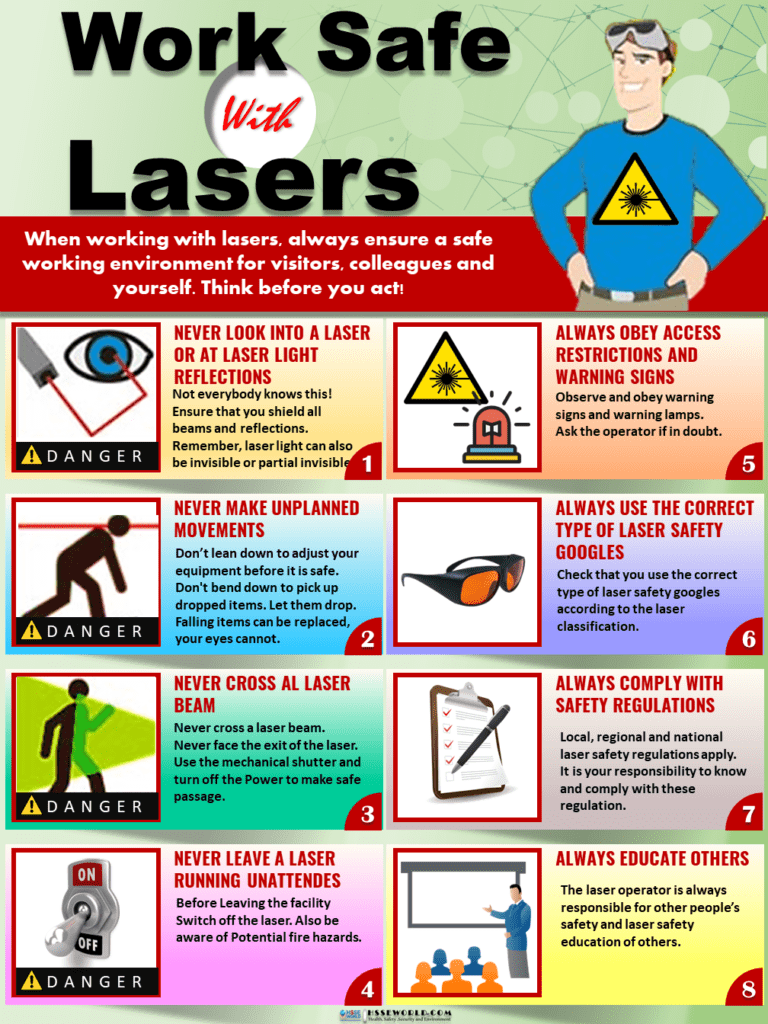

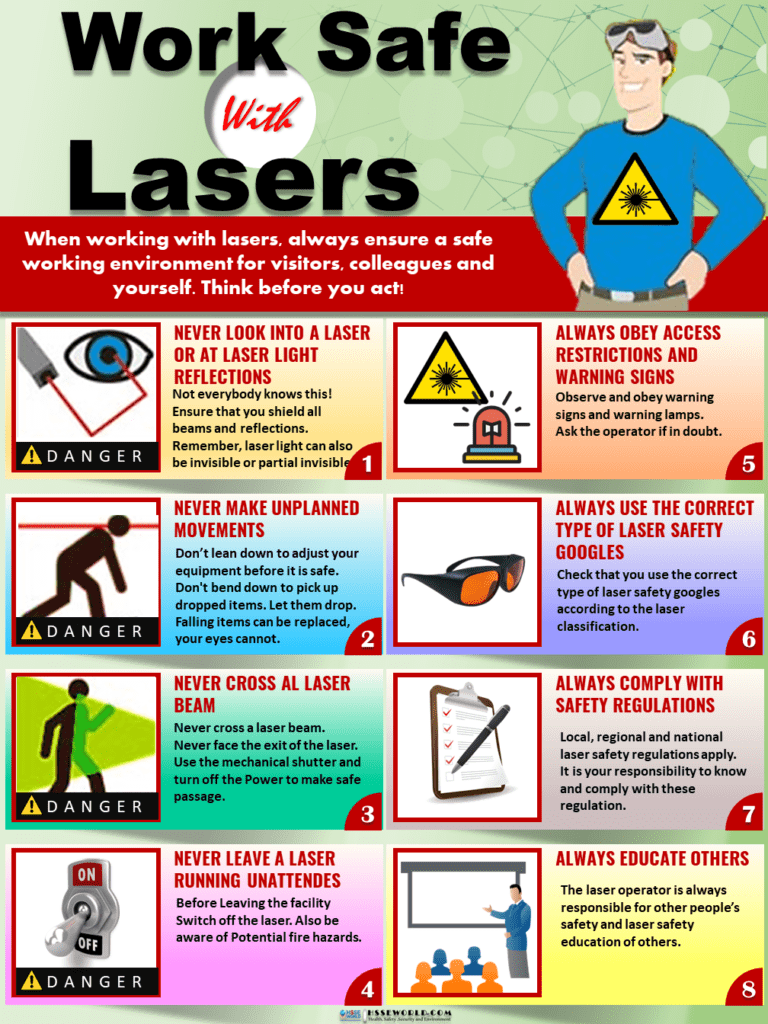

Photo of The day: Work Safe with Lasers-Laser Safety free

13 min readLASER is an acronym that stands for Light Amplification by Stimulated Emission of Radiation. The laser produces an intense, highly directional beam of light. The most common cause of laser-induced tissue damage is thermal in nature, where the tissue proteins are denatured due to the temperature rise following the absorption of laser energy.

Lasers are a common tool that can quickly injure workers. Operators can be hurt by the laser’s intense light. Co-workers could get hurt if they are struck by laser light reflecting off surfaces. Eye damage and serious burns are the most common injuries. Only trained workers should use this tool. In the photo of today you will be familiar with Laser safety and outline the following:

- How workers are exposed

- The laser risks and hazards recognition

- How to reduce the risks

- Laser Pointer and its Safety

Also Read: Protect Workers’ Vision with a Holistic View of Eye Safety

How workers are exposed

Lasers have become more common on worksites. Workers can be exposed by operating a laser. Simply being in the area where a laser is being used can also result in an exposure. Lasers can reflect in unpredictable ways off some surfaces, causing the beam to strike nearby workers.

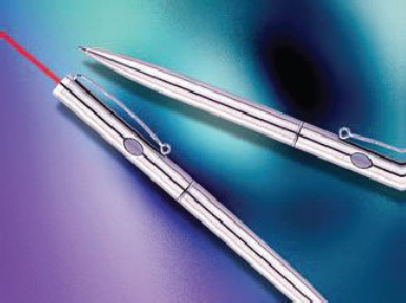

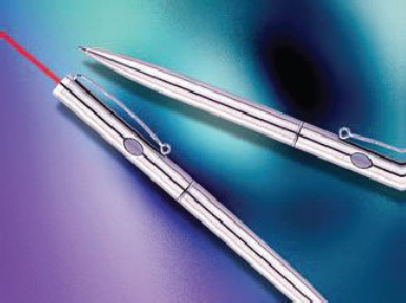

laser equipment, in particular, laser-based fiber optic equipment and medical devices have only recently been introduced into the telecommunications, health care, and manufacturing industries. Within the telecommunications industry, we should expect to see lasers in the form of fiber optic cables introduced at an increasing rate due to the fact that laser equipment can carry many more communications messages and require less maintenance than lead and polyurethane-encased cables.

