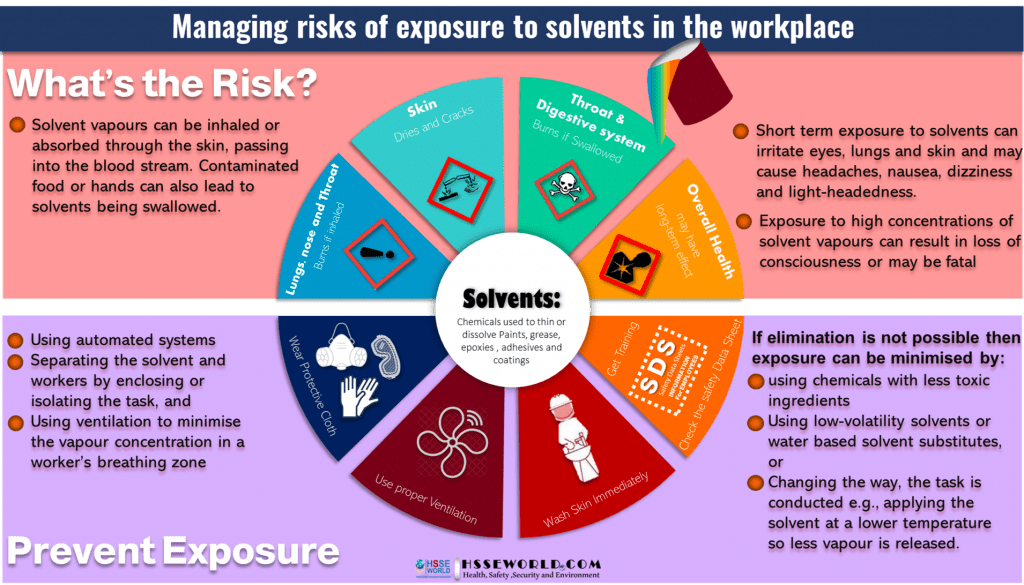

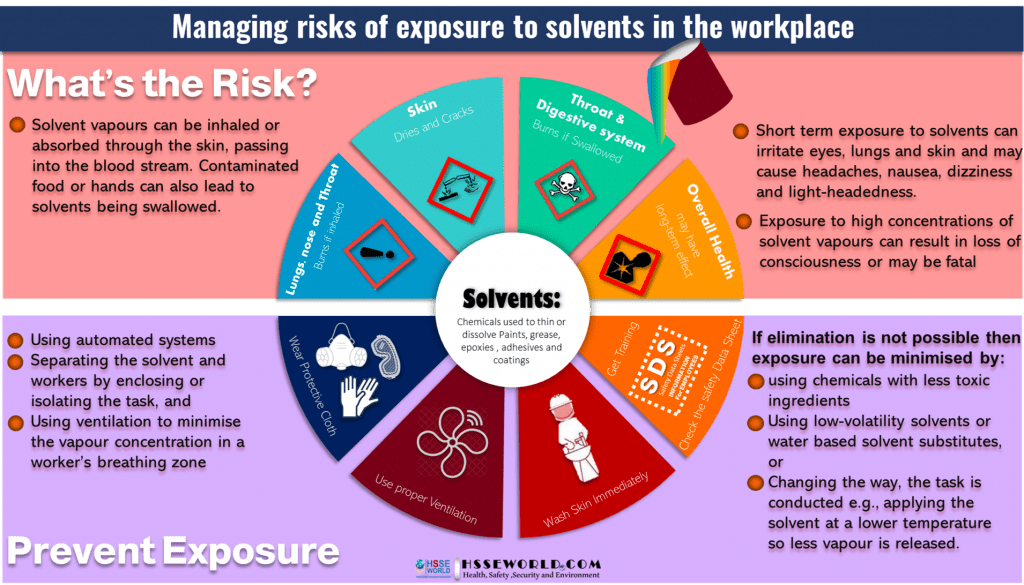

Photo of the day: Managing Risks of Exposure to Solvents in the workplace

7 min readSolvents, often known as VOCs (volatile organic compounds), are used to dissolve or dilute other substances and can be found in many construction products such as paints, paint strippers, thinners, and glues. Potentially harmful solvents include dichloromethane (DCM), also known as methylene chloride, toluene, xylene, white spirit, acetone, and ethyl acetate. Certain tasks, such as spraying, can produce very high exposures.

The Photo of the day provides advice on managing risks associated with exposure to solvents in the workplace. More information about specific solvents is in the relevant safety data sheet (SDS).

If you are using solvents in the workplace, you should have access to the relevant SDS. You should always read the SDS before using any type of solvent as it will provide important information about health and safety risks.

