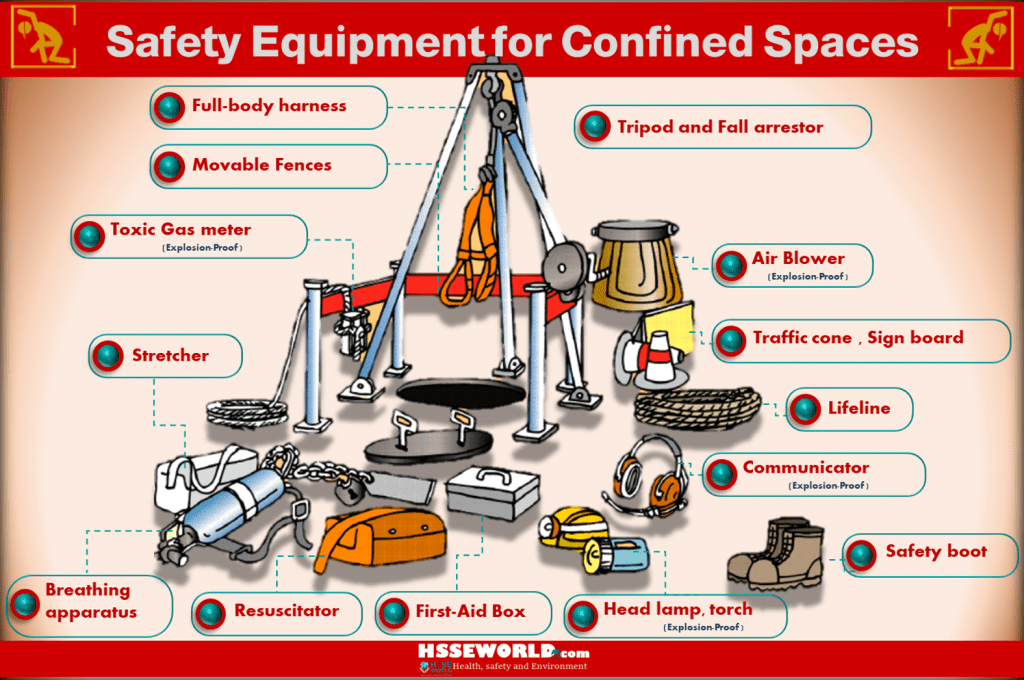

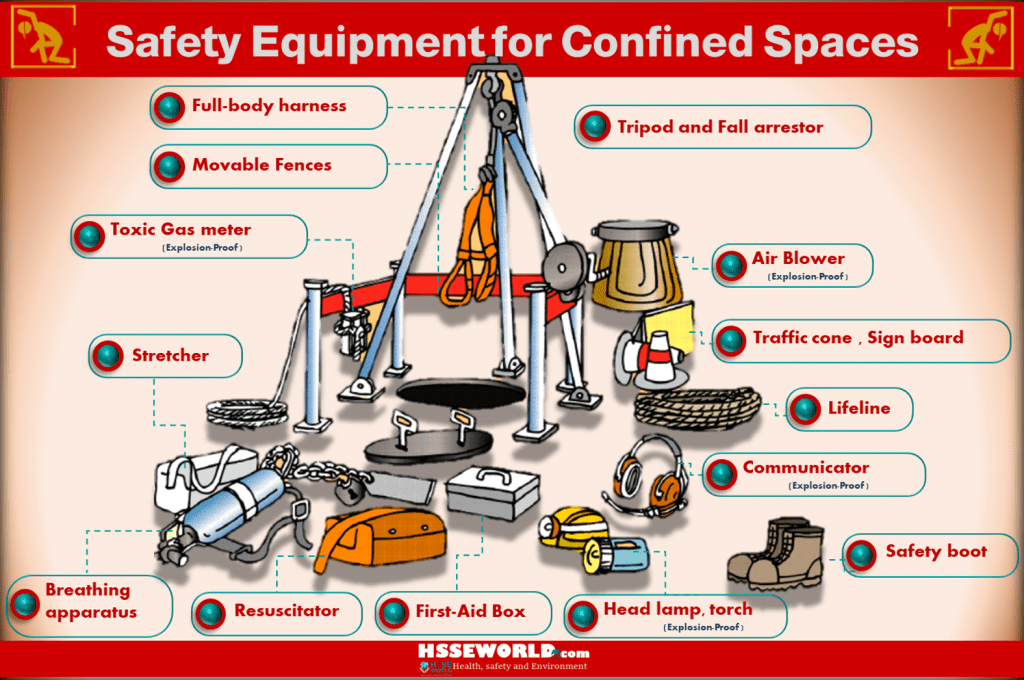

Photo of the day: Safety Equipment for Confined Spaces

12 min read Some of the deadliest hazards we can face are the conditions that exist inside confined spaces such as manholes, tanks, and similar areas. Controlling access to confined spaces and the hazards they contain can prevent injuries and save lives. The photo of the day provides an overview of confined space entry operations and explains the safe work practices required by OSHA to protect workers from confined space dangers.

will outline the required Safety equipment for confined spaces, in addition, will explain the confined space entry permit, atmospheric hazards, atmospheric testing and monitoring, other confined space hazards and how they are controlled, and the duties of the entry supervisor, the attendant, and the entrants.

After reading the article, the reader will be able to explain the following:

- Which atmospheric hazards can be found in a confined space;

- How the atmospheres of confined spaces are tested and monitored;

- What other hazards can exist in a confined space and how they are controlled;

- What the duties are of the entry supervisor, the attendant, and the entrants.

- Required Personal protective equipment (PPE) for working in a confined space

OSHA Confined space requirements

The Occupational Safety and Health Act of 1973 requires all employers to provide and maintain a safe and healthful workplace. OSHA provides us with specific regulatory requirements that are designed to protect workers from confined space hazards.

Specifically, the standards help employers to:

- Recognize, evaluate and control confined space hazards.

- Save lives and protect employees from job-related injuries and illnesses.

- Promote safe and effective work practices.

- Reduce preventable workers’ compensation losses.

- Comply with the law.

Definition of a confined space

Space can be considered a confined space if it meets the following criteria: space is not designed for continuous occupancy by an employee, is large enough for an employee to enter and perform work and the space has limited means of entry and exit.

Confined spaces can be classified as permit-required and non-permit required.

Spaces that do not have the potential to contain serious hazards are classified as non-permit required spaces. Non- permit spaces have no special requirements for entry.