In the healthcare field, laser medical devices are being widely introduced and used for enhanced medical treatment. In manufacturing, lasers are frequently used in welding, cutting, and sealing operations. also utilize laser equipment in medical micro-machinery, optical alignment, surveying, and writing operations.

Also, Read Overview of TLV and BEI and how they can make a big difference to workplace safety.

Workers employed as telecommunications installers, outside plant technicians, cable splicers, service technicians, manufacturing workers, and health care workers who use laser components or test equipment may be exposed to potentially hazardous laser equipment. In addition, members working at construction sites should be careful that they do not enter the path of a laser beam.

The laser risks and hazards recognition

Lasers are categorized into five different classifications: Class I, Class II, Class III-a, Class III-b, and Class IV. These classifications reflect the ability of the laser beam to cause damage to the eyes or skin with Class I categorized as the least hazardous and Class IV the most hazardous. Class I lasers do not emit hazardous levels of radiation under normal operating conditions. (However, direct eye exposure should be avoided.) Therefore, they are ruled to be exempt from guidelines established by the U.S. Center for Devices and Radiological Health (CDRH) and the American National Standards Institute (ANSI), a non-governmental organization involved in developing occupational safety and health standards.

Class II lasers are low-power devices that do not produce enough power to injure a person except when the source of the laser is stared at for a lengthy period. CDRH regulations require that employers put a caution label on Class II equipment.

Class III-a lasers include (visible) lasers that cannot cause injury to the unprotected eye except when viewing the laser with magnifying equipment such as a microscope. CDRH requires that a caution label be affixed to Class III-a lasers.