What is a solvent?

A solvent is a substance that dissolves a different substance to form a solution. It is usually a liquid but it can be a solid or gas.

Who can be exposed to solvents?

Solvents are widely used in workplaces. For example, workers can be exposed to solvents when cleaning and degreasing materials or when using paints, lacquers, and varnishes, adhesives, inks, or pesticides.

Industries, where solvents are commonly used, include engineering, construction, printing, rubber, plastics, footwear, textiles, foodstuffs, woodworking, dry cleaning, pharmaceutical and paint, and ink manufacturing.

Solvents may include:

- toluene, xylene, methyl ethyl ketone in paints and lacquers

- cyclohexane, acetone in adhesives

- trichloroethylene, perchloroethylene in degreasing solutions

- perchloroethylene in dry cleaning fluids, and

- turpentine, white spirits and xylene in used in printing.

What are the hazards?

Solvent vapors can be inhaled or absorbed through the skin, passing into the bloodstream. Contaminated food or hands can also lead to solvents being swallowed.

Short-term exposure to solvents can irritate eyes, lungs, and skin and may cause headaches, nausea, dizziness, and light-headedness.

Chronic effects can include dermatitis, toxicity to the nervous system, reproductive damage, liver and kidney damage, respiratory impairment, and cancer.

Exposure to high concentrations of solvent vapors can result in loss of consciousness or may be fatal.

Solvents can be highly volatile and may explode or catch fire if stored or handled incorrectly. Welding near solvents can present a risk of fire and explosion. Toxic gases like phosgene may be generated in the presence of halogenated solvents.

Information about other health effects (if any) can be found in the relevant SDS.

How do you control the risks?

Elimination is always the best control. If possible, use solvent-free materials or modify the task so it no longer requires the use of solvents. If elimination is not possible then exposure can be minimized by:

- using chemicals with less toxic ingredients

- using low-volatility solvents or water based solvent substitutes, or

- changing the way the task is conducted e.g. applying the solvent at a lower temperature so less vapour is released.

A combination of control measures is usually required.

Engineering controls

Engineering controls include:

- using automated systems

- separating the solvent and workers by enclosing or isolating the task, and

- using ventilation to minimise the vapour concentration in a worker’s breathing zone including:

- local exhaust ventilation e.g. capture hoods and duct systems to remove vapours

- dilution ventilation to increase the amount of fresh air supplied to a work area

- natural air flow—this may be improved by opening windows and doors or working in open air, or

- mechanical ventilation to introduce fresh air to the work area, particularly in small rooms and basements.

Other controls

Exposure to solvents can be minimized further by:

- preventing solvents evaporating by keeping lids on containers

- using only the minimum amount of solvent required for the work

- using barriers or splashguards and restricting access to non-essential workers

- using tools rather than hands to prevent skin contact

- scheduling work using solvents when the smallest number of workers are nearby

- disposing solvent-contaminated rags in sealed containers

- cleaning up spills immediately

- washing thoroughly before eating or smoking after working with solvents

- never using solvents to remove paints or grease from skin, and

- using appropriate personal protective equipment (PPE).

Personal Protective Equipment

PPE is the least effective method of controlling exposure to solvents and should only be used as a last resort. Always check the relevant SDS for the recommended PPE to be used with a particular solvent.

If respirators are used they must be:

- suitable for the type of solvent being used, and

- fitted, cleaned and maintained properly.

They should also be inspected and stored correctly. Disposable dust masks (P1 or P2) are ineffective against solvents. A combination air-purifying respirator that protects against gases, organic vapors, and particles is required. Further information on respiratory devices is in: Respiratory Protective Equipment (RPE) Guideline

Coveralls and gloves may be required to prevent skin contact.

Solvent-resistant barrier creams may also be appropriate when used with other PPE like impervious gloves.

Selecting the correct glove is important. This will depend on the concentration of the solvent, whether there is a risk of splash and if the gloves are going to be fully immersed in the solvent.

The relevant SDS should also be checked for recommendations on which type of glove to use.

( Read more: E-Books: Preparation safety data sheets for hazardous chemicals )

Working in enclosed or partially enclosed spaces

Solvent vapors cannot escape easily in an enclosed or partially enclosed space like a pit, small room or inside a vehicle. Dangerous and even fatal concentrations can build up very quickly. Some of these spaces may be ‘confined spaces’ therefore appropriate controls should be applied.

Further information is on the: Dangerous gases in confined spaces

A build-up of vapors or gases in enclosed and partially enclosed spaces can be explosive, flammable, or poisonous. Solvent vapors can also displace air and cause asphyxiation.

