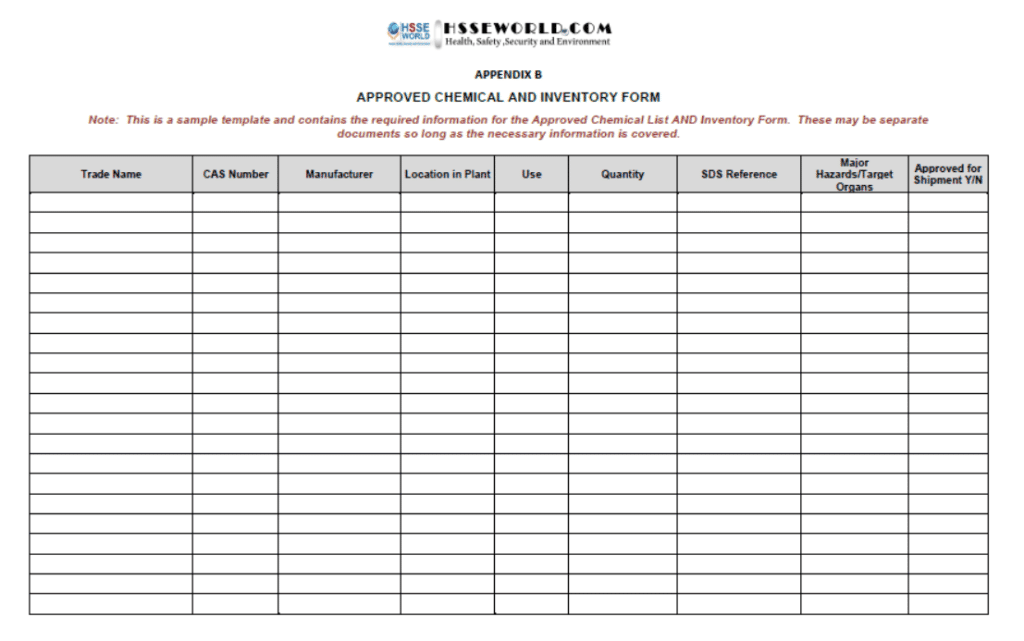

Chemical Inventory and Approved/Prohibited Chemical Lists

- Each Work site must maintain an inventory list of the hazardous chemicals that are present at the site.

- This inventory should be maintained electronically so it is searchable and can be updated easily. The system utilized to manage the chemical inventory is identified in SITE-SPECIFIC CHEMICAL MANAGEMENT INFORMATION LIST. ( Download ).

- The chemical inventory must include at least the following information for each product on the chemical inventory:

- Product name,

- Chemical name,

- Supplier,

- Area(s) where the product is used in the site or service operation, and

- The quantity used and/or stored at the site or service operation.

Note: Refer to Appendix B for a sample Chemical Inventory Form. ( Download from HERE )

- The initial chemical inventory should be generated from the initial chemical sweep, as described in this procedure. This chemical inventory will include all chemicals identified on site.

- Chemicals on this list and new chemicals shall be checked against:

- Regulatory lists, such as but not limited to, Extremely Hazardous Chemicals, TRI, PRTR.

- Company Targeted chemical lists.

- Limitations on storage capacities recommended to checking local building or fire codes.

- The chemical inventory will be maintained based on previous inventories and the changes to material usage at the site/service operation or the prohibited chemical list.

- New materials will be reviewed using the Material Approval Request Form (MARF),

- The chemical inventory will be the site’s initial ‘Approved Chemical List (ACL). New chemicals can be added to the ACL after they have been approved, per Chemical Procurement. Chemicals that are phased out will be deleted from the ACL when they are no longer needed and/or present.

Also Read: Hazard Communication and Health Hazards

Safety Data Sheets (SDS)

- Each work site shallmaintain an electronic (preferred) or hard copy SDS for each hazardous chemical that is used on site. The location of the site’s hard copy and/or electronic SDS is listed in SITE-SPECIFIC CHEMICAL MANAGEMENT INFORMATION LIST. ( Download ).