Class III-b laser equipment emits radiation that can cause injury to the eye if viewed directly or from a reflected beam. As with Class II and Class III-a lasers, caution labels must be displayed on Class III-b laser equipment. Technically, laser equipment that is used for telecommunications transmissions is categorized as Class III-b. However, since under normal operation the laser beam is totally enclosed and protected, the CDRH classifies such equipment as a Class I laser system and, thus, is exempt from CDRH regulations. Of importance, when light-guide or laser telecommunications cables become disconnected or broken, they should be considered Class III-b.

Class IV lasers produce radiation that may cause eye damage by direct viewing and/or from reflections. In addition, Class IV lasers may present a fire hazard. Thus where possible, the laser beam path should be controlled. When the beam path is not enclosed, a safety latch or interlock system should be used. Such a system would prevent operation unless the laser equipment is furnished with the proper enclosures. Class IV lasers must have a warning label affixed to them.

Hazard Recognition

The following references aid in recognizing laser hazards in the workplace.

Laser Hazard Classes (source: U.S. FDA Laser Hazard Classes)

| Class FDA | Class IEC | Laser Product Hazard | Product Example |

|---|---|---|---|

| I | 1, 1M | Considered non-hazardous. Hazard increases if viewed with optical aids, including magnifiers, binoculars, or telescopes. | laser printers CD players DVD players |

| IIa, II | 2, 2M | Hazard increases when viewed directly for long periods of time. Hazard increases if viewed with optical aids. | bar code scanners |

| IIa, II | 2, 2M | Hazard increases when viewed directly for long periods of time. Hazard increases if viewed with optical aids. | bar code scanners |

| IIIa | 3R | Depending on power and beam area, can be momentarily hazardous when directly viewed or when staring directly at the beam with an unaided eye. The risk of injury increases when viewed with optical aids. | laser pointers |

| IIIb | 3B | Immediate skin hazard from direct beam and immediate eye hazard when viewed directly. | laser light show projectors industrial lasers research lasers |

| IV | 4 | Immediate skin hazards and eye hazards from exposure to either the direct or reflected beam; may also present a fire hazard. | laser light show projectors industrial lasers research lasers medical device lasers for eye surgery or skin treatments |

Laser light shining into a worker’s eye is always a concern. The actual danger depends to some extent on the power of the laser. If the laser is low-powered, the worker should be able to blink, close, and protect the eye. But she or he could be distracted, and that could cause other workplace injuries.

More powerful lasers can damage eyes faster than workers can blink. Some lasers, such as CO2 lasers, use invisible infrared light. They won’t create a blink response. This can cause serious injury and loss of vision.

Lasers can also cause other types of harm. Direct or reflected light from a moderately intense laser can cause thermal burns to skin. The reddening and blistering would be akin to what people might get from a bad sunburn. With more powerful lasers, the consequences of exposure could be worse. Workers could suffer a serious third-degree burn.

Also Read: The 5 Main Hazards to the Eyes and Face

Health Effect

Laser light shining into a worker’s eye is always a concern. The actual danger depends to some extent on the power of the laser. If the laser is low-powered, the worker should be able to blink, close, and protect the eye. But she or he could be distracted, and that could cause other workplace injuries.

More powerful lasers can damage eyes faster than workers can blink. Some lasers, such as CO2 lasers, use invisible infrared light. They won’t create a blink response. This can cause serious injury and loss of vision.

The eye is the most susceptible to damage from laser radiation. Upon exposure, the cornea and the lens of the eye (located at the front of the eye) magnify and focus the radiation on the retina (located at the back of the eye). Direct exposure to a laser beam or a reflection of a laser beam may burn the retina causing partial or complete blindness. When a worker suffers eye damage, she/he should have an eye examination as soon as possible. Factors determining the amount of damage to the eye include the reaction of the cornea and lens, the presence or absence of reflective materials between the laser source and the eye, and the distance from the laser to the retina.

When working with lasers or laser equipment, optical aids like microscopes and binoculars should not be used (unless beam intensities are so low as to be absolutely safe). This practice should be followed because such optical aids serve as magnifiers of the laser beam, thus increasing the intensity of the beam.

Skin exposure to laser radiation may cause mild reddening and swelling, blistering, or charring. The degree of harm is dependent upon the duration of exposure, radiation wavelength, and the amount of radiation absorbed.

