E-Books: Safety With Machinery

5 min readSafety With Machinery By John Ridley and Dick Pearce. This book sets out to simplify and clarify how those obligations can be met while remaining sane and economically viable. It explains the principles involved in the protection techniques and the methods of application of safety equipment and gives the engineer sufficient basic information to enable a rational and reasonable selection from the range of equipment offered to be made in the confidence that this decision will ensure that the degree of protection demanded by laws and society is achieved. In dealing with the subject of safety with machinery it seemed logical to go beyond the design and manufacturing aspects and include consideration of the actual use of machinery, systems of work, and plant layout.

Safeguarding philosophy and strategy

Ever since machinery was first developed to help the man with his labors a

heavy price in injuries and damage has been paid for the convenience. In the early days of the Industrial Revolution when labor was cheap, little regard was paid to the pain and suffering of injured workers. But the late

18th and the 19th centuries saw great changes in social attitudes and a growing recognition of the value of the people who worked the machines. This resulted in great strides being made in ways and means of providing protection for them. The enormous advances in technology made in more recent years have brought new hazards that have required new techniques to be developed to provide the degree of protection that society now expects employers to provide for their employees.

This part deals with some of the principles involved in providing safeguards,

gives basic examples of common hazards and how they can be dealt with. It explains the process of hazard and risk reduction through the carrying out of risk assessments and how the findings can be used to determine safety integrity levels.

As machinery and plant have become more complex, so the techniques

for protecting the operators have become more sophisticated. However, there are many of the older, simpler machines still in use, some of which may date from before the days when the safety of the operator was a matter of concern.

This volume is aimed at all who design, manufacture, use, maintain, modify, manage, inspect, or advise on machinery, plant, and component parts. It is also relevant to those who, while not directly involved with this equipment, have legal and moral responsibilities for ensuring that it is safe when put to use.

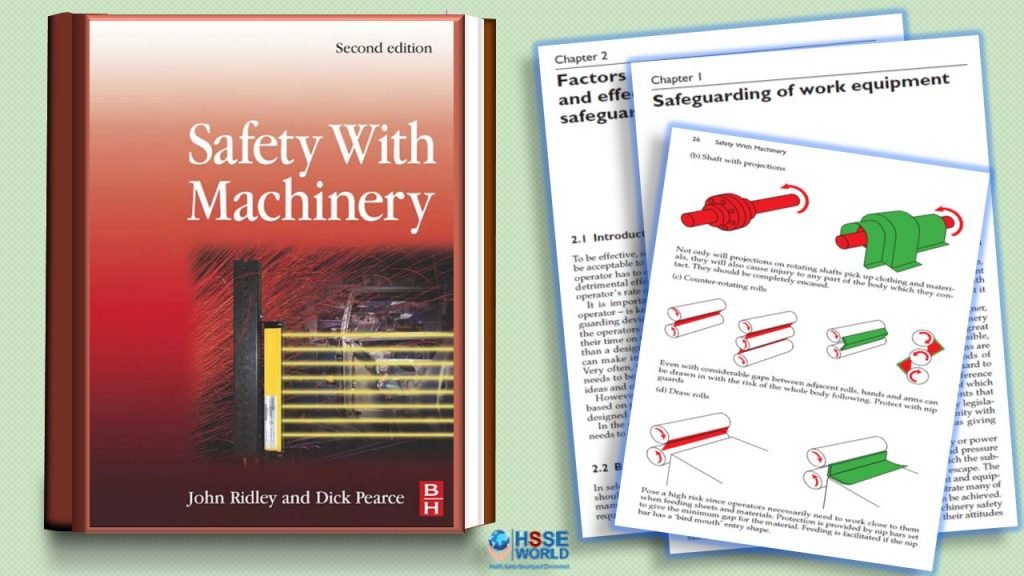

It sets out to describe the range of techniques available to the designer, works manager, and engineer for guarding a whole range of machinery against the simplest to the most complex. Necessarily it covers a great many techniques and practices but to keep the text as brief as possible, the techniques and practices are described in outline only. Diagrams are provided were pertinent to assist in understanding the methods of operation and to enable the selection of an appropriate type of guard to be made. For further information on techniques and practices reference should be made to international and European standards, many of which are listed in Appendix 1. These standards detail the requirements that need to be met to give conformity with current health and safety legislation and hence ensure a high degree of operator safety. Conformity with a national or international standard is normally recognized as giving compliance with legislative requirements. The text of this book applies to plant which may be manually or power-operated and extends to include equipment such as robots and pressure vessels that contain stored energy and to process plant in which the substances being processed may themselves be a hazard if they escape. The techniques described are applicable to the wide range of plant and equipment that is currently found in many workplaces and demonstrate many of the different methods by which protection of the operator can be achieved.

