Working with Electricity Electrical Accidents Guide for Electrical Workers

18 min readElectricity is a very potent energy form. Used carelessly, it can deliver Electrical Accidents as deadly shocks and injuries. During the past decade, the National Center for Health Statistics has reported about 1,000 accidental electrocutions annually in the United States. About a fourth of these deaths happen in industries or on farms. in this article, the guide has been developed to assist a qualified employee, one who has the training, skills, and technical knowledge of electrical safety including information about Electrical Accidents occurrence and the effect of electricity upon the human body followed with hazards associated with electricity and control measures to avoid.

Also Read: Your steps to chemical safety

The Effects of Electricity Upon the Human Body

Electricity is essential to modern life. Commonly used at both home and on the job, benefits offered by electricity are realized every day through its use. Many workers in different occupations and industries are exposed to electrical energy daily during the performance of their duties. Some employees work with electricity directly, as is the case with engineers, electricians, electronic technicians, and power line workers. Others, such as office workers and salespeople, work with it indirectly. Although you cannot taste or smell electricity, inadvertent contact can surely make one aware of its presence. Dangers posed by electricity are apparent, particularly when contact occurs accidentally or otherwise that can be felt and its effect noted on the human body. There are two kinds of electricity static (stationary) and dynamic (moving).

Dynamic electricity is characterized by the flow of electrons through a conductor. As a source of power, electricity is accepted without much thought to the hazards encountered. Perhaps because it has become such a familiar part of our sur- roundings, it often is not treated with the respect it deserves.

Also Read: Electrical Hazards Top 7 and it’s control Measures

OSHA’s electrical standards address concerns that electricity has long been recognized as a serious workplace hazard, exposing employees to such dangers as electric shock, electrocution, burns, fires, and explosions. In 2006, the Bureau of Labor Statistics reported that 5,703 deaths occurred in private sector workplaces having 11 or more workers. About 4 percent of the fatalities, 247 deaths, were the direct result of electrocutions at work. OSHA’s electrical standards help minimize these potential hazards by specifying safety aspects in the design and use of electrical equipment and systems.

To handle electricity safely, it is necessary to understand how it acts, how it can be directed, what hazards it presents, and how these hazards can be controlled. Operating an electric switch may be considered in comparison to turning on a water faucet. Behind the faucet or switch there must be a source of water or electricity, with something to transport it and with pressure to make it flow. In the case of water, the source is a reservoir or pumping station; the transportation is through pipes; and the force to make it flow is pressure, provided by a pump. For electricity, the source is the power generating station; current travels through electric conductors in the form of wires; and pressure, measured in volts, is provided by a generator.

When you turn on an electrical power tool or device, such as your circular saw, or throw a circuit breaker, you allow current to flow from the generating source, through conductors (wiring), to the area of demand or load (i.e., equipment or lighting). A complete circuit is necessary for the flow of electricity through a conductor. A complete circuit is made up of a source of electricity, a conductor, and a consuming device (load), such as a portable drill. The equation known as Ohm’s law (volts = current x resistance; or V = IR) shows the relationship between three factors. This relationship makes it possible to change the qualities of an electrical current but keep an equivalent amount of power.

Resistance to the flow of electricity is measured in ohms and varies widely. It is determined by three factors: the nature of the substance itself, the length and cross-sectional area (size) of the substance, and the temperature of the substance. Some substances, such as metals, offer very little resistance to the flow of electric current and are called conductors. Other substances, such as porcelain, pottery, and dry wood, offer such a high resistance that they can be used to prevent the flow of electric current and are called insulators. Dry wood has a high resistance, but when saturated with water its resistance drops to the point where it will readily conduct electricity. The same is true of human skin. When it is dry, the skin has a fairly high resistance to an electric current; but when it is moist, there is a radical drop in resistance. Pure water is a poor conductor, but small amounts of impurities, such as salt and acid (both of which are contained in perspiration), make it a ready conductor. When water is present either in the environment or on the skin, anyone working with electricity should exercise even more caution than they normally would

How Shocks Occur

Electricity travels in closed circuits, and its normal route is through a conductor. Electric shock occurs when the body becomes a part of the electric circuit. The current must enter the body at one point and leave at another. Electric shock normally occurs in one of three ways. The individual, while in contact with the ground, must come in contact with both wires of the electric circuit, one wire of an energized circuit and the ground, or a metallic part that has become “hot” by contact with an energized conductor.