Where possible try to avoid using solvents in enclosed or partially enclosed spaces. If using solvents in these spaces is unavoidable, you must follow a safe system of work including emergency procedures.

Now you can download the Infographic of Managing Risks of Exposure to Solvents in the workplace

Download the infographic

Managing Risks of Exposure to Solvents in the workplace

More Photos

- Photo of the day: 10 Essential Safety Tips for Driving in Hot Weather Conditions

- Photo of the day: best workplace safety tips

- Photo of the day: The Importance of Stop Work Authority in Maintaining Workplace Safety

- Photo of the day: Tomorrow’s Reward for Working Safely Today: Cultivating a Culture of Safety

- Photo of the day: Preventing slips and trips at work

- Photo of the day: Learn the DRSABCD action Plan

- Working with Electricity Electrical Accidents Guide for Electrical Workers

- Photo of the day: Hearing Protection Device Selection

- Photo of the day: If An Earthquake Shakes You-Infographic free

- Fire Safety Posters Free Download

- Photo of the day: First Aid for Electrical Burns-Infographic free

- Infographic: First Aid for Cuts and Scrapes free download

- Photo of The day: Work Safe with Lasers-Laser Safety free

- Photo of the day: Working Safely with chemicals and chemical Management

- Photo of the day: Safe work practices when using MEWPs ( updated)

- Photo of the day: Preventing Common Kitchen Hazards

- Photo of the day: Safe handling of Gas Cylinders and lecture bottles

- Photo of the day: Forklift Stability Triangle

- Photo of the day: Defective Tools Safe Work Practice

- Photo of the day: Lift With Your Legs Not With Your Back

- Photo of the day: First Aid for burns

- Photo of the day: The 7 Principles of HACCP

- Photo of the day: Working Safely with Suspended Loads

- Photo of the day: Heat Stroke First Aid and safety posters

- Photo of the day: Near-Miss Reporting and Posters

- Photo of the day: Ergonomic chair and office chair safety tips

- Photo of the day: Whole Body Vibration

- Photo of the day: Substation Safety Equipment

- Photo of the day: Bypassing Safety Controls Rules

- Photo of the day: Lightning Safety Tips

- Photo of the day: Overhead Power lines Clearance

- Photo of the day: Floor Marking

- Photo of the day: Types of Foot Protection

- Photo of the day: Types of Hand Protection

- Photo of the day: Lockout and Tagout Safety

- Photo of the day: Fall Protection Plans

- Photo of the day: Flood Safety Tips

- Photo of the day: Read All Labels Work safe

- Photo of the day: Run Project safely with Crane Hand Signals

- Photo of the day: Flagman and Traffic control

- Photo of the day: Managing Risks of Exposure to Solvents in the workplace

- Photo of the day: Scissor Lift Safety

- Photo of the day: HSE Bulletin Board

- Photo of the day: Arc-Fault Circuit Interrupters (AFCI)

- Photo of the day: Safe use of ladders and step ladders

- Photo of the day: Concrete Truck Driver Hand Signals

- Photo of the day: Extension Cord Safety Tips

- Photo of the day: Protect your Head

- Photo of the day: choosing the right Anchorage

- Photo of the day: Work-Related Asthma

- Photo of the day: Top FIVE Heavy Equipment Construction Site Safety Tips

- Photo of the day: sun safety in the workplace

- Photo of the day: Cannabis and Impairment in the Workplace

- Photo of the day: Position for safety and comfort-Safety Tips

- Photo of the day: Generator Safety

- Photo of the day: Controlling COVID-19 in the Workplace-Physical Barriers

- Photo of the day: Manual Material handling

- Photo of the day: Personal Protective Equipment last resort

- Photo of the day: WHMIS 2015 – Pictograms

- Photo of the day: Indoor Air Quality

- Photo of the day: Noise in the affected workplace

- Photo of the day: Fatigue at Work

- Photo of the day: Don’t be Driven to Distraction

- Photo of the day: working in heat and Humidex Rating

- How to use Plate Clamps Safely: Safety Moment#34

- Photo of the day: Sitting at work

- Photo of the day: 5 ways to reduce the risk of Slipping and Tripping

- Photo of the day: Preventing the spread of contagious illness

- Photo of the day: Incident Investigations

- Photo of the day: 10 Scaffold Safety Essentials

- Photo of the day: Effective Health and Safety Committees

- Photo of the day: New worker Orientation & Safety Orientation checklist

- Photo of the day: Workplace Inspection

- Photo of the day: musculoskeletal disorders

- Photo of the day: Emergency preparedness in the workplace

- Photo of the day: Mental health in the workplace

- Photo of the day: Trenching Safety Tips That Can Save a Life

- Photo of the day: Dangerous Goods Classes