- SDS shall be made available to all shifts. If SDS is kept electronically, then employees must know how to gain access to SDS.

- All chemicals brought to a customer site must have the appropriate SDS available at the site.

- Sites shall ensure SDSs are in country’s required language(s). SDSs for onsite chemicals can be obtained in the required language by one of the following methods:

- Using the SDS “fetch system.”

- Contacting the manufacture or supplier and request necessary SDS

- Searching company electronic system for existing SDS

- Utilizing a consulting firm to translate

- When it is necessary for SDS to be translated by the Business EHS HQ via a translation service, the translated version should always be attached to the original language version of the SDS. The following statement should be included on the translated version in English and the translation language: ‘This Safety Data Sheet has been translated from the language in which it was originally created. FieldCore accepts no liability for any errors in translation.”

- SDSs must be current; no more than 3 years old if the manufacturer has updated the SDS.

- For sites that utilize the SDS electronic System, SDS are updated automatically.

- For sites not using the SDS electronic system, dates must be verified with the manufacturer as the most recent following each chemical sweep.

- Should a site find a newer version of an SDS than is available on the SDS electronic System, they should send a copy to the company Chemical Management Lead, who will ensure that the SDS electonic System is updated. .

- SDS for new chemicals that are approved at the site will be added to the site or service operation’s hard copy or electronic records as soon as the chemical is approved .

Also Read: E-Books:Preparation safety data sheets for hazardous chemicals

Contractor Use of Chemicals

- Contractors may bring chemicals on site with approval of the Chemical Management Lead and company Contact for the contractor. Obtain approval before bringing the chemical to the site. The pre-job meeting should include a discussion of the following:

- What chemicals will be allowed on site,

- Verification that SDS are available on site for all chemicals to be used,

- Review of proper chemical storage and labeling, and

- Disposal of waste materials.

General Chemical Handling

- Prior to handling any chemical product, the Material Safety Data Sheet, and other related information provided by the manufacturer should be thoroughly reviewed.

- All safety precautions must be observed and all employees must be knowledgeable on the emergency actions to take in the event of a spill, as well as the location of eyewash or safety shower stations and exits. ( Read: Eyewash and Emergency Shower Safety ).

- Sites should attempt to minimize the number of employees that handle hazardous chemicals. This reduces the potential for exposure, reduces training and PPE requirements and costs, and helps to ensure consistency in handling practices, labeling, disposal, and spill clean-up and reporting.

- Health and safety issues are a primary concern when addressing chemical handling issues. Chemical handling concerns should be addressed in each Safety Risk Assessment (SRA) or Job Safety Analysis (JSA) developed at the site in order to reduce risks associated with chemical handling .

General Chemical Storage

- All chemicals must be stored and used in approved containers, which are compatible with the material and in good condition. These containers must be labeled with the contents and hazards.

- Liquids that are adjacent to drains or being dispensed should include appropriate secondary containment during storage (i.e., 55 gallon drums should be stored on spill pads or in flammable cabinets). Outdoor areas should be covered to prevent contact of containers with precipitation unless a drainage system is installed to properly direct potentially contaminated stormwater to appropriate treatment and handling.

- Chemical storage requirements and information can be found on each material’s SDS.

- Incompatible chemicals must be stored so that they do not come into physical contact with one another (e.g. flammables and oxidizers, acids and caustics).

- Primary and secondary containers shall be labeled according to government regulations. Refer to Appendix C of this procedure for an example of approved labeling.

- (China only) Alarm and communication systems shall be established near chemical storage areas.

- Chemical storage in certain quantities may trigger other regulatory requirements (e.g. US Spill Prevention Countermeasures and Controls (SPCC), Process Safety Management (PSM), UK Control of Major Accident Hazards (COMAH)). The quantity and storage limitations shall be taken into account during the chemical review process. If unsure of regulatory triggers, contact business EHS HQ.

