E-Books: Handbook of Rigging Lifting, Hoisting, and Scaffolding for Construction and Industrial Operations

5 min readThis fifth edition of the industry acknowledged standard rigging reference, first published in 1950—Handbook of Rigging for Construction & Industrial Operations (Lifting, Hoisting, and Scaffolding), has been comprehensibly revised, expanded, and updated to include the current best practices for safe rigging procedures on the construction site, as well as in industrial and utility facility environments. The emphasis in each chapter is on the legal obligation of rigging contractors and project management to comply with safety and health requirements, as set forth in OSHA 1926 federal regulations; ANSI/ ASTM safe operation standards for lifting and hoisting equipment for materials and personnel; as well as specific industry standards and guidelines applicable to various rigging procedures, equipment, and devices. The handbook is intended to provide a ready reference and guide for:

• Engineers and contractors engaged in rigging design and operations.

• Expert riggers and erectors of buildings and other structures.

• Maintenance mechanics in industrial plants and electric power generation facilities having less frequent rigging jobs to perform.

• Operators of all types of hoists, derricks, and cranes.

• Workers engaged in the erection of scaffolds or signages, or in climbing tall structures (towers and chimneys) for repair or maintenance work.

Accident statistics show that construction is a high-hazard industry to work in. As most of the accidents that occur are the result of human error, it’s important for everyone involved in the rigging lifting,

hoisting, and scaffolding procedures to accept responsibility for the part they play in the operations.

Almost all the crane accidents reported each year, however, could have been avoided if the workers controlling the cranes’ operation had paid more attention to what they were doing, checked the condition of slings and lifting equipment before use, ensured that loads were not lifted over any public place or work area, and not allowed anyone to ride on a suspended load.

A key aspect of this handbook is to encourage managers and workers to accept their responsibility to minimize the risk of accidents to persons and property through proper training that can significantly improve accident prevention on the construction site.

The handbook attempts to identify the elements of safe rigging practice and expand on the minimum safety regulations promulgated by OSHA and the various standards organizations. It should be used as a guide, in conjunction with the applicable safety regulations by everyone concerned with or responsible for the safety of employees at work on a project, as well as for the general public and surrounding property and structures.

Information in specific chapters on rigging equipment, systems, and devices can provide the basis for developing instructional material used in training personnel engaged in rigging operations. It also can be included in standard instructions issued to employees for the safe use of rigging equipment and handling of construction materials.

Safe practices recommendations in the handbook, of necessity, are framed in general terms to accommodate the many variations in rigging practices and the different ways in which rigging is used. Because these recommendations are only advisory in nature, they must be supplemented by strict observance of specific relevant regulations—as well as individual equipment manufacturers’ recommendations and requirements.

