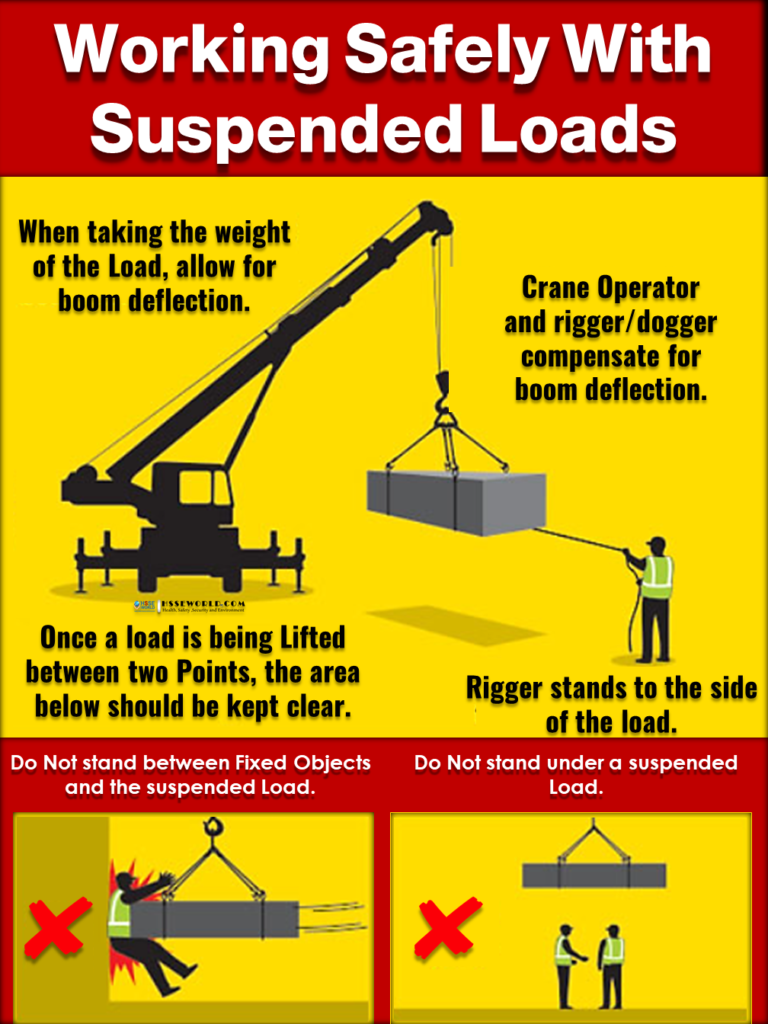

Photo of the day: Working Safely with Suspended Loads

In almost every industry, a load of some kind is being lifted, manipulated, lowered, or carried in a way that poses risk to workers. The U.S. Bureau of Labor Statistics reports that there are more than 50,000 “struck by falling objects” recordable injuries every year in the United States. That’s one injury every 10 minutes caused by a dropped object in the workplace and working under suspended loads.

Employers and managers, your policy is that you will create and sustain a safe work environment for your employees. When your workers operate or carry out duties around cranes and hoists, it is your responsibility to ensure that employees follow the Occupational Safety and Health Administration’s (OSHA) suspended load safety standards.

In our photo of today you will be familiar with :

- What Is a Suspended Load?

- Understanding the Fall Zone

- The Dangers of Working Under a Suspended Load

- Safety Tips for Working Under Suspended Loads

Also, Read the Cranes Stability and Tipping: Safety Moment#29

What Is a Suspended Load?

Loads may be suspended by forklifts; wheel loaders, and overhead, boom, and jib cranes. Essentially, anything that is lifted above ground is considered a suspended load. You’ll find such loads on riggings, slings, pallets, and various pieces of equipment. The larger weight and size of the material lifted, the more hazardous the job and its surrounding areas become.

Understanding the Fall Zone

The fall zone as defined by OSHA is “the area including, but not limited to, the area directly beneath the load in which it is reasonably foreseeable that partially or completely suspended materials could fall in the event of an accident.” OSHA goes on to state that standing under a suspended load is prohibited and that “while the operator is not moving a suspended load, no employee must be within the fall zone, except for employees (who are): engaged in hooking, unhooking or guiding a load; engaged in the initial attachment of the load to a component or structure…”

As a safety practitioner, there’s a simpler approach. Whether the load is suspended and static or moving in any motion, respect the fall zone because your life and the lives of others depend on it.

Also Read: Photo of the day: Safe Lifting at work

The Dangers of Working Under a Suspended Load

The most obvious danger is that what goes up usually comes down and not always in the fashion we plan it. Sometimes, the material being lifted and/or transported won’t simply crash with a boom. Even a small overhead load can become lethal.

If a load falls, it can quickly break and split, becoming a series of injurious and deadly projectiles. Harmful splashes, flooding, shattered bones, and injuries to the eyes, head, and soft tissues can occur. Contact with power lines is possible, which could, of course, lead to potentially life-altering electrical shock.