Flammable & Combustible Liquids, Gases and Explosive Mixtures

General

- RequirementsApproved metal safety cans are required when the quantity of flammable liquid being handled or used is greater than one gallon. Storage tanks, including 55-gallon drums mounted on racks for dispensing flammable or combustible liquids, shall be electrically interconnected (bonded) and grounded.Transfer of flammable liquids from one container to another shall be done only when the containers are electrically interconnected (bonded) and grounded.

- Storage of flammable and combustible liquids outside of a cabinet or storage room should be limited to a quantity necessary for current work operations.

- Store flammable and reactive materials at least 50 feet (17 meters) inside the facility property line.

- Storage rooms inside buildings for flammable and combustible liquids shall be constructed to meet building fire code requirements including materials of construction, appropriate fire suppression systems and ventilation. Ventilation shall be provided to ensure that both lighter-than-air vapors (rise to ceiling) and heavier-than-air vapors (descend into depressions) are properly evacuated with a minimum of 6 air changes per hour.

- Storage of flammable and combustible liquids in containers adjacent to buildings shall not exceed 1,100 gallons in any one area unless approved and permitted as necessary by local regulations or Fire Marshall. The storage area shall be graded to contain possible spills and divert material away from buildings. Storage areas for flammable and combustible liquids shall be located at least 20 feet from any building and be kept free of weeds, debris, and unnecessary combustible materials to allow for regular inspections of its integrity and for any possible leaks.

- Flammable liquids shall be kept in closed, properly labeled containers when not in use.

- Conspicuous and legible signs prohibiting smoking shall be posted in service, refueling, tank/drum storage areas, paint booth areas, and/or specified locations for handling and usage of flammable materials. Signs in the area shall be posted warning of “No Smoking Within 50 Feet” (or less or as required by local regulations.)

- Combustible materials such as wood, pallets, packaging material, trash dumpsters, etc. shall not be stored near flammable storage.

- Flammable cabinets shall be:

- As a best practice, if the flammable cabinet is manufactured with a grounding screw or landing, then ground appropriately in accordance with the manufacturer’s instructions. DO NOT modify a flammable cabinet (drill holes, attached ground landing, etc. in order to ground it.

- Clear of combustible materials inside, on top of, or around;

- Contain no open containers (e.g. paint cans, varnish cans);

- Labeled as a “Flammable – Keep Fire Away”;

- Construction shall comply with government regulations; and

- Storage limitations may not exceed the following or the design capacity of the cabinet;

- 60 gallons of flammable materials, or

- 120 gallons of combustible materials.

- Fire extinguishers for flammable and combustible liquid storage areas are required as follows:

- At least one fire extinguisher shall be located outside of, but not more than 10 feet, from the door opening into any room used for storage of more than 60 gallons of flammable or combustible liquids.

- At least one fire extinguisher shall be located not less than 25 feet, nor more than 75 feet, from any flammable liquid storage areas located outside.

Also Read: Flammable Liquid Storage -Safety Moment #1

Hydrogen

- Personnel should not start work or should immediately cease work on or near hydrogen-cooled generators, synchronous condensers or accessories, and piping known or suspected to be leaking hydrogen and should immediately report the suspected leak to their supervisor or manager.

- Any work or activity that could potentially cause leaks should not be done on hydrogen-filled generators, synchronous condensers or accessories, and piping. An example of such work is the drilling of holes for attachment of nameplates.

- No work on or near hydrogen-cooled generators, synchronous condensers or accessories, and piping shall be started until the system has been purged with an inert gas and air and assurance has been obtained that hydrogen is not present and cannot enter the equipment by any means (e.g., due to leakage or faulty operation of valves, etc.). Also, ensure proper lockout/tagout has been performed before any work is to be conducted.