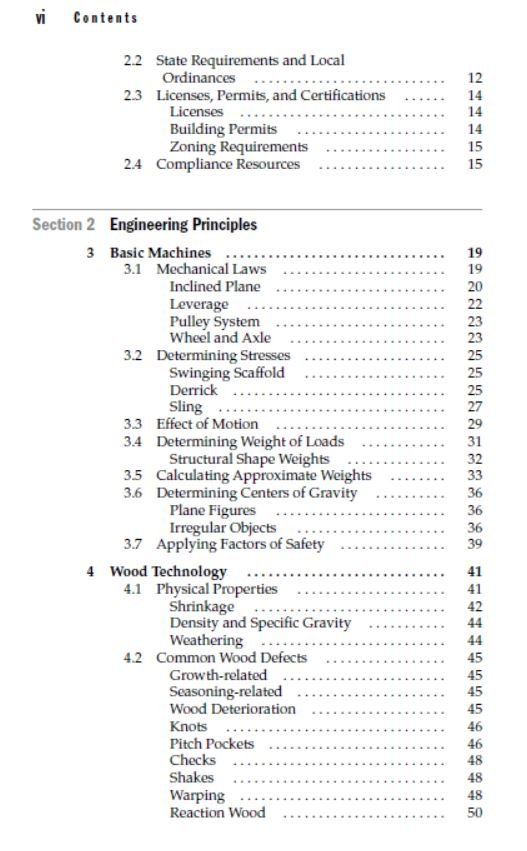

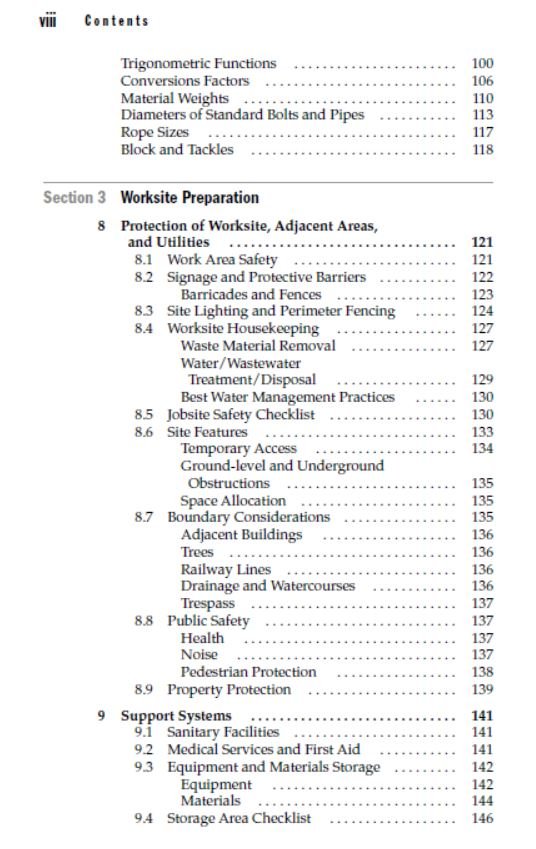

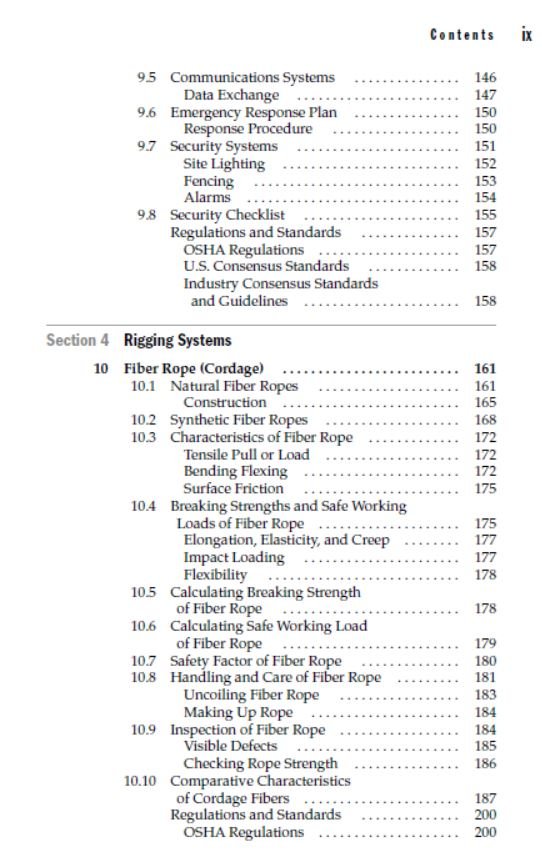

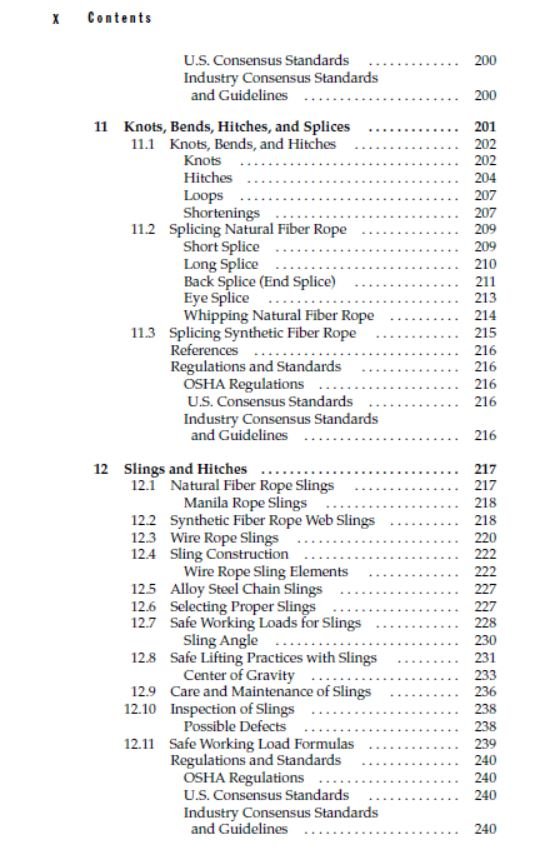

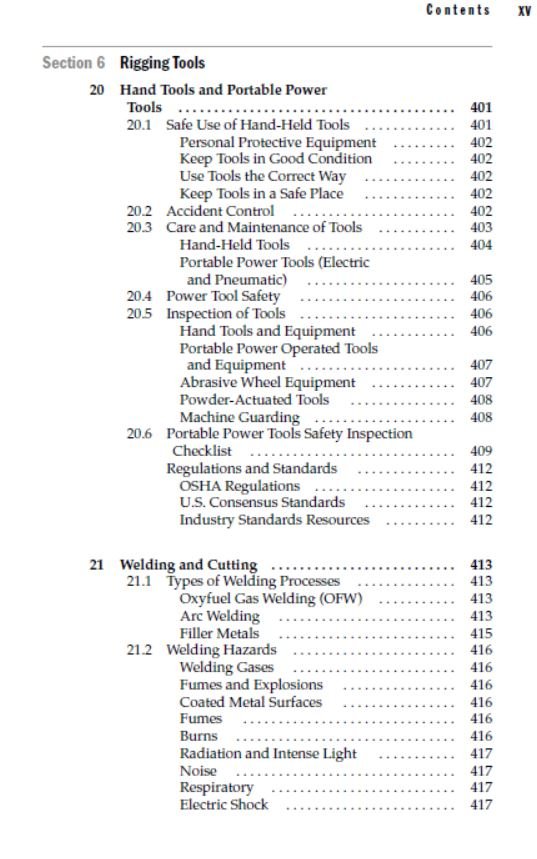

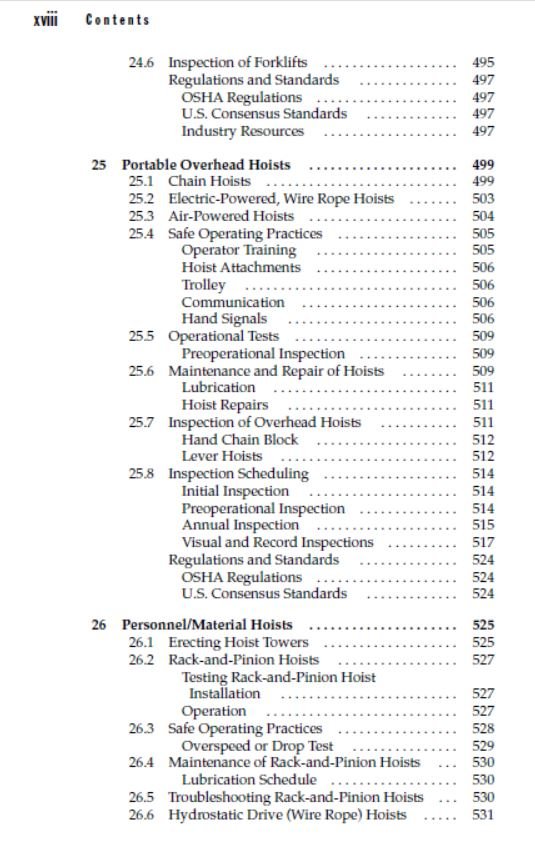

