Photo of the day: Forklift Stability Triangle

Understanding the forklift stability triangle is essential for workplace safety. When workers understand their vehicle’s capacity limits and the general principle of the stability triangle, they can operate safely on the job and reduce the risk of hazardous incidents.

The forklift stability triangle is a fundamental concept that operators of counterbalanced lift trucks must understand. In order to maintain longitudinal, lateral, and dynamic stability, operators must be able to locate the center of gravity of a loaded truck and ensure that it falls within this imaginary triangle that spans the front axle to the center of the steer axle. int the photo of today you will learn :

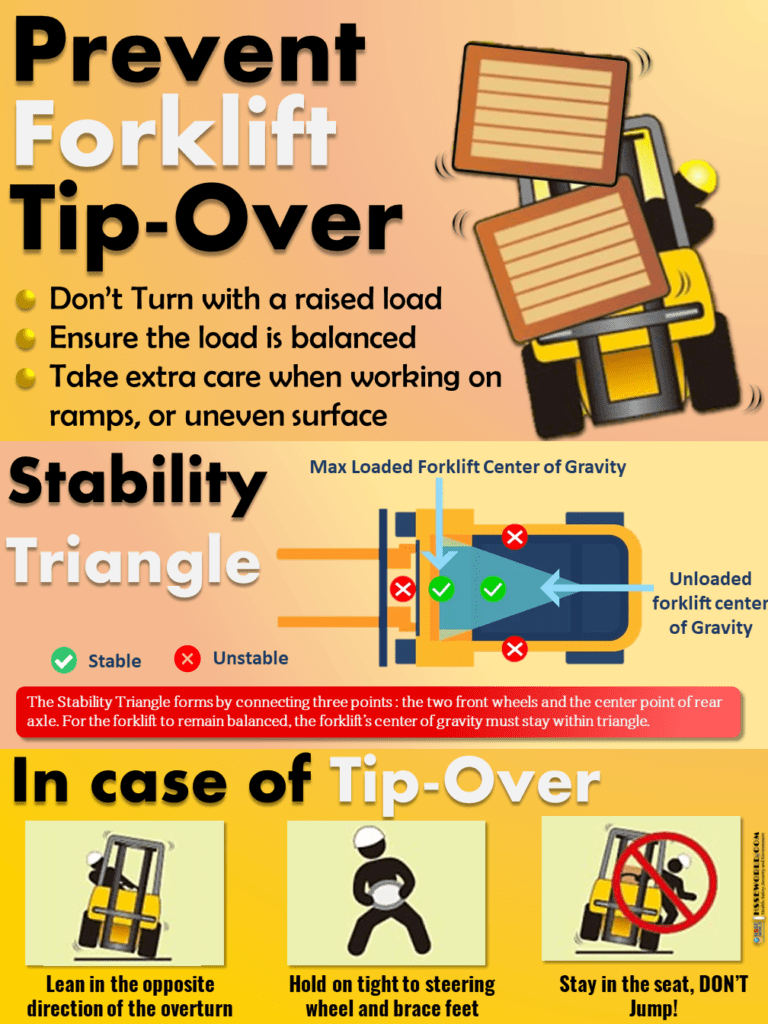

- How to prevent forklift Tip-over

- Forklift stability triangle

- What Determines the Stability of a Forklift?

- Tips to Improve Forklift Stability

- what operator shall do in case of forklift tip-over

Also, Read: Cranes Stability and Tipping: Safety Moment#29

What Is the Forklift Stability Triangle?

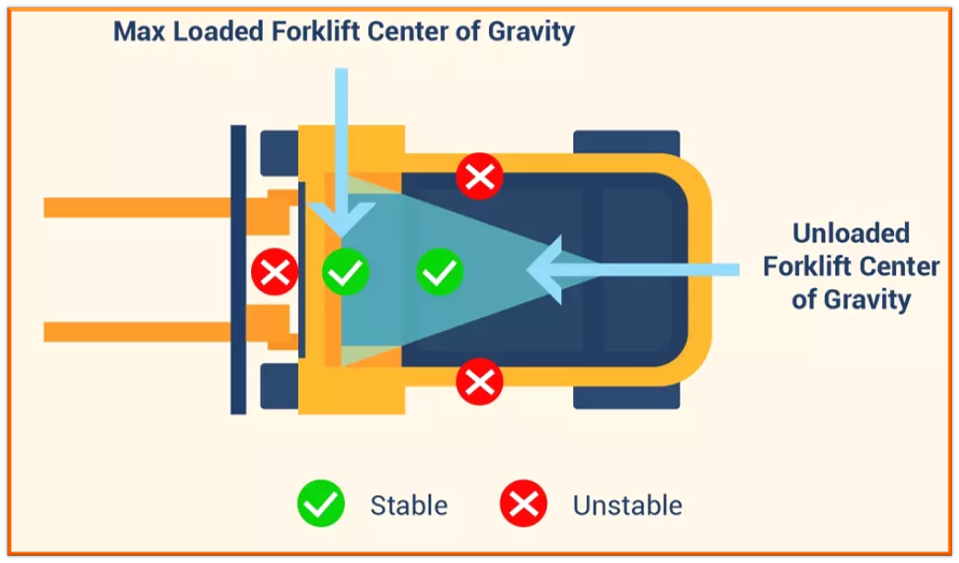

Most counterbalanced forklifts have a three-point suspension system, meaning that the truck is supported at the two front wheels and the center of the steer axle. If you imagine all three points connected into a triangle, this is the forklift’s stability triangle. When the lift truck’s center of gravity falls within the perimeter of this triangle, a load is safe to carry.