- Those areas in which a large volume of hydrogen is delivered to an open-ended circuit must have appropriate hydrogen detection devices installed to detect a leak prior to it reaching a concentration in the air of 1% by volume which is 25% of the lower explosive limit (LEL).

Also Read: Chemical Risk Assessment form

Liquefied Petroleum Gas

- (LPG)LPG must be stored and used in well-ventilated areas and away from heat, ignition sources, and oxygen and chlorine cylinders.

- Each LPG system shall have approved containers, valves, connectors, manifold valve assemblies, and regulators.All LPG cylinders shall meet Department of Transportation (DOT) or applicable regulations and specifications.

- Every LPG container and vaporizer shall be provided with at least one approved safety relief device.

- Portable LPG heaters shall be equipped with an approved automatic device to shut off gas flow in case of flame failure.

- LPG shall not be stored within buildings, unless the following criteria is met:

- LPG is for welding or cutting purposes;

- Total LPG gas capacity is less than 300 pounds;

- LPG is actively in use or attached ready for use.

- LPG storage locations shall be provided with at least one 20-pound fire extinguisher rated for flammable or combustible gases, such as a powder fire extinguisher.

Read: E-Books:Guidelines for Gas cylinders safety(

Natural Gas (Methane)

- When contained and not mixed with air or other oxidizing agents, natural gas is stable under normal storage and handling conditions.

- When mixed with air, it readily becomes flammable or explosive.

- Cylinders must be stored in well-ventilated and low fire hazard areas.

- Ground all lines and equipment used with natural gas to prevent static sparks.Use non-sparking tools, and allow no smoking where natural gas is used or stored.

Also Read:Compressed Gases Safety Tips

Control and Handling of Corrosive Liquids

- Safety showers and eyewash stations shall be provided in accordance with ANSI Z358.1-2004.

- Within 25 feet of work areas where corrosive liquids are used or stored.

- Showers shall have deluge-type heads and quick opening or automatic valves.

- Formal preventive maintenance operational checks on all showers and eyewashes shall be performed weekly and shall be documented accordingly.

- Temporary conditions may be ventilated by portable equipment, or personnel should wear respirators approved for the type and concentration of the contaminant. Further guidance on ventilation is provided in Introduction to industrial ventilation.

- Corrosives shall be stored in the original container or poly drums, unless otherwise indicated by manufacturer.

- Unless the results of a reaction are definitely known, corrosive liquids shall not be mixed with other chemicals.

- Acid should always be added to water, not water to acid. The addition should be done slowly with constant stirring. The diluting of acids with water can generate considerable heat and may result in a violent reaction.

- Depending on the severity of exposure, employees should wear the following impervious protective clothing while handling corrosives:

- Chemically resistant rubber or plastic gloves,

- Rubber or plastic chemical goggles. If complete face protection is required, plastic face shields should be worn in addition to the chemical goggles. A face shield is not a substitute for chemical goggles,

- Chemically resistant rubber boots or overshoes, or shoes with resistant soles, depending on the nature of the exposure,

- Rubber aprons and/or acid suit, depending on the nature of the exposure. The apron should cover the top of the boot,

- Suitable head protection in the form of protective helmets and/or chemically resistant hoods, depending on the nature of the exposure, and

- For severe conditions requiring full protection, a Level C HazMat suit is required including a full-face air-purifying respirator, chemical resistant hood, coat, and overalls, inner and outer chemical resistant gloves, chemical resistant safety boots, and hardhat. Atmospheric concentration of chemicals must not exceed the IDHL and the atmosphere must contain at least 19.5% oxygen.

If you have questions, contact Site EHS Representative or refer to the applicable Safety Risk Assessment (SRA) / Job Safety Analysis (JSA) and SDS.

Compressed Gas Cylinders Handling and Storage

- Label cylinder storage areas appropriately.

- Label the contents of a compressed gas cylinder on the cylinder.

