Safety science is a twenty-first-century term for everything that goes into the prevention of accidents, illnesses, fires, explosions, and other events that harm people, property, or the environment (ASSE and BCSP 2000,3). Of these events, fire losses can be one of the greatest threats to an industrial organization in terms of financial losses, loss of life, loss of property, and property damage. Therefore, industrial fire protection and prevention are crucial components of any safety professional’s job, be it serving as a loss-control consultant or a safety manager.

Fires can strike any type of workplace at any time, resulting in property damage, injuries, and deaths. The adverse financial effects can be felt by an organization long after the fire is extinguished. Fire is a hazard that can potentially strike any workplace. The problem of ‘‘fire’’ in the United States today can be summarized as follows (U.S. Fire Administration [USFA] 1987, 22):

The United States has one of the highest fire-death rates per capita in the industrialized world. Each year, fires kill more Americans than all other natural emergencies combined, including floods, hurricanes, tornadoes and earthquakes.

Fire experience in the United States indicates that fires are a major problem. The United States, along with Canada, still has the worst fire-death rate for all the industrialized countries for which we have comparable data. U.S. fire deaths, based on one million per population, are almost twice the average fire-death rates for other industrialized countries (USFA 1987, 50).

As the federal government agency responsible for setting the national standards for worker safety and health, the Occupational Safety and Health Administration (OSHA) has established standards addressing each of the three key elements of fire safety (OSHA 2004, www.osha.gov):

1. Fire prevention

2. Safe evacuation of the workplace in the event of fire

3. Protection of workers who fight fires or who work around fire-suppression equipment

Industrial fire protection and prevention involves recognizing those situations that may result in an unwanted fire, evaluating the potential for an unwanted event, and developing control measures that can be used to eliminate or reduce those fire risks to an acceptable level. As is the case with any safety control measure, these controls can range from engineering strategies to administrative strategies or a combination of the two. Included in fire protection and prevention is emergency response. Emergency

response involves organizing, training, and coordinating skilled employees with regard to emergencies such as fires, accidents, or other disasters (ASSE and BCSP 2000, 6).