Now, when there is no load present, the lift truck’s center of gravity is firmly inside the triangle. Because there is no load, the center of gravity is nearly in the center of the forklift’s counterbalance. As you add weight to the forks, the center of gravity shifts closer to the front axle. Once the center of gravity reaches the front axle, it is at the edge of the stability triangle, and the load becomes unsafe to carry.

You should understand these helpful terms related to the stability triangle:

- Lateral stability: A lift truck’s resistance to overturning sideways

- Longitudinal stability: A lift truck’s resistance to overturning forward or rearward

- Dynamic stability: The idea that an unloaded or loaded forklift can shift due to sudden stops, starts, turns, or tilts

- Line of action: An imaginary vertical line through an object’s center of gravity

- Load center: The horizontal distance from the forklift’s line of action through the load’s center of gravity

What Determines the Stability of a Forklift?

Three main factors govern the stability of a forklift: the size of the load, the terrain on which it is operating, and what type of forklift you are using.

The Load Size

When it comes to loads, you should consider both the size and distribution of that heavy load. Each forklift will have a specifically defined load capacity you should adhere to that will describe both of these factors. For example, a forklift may be rated to carry 4,000 pounds at 24 inches load center, but just 2,666 pounds at 36 inches load center. Never exceed the capacity of the forklift described on its data plate or a name plate or you risk tipping.

The Terrain

The terrain on which the forklift operates also impacts its stability, as slippery and uneven surfaces can risk tipping the vehicle even if it is not exceeding load limits. Forklift operators should avoid traveling on oil, water, or other spills due to the risk of skidding. They should also avoid steep inclines and declines, or generally uneven surfaces. Finally, forklift operators should be aware of obstructions, holes, and speed bumps that can also cause the vehicle’s wheels to elevate.

The Type of Forklift

You can use many different types of forklifts, and each has its own stability profile. If you’re in the market for a forklift, carefully examine the specs on forklifts to determine which is the right one for your job.

Although you can find several types of forklifts, each forklift is best suited for a particular job. For example, you wouldn’t want to use a forklift meant for smaller tasks to do heavy-duty warehouse lifting. Or, if you need long objects moved like pipes and timber, you’d want a forklift ideally suited for that job, such as a side loader.

Tips to Improve Forklift Stability

Proper safety training is key to forklift stability, and you can improve the stability of your forklift to minimize the risks of tipping. Keep in mind these are general tips: check your forklift safety manual for more safety instructions.

1-Keep the load low to the ground

The higher the load is, the more unstable it becomes, so keeps the load as low to the ground as possible. Ideally, you want the load to be just 4 to 6 inches from the ground. OSHA recommends tilting the mast back and positioning the heaviest part of the load as close to the carriage as possible, keeping your center of gravity from shifting too far forward. Keep the mast tilted back when traveling for maximum stability.

What May Happen:

higher loads may cause the lift truck to

be less stable

2-Do not accelerate or brake suddenly

Sudden movements affect forklift stability, so do not accelerate or brake suddenly. Keep your movements slow, gradual, and deliberate. Maintain control of the forklift at all times, and adjust your speed as needed.

Also, don’t suddenly change direction, which can shift the combined center of gravity rapidly and cause the vehicle to tip. Never turn on a ramp or any kind of surface grade.

What May Happen:

Sudden stops may cause the forklift to

destabilize and load to tip over.

Download: Forklift Operator’s Daily Checklist and Safety Tips

3-Do not exceed your lift’s maximum load capacity

As discussed above, the load capacity has a huge impact on forklift stability, so never exceed the load capacity of your vehicle as described on the data plate or nameplate. Exceeding load capacity can very quickly cause the operator to either tip over or lose control of the steering. Make sure all lift truck operators on your job site are familiar with the vehicle’s maximum lift capacity.

What May Happen:

Oversized or Imbalanced loads may cause your

forklift to become unstable.

Also Read: Photo of the day: Safe Lifting at work

Download the Infographic

Now you can download the Infographic ” Forklift Stability Triangle” and post it at the workplace to communicate with everyone to be familiar with the Tips to improve forklift stability and avoid workplace incidents.