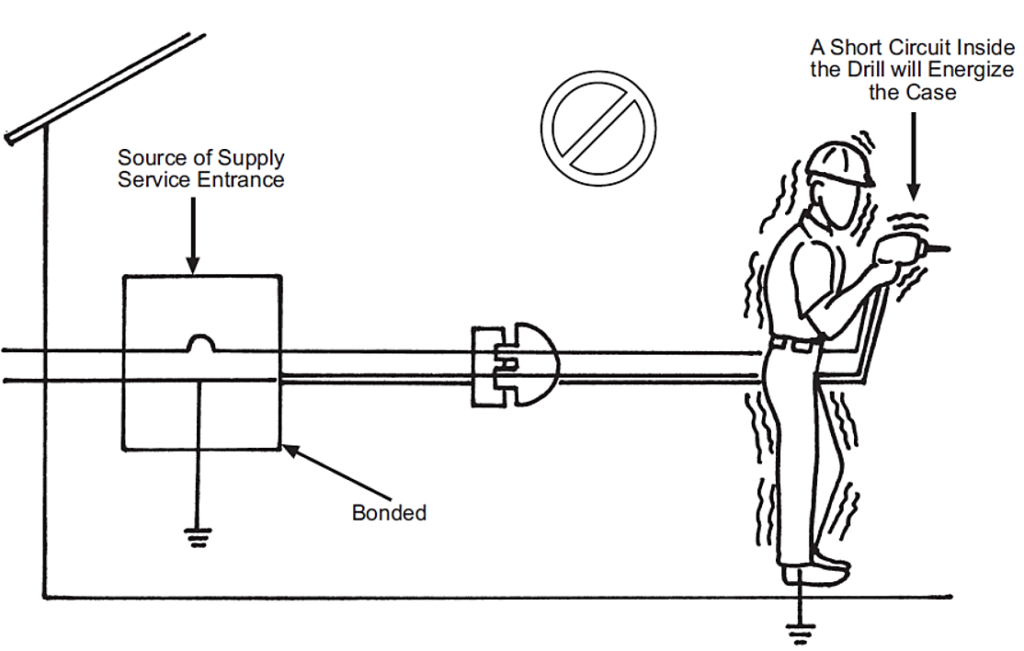

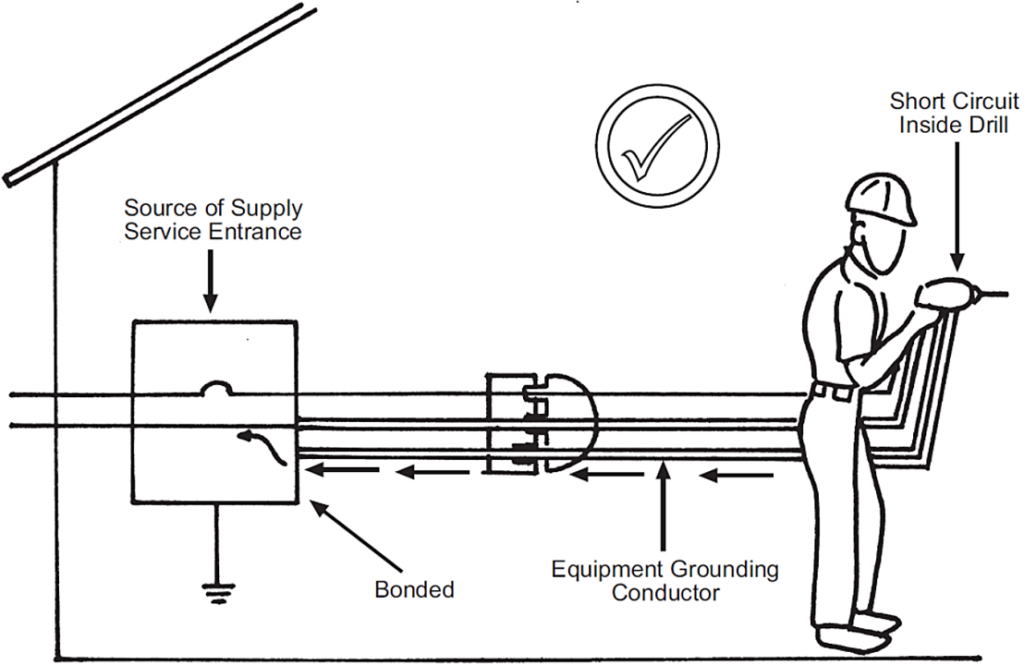

The metal parts of electric tools and machines may become energized if there is a break in the insulation of the tool or machine wiring. The worker using these tools and machines is made less vulnerable to electric shock when there is a low- resistance path from the metallic case of the tool or machine to the ground. This is done through the use of an equipment grounding conductor, a low-resistance wire that causes the unwanted current to pass directly to the ground, thereby great- ly reducing the amount of current passing through the body of the person in contact with the tool or machine. If the equipment grounding conductor has been properly installed, it has a low resistance to ground, and the worker is protected.

Controlling Electrical Hazards

The severity of the shock received when a person becomes part of an electric circuit is affected by three primary factors: the amount of current flowing through the body (measured in amperes), the path of the current through the body, and the length of time the body is in the circuit. Other factors that may affect the severity of shock are the frequency of the current, the phase of the heart cycle when shock occurs, and the general health of the person.

The effects of electric shock depend upon the type of circuit, its voltage, resistance, the current, pathway through the body, and the duration of the contact. Effects can range from a barely perceptible tingle to immediate cardiac arrest. Although there are no absolute limits or even known values that show the exact injury from any given current, Table 1 shows the general relationship between the degree of injury and the amount of current for a 60-cycle hand-to-foot path of one-second duration of the shock.