Spaces that are likely to contain serious health or safety hazards will be classified as permit-required confined spaces.

The written confined space entry program

Under the law, employers that have permit-required confined spaces need to have a written confined space entry program.

At a minimum, the written permit-required confined space program must address:

- posting of warning signs.

- preventing unauthorized entry.

- hazard identification procedures.

- workplace evaluation procedures.

- procedures, practices, and means are necessary for safe permit space entry and closure operations.

- an entry permit system.

- employee training for entrants, attendants, and entry supervisors.

- providing work equipment and PPE at no cost to employees.

- a system for ensuring that pre-entry testing is performed, pre-entry preparations are completed; acceptable conditions are attained.

- monitoring the space as needed.

- developing and implementing rescue and emergency measures.

The confined space entry permit

Entry into permit-required spaces is prohibited unless a written entry permit is issued. The confined space entry permit will document the methods used to control a confined space’s hazards and ensure a worker is safe while entering, working in, and exiting the space.

Some of the information included on the permit is the identity of the space to be entered, a list of personnel involved in the entry process and their responsibilities, the acceptable conditions for entry, the results of testing used to certify the space safe to enter, and the list of specific personal protective equipment, specialized tools or rescue devices required for the operation.

Atmospheric hazards

Unfortunately, many fatalities have occurred in confined spaces due to various types of atmospheric hazards. To enter a confined space safely, workers must make a point of testing for and controlling any type of atmospheric hazard.

According to OSHA, an atmospheric hazard exists when something in the air may expose workers to the risk of death, incapacitation, impairment of the ability to self-rescue, injury, or acute illness.

One atmospheric hazard that exists in many confined spaces involves the concentration of oxygen. An oxygen-deficient atmosphere exists when space’s oxygen level in the air is below 19.5 percent. This means there is not enough oxygen for sufficient breathing by workers.