Table of Contents

1 Introduction to Industrial Fire Protection 1

Fire Prevention versus Fire Protection 2

Importance of Fire Safety 4

Historical Major Fire Losses in the United States 4

Trends in Fires in the United States 5

Economic Impact of Industrial Fires in the United States 5

Deaths and Injuries Due to Industrial Fires 6

OSHA and Fire Safety 12

Sources of Information 14

Summary 26

Chapter Questions 27

References 27

2 Chemistry and Physics of Fire 29

Fire Tetrahedron 29

Combustion 31

Unique Combustion Phenomena 34

Heat versus Temperature 36

Heat Transfer 37

Sources of Heat 40

Physics of Combustion 41

Fire Hazards of Materials 42

Hazardous Materials 44

Sources of Information on Hazardous Materials 47

Chapter Questions 51

References 52

3 Common and Special Hazards 55

Electricity as an Ignition Source 55

Hazardous Locations and the National Electrical Code 57

Defining Hazardous Locations 61

Safe Design of Electrical Equipment 62

National Testing Laboratories 64

Flammable Liquids and Combustible Liquids 65

Upper and Lower Explosive Limits 67

Flammable- and Combustible-Liquid Storage 67

Containers and Portable Tanks 67

Transferring Flammable and Combustible Liquids 68

Storage Cabinets 69

Inside Storage Rooms 70

Storage Tanks 73

Outside Aboveground Tanks 73

Underground Tanks 77

Tank-Vehicle and Tank-Car Loading and Unloading 78

Workplace Practices 79

Hydrogen 80

Liquefied-Hydrogen Systems 82

Acetylene 85

Oxygen 87

Liquefied-Petroleum Gas 88

Tank-Car and Truck-Loading or Unloading 90

Chapter Questions 91

References 91

4 Mechanical and Chemical Explosions 93

Anatomy of an Explosion 93

Explosives and Blasting Agents 94

Labels and Placards 95

Explosives-Handling and -Storage Procedures 97

Transporting Explosives 98

Use of Explosives and Blasting Agents 100

Oxidizing Agents 101

Ammonium Nitrate 102

Boiling-Liquid Expanding-Vapor Explosions 104

Dust Explosions 106

Cylinder Failures 107

Boilers and Unfired Pressure Vessels 107

Boiler Maintenance 110

Chapter Questions 111

References 112

5 Building Construction 113

Basic Terminology 113

Structural Elements 114

Characteristics of Building Materials 116

Fire-Resistance Ratings 120

Major Types of Building Construction 122

Fire-Protection Features 125

Protection of Openings in Fire Walls 128

Impact of Ventilation on Building Fires and Smoke

Movement 129

Interior Finish 130

Building Contents 131

Fire Loading 131

Occupancy and Commodity Classifications 132

Unique Risks for Fire in High-Rise Buildings 135

Building Codes 136

Major Provisions of Building Codes 136

Model Building Codes 137

Chapter Questions 138

References 138

6 Life Safety in Buildings 141

Loss of Life in Buildings 141

Triangle Shirtwaist Fire 141

Imperial Food Products Plant Fire 142

People’s Behaviors and Actions in a Fire 142

Origin and Development of NFPA 101 143

Building Occupancies and Life Safety 144

Building Codes and Life Safety 146

NFPA Requirements for Life Safety in Industrial Occupancies 146

Emergency-Action Plans 153

Fire-Prevention Plans 154

Chapter Questions 156

References 156

7 Hazardous Processes 159

Processes Involving Flammable and Combustible Liquids 160

Electrostatic Spray Operations 160

Spray Booths 162

Sources of Ignition 162

Ventilation 163

Flammable and Combustible Liquids: Storage and

Handling 164

Fire Protection 165

Operations and Maintenance 166

Drying, Curing, and Fusion Apparatuses 166

Aerated-Powder Coating Operations 168

Electrostatic Fluidized Beds 168

Dip Tanks and Coating Operations 169

Design and Construction of Dipping and Coating

Equipment and Systems 172

Electrical and Other Sources of Ignition 173

Ventilation 174

Storage, Handling, and Distribution of Flammable and

Combustible Liquids 175

Liquid Piping Systems 175

Fire Protection 176

Operations and Maintenance 177

Inspection and Testing 178

Training 179

Chapter Questions 179

References 179

8 Alarm and Detection Systems 181

NFPA 72 Classifications for Fire Alarm Systems 182

Power Supplies for Alarm Systems 182

Initiating Devices 183

Basic Considerations for Installation 184

Selection of Initiating Devices 184

Heat-Sensing Fire Detectors 185

Location of Heat-Sensing Fire Detectors: Spot versus Line

Devices 185

Smoke-Sensing Fire Detectors 186

Location and Spacing of Smoke Detectors 187

Radiant-Energy-Sensing Fire Detectors 188

Location and Spacing of Radiant-Energy-Sensing Fire

Detectors 189

Sprinkler-Water-Flow Alarm-Initiating Devices 189

Signal Annunciation 190

Notification Devices 191

Audible and Visible Criteria of Notification Devices 191

Reporting Systems 193

Public Fire Alarm Systems 193

Central-Station Fire Alarm Systems 193

Proprietary Supervising-Station Systems 194

Remote-Supervising-Station Fire Alarm Systems 195

Inspection, Testing, and Maintenance of Fire Alarm

Systems 196

Chapter Questions 197

References 199

9 Fire Extinguishment 201

Classifications of Fires 201

Extinguishing Agents 202

Water 202

Water Use on Special Hazards 204

Carbon Dioxide 204

Halogenated Agents 205

Dry Chemicals 206

Foam Extinguishing Agents 208

Combustible Metal Extinguishing Agents 208

Portable Fire Extinguishers 209

Labeling 209

Fire Extinguisher Rating Systems 210

Fire Extinguisher Use in the Workplace 212

Fire Extinguisher Distribution and Mounting 212

Maintenance, Inspection, and Testing 213

Training 214

Water-Based Sprinkler Systems 214

Impact of Sprinkler Systems on Fires 215

Wet-Pipe Systems 215

Water Supply and Distribution 216

Piping 217

Outside Stem and Yoke Valves 218

Water-Flow Alarms 219

Dry-Pipe Systems 220

Cross-Mains and Branch Lines 220

Sprinkler Heads 222

Fire Department Connections 223

Sprinkler-System Inspections 223

Fire Hydrants 225

Standpipe and Hose Systems 225

Chapter Questions 228

References 230

10 Fire-Program Management 231

Introduction 231

Hazard Identification 232

Quantification of Risk 232

Fire-Protection and -Prevention Strategies 234

Measurement of the Effectiveness of Fire Strategies 235

Emergency-Response Plans 236

Federal Regulations Related to Emergency Response 236

FEMA 237

OSHA 237

EPA 243

NFPA 1600: Recommended Practice for Emergency

Management 247

Planning an Emergency-Response Strategy 248

Developing the Written Emergency-Response Plan 252

Emergency Medical Care 253

Training 255

Personal Protective Equipment 256

Media Control 257

Recovery after an Emergency 258

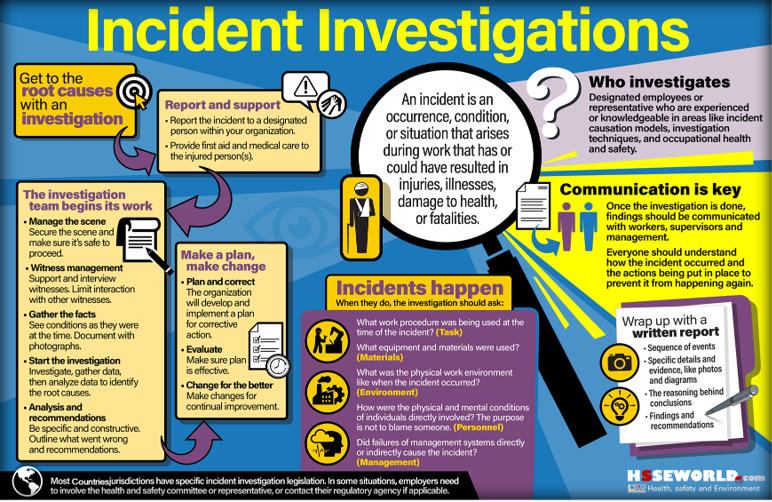

Investigation of Emergency Incidents 260

Maintenance of Fire-Protection Systems 261

Fire Inspections 262

Hot-Work-Permit Programs 267

Chapter Questions 269

References 270

Appendix A: U.S. Environmental Protection Agency’s Integrated

Contingency Plan 275

Solutions to Chapter Questions 287

Glossary: Fire Safety Terminology 307

Index 319