The table also illustrates that a difference of fewer than 100 milliamperes exists between a current that is barely perceptible and one that can kill. Muscular contraction caused by stimulation may not allow the victim to free himself or herself from the circuit, and the increased duration of exposure increases the dangers to the shock victim. For example, a current of 100 milliamperes for 3 seconds is equivalent to a current of 900 milliamperes applied for .03 seconds in causing ventricular fibrillation. The so-called low voltages can be extremely dangerous because, all other factors being equal, the degree of injury is proportional to the length of time the body is in the circuit. Low voltage does not imply low hazard! A severe shock can cause considerably more damage to the body than is visible. For example, a person may suffer internal hemorrhages and the destruction of tissues, nerves, and muscles. In addition, shock is often only the beginning of a chain of events. The final injury may well be from a fall, cuts, or burns.

Electrical injuries may occur in various ways: direct contact with electrical energy, injuries that occur when electricity arcs (an arc is a flow of electrons through a gas, such as air) to a victim at ground potential (supplying an alternative path to ground), flash burns from the heat generated by an electrical arc, and flame burns from the ignition of clothing or other combustible, nonelectrical materials. Direct contact and arcing injuries produce similar effects. Burns at the point of contact with electrical energy can be caused by arcing to the skin, and heating at the point of contact by a high-resistance contact or higher voltage currents. Contact with a source of electrical energy can cause external as well as internal burns. ( Read: Types of electrical injuries)

Exposure to higher voltages will normally result in burns at the sites where the electrical current enters and exits the human body. High voltage contact burns may display only small superficial injury; however, the danger of these deep

burns destroying tissue just beneath the skin exists. In addition, internal blood vessels may clot, nerves in the area of the contact point may be damaged, and muscle contractions may cause skeletal fractures either directly or in association with falls from elevation. It is also possible to have a low-voltage electrocution without visible marks on the body of the victim.