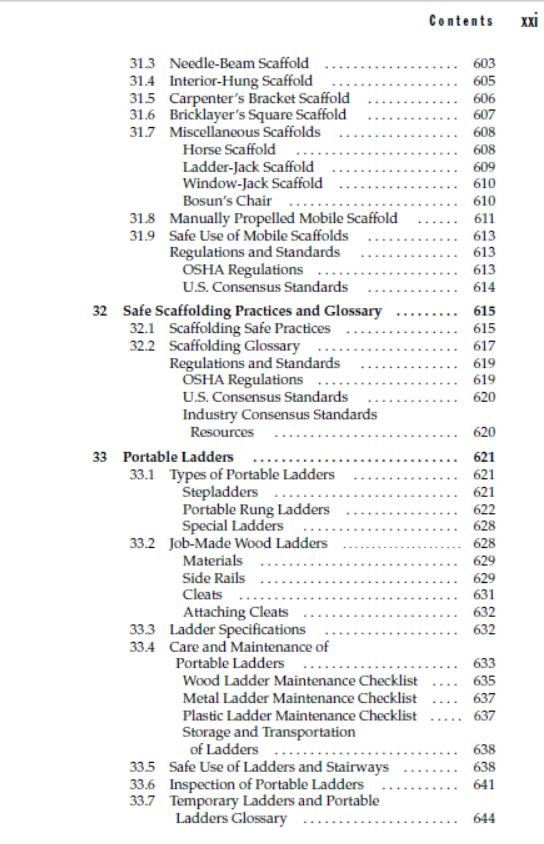

Contents

More Downloads

- E-Books: Healthcare Hazard Control & Safety Management

- Downloadable Kitchen Safety Inspection Checklist for Restaurants

- Photo of the day: 10 Essential Safety Tips for Driving in Hot Weather Conditions