- When the cylinder is not connected for use, place the metal cap to protect the cylinder valve.

- Open the cylinder valve slowly.

- Before removing a regulator from a cylinder, close the cylinder valve and release the gas from the regulator.

- Do not take cylinders into process vessels, tanks, unventilated rooms or other confined spaces. This requirement does not apply to gas cylinders associated with self–contained breathing apparatus.

- When cylinders are connected to a process where there is the potential for backflow of process materials to contaminate the cylinder, use a check valve or other suitable device to prevent backflow into the regulator.

- Store cylinders upright and fasten them securely to prevent falling.

- Store oxygen cylinders at least 20 feet (6.1 meters) from cylinders containing flammable gases or place a firewall rated for at least 30 minutes between the cylinders.

- Do not store cylinders near sources of heat, such as radiators or furnaces, or near highly flammable substances, like gasoline.

- Label empty cylinders or separate them from full cylinders.

- When handling cylinders, consider them to be full.

- Transport cylinders only when they are secure and in the upright position.

- Do not roll or drag cylinders.

Note: Do not drop cylinders or allow them to strike violently.

Also Read: Photo of the day: Safe handling of Gas Cylinders and lecture bottles

Control and Handling of Cryogenic Liquids

- Skin contact with cryogenic liquids should be avoided through use of engineering controls for processes that contain liquids and PPE (e.g. appropriate protective gloves, face shield, apron, etc.).

- Evaporation of any quantities of cryogenic liquid into an enclosed space should be avoided. In a workspace this may present an asphyxiation hazard due to lack of or excess of oxygen. In a container an explosion hazard could be created due to high pressures that can be generated.

- Handling and transfer of cryogenic liquids should always take place in appropriate dewars, with gloves and face shield for splash protection where splashes of the cryogenic liquid are expected.

Records

Recordkeeping requirements under the Chemical Management Procedures include

- SDSs or similar documents must be retained for 30 years after the last use of the material. The electronic SDS system accommodates this retention requirement.

- Chemical Exposure records including Industrial Hygiene monitoring shall be maintained indefinitely. Records related to specific employees should accompany their personnel files.

- Records related to chemical reporting requirements such as US Tier I/II reporting shall be maintained indefinitely.

Training

- Procedural training is required for all site employees who are involved in purchasing, handling, shipping, receiving, and storing of chemicals.

Auditing

- Each work site shall subjected to an annual audit of the site’s Chemical Management program and track all findings to closure.

- company HQ Personnel shall annually review and update the ES Chemical Management procedures if necessary.

Also Read: Tool Box Talk: Don’t Let Chemicals Get to You

Download Infographic

Working Safely with chemicals

More Photos

- Photo of the day: 10 Essential Safety Tips for Driving in Hot Weather Conditions

- Photo of the day: best workplace safety tips

- Photo of the day: The Importance of Stop Work Authority in Maintaining Workplace Safety

- Photo of the day: Tomorrow’s Reward for Working Safely Today: Cultivating a Culture of Safety

- Photo of the day: Preventing slips and trips at work

- Photo of the day: Learn the DRSABCD action Plan

- Working with Electricity Electrical Accidents Guide for Electrical Workers

- Photo of the day: Hearing Protection Device Selection

- Photo of the day: If An Earthquake Shakes You-Infographic free

- Fire Safety Posters Free Download

- Photo of the day: First Aid for Electrical Burns-Infographic free

- Infographic: First Aid for Cuts and Scrapes free download

- Photo of The day: Work Safe with Lasers-Laser Safety free

- Photo of the day: Working Safely with chemicals and chemical Management

- Photo of the day: Safe work practices when using MEWPs ( updated)