In addition, the health hazard of electrical shock exists when CWA members are working with high-voltage laser transmission components. Highly powered lasers also set off electrical discharges into the atmosphere, emitting ozone. Hazardous exposure to ozone may result in eye and upper respiratory irritation.

How to reduce the risks ( laser safety)

Workers should only use a laser if they have been trained. They should know what class it is and how it works. They should know what protective equipment is needed and what safety measures need to be taken. If the worksite has a Class 3B or Class 4 laser, regulations require a laser safety program and a trained laser safety officer.

The most effective way to reduce the risk of lasers is to eliminate the source of exposure. If that’s not possible, there are other risk controls to use. These should be identified in an exposure control plan. When choosing risk controls, start by asking yourself the questions in the following steps. The steps are listed in order of effectiveness.

Laser hazard controls should be designed to eliminate or minimize potential eye/ocular hazards resulting from a direct laser beam or a reflection of the beam, as well as skin burns. Employers should utilize proper engineering controls to minimize/eliminate harmful occupational exposures. Engineering controls may depend on whether the laser equipment is used in or out-of-doors. As required, backstops and shields should be utilized to protect workers from possible exposure.

Employees should also be provided with necessary personal protective equipment such as gloves, eyewear, and clothing. Warning signs should be affixed to laser equipment that indicates the type of laser and potential eye and skin hazards. All surfaces in the laser area should be non-reflective and the work area should be brightly lit to prevent the dilation of the pupils. All flammable materials should be stored in proper containers and shielded from the laser beam. All electrical hazards should be safeguarded. Where possible, audible signals should be used to indicate when the laser equipment is in operation. Employers should also establish and maintain effective maintenance programs/ laser safety programs.

Employers should establish a medical surveillance program for all workers working with or around laser equipment. Such a program would consist of a pre-placement medical examination that should include opthamologic (eye) and dermatologic (skin) tests as well as a review of the worker’s medical and work history. Information obtained from these medical examinations would allow for accurate detection and documentation of medical problems. Also, medical information and test results should be made available to all employees upon request.

Laser Pointer and its Safety

Commercial laser pointers have become common tools in the workplace. Most often laser pointers are used as a substitute for the retractable metal pointer used during lectures or presentations.

Laser pointers can also be found in construction work as an aid to laying pipe, in building

construction for leveling purposes, and in security and police services as an aiming device for firearms. But as familiar as laser pointers have become to many people, they still

present a very real occupational hazard. “Even momentary exposure from a laser pointer can

cause discomfort and temporary visual impairment,” warns the American Optometric Association (AOA).

“There can be glare, similar to that encountered with oncoming headlights at night; flash blindness, such as from a flashbulb; and afterimages, which involve the perception of spots in the field of vision. This temporary visual impairment can be dangerous if the person is engaged in any vision-critical activity.”

“Glare ceases when the laser beam disappears. Flash blindness and afterimages may last for several minutes. If afterimages persist for several hours, or if a disturbance in vision is apparent, an eye examination should be performed to determine if there is any permanent eye damage.”

How to Protect Yourself and Others

The following tips for safely using laser pointers are courtesy of the AOA and the Laser Institute of America.

- When buying a laser pointer, choose one that is labeled Class II and operates with a wavelength between 630 nm and 680 nm. The maximum output should be less than 5m watts.

- Do not purchase a laser pointer if it does not have a caution or danger sticker on it identifying the class. Report suspicious devices to the Food and Drug Administration (FDA).

- Before you use a laser pointer, either yours or someone else’s, read the caution or danger sticker carefully.

- Never point the laser at another person.

- Do not point a laser pointer at mirror-like surfaces. A reflected beam can act like a direct beam on the eye.

- Do not allow children to use laser pointers unless under adult supervision and never as toys.

- Never look directly at the laser beam.

- Never view a laser beam using an optical instrument, such as binoculars or a microscope.

Also, Read: Sunglasses Safety and Eye Health

Before you Leave do not Miss out free Download the free Infographic

Work Safely with Lasers-Laser Safety

More Photos

- Photo of the day: 10 Essential Safety Tips for Driving in Hot Weather Conditions

- Photo of the day: best workplace safety tips

- Photo of the day: The Importance of Stop Work Authority in Maintaining Workplace Safety

- Photo of the day: Tomorrow’s Reward for Working Safely Today: Cultivating a Culture of Safety