Also Read: Guideline for Crane Stability and Ground Pressure

Staying Outside the Fall Zone

One of the biggest concerns working with overhead loads is judging what is a safe distance from the load. The size of the fall zone should expand as the complexity of the lift is understood and planned. OSHA and other regulatory agencies mandate that carrying loads over people should be avoided, so it’s reasonable that the fall zone moves along the direction of travel to ensure measures are taken to eliminate exposure.

Load height is another critical factor, because as load height grows, so does the radius of the fall zone.

Load size, weight, shape, and rigging should all be considered as well as issues like operator knowledge and skill, environmental conditions and equipment. There are a lot of variables to consider in ensuring safe load handing but be sure to think about it 360 degrees around the load.

Also Read: Critical Lifts

Safety Tips for Working Under Suspended Loads

It’s very common for construction crews to work with and around suspended loads. Many times, workers are not trained properly or fully aware of their particular exposure. Such lack of communication and knowledge makes great room for carelessness, injury, and even death. It’s vital to your business operations that employees remain safe and productive.

Implement this list of OSHA suspended load safety tips for a safer place of employment.

- All employees operating equipment should be properly trained regarding hoist and overhead crane safety rules and procedures. They should also be certified and licensed to operate said equipment.

- A responsible company employee familiar with the hoist and overhead crane safety tips should test hoisting and crane equipment monthly. Rigging equipment should be tested annually.

- Do not carry loads over people. Equipment can fail unexpectedly, and operator errors can have serious ramifications.

- Parts of the equipment itself such as empty buckets, forks, and masts are still considered suspended loads. One does not have to be moving material.

- Further, it’s important to be aware of a suspended load’s stability or swing. When material or equipment is moved, the contents might also be susceptible to movement.

- Put a “10-feet rule” in place. No company employee is allowed to be within a 10 feet radius of the suspended load in case of equipment malfunction and/or an accidental drop. If a load is suspended more than 15 feet high, then increase that radius.

- You might look into purchasing remote controls for hoists and overhead cranes. Operators may then safely maneuver the equipment from a distance.

- Check the load rating for straps, slings, and chains. Be certain that they can bear the load of the forklift, crane, or bucket. Remember to always limit the load based on the lowest rating of the lifting system. If unclear at all, cease all operations until certain!

- All hoists, cranes, slings, and other machine components should be inspected before use. They must adhere to the company’s set preventative maintenance and manufacturer’s requirements.

- All buckets, forks, and slings should rest on the ground when not in use, even if they contain or carry no load. This is in reference to 1910.179(n)(3)(vi), “The employer shall require that the operator avoid carrying loads over people.” As noted in 2007 by an OSHA Standard interpretation (https://www.osha.gov/laws-regs/standardinterpretations/2007-11-16), all load handling fixtures are considered part of the load (even if they carry nothing themselves). Our tip takes form when considered alongside 1910.179(n)(3)(x), “The employer shall ensure that the operator does not leave his position at the controls while the load is suspended,” while understanding that a load can mean any attached load-handling fixture, and the load would be considered not in use if there is no operator at the controls.

- Avoid “shock loading.” That is, do not activate the lift controls suddenly by issuing excessive force on the load. Be cautious, applying power easily. Do not jerk the controls; accelerate and decelerate slowly.

- Don’t raise the load more than is necessary.

- Multiple employees should never be in charge of operating a single piece of equipment. Hand signals should only be given to warn of hazards.

- At times, surroundings can grow noisy or a voice may simply not be heard over a distance. Establish hand signals, and teach these to all company employees.

- Equipment operators should watch their load the entire time it is in motion, from liftoff to landing.

- No persons should ever be permitted to ride in a tractor bucket or on the load itself.

- Always check for load balance, and clear a pathway prior to movement.

- Take weather conditions into consideration before moving a load.

- Loads that can potentially shift during movement must be secured in place.

- Be careful that the load does not shift outside of the equipment’s tires or tracks. The equipment may tip over.

- Check that all alarms and horns are in working order.

- Maintain a distance of 10 feet from power lines.

Also Read: Photo of the day: Top10 Injuries in office work

Download the Infographic

Now you can download the Infographic ” Working Safely with Suspended Loads” and post it at the workplace to communicate with everyone to be familiar with the Dangerous of lifting zone and working under suspended loads.