Flash burns and flame burns are actually thermal burns. In these situations, electrical current does not flow through the victim, and injuries are often confined to the skin. Contact with an electrical current could cause a muscular contraction or a startle reaction that could be hazardous if it leads to a fall from elevation (ladder, aerial bucket, etc.) or contact with dangerous equipment. The NEC describes high voltage as greater than 600 volts AC. Most utilization circuits and equipment operate at voltages lower than 600 volts, including common household circuits (110/120 volts); most overhead lighting systems used in industry or office buildings and department stores; and much of the electrical machinery used in industry, such as conveyor systems, and manufacturing machinery such as weaving machines, paper rolling machines or industrial pumps.

Voltages over 600 volts can rupture human skin, greatly reducing the resistance of the human body, allowing more current to flow, and causing greater damage to internal organs. The most common high voltages are transmission volt- ages (typically over 13,800 volts) and distribution voltages (typically under 13,800 volts). The latter are the voltages transferred from the power generation plants to homes, offices, and manufacturing plants. Standard utilization voltages produce currents passing through a human body in the milliampere range (1,000 mA = 1 amp). The estimated effects of 60 Hz AC currents passing through the chest are shown in Table 2.

Note: 1 mA = 1/1000 A = 0.001 A

Hazards Associated With Electricity

The most common shock-related injury is a burn. Burns suffered in electrical accidents may be of three types: electrical burns, arc burns, and thermal contact burns. Electrical burns are the result of the electric current flowing through tissues or bones. Tissue damage is caused by the heat generated by the current flow through the body.

Electrical burns are one of the most serious injuries you can receive and should be given immediate attention. Arc or flash burns, on the other hand, are the result of high temperatures near the body and are produced by an electric arc or explosion. They should also be attended to promptly. Finally, thermal contact burns are those normally experienced when the skin comes in contact with hot surfaces of overheated electric conductors, conduits, or other energized equipment.

Additionally, clothing may be ignited in an electrical accident and a thermal burn will result. All three types of burns may be produced simultaneously.

Electric shock can also cause injuries of an indirect or secondary nature in which involuntary muscle reaction from the electric shock can cause bruises, bone fractures, and even death resulting from collisions or falls. In some cases, injuries caused by electric shock can be a contributory cause of delayed fatalities. In addition, to shock and burn hazards, electricity poses other dangers. For example, when a short circuit occurs, the arcs can cause injury or start a fire. Extremely high-ener- gy arcs can damage equipment, causing the fragmented metal to fly in all directions. Even low-energy arcs can cause violent explosions in atmospheres that contain flammable gases, vapors, or combustible dust. Electrical accidents appear to be caused by a combination of three possible factors—unsafe equipment and/or installation, workplaces made unsafe by the environment, and unsafe work practices. There are various ways of protecting people from the hazards caused by electricity. These include insulation, guarding, grounding, electrical protective devices, and safe work practices.

Insulation

One way to safeguard individuals from electrically energized wires and parts is through insulation. An insulator is any material with high resistance to electric current. Some examples of insulators include glass, mica, rubber, and plastic.

These are put on conductors to prevent shock, fires, and short circuits. Before employees prepare to work with electric equipment, it is always a good idea for them to check the insulation before making a connection to a power source to be sure there are no exposed wires. The insulation of flexible cords, such as extension cords, is particularly vulnerable to damage. The insulation that covers conductors is regulated by Subpart S of the Safety and Health Standards for General Industry (29 Code of Federal Regulations Part 1910.302, Design Safety Standards for Electrical Systems). Subpart K contains the Safety and Health Standards for the Construction Industry (29 Code of Federal Regulations Part 1926.404, Installation Safety Requirements).

Subpart S generally requires that circuit conductors (the material through which current flows) be insulated to prevent people from coming into accidental contact with the current. Also, the insulation should be suitable for the voltage and existing conditions, such as temperature, moisture, oil, gasoline or corrosive fumes. All these factors must be evaluated before the proper choice of insulation can be made. Conductors and cables are marked by the manufacturer to show the maximum voltage and American Wire Gage size, the type letter of the insulation, and the manufacturer’s name or trade- mark.