Also Read: Guideline for Crane Stability and Ground Pressure

Photo of the day: Forklift Stability Triangle

Download more resources at SAFETY BAG

More photos:

- Photo of the day: 10 Essential Safety Tips for Driving in Hot Weather Conditions

- Photo of the day: best workplace safety tips

- Photo of the day: The Importance of Stop Work Authority in Maintaining Workplace Safety

- Photo of the day: Tomorrow’s Reward for Working Safely Today: Cultivating a Culture of Safety

- Photo of the day: Preventing slips and trips at work

- Photo of the day: Learn the DRSABCD action Plan

- Working with Electricity Electrical Accidents Guide for Electrical Workers

- Photo of the day: Hearing Protection Device Selection

- Photo of the day: If An Earthquake Shakes You-Infographic free

- Fire Safety Posters Free Download

- Photo of the day: First Aid for Electrical Burns-Infographic free

- Infographic: First Aid for Cuts and Scrapes free download

- Photo of The day: Work Safe with Lasers-Laser Safety free

- Photo of the day: Working Safely with chemicals and chemical Management

- Photo of the day: Safe work practices when using MEWPs ( updated)

- Photo of the day: Preventing Common Kitchen Hazards

- Photo of the day: Safe handling of Gas Cylinders and lecture bottles

- Photo of the day: Forklift Stability Triangle

- Photo of the day: Defective Tools Safe Work Practice

- Photo of the day: Lift With Your Legs Not With Your Back

- Photo of the day: First Aid for burns

- Photo of the day: The 7 Principles of HACCP

- Photo of the day: Working Safely with Suspended Loads

- Photo of the day: Heat Stroke First Aid and safety posters

- Photo of the day: Near-Miss Reporting and Posters

- Photo of the day: Ergonomic chair and office chair safety tips

- Photo of the day: Whole Body Vibration

- Photo of the day: Substation Safety Equipment

- Photo of the day: Bypassing Safety Controls Rules

- Photo of the day: Lightning Safety Tips

- Photo of the day: Overhead Power lines Clearance

- Photo of the day: Floor Marking

- Photo of the day: Types of Foot Protection

- Photo of the day: Types of Hand Protection

- Photo of the day: Lockout and Tagout Safety

- Photo of the day: Fall Protection Plans

- Photo of the day: Flood Safety Tips

- Photo of the day: Read All Labels Work safe

- Photo of the day: Run Project safely with Crane Hand Signals

- Photo of the day: Flagman and Traffic control

- Photo of the day: Managing Risks of Exposure to Solvents in the workplace

- Photo of the day: Scissor Lift Safety

- Photo of the day: HSE Bulletin Board

- Photo of the day: Arc-Fault Circuit Interrupters (AFCI)

- Photo of the day: Safe use of ladders and step ladders

- Photo of the day: Concrete Truck Driver Hand Signals

- Photo of the day: Extension Cord Safety Tips

- Photo of the day: Protect your Head

- Photo of the day: choosing the right Anchorage

- Photo of the day: Work-Related Asthma

- Photo of the day: Top FIVE Heavy Equipment Construction Site Safety Tips

- Photo of the day: sun safety in the workplace

- Photo of the day: Cannabis and Impairment in the Workplace

- Photo of the day: Position for safety and comfort-Safety Tips

- Photo of the day: Generator Safety

- Photo of the day: Controlling COVID-19 in the Workplace-Physical Barriers

- Photo of the day: Manual Material handling

- Photo of the day: Personal Protective Equipment last resort

- Photo of the day: WHMIS 2015 – Pictograms

- Photo of the day: Indoor Air Quality

- Photo of the day: Noise in the affected workplace

- Photo of the day: Fatigue at Work

- Photo of the day: Don’t be Driven to Distraction

- Photo of the day: working in heat and Humidex Rating

- How to use Plate Clamps Safely: Safety Moment#34

- Photo of the day: Sitting at work

- Photo of the day: 5 ways to reduce the risk of Slipping and Tripping

- Photo of the day: Preventing the spread of contagious illness

- Photo of the day: Incident Investigations

- Photo of the day: 10 Scaffold Safety Essentials

- Photo of the day: Effective Health and Safety Committees

- Photo of the day: New worker Orientation & Safety Orientation checklist

- Photo of the day: Workplace Inspection

- Photo of the day: musculoskeletal disorders

- Photo of the day: Emergency preparedness in the workplace

- Photo of the day: Mental health in the workplace

- Photo of the day: Trenching Safety Tips That Can Save a Life

- Photo of the day: Dangerous Goods Classes

- Photo of the day: Safety Equipment for Confined Spaces

- Photo of the day: Tips to reduce Heat stress in the workplace

- Photo of the day: hierarchy of controls

- Your steps to chemical safety

- H2S Gas and how to handle its Emergency

- Photo of the day: Importance of Mock drill and Fire Action Emergency Procedure

- Photo of the day: Choosing the Right Face Mask and the difference between a respirator and face mask

- Photo of the day: Confined space safety Precautions

- Breath Safely: The Proper Use of Respiratory Protection

- Photo of the day: Electric shock survival

- Photo of the day: Chemical Spill Emergency Response

- Photo of the day: Construction Site fire Safety

- Photo of the day: Confined Space rescue

- Photo of the day: Conveyors Safety Tips

- Photo of the day: 5 Essential outcomes of an effective leadership survey process