When oxygen levels exceed 23.5 percent, an explosive atmosphere exists in which any source of ignition could cause a fire or explosion. This is known as an oxygen-rich atmosphere.

Explosive atmospheres are also created when any flammable gas exceeds 10 percent of its lower explosive limit and when airborne combustible dust is present that meets or exceeds its lower flammable limit.

Another type of hazardous atmosphere that can exist in a confined space is a toxic atmosphere. A toxic atmosphere exists when a confined space contains levels of a toxic substance that exceeds its permissible exposure limit.

Sometimes the atmospheric conditions inside a space are so hazardous that they pose an immediate danger to life or health, would cause irreversible adverse health effects, or would interfere with a person’s ability to escape without help from a confined space.

OSHA refers to this type of condition as an IDLH condition. IDLH stands for “immediately dangerous to life and health.”

Toxic gases and vapors in confined spaces come from a wide variety of sources. Carbon monoxide, hydrogen sulfide, and methane are three of the most common naturally produced gases that can be fatal for confined space occupants.

Atmospheric testing & monitoring

The confined space entry program requires that all atmospheric hazards be controlled or eliminated before anyone is allowed to enter the space.

The first step is to test the atmosphere of the space with a calibrated direct-reading instrument.

This atmospheric testing must check for oxygen content, combustible gases and vapors, and toxic air contaminants, in that order.

The entry permit will list the atmospheric conditions acceptable for entry, but at a minimum, your test should ensure that oxygen levels are between 19.5 and 23.5 percent, that combustible gases do not exceed 10 percent of their lower flammable limit, and that any toxic gases do not exceed their permissible exposure limits.

When testing the atmosphere of a confined space, you must take readings at the top, middle, and bottom of the space to locate varying concentrations of gas and vapors. Gases can accumulate at the top or bottom of space depending on if they are more or less dense than air.

If atmospheric testing indicates a hazardous atmosphere exists, forced-air ventilation must be used to eliminate the hazard before space may be entered.

Monitoring of the atmosphere must continue during the entry to make sure the ventilation is maintaining a safe atmosphere. Ventilation must continue until all employees have exited the space.

( Read more:Dangerous-gases-in-confined-spaces/)

Other hazards & controls

Besides hazardous atmospheres, there are often other hazards inside a confined space that must be controlled to ensure a safe entry.

Mechanical hazards such as rotating shafts and cutting blades often pose a risk of injury to entrants of confined spaces.

Engulfment hazards exist when workers can stand or fall into certain materials that can trap and engulf them.

Workers can also be engulfed when materials are released into space, resulting in crushing injuries and suffocation.

There are a variety of procedures that are used to control these types of hazards inside a confined space.

Line-breaking and blanking may be required to isolate a space and prevent the inflow of materials.

Lockout/Tagout procedures will be required to safely de-energize any type of moving equipment or machinery.

An important part of the permitting process includes certifying that all hazards have been properly controlled before the entry permit is issued.

The entry supervisor

The entry supervisor oversees the entry and uses the written permit as a checklist to verify that all precautions to make a safe entry have been followed.

The supervisor also makes sure all testing has been completed, all procedures and equipment listed on the permit are in place, and that the confined space rescue service is available if needed.

To approve entry into space, the supervisor must sign the entry permit.

During the entry, the supervisor must periodically check to see that conditions remain consistent with the terms of the entry permit.

If the entry supervisor discovers any condition that violates the terms of the permit, the permit must be canceled and space must be vacated.

The attendant

The attendant monitors the conditions inside and outside the space as well as the condition of the entrants inside the space.

The attendant must be familiar with any potential hazards of the space and be able to recognize the signs and symptoms of exposure to those hazards.

Attendants must be able to identify the personnel inside the space at all times and maintain contact with them through hand signals, radio, or some other means.

If the attendant discovers conditions prohibited by the permit or an entrant displays behavior that could indicate hazardous conditions, he or she must call for all entrants to exit the space.

In the event that an entrant is injured, overcome, or is otherwise unable to exit the space under his own power, the attendant must contact the rescue service immediately.