Insulation is often color coded. In general, insulated wires used as equipment grounding conductors are either continuous green or green with yellow stripes. The grounded conductors that complete a circuit are generally covered with continuous white or natural gray-colored insulation. The ungrounded conductors, or “hot wires,” may be any color other than green, white, or gray. They are often colored black or red.

Guarding

Live parts of electric equipment operating at 50 volts or more must be guarded against accidental contact. Guarding of live parts may be accomplished by:

- Location in a room, vault, or similar enclosure accessible only to qualified persons;

- Use of permanent, substantial partitions or screens to exclude unqualified persons;

- Location on a suitable balcony, gallery, or platform elevated and arranged to exclude unqualified persons; or

- Elevation of 8 feet (2.44 meters) or more above the floor.

Entrances to rooms and other guarded locations containing exposed lives parts must be marked with conspicuous warning signs forbidding unqualified persons to enter. Indoor electric wiring of more than 600 volts that is open to unqualified persons must be made with metal-enclosed equipment or enclosed in a vault or area controlled by a lock. In addition, equipment must be marked with appropriate caution signs.

Grounding

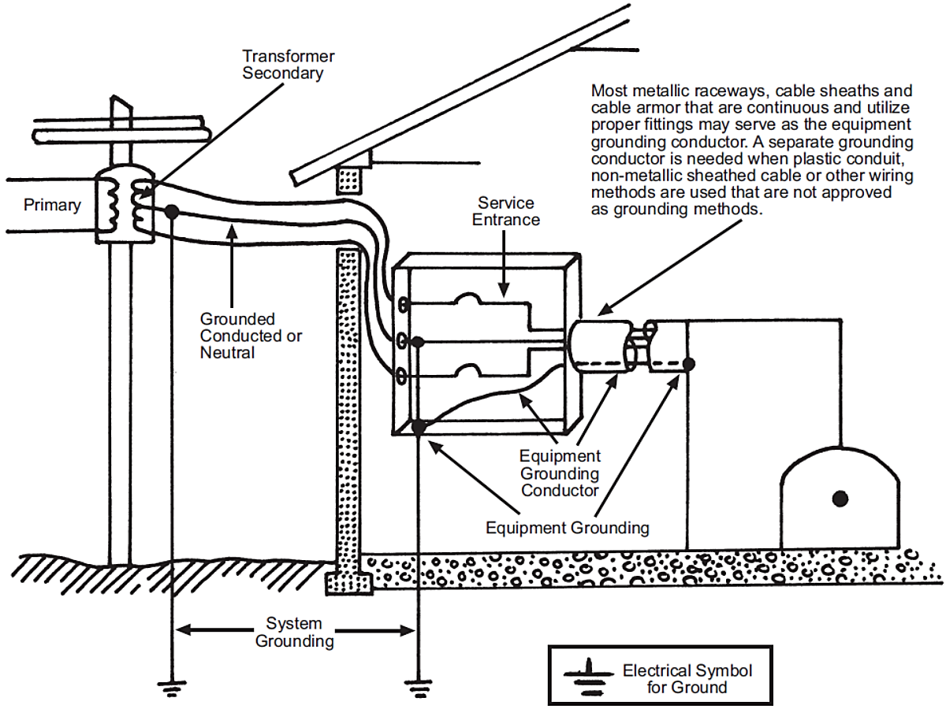

Grounding is another method of protecting employees from electric shock; however, it is normally a secondary protective measure. The term “ground” refers to a conductive body, usually the earth, and means a conductive connection, whether intentional or accidental, by which an electric circuit or equipment is connected to the earth or the ground plane. By grounding a tool or electrical system, a low-resistance path to the earth is intentionally created. When properly done, this path offers sufficiently low resistance and has sufficient current carrying capacity to prevent the buildup of voltages that may result in a personnel hazard. See Figure 1. This does not guarantee that no one will receive a shock, be injured, or be killed. It will, however, substantially reduce the possibility of such accidents, especially when used in combination with other safety measures discussed in this booklet.