- Photo of the day: Preventing Common Kitchen Hazards

- Photo of the day: Safe handling of Gas Cylinders and lecture bottles

- Photo of the day: Forklift Stability Triangle

- Photo of the day: Defective Tools Safe Work Practice

- Photo of the day: Lift With Your Legs Not With Your Back

- Photo of the day: First Aid for burns

- Photo of the day: The 7 Principles of HACCP

- Photo of the day: Working Safely with Suspended Loads

- Photo of the day: Heat Stroke First Aid and safety posters

- Photo of the day: Near-Miss Reporting and Posters

- Photo of the day: Ergonomic chair and office chair safety tips

- Photo of the day: Whole Body Vibration

- Photo of the day: Substation Safety Equipment

- Photo of the day: Bypassing Safety Controls Rules

- Photo of the day: Lightning Safety Tips

- Photo of the day: Overhead Power lines Clearance

- Photo of the day: Floor Marking

- Photo of the day: Types of Foot Protection

- Photo of the day: Types of Hand Protection

- Photo of the day: Lockout and Tagout Safety

- Photo of the day: Fall Protection Plans

- Photo of the day: Flood Safety Tips

- Photo of the day: Read All Labels Work safe

- Photo of the day: Run Project safely with Crane Hand Signals

- Photo of the day: Flagman and Traffic control

- Photo of the day: Managing Risks of Exposure to Solvents in the workplace

- Photo of the day: Scissor Lift Safety

- Photo of the day: HSE Bulletin Board

- Photo of the day: Arc-Fault Circuit Interrupters (AFCI)

- Photo of the day: Safe use of ladders and step ladders

- Photo of the day: Concrete Truck Driver Hand Signals

- Photo of the day: Extension Cord Safety Tips

- Photo of the day: Protect your Head

- Photo of the day: choosing the right Anchorage

- Photo of the day: Work-Related Asthma

- Photo of the day: Top FIVE Heavy Equipment Construction Site Safety Tips

- Photo of the day: sun safety in the workplace

- Photo of the day: Cannabis and Impairment in the Workplace

- Photo of the day: Position for safety and comfort-Safety Tips

- Photo of the day: Generator Safety

- Photo of the day: Controlling COVID-19 in the Workplace-Physical Barriers

- Photo of the day: Manual Material handling

- Photo of the day: Personal Protective Equipment last resort

- Photo of the day: WHMIS 2015 – Pictograms

- Photo of the day: Indoor Air Quality

- Photo of the day: Noise in the affected workplace

- Photo of the day: Fatigue at Work

- Photo of the day: Don’t be Driven to Distraction

- Photo of the day: working in heat and Humidex Rating

- How to use Plate Clamps Safely: Safety Moment#34

- Photo of the day: Sitting at work

- Photo of the day: 5 ways to reduce the risk of Slipping and Tripping

- Photo of the day: Preventing the spread of contagious illness

- Photo of the day: Incident Investigations

- Photo of the day: 10 Scaffold Safety Essentials

- Photo of the day: Effective Health and Safety Committees

- Photo of the day: New worker Orientation & Safety Orientation checklist

- Photo of the day: Workplace Inspection

- Photo of the day: musculoskeletal disorders

- Photo of the day: Emergency preparedness in the workplace

- Photo of the day: Mental health in the workplace

- Photo of the day: Trenching Safety Tips That Can Save a Life

- Photo of the day: Dangerous Goods Classes

- Photo of the day: Safety Equipment for Confined Spaces

- Photo of the day: Tips to reduce Heat stress in the workplace

- Photo of the day: hierarchy of controls

- Your steps to chemical safety

- H2S Gas and how to handle its Emergency

- Photo of the day: Importance of Mock drill and Fire Action Emergency Procedure

- Photo of the day: Choosing the Right Face Mask and the difference between a respirator and face mask

- Photo of the day: Confined space safety Precautions

- Breath Safely: The Proper Use of Respiratory Protection

- Photo of the day: Electric shock survival

- Photo of the day: Chemical Spill Emergency Response

- Photo of the day: Construction Site fire Safety

- Photo of the day: Confined Space rescue