According to the California Department of industrial relations, two-thirds of all confined space fatalities occur among would-be rescuers.

To prevent deaths, it is critical to use good, confined space entry practices so that there is no need for rescue operations. But if a rescue does become necessary, the attendant must not enter the space and must prevent unauthorized employees from entering while waiting for rescue personnel to arrive.(read:Confined-space-rescue/)

The entrants

The entrants are the employees who actually enter the space to perform work. They are the only members of the entry team permitted to enter the space.

Entrants must understand the specific hazards of every space they enter and be aware of any symptoms of exposure and warning signs that indicate the onset of dangerous conditions.

Entrants must be allowed to review the results of any atmospheric testing used to verify the space safe for entry.

While inside the space, the entrants must maintain communications with the attendant so the attendant can monitor the condition of the entrant and the operation’s status.

Entrants can also call for an evacuation of the space and must do so when they discover any sign or symptom of exposure to a dangerous situation or any conditions that violate the entry permit.

Required Personal protective equipment (PPE) for working in a confined space

PPE is traditionally regarded as the last line of protection with the emphasis being placed on avoidance and appropriate managerial control methods. However, the potentially hazardous nature and isolated position of those entering a confined space mean that, for the surveyor, PPE may be the first line of protection. Each confined space will present different hazards and degrees of risk to health and safety, the final provision of PPE should therefore be based on an assessment of risk. As a general rule, the following guidance is offered.

Basic surveyor PPE should include:

i) Body protection (hard-wearing overalls with suitable pockets for notebook etc).

ii) Foot protection (steel toecaps (200 joules), steel midsoles, good grip, oil resistance).

iii) Head protection (hard hat with chinstraps)

iv) Hand protection (hard-wearing gloves).

v) Eye protection (protective glasses, goggles).

vi) Ear protection (ear defenders or earplugs worn subject to communication system).

vii) Lighting (hand-held torch with lanyard and appropriate beam width).

viii) Safety harness

Breathing apparatus – Equipment that enables a person to get a supply of oxygen in an environment where little or no air exists, e.g. a smoke-filled compartment. Two types are in use; the smoke helmet and the self-contained unit using air cylinders. The smoke helmet covers the head and is connected to an air hose. A hand-operated pump supplies the air. The self-contained unit consists of one or two cylinders of compressed air kept in a harness, which is carried on the back. The high-pressure air is fed through a reducing valve and then to a demand valve fitted into a facemask.

Breathing air cylinder – Each cylinder is to contain not less than 1200 liters of fresh air. Every set of self-contained breathing apparatus must be provided with spare cylinders having a total air capacity of 2400 liters.

A safety harness is meant to be worn correctly so that it can fulfil its design requirements, which is to provide security against falling and allowing the wearer to use both hands to complete tasks, especially when working aloft. By not using a harness one increases the risk of falling and, in doing so, causing possible injury to others as well. A ‘5 point’ safety harness fitted with a ‘fall arrest’ device should always be used. Fall arresters act as shock absorbers and slow the fall gradually over short distances. The harness webbing and lanyard should be inspected regularly for cuts, abrasions or damage to stitching.

Download Infographic

Safety Equipment for Confined Spaces

More Photos

- Photo of the day: 10 Essential Safety Tips for Driving in Hot Weather Conditions

- Photo of the day: best workplace safety tips

- Photo of the day: The Importance of Stop Work Authority in Maintaining Workplace Safety

- Photo of the day: Tomorrow’s Reward for Working Safely Today: Cultivating a Culture of Safety

- Photo of the day: Preventing slips and trips at work

- Photo of the day: Learn the DRSABCD action Plan

- Working with Electricity Electrical Accidents Guide for Electrical Workers

- Photo of the day: Hearing Protection Device Selection

- Photo of the day: If An Earthquake Shakes You-Infographic free

- Fire Safety Posters Free Download

- Photo of the day: First Aid for Electrical Burns-Infographic free

- Infographic: First Aid for Cuts and Scrapes free download

- Photo of The day: Work Safe with Lasers-Laser Safety free

- Photo of the day: Working Safely with chemicals and chemical Management

- Photo of the day: Safe work practices when using MEWPs ( updated)

