Once you’ve completed a risk assessment in your workplace, those risks that you have identified as high or moderate may require additional controls

The highest risk should be addressed first. If you cannot eliminate a risk, you’ll need to implement control measures to minimize the risk. The hierarchy of controls can help you systematically take action to minimize risk.

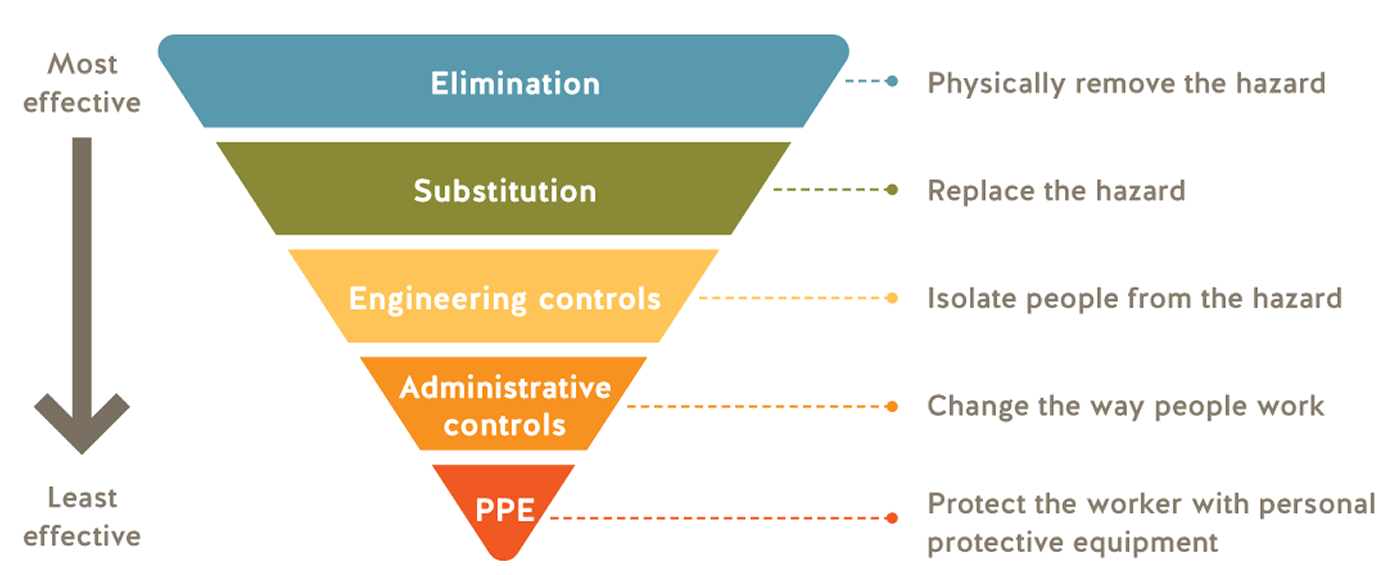

The hierarchy of controls

When considering how to reduce the risk, there’s a certain order you should follow. This is called the hierarchy of controls. It’s important to follow the hierarchy, as shown below, rather than start with the easiest control measures.

Note that while the controls are listed in order of effectiveness, all four types of controls should be considered. They often work best in combination. For example, first responders cannot eliminate risks by choosing not to enter a burning building, but they can use engineering controls, administrative controls, and personal protective equipment and clothing to minimize the risks when they enter that building.

- 0 Elimination or substitution

Eliminating the hazard completely is always the first choice. Substitution involves replacing the material or process with a less hazardous one.

When considering these options, ask yourself:

- Can I find safer ways to perform the task? For example, if falling is a hazard, eliminate the risk by storing stock at lower heights so workers don’t have to climb ladders to reach the goods.

- Can I use something less harmful? For example, if chemical-heavy industrial cleaners are a hazard, consider substituting cleaners made of vinegar and water mixed with salt, borax, or baking soda. Just make sure the substitutions don’t create new hazards.

- 0 Engineering controls

If you can’t eliminate the hazards or substitute safer alternatives, engineering controls are the next best options. These involve using work equipment or other means to prevent workers from being exposed to a hazard. Engineering controls are physical changes to the workplace and may include equipment guarding, guardrails, traffic control lanes and barriers between vehicles and pedestrians, and many other options.

For example, while working at heights cannot be avoided in construction, guardrails can be installed to prevent falls from happening. Guardrails are an example of an engineering control.

- 0 Administrative controls

Administrative controls involve identifying and implementing safe work procedures so your workers can perform their job duties safely. The findings of your risk assessment will form the basis of these safe work procedures.

Examples of administrative controls include implementing person-check procedures and prohibiting the use of mobile phones while workers are driving.

- 0 Personal protective equipment and clothing

Using personal protective equipment (PPE) is another important control to protect workers.

For example, while working with toxic chemicals may be necessary in certain workplaces such as laboratories, the use of PPE such as protective eyewear and gloves will help to reduce the exposure risk. Similarly, first responders enter hazardous sites as a regular part of their job, but they diligently use various types of PPE to protect themselves.

Monitoring control measures

Improving health and safety doesn’t have to be costly, but the potential return on investment is huge. For example, placing a mirror on a dangerous, blind corner of your worksite can help prevent vehicle incidents. Considering how serious a resulting injury might be, this is a low-cost precaution.

Protecting employees from harm requires ongoing effort. You’ll need to monitor the effectiveness of the hazard controls in place and improve those that don’t measure up. It’s a good idea to:

- Conduct regular safety inspections to track exposure to hazards.

- Organize a joint occupational health and safety committee and hold monthly meetings to discuss health and safety issues.

- Deal with safety issues as soon as possible.

Record your findings

It is a good practice to document what you find from your risk assessment. This includes noting the hazards, how people might be harmed by them, and what’s already in place to control the risk. This documentation doesn’t need to be complicated, but it can help you communicate and manage risks in your workplace.