There are two kinds of grounds required by Design Safety Standards for Electrical Systems (Subpart S). One of these is called the “service or system ground.” In this instance, one wire—called “the neutral conductor” or “grounded conductor”—is grounded. In an ordinary low-voltage circuit, the white (or gray) wire is grounded at the generator or transformer and again at the service entrance of the building. This type of ground is primarily designed to protect machines, tools, and insulation against damage.

To offer enhanced protection to the workers themselves, an additional ground called the “equipment ground,” must be furnished by providing another path from the tool or machine through which the current can flow to the ground. This additional ground safeguards the electric equipment operator in the event that a malfunction causes the metal frame of the tool to become accidentally energized. The resulting heavy surge of current will then activate the circuit protection devices and open the circuit. See Figures 2a and 2b.

Electrocutions From Contact With High Voltage Transmission Lines

Anyone who works in the vicinity of electrical power lines should be aware of the consequences of contacting energized lines. Anyone working on or around electrically energized conductors should:

- Ensure adequate clearance between power lines and cranes, booms, measuring rods, boat masts, irrigation pipes, radio and TV antennas, or any other metal object or structure.

- Consider all overhead wires to be energized unless they have been visibly grounded and tested.

- Designate a person to observe clearance of equipment and give timely warning of all operations where it is difficult for the operator to observe the required clearance.

- Use nonmetallic ladders, insulated tools, nonconductive equipment, and appropriate personal protective equipment.

- Never depend solely on cage-type boom guards, insulating links, or proximity devices to ensure the required distance between a crane and power lines.

- Ensure that all electrical work safety practices and procedures are thoroughly reviewed and discussed prior to beginning a job.

- Instruct new workers and retrain others who work with energized conductors and/or equipment, regardless of a voltage level (one-tenth ampere flowing through the human body for only two seconds can be fatal).

- Use the buddy system with at least one member of each pair of workers trained in basic first aid and cardiopulmonary resuscitation (CPR).

- Until the current has been cleared, refrain from touching the victim of an electrocution or the electrical apparatus that caused the injury, or use appropriate electrical protective equipment to remove the victim.

In addition to the preceding measures recommended for preventing electric shock and electrocutions, one should conduct a thorough and frequent review of all applicable Occupational Safety and Health Act standards.

Also Read: High-Voltage Electrical Safety

Electrocutions From the Use of Portable Metal Ladders Near Overhead Power Lines

Workers using portable metal ladders, including aluminum ladders, near overhead power lines are at risk of electrocution. In 2002, the contact of metal ladders with overhead power lines accounted for 6 percent of all work-related electrocutions in the United States. The lack of compliance with existing OSHA regulations regarding portable metal ladders suggests that many employers are unaware of the regulations, misinterpret the requirements or fail to inform their workers about the dangers of using metal ladders near power lines.

OSHA requirements prohibit the use of portable metal or conductive ladders for electrical work or in locations where they may contact electrical conductors. Nonconductive ladders, such as those made of wood or fiberglass, should be used instead.

If portable metal ladders are used in the vicinity of energized power lines, all employers and workers should strictly adhere to OSHA standards requiring the proper balancing and securing of ladders and maintenance of safe working distances to avoid contact with electrical conductors. To ensure proper protection for anyone working near electrical power lines, arrangements should be made with the power company to de-energize the lines or to cover the lines with insulating line hoses or blankets.

Employers should fully inform workers about the hazards of using portable metal ladders near energized power lines. Fatalities may be prevented by prompt emergency medical care. Workers should be trained in emergency medical procedures such as CPR. ( Also Read: AEDs: The Life-Saving Devices that Everyone Should Know How to Use)

Preventing Fatalities of Workers Who Contact Electrical Energy

National Institute for Occupational Safety and Health recommendations for helping to save the lives of workers who contact electrical energy call for the use of a buddy system. That system ensures that no one works alone with electrical energy and makes first aid and CPR immediately available.

