E-Books: The Safety-Critical Systems Handbook 4th edition

2 min readThe Safety-Critical Systems Handbook 4th edition is a Straightforward Guide to Functional Safety_ IEC 61508 (2010 Edition), IEC 61511 (2015 Edition) and Related Guidance Including Machinery and other industrial sectors

Functional safety engineering involves identifying specific hazardous failures which lead to serious consequences (e.g., death) and then establishing maximum tolerable frequency targets for each mode of failure. Equipment whose failure contributes to each of these hazards is identified and usually referred to as “safety-related.” Examples are industrial process control systems, process shut down systems, rail signaling equipment, automotive controls, medical treatment equipment, etc. In other words, any equipment (with or without the software) whose failure can contribute to a hazard is likely to be safety-related.

A safety function is thus defined as a function, of a piece of equipment, which maintains it in a safe state or brings it to a safe state, in respect of some particular hazard. Since the publication of the first three editions of this book, in 2001, 2004, and 2011, the application of IEC 61508 has spread rapidly through most sectors of industry. Also, the process sector IEC 61511 has been published and now updated. IEC 61508 (BS EN 61508 in the UK) was re-issued in 2010. The opportunity has therefore been taken to update and enhance this book in the light of the authors’ recent experience. There are still three chapters on industry sectors, and Chapters 15 and 16 provide even more examples.

There are both random hardware failures that can be quantified and assessed in terms of failure rates AND systematic failures which cannot be quantified. Therefore it is necessary to have the concept of integrity levels so that the systematic failures can be addressed by levels of rigor in the design techniques and operating activities.

The maximum tolerable failure rate that we set, for each hazard, will lead us to an integrity target for each piece of equipment, depending upon its relative contribution to the hazard in question. These integrity targets, as well as providing a numerical target to meet, are also expressed as “safety-integrity levels” according to the severity of the numerical target. This usually involves four discrete bands of “rigor” and is explained in Chapters 1 and 2.

SIL 4: the highest target and most onerous to achieve, requiring state-of-the-art techniques (usually avoided)

SIL 3: less onerous than SIL 4 but still requiring the use of sophisticated design techniques

SIL 2: requiring good design and operating practice to a level such as would be found in an ISO 9001 management system

SIL 1: the minimum level but still implying good design practice

<SIL 1: referred to (in IEC 61508 and other documents) as “not-safety related” in terms of compliance An assessment of the design, the designer’s organization and management, the operator’s and the maintainer’s competence and training should then be carried out in order to determine if the proposed (or existing) equipment actually meets the target SIL in question.

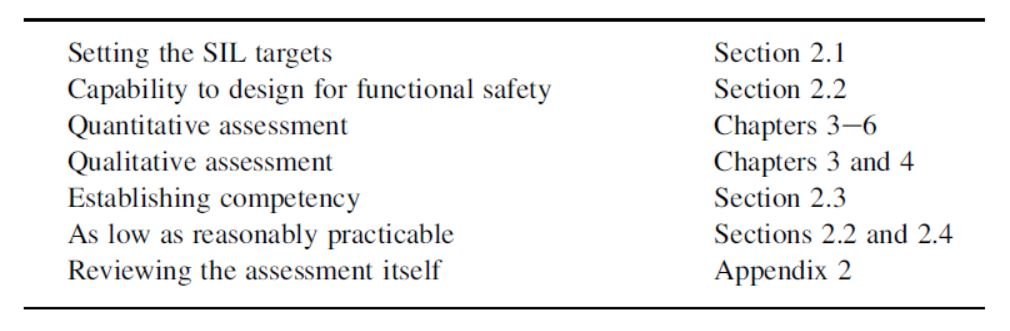

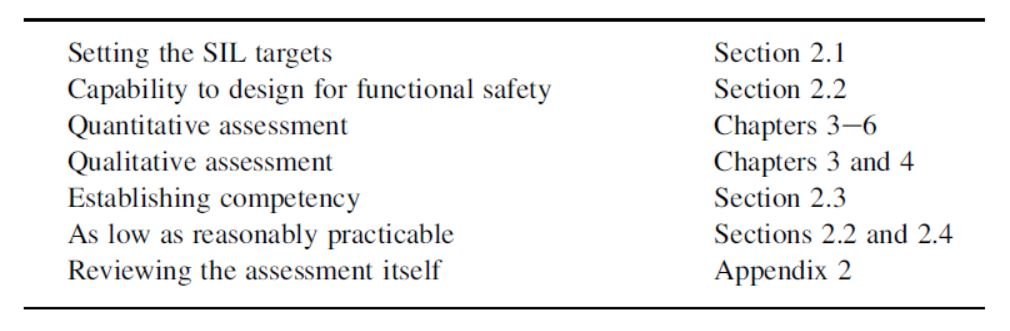

Overall, the steps involve:

IEC 61508 is a generic standard which deals with the above. It can be used on its own or as a basis for developing industry-sector-specific standards (Chapters 8e10). In attempting to fill the roles of being both a global template for the development of application-specific standards and a standard in its own right, it necessarily leaves much to the discretion and interpretation of the user. IEC 61511 is a simplified form of IEC 61508 catering for the more consistent equipment architectures found in the process industries.

One should bear in mind that the above documents are, largely, nonprescriptive guidance and a large amount of interpretation is required on the part of the user. There are few absolute right/wrong answers and, as always, the judgment of the professional (i.e., chartered) engineer must always prevail. It is also vital to bear in mind that no amount of assessment will lead to enhanced integrity unless the assessment process is used as a tool during the design cycle.