- Photo of the day: Preventing slips and trips at work

- Photo of the day: Learn the DRSABCD action Plan

- Working with Electricity Electrical Accidents Guide for Electrical Workers

- Photo of the day: Hearing Protection Device Selection

- Photo of the day: If An Earthquake Shakes You-Infographic free

- Fire Safety Posters Free Download

- Photo of the day: First Aid for Electrical Burns-Infographic free

- Infographic: First Aid for Cuts and Scrapes free download

- Photo of The day: Work Safe with Lasers-Laser Safety free

- Photo of the day: Working Safely with chemicals and chemical Management

- Photo of the day: Safe work practices when using MEWPs ( updated)

- Photo of the day: Preventing Common Kitchen Hazards

- Photo of the day: Safe handling of Gas Cylinders and lecture bottles

- Photo of the day: Forklift Stability Triangle

- Photo of the day: Defective Tools Safe Work Practice

- Photo of the day: Lift With Your Legs Not With Your Back

- Photo of the day: First Aid for burns

- Photo of the day: The 7 Principles of HACCP

- Photo of the day: Working Safely with Suspended Loads

- Photo of the day: Heat Stroke First Aid and safety posters

- Photo of the day: Near-Miss Reporting and Posters

- Photo of the day: Ergonomic chair and office chair safety tips

- Photo of the day: Whole Body Vibration

- Photo of the day: Substation Safety Equipment

- Photo of the day: Bypassing Safety Controls Rules

- Photo of the day: Lightning Safety Tips

- Photo of the day: Overhead Power lines Clearance

- Photo of the day: Floor Marking

- Photo of the day: Types of Foot Protection

- Photo of the day: Types of Hand Protection

- Photo of the day: Lockout and Tagout Safety

- Photo of the day: Fall Protection Plans

- Photo of the day: Flood Safety Tips

- Photo of the day: Read All Labels Work safe

- Photo of the day: Run Project safely with Crane Hand Signals

- Photo of the day: Flagman and Traffic control

- Photo of the day: Managing Risks of Exposure to Solvents in the workplace

- Photo of the day: Scissor Lift Safety

- Photo of the day: HSE Bulletin Board

- Photo of the day: Arc-Fault Circuit Interrupters (AFCI)

- Photo of the day: Safe use of ladders and step ladders

- Photo of the day: Concrete Truck Driver Hand Signals

- Photo of the day: Extension Cord Safety Tips

- Photo of the day: Protect your Head

- Photo of the day: choosing the right Anchorage

- Photo of the day: Work-Related Asthma

- Photo of the day: Top FIVE Heavy Equipment Construction Site Safety Tips

- Photo of the day: sun safety in the workplace

- Photo of the day: Cannabis and Impairment in the Workplace

- Photo of the day: Position for safety and comfort-Safety Tips

- Photo of the day: Generator Safety

- Photo of the day: Controlling COVID-19 in the Workplace-Physical Barriers

- Photo of the day: Manual Material handling

- Photo of the day: Personal Protective Equipment last resort

- Photo of the day: WHMIS 2015 – Pictograms

- Photo of the day: Indoor Air Quality

- Photo of the day: Noise in the affected workplace

- Photo of the day: Fatigue at Work

- Photo of the day: Don’t be Driven to Distraction

- Photo of the day: working in heat and Humidex Rating

- How to use Plate Clamps Safely: Safety Moment#34

- Photo of the day: Sitting at work

- Photo of the day: 5 ways to reduce the risk of Slipping and Tripping

- Photo of the day: Preventing the spread of contagious illness

- Photo of the day: Incident Investigations

- Photo of the day: 10 Scaffold Safety Essentials

- Photo of the day: Effective Health and Safety Committees

- Photo of the day: New worker Orientation & Safety Orientation checklist

- Photo of the day: Workplace Inspection

- Photo of the day: musculoskeletal disorders

- Photo of the day: Emergency preparedness in the workplace

- Photo of the day: Mental health in the workplace

- Photo of the day: Trenching Safety Tips That Can Save a Life

- Photo of the day: Dangerous Goods Classes

- Photo of the day: Safety Equipment for Confined Spaces

- Photo of the day: Tips to reduce Heat stress in the workplace

- Photo of the day: hierarchy of controls

- Your steps to chemical safety

- H2S Gas and how to handle its Emergency

- Photo of the day: Importance of Mock drill and Fire Action Emergency Procedure

- Photo of the day: Choosing the Right Face Mask and the difference between a respirator and face mask

- Photo of the day: Confined space safety Precautions

- Breath Safely: The Proper Use of Respiratory Protection

- Photo of the day: Electric shock survival

- Photo of the day: Chemical Spill Emergency Response

- Photo of the day: Construction Site fire Safety

- Photo of the day: Confined Space rescue