- Photo of the day: Preventing Common Kitchen Hazards

- Photo of the day: Safe handling of Gas Cylinders and lecture bottles

- Photo of the day: Forklift Stability Triangle

- Photo of the day: Defective Tools Safe Work Practice

- Photo of the day: Lift With Your Legs Not With Your Back

- Photo of the day: First Aid for burns

- Photo of the day: The 7 Principles of HACCP

- Photo of the day: Working Safely with Suspended Loads

- Photo of the day: Heat Stroke First Aid and safety posters

- Photo of the day: Near-Miss Reporting and Posters

- Photo of the day: Ergonomic chair and office chair safety tips

- Photo of the day: Whole Body Vibration

- Photo of the day: Substation Safety Equipment

- Photo of the day: Bypassing Safety Controls Rules

- Photo of the day: Lightning Safety Tips

- Photo of the day: Overhead Power lines Clearance

- Photo of the day: Floor Marking

- Photo of the day: Types of Foot Protection

- Photo of the day: Types of Hand Protection

- Photo of the day: Lockout and Tagout Safety

- Photo of the day: Fall Protection Plans

- Photo of the day: Flood Safety Tips

- Photo of the day: Read All Labels Work safe

- Photo of the day: Run Project safely with Crane Hand Signals

- Photo of the day: Flagman and Traffic control

- Photo of the day: Managing Risks of Exposure to Solvents in the workplace

- Photo of the day: Scissor Lift Safety

- Photo of the day: HSE Bulletin Board

- Photo of the day: Arc-Fault Circuit Interrupters (AFCI)

- Photo of the day: Safe use of ladders and step ladders

- Photo of the day: Concrete Truck Driver Hand Signals

- Photo of the day: Extension Cord Safety Tips

- Photo of the day: Protect your Head

- Photo of the day: choosing the right Anchorage

- Photo of the day: Work-Related Asthma

- Photo of the day: Top FIVE Heavy Equipment Construction Site Safety Tips

- Photo of the day: sun safety in the workplace

- Photo of the day: Cannabis and Impairment in the Workplace

- Photo of the day: Position for safety and comfort-Safety Tips

- Photo of the day: Generator Safety

- Photo of the day: Controlling COVID-19 in the Workplace-Physical Barriers

- Photo of the day: Manual Material handling

- Photo of the day: Personal Protective Equipment last resort

- Photo of the day: WHMIS 2015 – Pictograms

- Photo of the day: Indoor Air Quality

- Photo of the day: Noise in the affected workplace

- Photo of the day: Fatigue at Work

- Photo of the day: Don’t be Driven to Distraction

- Photo of the day: working in heat and Humidex Rating

- How to use Plate Clamps Safely: Safety Moment#34

- Photo of the day: Sitting at work

- Photo of the day: 5 ways to reduce the risk of Slipping and Tripping

- Photo of the day: Preventing the spread of contagious illness

- Photo of the day: Incident Investigations

- Photo of the day: 10 Scaffold Safety Essentials

- Photo of the day: Effective Health and Safety Committees

- Photo of the day: New worker Orientation & Safety Orientation checklist

- Photo of the day: Workplace Inspection

- Photo of the day: musculoskeletal disorders

- Photo of the day: Emergency preparedness in the workplace

- Photo of the day: Mental health in the workplace

- Photo of the day: Trenching Safety Tips That Can Save a Life

- Photo of the day: Dangerous Goods Classes

- Photo of the day: Safety Equipment for Confined Spaces

- Photo of the day: Tips to reduce Heat stress in the workplace

- Photo of the day: hierarchy of controls

- Your steps to chemical safety

- H2S Gas and how to handle its Emergency

- Photo of the day: Importance of Mock drill and Fire Action Emergency Procedure

- Photo of the day: Choosing the Right Face Mask and the difference between a respirator and face mask

- Photo of the day: Confined space safety Precautions

- Breath Safely: The Proper Use of Respiratory Protection

- Photo of the day: Electric shock survival

- Photo of the day: Chemical Spill Emergency Response

- Photo of the day: Construction Site fire Safety

- Photo of the day: Confined Space rescue