Over the years, individual countries have developed machinery safety standards to suit their particular methods of operating and their attitudes

Contents

Table of Contents of the Safety With Machinery book

- Safeguarding philosophy and strategy

- Safeguarding of work equipment

- Factors affecting the selection and effectiveness of machine

- Typical hazards of machinery

- Risk assessment, risk reduction, and selection of safeguards

- Guarding techniques

- Mechanical guarding

- Interlocking safeguards

- Ergonomic aspects of machinery safeguarding

- Safeguarding systems

- Mechanical safety arrangements

- Electrical safety circuits

- Hydraulic safety circuits

- Pneumatic safety circuits

- Safety in the use of lifting equipment

- Safety with pressure systems

- Safe working with equipment

- Plant layout and the working environment

Download the book

More Downloads

- E-Books: Healthcare Hazard Control & Safety Management

- E-Books: Safety, Health and Working Conditions Training Manual

- E-Books: Energy Efficiency in Water and Wastewater Facilities

- E-Books: Fire Service Features of Buildings and Fire Protection Systems

- E-Books: Evaluation of Fire Safety free download

- E-Books: PPE for Chemical, Biological, and Radiological Hazards free

- E-Books: Changing the Workplace Safety Culture free download

- E-Books: Site Emergency Planning Workbook

- E-Books: Load Restraint Guide

- E-Books: Essential Practices for Creating, Strengthening, and Sustaining Process Safety Culture

- E-Books: System Safety Engineering and Risk Assessment

- E-Books: Permit-Required Confined Spaces

- E-Books: Is it Safe to Enter Confined Space?

- E-Books: 5-Minute Workplace Safety Talks

- E-Books: Safety Culture and High-Risk Environments

- E-Books: Practical Guide to Industrial Safety

- E-Books: Slip, Trip, and Fall Prevention for Healthcare Workers

- E-Books: Health and Safety at Work Key Terms

- E-Books: Fundamentals of Process Safety Engineering

- E-Books: Gas Detection Hand Book

- E-Books: Occupational health and safety management systems ANSI-AIHA-z10-2012

- E-Books: Hot Work on Drums and Tanks

- E-Books: Human Fatigue Risk Management

- E-Books: Guidelines for the provision of facilities and general safety in the construction industry

- E-Books: Handbook of Training in Mine Rescue and Recovery Operations ( 2021)

- E-Books: Code of Practice for the Safe Use of Lifting Equipment – Edition 9 (Nov 2019)

- E-Books: Free Forklift Health and Safety Best Practices Guideline

- E-Books: Handbook of Hazardous Chemical Properties

- E-Books: Human Performance Improvement through Human Error Prevention

- E-Books: Principles Of Fire Risk Assessment In Buildings

- E-Books: Investigation of Occupational Accidents and Diseases

- E-Books: Radiation Protection and Safety in Industrial Radiography

- E-Books: Basic Guide to System Safety, Third Edition

- E-Books: Food Safety Management-A Practical Guide for the Food Industry

- E-Books: Safety identification: Escape and evacuation plan signs- ISO 23601

- E-Books: Safety at Work

- E-Books: The Safety-Critical Systems Handbook 4th edition

- E-Books: Fundamental principles of occupational health and safety

- E-Books: Fire Safety Risk assessment Guide – Sleeping Accommodation

- E-Books: Mental health at work series

- E-Books: Live Fire Training: Principles and Practice

- E-Books: Pre-Startup Safety Review Guide

- E-Books: Fire and Emergency Drill Manual and Building Inspection Guide

- E-Books: Health and Safety: Risk Management 5th edition

- E-Books: Fire Protection systems -Third edition 2021

- E-Books: Fire Safety Logbook templates

- E-Books: From Accidents to Zero

- E-Books: Electric Safety Practice and Standards

- Your steps to chemical safety

- E-Books: Ergonomics and Psychology Developments in Theory and Practice

- E-Books: HAZOPS Should BE fun-The Stream-Based HAZOP

- E-Books: Safety Health and Environmental Auditing

- E-Books: A Quick Guide to Health and Safety

- E-Books: Occupational Ergonomics A Practical Approach

- E-Books: Job Hazard Analysis A Guide for Voluntary Compliance and Beyond

- E-Books: Electrical Safety of Low Voltage Systems

3 thoughts on “E-Books: Safety With Machinery”