Photo of the day: The 7 Principles of HACCP

The Hazard Analysis and Critical Control Point (HACCP) food safety management system is a preventive risk assessment tool operated by the food industry to ensure that all food safety hazards are assessed and that appropriate controls are put in place to eliminate or reduce contamination of food from those hazards. It is a regulatory requirement in many parts of the world and is a demand placed upon the whole food chain as a means of demonstrating due diligence.

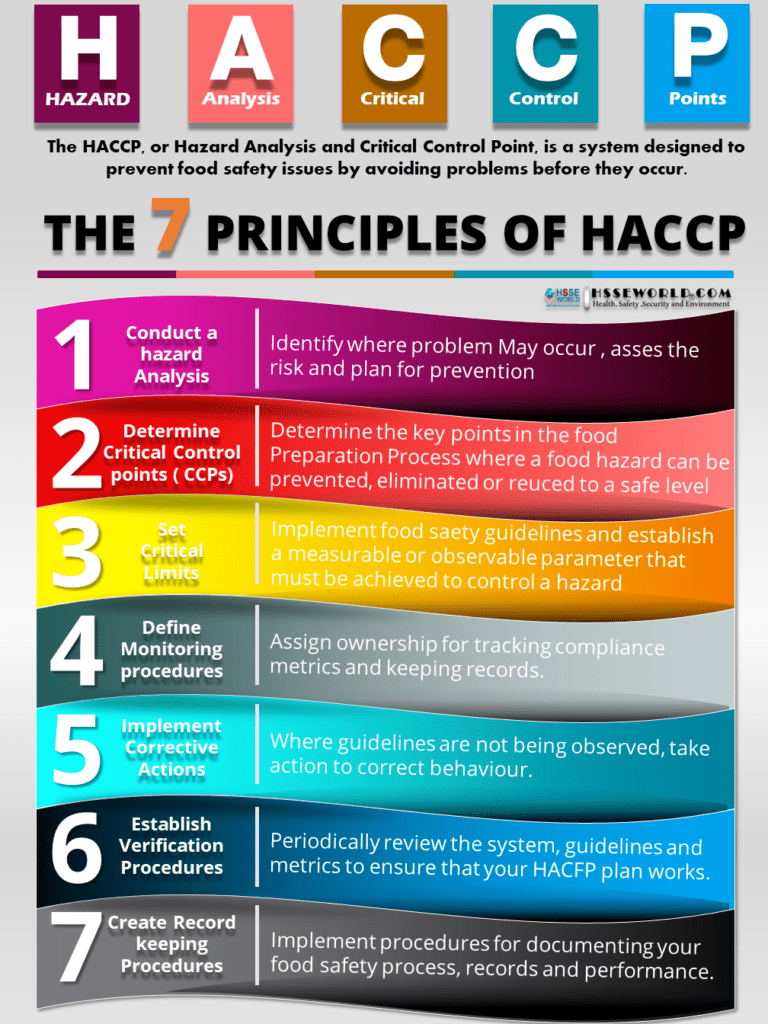

It provides the means to reduce process hazards arising from issues such as poor temperature control, foreign body hazards from machinery, or contamination from food handlers. But it also requires that food safety hazards that stem from layout and facility are controlled and this includes the specification of materials and equipment such as flooring. In our photo of today, you will be familiar with the 7 Principles of HACCP.

Read: E-Books: Food Safety Management-A Practical Guide for the Food Industry

The HACCP principles are designed to protect food safety and thus the consumer across the entire food manufacturing process, from harvesting to consumption. The cost of failing to protect against contamination is high, as it can lead to financial and reputational damage to the producer as well as outbreaks of foodborne illness and in the worst-case scenario public fatalities.

The Development of HACCP

HACCP was first devised in the 1960s by a project team made up of experts from NASA, the US Army, and the Pillsbury Food Group, who had been tasked with designing a risk-assessed based protocol for identifying and managing food safety hazards to prevent food poisoning resulting from rations taken aboard spacecraft.

The hazard analysis aspect of the system makes for an exhaustive list of all the possible factors within a food plant that could pose a risk, such as contamination through poorly cleaned or designed equipment, taints through unsuitable chemical usage, physical risks resulting from broken plastic or metals found in the factory and dirt from raw ingredients to name just a few.

Regulatory Importance

National and European food and beverage legislation stress the importance of implementing due diligence procedures, many of which rely on HACCP’s advisory framework for facility design and construction.

Also Read: Hygiene and Sanitation Inspection Checklist

The Food Safety & Hygiene (England) Regulations 2013 reiterates Article 5 (1) of Regulation 852/2004 of the European Parliament, which states that “food business operators put in place, implement and maintain a permanent procedure or procedures based on the HACCP principles”. Parallel legislation is also in force in Scotland, Wales, and Northern Ireland.

Within the UK, a number of Food Standards Agency (FSA) recognized guides have been developed in association with various organizations to advise food business operators on how to comply with the EU and national regulations on food hygiene.