Incidents studied by NIOSH revealed that electrocution victims can be revived if immediate CPR or defibrillation is provided. While immediate defibrillation would be ideal, CPR was given within approximately four minutes of the electrocution, followed by advanced cardiac life support (ACLS) measures within approximately eight minutes, which can be lifesaving.

An estimated 300 occupational electrocutions occur each year. Therefore, a primary goal of occupational safety pro- grams is to prevent workers from contacting electrical energy. Effective means of prevention include safe work practices, job training, proper tools, protective equipment, and lockout/ tagout procedures. A secondary goal is ensuring appropriate emergency medical care to workers who contact with electrical energy.

The National Electrical Code divides voltages into two categories: greater than 600 volts (high voltage) and less than or equal to 600 volts (low voltage). Momentary contact with low voltages produces no thermal injury but may cause ventricular fibrillation (very rapid, ineffective heartbeat).

In contact with high voltage, massive current flows may stop the heart completely. When the circuit breaks, the heart may start beating normally. Supporting respiration by immediate mouth-to-mouth techniques may be required, even if heartbeat and pulse are present. If extensive burns are present, death may result from subsequent complications. ( Photo of the day: Overhead Power lines Clearance )

Standards and Guidelines for Medical Care for Workers Who Contact Electrical Energy

The National Conference on CPR and ECC [Emergency Cardiac Care] produced revised standards and guidelines for medical care for workers who contact electrical energy. There are two parts: CPR and ACLS. A layperson can be trained in CPR to support the circulation and ventilation of the victim of cardiac or respiratory arrest until ACLS (provided by medical professionals using special equipment) can restore the normal heart and ventilatory action.

Speed is critical to resuscitation. The highest success rate has been achieved with patients for whom CPR followed cardiac arrest within approximately four minutes and ACLS was begun within approximately eight minutes of the arrest.

CPR often must be initiated immediately by lay individuals at the scene of the incident. CPR skills can be gained in four-hour courses taught by the American Heart Association, American Red Cross, and other agencies.

Also Read: Photo of the day: First Aid for Electrical Burns-Infographic free(

Also Read: Electrical Contact Release

Recommendations Regarding Employees Who Work Around or With Electrical Energy

For employees who work around or with electrical energy, the following safeguards are recommended:

- Prevention. Prevention must be the primary goal of any occupational safety program. Since contact with electrical energy occurs even in facilities that promote safety, safety programs should provide for an appropriate emergency medical response.

- Safe Work Practices. No one who works with electrical energy should work alone, and in many instances, a buddy system should be established. It may be advisable to have both members of the buddy system trained in CPR, as one can- not predict who will contact electrical energy.

Every individual who works with or around electrical energy should be familiar with emergency procedures. This should include knowing how to de-energize the electrical system before rescuing or beginning resuscitation on a worker who remains in contact with an electrical energy source.

All workers exposed to electrical hazards should be made aware that even low-voltage circuits can be fatal and that prompt emergency medical care can be lifesaving.

- CPR and ACLS Procedures. CPR and first aid should be immediately available at every worksite. This capability is necessary to provide prompt (within four minutes) care for victims of cardiac or respiratory arrest from any cause.

Employers may contact the local office of the American Heart Association, the American Red Cross, or equivalent groups or agencies to set up a course on CPR for employees.

Provision should be made for the availability of ACLS at each worksite. ACLS should be available within eight minutes. ACLS may be available through an ambulance staffed with paramedics. Signs should be placed on or near telephones to provide the correct emergency number for the area. Workers should be educated regarding the information to give when a call is made. For large facilities, a prearranged place should be established where company personnel is to meet paramedics in an emergency.

Also Read: E-Books: Electrical Safety of Low Voltage Systems

Download Safety Posters

Also Read: E-Books: Electric Safety Practice and Standards

For more safety Resources Please Visit Safetybagresources