- Photo of the day: best workplace safety tips

- Mastering LOTO: Protecting Workers with Energy Isolation and Isolation Confirmation Certificates

- Photo of the day: The Importance of Stop Work Authority in Maintaining Workplace Safety

- E-Books: Safety, Health and Working Conditions Training Manual

- Photo of the day: Tomorrow’s Reward for Working Safely Today: Cultivating a Culture of Safety

- Flammable and Combustible Storage Checklist Free Download

- Tool Box Talk: Rough Terrain Fork Truck Scaffolds

- E-Books: Energy Efficiency in Water and Wastewater Facilities

- Secure Your Lifts:Guidelines for Safe Lifting Operations Free Planning Tool

- Photo of the day: Preventing slips and trips at work

- E-Books: Fire Service Features of Buildings and Fire Protection Systems

- Sample of Accident Prevention Program ( APP) Template for General Industry Free Download

- E-Books: Evaluation of Fire Safety free download

- E-Books: PPE for Chemical, Biological, and Radiological Hazards free

- Photo of the day: Learn the DRSABCD action Plan

- Photo of the day: Hearing Protection Device Selection

- Photo of the day: If An Earthquake Shakes You-Infographic free

- Free ISO 14001:2015 Environmental Management System Audit Checklist Download

- Free Download Common Firefighter Job Interview Questions and Answers

- E-Books: Changing the Workplace Safety Culture free download

- Guides for Walking and Working Surfaces Safety Program

- Sample Written Program For Fire Prevention Plan

- Photo of the day: First Aid for Electrical Burns-Infographic free

- Infographic: First Aid for Cuts and Scrapes free download

- E-Books: Site Emergency Planning Workbook

- Machine Safety and 43-Equipment Inspection Checklists

- E-Books: Load Restraint Guide

- Photo of the day: Preventing Common Kitchen Hazards

- Photo of the day: Safe handling of Gas Cylinders and lecture bottles

- Photo of the day: Forklift Stability Triangle

- E-Books: Essential Practices for Creating, Strengthening, and Sustaining Process Safety Culture

- Photo of the day: Defective Tools Safe Work Practice

- Photo of the day: Lift With Your Legs Not With Your Back

- Facts about Fire Prevention

- Photo of the day: First Aid for burns

- E-Books: System Safety Engineering and Risk Assessment

- Photo of the day: The 7 Principles of HACCP

- Photo of the day: Working Safely with Suspended Loads

- Photo of the day: Heat Stroke First Aid and safety posters

- E-Books: Permit-Required Confined Spaces

- Photo of the day: Near-Miss Reporting and Posters

- Scaffold Safety self Audit and checklist

- E-Books: Is it Safe to Enter Confined Space?

- E-Books: 5-Minute Workplace Safety Talks

- Hot Work Controls and its Permit to work Form

- E-Books: Safety Culture and High-Risk Environments

- E-Books: Practical Guide to Industrial Safety

- Tool Box Talk: Don’t Let Chemicals Get to You

- E-Books: Slip, Trip, and Fall Prevention for Healthcare Workers

- Photo of the day: Lockout and Tagout Safety

- E-Books: Health and Safety at Work Key Terms

- Safety Flash: Not Following Work permit and Isolation Procedure

- Photo of the day: Fall Protection Plans

- Tool Box Talk: Hand Grinder Safety

- Safety Observation Report Template

- E-Books: Fundamentals of Process Safety Engineering

- Tool Box Talk: Lockout and Tagging

- Tool Box Talk: Winter Driving Safety Tips

- Forklift Operator’s Daily Checklist and safety Tips

- E-Books: Gas Detection Hand Book

- Tool Box Talk: Working Around Heavy Equipment

- E-Books: Occupational health and safety management systems ANSI-AIHA-z10-2012

- E-Books: Hot Work on Drums and Tanks

- Tool Box Talk: Rotary Hammers-Hammer Drills

- Inspecting Fall Protection Equipment Forms

- Safety Flash: Floorman arm pinned by Pipe Handling Equipment

- E-Books: Human Fatigue Risk Management

- Templates: HSE Incentives and rewards

- E-Books: Guidelines for the provision of facilities and general safety in the construction industry

- E-Books: Handbook of Training in Mine Rescue and Recovery Operations ( 2021)

- E-Books: Code of Practice for the Safe Use of Lifting Equipment – Edition 9 (Nov 2019)

2 thoughts on “E-Books: Handbook of Rigging Lifting, Hoisting, and Scaffolding for Construction and Industrial Operations”