The FSA is acutely aware of the importance of minimizing contamination risks and the danger posed by foodborne illnesses was highlighted in its Annual Report of Incidents 2015. In this report, 1,645 contamination incidents were investigated and microbiological contamination was at the root of nearly a quarter of them.

The costs of these incidents are significant! Not only could a foodborne illness outbreak lead to serious financial and reputational damage for the producer, but every year the FSA estimates that nearly a million people in the UK are affected, which has a net cost to the country of £1.5 billion.

This has led to the FSA’s Foodborne Disease Strategy, a compliance and enforcement plan that aims to secure major improvements in public protection and health through an overall better and more efficient risk-based regulatory system.

Central to this strategy is the development of a program that covers themes such as how risk is assessed and profiled, the monitoring of risk, incentivizing complaint behavior, and tackling non-compliance. One of these activities is the dissemination of practical advice to assist food businesses to comply with HACCP requirements enshrined in food hygiene legislation. FSA enforcement officers will also check during routine inspections that a business has an appropriate HACCP-based food safety management system in place.

Other key bodies and regulations to be aware of that cover food hygiene and HACCP compliance include the Global Food Safety Initiative (GFSI), the British Retail Consortium (BRC), Food Safety System Certification 22000 (FSSC22000), the International Featured Standard for Food (IFS), the European Union’s Regulation 1169/2011 and the European Food Safety Authority (EFSA).

As a globally accepted benchmark of food safety, HACCP is also important for businesses eager to gain access to export markets. Many nations will require food to have been produced according to a HACCP standard, for example, produce sold in the United States needs to comply with the Food Safety Modernization Act. Proving that a business can meet the necessary level of due diligence is essential for clients abroad to know that the food in question has been manufactured to a hygiene standard that they recognize.

Also Read:Food and Kitchen Hygiene Tips

The Seven Principles of HACCP

HACCP is based on seven principles, which are the most important steps in writing a HACCP plan. The first two steps provide the foundation for the HACCP plan. The remaining five steps are the application steps of the HACCP plan and provide the structure for conducting the workings of the HACCP plan in the processing plant.

Principle 1: Conduct a Hazard Analysis

The application of this principle involves listing the steps in the process and identifying where significant hazards are likely to occur. The HACCP team will focus on hazards that can be prevented, eliminated or controlled by the HACCP plan. A justification for including or excluding the hazard is reported and possible control measures are identified.

Principle 2: Determine Critical Control Points (CCPs)

A critical control point (CCP) is a point, step, or procedure at which control can be applied and a food safety hazard can be prevented, eliminated, or reduced to acceptable levels. The HACCP team will use a CCP decision tree to help identify the critical control points in the process. A critical control point may control more than one food safety hazard or in some cases, more than one CCP is needed to control a single hazard. The number of CCP’s needed depends on the processing steps and the control needed to assure food safety.

Principle 3: Establish Critical Limits

A critical limit (CL) is the maximum and/or minimum value to which a biological, chemical or physical parameter must be controlled at a CCP to prevent, eliminate, or reduce to an acceptable level the occurrence of a food safety hazard. The critical limit is usually a measure such as time, temperature, water activity (aw), pH, weight, or some other measure that is based on scientific literature and/or regulatory standards.

Principle 4: Establish Monitoring Procedures

The HACCP team will describe monitoring procedures for the measurement of the critical limit at each critical control point. Monitoring procedures should describe how the measurement will be taken when the measurement is taken, who is responsible for the measurement and how frequently the measurement is taken during production.

Principle 5: Establish Corrective Actions

Corrective actions are the procedures that are followed when a deviation in a critical limit occurs. The HACCP team will identify the steps that will be taken to prevent potentially hazardous food from entering the food chain and the steps that are needed to correct the process. This usually includes the identification of the problems and the steps taken to assure that the problem will not occur again.

Principle 6: Establish Verification Procedures

Those activities, other than monitoring, determine the validity of the HACCP plan and that the system is operating according to the plan. The HACCP team may identify activities such as auditing of CCP’s, record review, prior shipment review, instrument calibration, and product testing as part of the verification activities.

Principle 7: Establish Record-keeping and Documentation Procedures

A key component of the HACCP plan is recording information that can be used to prove that the food was produced safely. The records also need to include information about the HACCP plan. The record should include information on the HACCP Team, product description, flow diagrams, the hazard analysis, the CCP’s identified, Critical Limits, Monitoring System, Corrective Actions, Recordkeeping Procedures, and Verification Procedures.

Also Read: E-Books: Occupational Safety and Health Simplified for the Food Manufacturing Industry

Download the Infographic

Now you can download the Infographic ” The 7 Principles of HACCP” and post it at the workplace to communicate with everyone to be familiar with the HACCP and I’ts Principles.