Also Read: Suspended Scaffold Pre-Operation Inspection

Photo of the day: Working Safely with Suspended Loads

Download more resources at SAFETY BAG

More photos:

- Photo of the day: 10 Essential Safety Tips for Driving in Hot Weather Conditions

- Photo of the day: best workplace safety tips

- Photo of the day: The Importance of Stop Work Authority in Maintaining Workplace Safety

- Photo of the day: Tomorrow’s Reward for Working Safely Today: Cultivating a Culture of Safety

- Photo of the day: Preventing slips and trips at work

- Photo of the day: Learn the DRSABCD action Plan

- Working with Electricity Electrical Accidents Guide for Electrical Workers

- Photo of the day: Hearing Protection Device Selection

- Photo of the day: If An Earthquake Shakes You-Infographic free

- Fire Safety Posters Free Download

- Photo of the day: First Aid for Electrical Burns-Infographic free

- Infographic: First Aid for Cuts and Scrapes free download

- Photo of The day: Work Safe with Lasers-Laser Safety free

- Photo of the day: Working Safely with chemicals and chemical Management

- Photo of the day: Safe work practices when using MEWPs ( updated)

- Photo of the day: Preventing Common Kitchen Hazards

- Photo of the day: Safe handling of Gas Cylinders and lecture bottles

- Photo of the day: Forklift Stability Triangle

- Photo of the day: Defective Tools Safe Work Practice

- Photo of the day: Lift With Your Legs Not With Your Back

- Photo of the day: First Aid for burns

- Photo of the day: The 7 Principles of HACCP

- Photo of the day: Working Safely with Suspended Loads

- Photo of the day: Heat Stroke First Aid and safety posters

- Photo of the day: Near-Miss Reporting and Posters

- Photo of the day: Ergonomic chair and office chair safety tips

- Photo of the day: Whole Body Vibration

- Photo of the day: Substation Safety Equipment

- Photo of the day: Bypassing Safety Controls Rules

- Photo of the day: Lightning Safety Tips

- Photo of the day: Overhead Power lines Clearance

- Photo of the day: Floor Marking

- Photo of the day: Types of Foot Protection

- Photo of the day: Types of Hand Protection

- Photo of the day: Lockout and Tagout Safety

- Photo of the day: Fall Protection Plans

- Photo of the day: Flood Safety Tips

- Photo of the day: Read All Labels Work safe

- Photo of the day: Run Project safely with Crane Hand Signals

- Photo of the day: Flagman and Traffic control

- Photo of the day: Managing Risks of Exposure to Solvents in the workplace

- Photo of the day: Scissor Lift Safety

- Photo of the day: HSE Bulletin Board

- Photo of the day: Arc-Fault Circuit Interrupters (AFCI)

- Photo of the day: Safe use of ladders and step ladders

- Photo of the day: Concrete Truck Driver Hand Signals

- Photo of the day: Extension Cord Safety Tips

- Photo of the day: Protect your Head

- Photo of the day: choosing the right Anchorage

- Photo of the day: Work-Related Asthma

- Photo of the day: Top FIVE Heavy Equipment Construction Site Safety Tips

- Photo of the day: sun safety in the workplace

- Photo of the day: Cannabis and Impairment in the Workplace

- Photo of the day: Position for safety and comfort-Safety Tips

- Photo of the day: Generator Safety

- Photo of the day: Controlling COVID-19 in the Workplace-Physical Barriers

- Photo of the day: Manual Material handling

- Photo of the day: Personal Protective Equipment last resort

- Photo of the day: WHMIS 2015 – Pictograms

- Photo of the day: Indoor Air Quality

- Photo of the day: Noise in the affected workplace

- Photo of the day: Fatigue at Work

- Photo of the day: Don’t be Driven to Distraction

- Photo of the day: working in heat and Humidex Rating

- How to use Plate Clamps Safely: Safety Moment#34

- Photo of the day: Sitting at work

- Photo of the day: 5 ways to reduce the risk of Slipping and Tripping

- Photo of the day: Preventing the spread of contagious illness

- Photo of the day: Incident Investigations

- Photo of the day: 10 Scaffold Safety Essentials

- Photo of the day: Effective Health and Safety Committees

- Photo of the day: New worker Orientation & Safety Orientation checklist

- Photo of the day: Workplace Inspection

- Photo of the day: musculoskeletal disorders

- Photo of the day: Emergency preparedness in the workplace

- Photo of the day: Mental health in the workplace

- Photo of the day: Trenching Safety Tips That Can Save a Life

- Photo of the day: Dangerous Goods Classes

- Photo of the day: Safety Equipment for Confined Spaces

- Photo of the day: Tips to reduce Heat stress in the workplace

- Photo of the day: hierarchy of controls

- Your steps to chemical safety

- H2S Gas and how to handle its Emergency

- Photo of the day: Importance of Mock drill and Fire Action Emergency Procedure

- Photo of the day: Choosing the Right Face Mask and the difference between a respirator and face mask

- Photo of the day: Confined space safety Precautions

- Breath Safely: The Proper Use of Respiratory Protection

- Photo of the day: Electric shock survival

- Photo of the day: Chemical Spill Emergency Response

- Photo of the day: Construction Site fire Safety

- Photo of the day: Confined Space rescue

- Photo of the day: Conveyors Safety Tips

- Photo of the day: 5 Essential outcomes of an effective leadership survey process