Now Download and read on!

Contents

The Contents of The Safety-Critical Systems Handbook 4th edition

- A Quick Overview

- The 2010 Version of IEC 61508

- The 2016 Version of IEC 61511

- Acknowledgments

- PART A: THE CONCEPT OF SAFETY INTEGRITY

- Chapter 1 The Meaning and Context of Safety Integrity Targets

- Chapter 2 Meeting IEC 61508 Part 1

- Chapter 3 Meeting IEC 61508 Part 2

- Chapter 4 Meeting IEC 61508 Part 3

- Chapter 5 Reliability Modeling Techniques

- Chapter 6 Failure Rate and Mode Data

- Chapter 7 Demonstrating and Certifying Conformance

- PART B: SPECIFIC INDUSTRY SECTORS

- Chapter 8 Second Tier DocumentsdProcess, Oil and Gas Industries

- Chapter 9 Machinery Sector

- Chapter 10 Other Industry Sectors

- PART C: CASE STUDIES IN THE FORM OF EXERCISES AND EXAMPLES

- Chapter 11 Pressure Control System (Exercise)

- Chapter 12 Burner Control Assessment (Example)

- Chapter 13 SIL TargetingdSome Practical Examples

- Chapter 14 Hypothetical Rail Train Braking System (Example)

- Chapter 15 Rotorcraft Accidents and Risk Assessment

- Chapter 16 Hydroelectric Dam and Tidal Gates

- Appendix 1 Functional Safety Management

- Appendix 2 Assessment Schedule

- Appendix 3 BETA PLUS CCF Model, Scoring Criteria

- Appendix 4 Assessing Safe Failure Fraction and Diagnostic Coverage

- Appendix 5 Answers to Examples

- Appendix 6 References

- Appendix 7 Quality and Safety Plan

- Appendix 8 Some Terms and Jargon of IEC 61508

- Index

Download the book

The Safety-Critical Systems Handbook 4th edition

More Downloads

- E-Books: Healthcare Hazard Control & Safety Management

- E-Books: Safety, Health and Working Conditions Training Manual

- E-Books: Energy Efficiency in Water and Wastewater Facilities

- E-Books: Fire Service Features of Buildings and Fire Protection Systems

- E-Books: Evaluation of Fire Safety free download

- E-Books: PPE for Chemical, Biological, and Radiological Hazards free

- E-Books: Changing the Workplace Safety Culture free download

- E-Books: Site Emergency Planning Workbook

- E-Books: Load Restraint Guide

- E-Books: Essential Practices for Creating, Strengthening, and Sustaining Process Safety Culture

- E-Books: System Safety Engineering and Risk Assessment

- E-Books: Permit-Required Confined Spaces

- E-Books: Is it Safe to Enter Confined Space?

- E-Books: 5-Minute Workplace Safety Talks

- E-Books: Safety Culture and High-Risk Environments

- E-Books: Practical Guide to Industrial Safety

- E-Books: Slip, Trip, and Fall Prevention for Healthcare Workers

- E-Books: Health and Safety at Work Key Terms

- E-Books: Fundamentals of Process Safety Engineering

- E-Books: Gas Detection Hand Book

- E-Books: Occupational health and safety management systems ANSI-AIHA-z10-2012

- E-Books: Hot Work on Drums and Tanks

- E-Books: Human Fatigue Risk Management

- E-Books: Guidelines for the provision of facilities and general safety in the construction industry

- E-Books: Handbook of Training in Mine Rescue and Recovery Operations ( 2021)

- E-Books: Code of Practice for the Safe Use of Lifting Equipment – Edition 9 (Nov 2019)

- E-Books: Free Forklift Health and Safety Best Practices Guideline

- E-Books: Handbook of Hazardous Chemical Properties

- E-Books: Human Performance Improvement through Human Error Prevention

- E-Books: Principles Of Fire Risk Assessment In Buildings

- E-Books: Investigation of Occupational Accidents and Diseases

- E-Books: Radiation Protection and Safety in Industrial Radiography

- E-Books: Basic Guide to System Safety, Third Edition

- E-Books: Food Safety Management-A Practical Guide for the Food Industry

- E-Books: Safety identification: Escape and evacuation plan signs- ISO 23601

- E-Books: Safety at Work

- E-Books: The Safety-Critical Systems Handbook 4th edition

- E-Books: Fundamental principles of occupational health and safety

- E-Books: Fire Safety Risk assessment Guide – Sleeping Accommodation

- E-Books: Mental health at work series

- E-Books: Live Fire Training: Principles and Practice

- E-Books: Pre-Startup Safety Review Guide

- E-Books: Fire and Emergency Drill Manual and Building Inspection Guide

- E-Books: Health and Safety: Risk Management 5th edition

- E-Books: Fire Protection systems -Third edition 2021

- E-Books: Fire Safety Logbook templates

- E-Books: From Accidents to Zero

- E-Books: Electric Safety Practice and Standards

- Your steps to chemical safety

- E-Books: Ergonomics and Psychology Developments in Theory and Practice

- E-Books: HAZOPS Should BE fun-The Stream-Based HAZOP

- E-Books: Safety Health and Environmental Auditing

- E-Books: A Quick Guide to Health and Safety

- E-Books: Occupational Ergonomics A Practical Approach

- E-Books: Job Hazard Analysis A Guide for Voluntary Compliance and Beyond

- E-Books: Electrical Safety of Low Voltage Systems