Also Read: Suspended Scaffold Pre-Operation Inspection

Photo of the day: The 7 Principles of HACCP

Download more resources at SAFETY BAG

More photos:

- Photo of the day: 10 Essential Safety Tips for Driving in Hot Weather Conditions

- Photo of the day: best workplace safety tips

- Photo of the day: The Importance of Stop Work Authority in Maintaining Workplace Safety

- Photo of the day: Tomorrow’s Reward for Working Safely Today: Cultivating a Culture of Safety

- Photo of the day: Preventing slips and trips at work

- Photo of the day: Learn the DRSABCD action Plan

- Working with Electricity Electrical Accidents Guide for Electrical Workers

- Photo of the day: Hearing Protection Device Selection

- Photo of the day: If An Earthquake Shakes You-Infographic free

- Fire Safety Posters Free Download

- Photo of the day: First Aid for Electrical Burns-Infographic free

- Infographic: First Aid for Cuts and Scrapes free download

- Photo of The day: Work Safe with Lasers-Laser Safety free

- Photo of the day: Working Safely with chemicals and chemical Management

- Photo of the day: Safe work practices when using MEWPs ( updated)

- Photo of the day: Preventing Common Kitchen Hazards

- Photo of the day: Safe handling of Gas Cylinders and lecture bottles

- Photo of the day: Forklift Stability Triangle

- Photo of the day: Defective Tools Safe Work Practice

- Photo of the day: Lift With Your Legs Not With Your Back

- Photo of the day: First Aid for burns

- Photo of the day: The 7 Principles of HACCP

- Photo of the day: Working Safely with Suspended Loads

- Photo of the day: Heat Stroke First Aid and safety posters

- Photo of the day: Near-Miss Reporting and Posters

- Photo of the day: Ergonomic chair and office chair safety tips

- Photo of the day: Whole Body Vibration

- Photo of the day: Substation Safety Equipment

- Photo of the day: Bypassing Safety Controls Rules

- Photo of the day: Lightning Safety Tips

- Photo of the day: Overhead Power lines Clearance

- Photo of the day: Floor Marking

- Photo of the day: Types of Foot Protection

- Photo of the day: Types of Hand Protection

- Photo of the day: Lockout and Tagout Safety

- Photo of the day: Fall Protection Plans

- Photo of the day: Flood Safety Tips

- Photo of the day: Read All Labels Work safe

- Photo of the day: Run Project safely with Crane Hand Signals

- Photo of the day: Flagman and Traffic control

- Photo of the day: Managing Risks of Exposure to Solvents in the workplace

- Photo of the day: Scissor Lift Safety

- Photo of the day: HSE Bulletin Board

- Photo of the day: Arc-Fault Circuit Interrupters (AFCI)

- Photo of the day: Safe use of ladders and step ladders

- Photo of the day: Concrete Truck Driver Hand Signals

- Photo of the day: Extension Cord Safety Tips

- Photo of the day: Protect your Head

- Photo of the day: choosing the right Anchorage

- Photo of the day: Work-Related Asthma

- Photo of the day: Top FIVE Heavy Equipment Construction Site Safety Tips

- Photo of the day: sun safety in the workplace

- Photo of the day: Cannabis and Impairment in the Workplace

- Photo of the day: Position for safety and comfort-Safety Tips

- Photo of the day: Generator Safety

- Photo of the day: Controlling COVID-19 in the Workplace-Physical Barriers

- Photo of the day: Manual Material handling

- Photo of the day: Personal Protective Equipment last resort

- Photo of the day: WHMIS 2015 – Pictograms

- Photo of the day: Indoor Air Quality

- Photo of the day: Noise in the affected workplace

- Photo of the day: Fatigue at Work

- Photo of the day: Don’t be Driven to Distraction

- Photo of the day: working in heat and Humidex Rating

- How to use Plate Clamps Safely: Safety Moment#34

- Photo of the day: Sitting at work

- Photo of the day: 5 ways to reduce the risk of Slipping and Tripping

- Photo of the day: Preventing the spread of contagious illness

- Photo of the day: Incident Investigations

- Photo of the day: 10 Scaffold Safety Essentials

- Photo of the day: Effective Health and Safety Committees

- Photo of the day: New worker Orientation & Safety Orientation checklist

- Photo of the day: Workplace Inspection

- Photo of the day: musculoskeletal disorders

- Photo of the day: Emergency preparedness in the workplace

- Photo of the day: Mental health in the workplace

- Photo of the day: Trenching Safety Tips That Can Save a Life

- Photo of the day: Dangerous Goods Classes

- Photo of the day: Safety Equipment for Confined Spaces

- Photo of the day: Tips to reduce Heat stress in the workplace

- Photo of the day: hierarchy of controls

- Your steps to chemical safety

- H2S Gas and how to handle its Emergency

- Photo of the day: Importance of Mock drill and Fire Action Emergency Procedure

- Photo of the day: Choosing the Right Face Mask and the difference between a respirator and face mask

- Photo of the day: Confined space safety Precautions

- Breath Safely: The Proper Use of Respiratory Protection

- Photo of the day: Electric shock survival

- Photo of the day: Chemical Spill Emergency Response

- Photo of the day: Construction Site fire Safety

- Photo of the day: Confined Space rescue

- Photo of the day: Conveyors Safety Tips

- Photo of the day: 5 Essential outcomes of an effective leadership survey process