Workers in industries such as construction, manufacturing, and transportation can avoid workplace accidents by taking the appropriate safety precautions. However, despite their best efforts, workers may still become injured by defective tools or equipment.

Those who are injured in defective tool accidents may be able to obtain compensation from their employers and/or responsible third parties.

The photo of today Below will outline the following:

- Types of Defective Tools

- Tool Safety Standards

- Types of Defective Tool Injuries

- Workers’ Compensation for Defective Tools Accidents

- Defective Tools Safe Work Practice

Also, Read: Back Injury Prevention

Types of Defective Tools

Any tool or piece of equipment can be dangerous if not manufactured or maintained properly. Defective hand tools, power tools, heavy machinery, and industrial equipment may cause workers to suffer serious injuries.

Some types of defective or malfunctioning tools include:

- Bulldozers

- Conveyor belts

- Cranes

- Forklifts

- Hammers

- Jackhammers

- Ladders/scaffolding

- Lawnmowers

- Nail guns

- Power drills

- Snowblowers

- Table saws

- Tractors

- Welding equipment

Tool Safety Standards

The Occupational Safety and Health Administration (OSHA) sets workplace safety standards for hand and power tools in the workplace. There are standards that apply to the general industry, as well as those that apply to specific industries such as shipyards, marine terminals, longshoring, and construction.

Generally, employers are responsible for the safe condition of tools and equipment that their employees use. When employers fail to uphold this duty, workers may become injured – and entitled to compensation – as a result.

Types of Defective Tool Injuries

Workers may sustain a variety of defective tool injuries, ranging from minor to fatal. Some common types of injuries may include:

- Amputations

- Broken bones

- Burns

- Crushing injuries

- Degloving injuries

- Electrocution/electric shock

- Eye injuries

- Lacerations

- Neck/back injuries

- Puncture wounds

- Scarring/disfigurement

- Traumatic brain injury (TBI)

Also Read: Photo of the day: Mental health in the workplace

Workers’ Compensation for Defective Tool Accidents

Most employees are eligible for workers’ compensation benefits for their workplace injuries under the Workers’ Compensation Act (the Act), with the exception of longshoremen, railroad workers, and other types of federal employees. Under the Act, employers are required to carry workers’ compensation insurance to cover the cost of medical, wage loss, and other types of expenses associated with their employees’ work injuries.

Employees must give notice of their work injury to their employers within 120 days. Their employer may then decide to accept or deny the claim. If the claim is accepted, the worker may begin receiving various forms of workers’ compensation, including a percentage of their lost wages if the injury caused them to miss work for more than seven days.

If the claim is denied, the worker has several opportunities for appeal. T

Third-Party Products Liability Claims

workers may also be able to sue negligent third parties for their workplace injuries and recover damages that are not provided by workers’ compensation. Tool and equipment manufacturers are responsible for ensuring the safety of their products. Workers who are injured by defective tools may, therefore, file a third-party product liability claim against the manufacturers or suppliers of defective tools.

Tool manufacturers or suppliers may be held legally responsible for three types of tool defects:

- Design defects: Those that render a product inherently unsafe from conception, before it is even manufactured

- Manufacturing defects: Defects that occur during the manufacturing process

- Marketing Defects: This type of defect typically involves improper labeling, insufficient warnings, or inadequate instructions

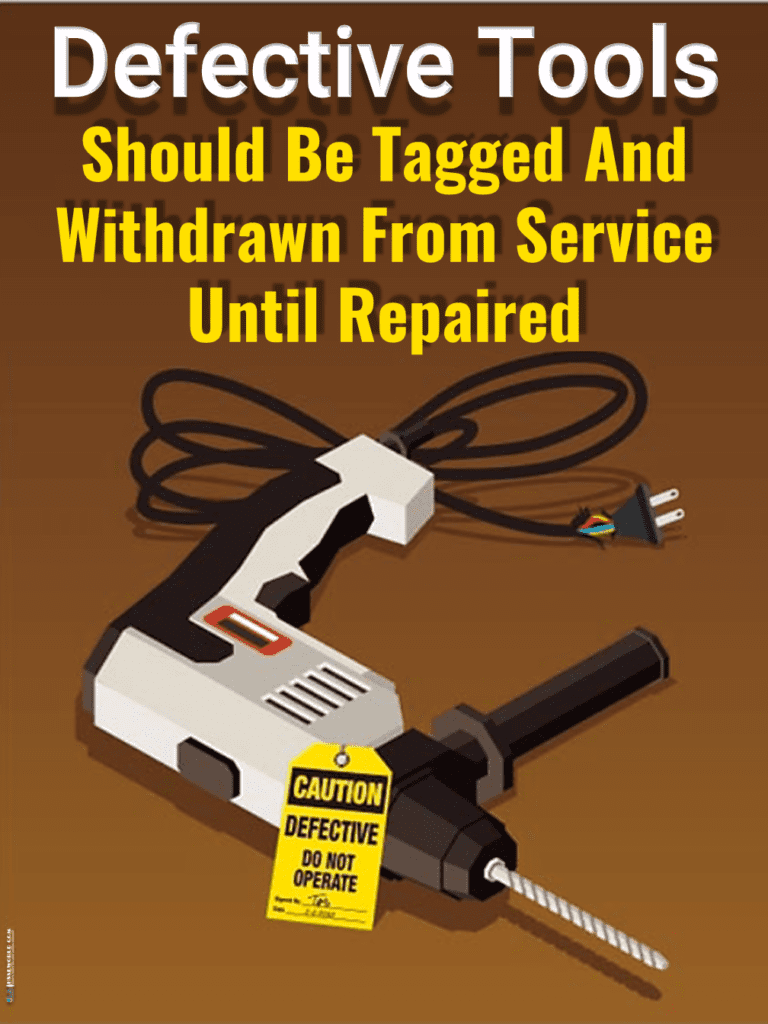

Safe Work Practice

What are some good general safe work practices?

DO INSPECT TOOLS FOR PROBLEMS LIKE:

- chisels and wedges with mushroomed heads

- split or cracked handles

- chipped or broken drill bits

- wrenches with worn-out jaws

- tools that are not complete, such as files without handles

- DO NOT use a defective tool;

- DO double-check all tools prior to use; and

- DO ensure defective tools are repaired

DO NOT USE TOOLS WHEN THEY ARE

- broken or inoperative guards,

- insufficient of improper grounding due to dame on double insulated tools,

- missing ground wire or grounding lug (on plug) on cords of non-double insulated tools;

- on/off switch not in good working order,

- cracked tool blade,

- wrong speed grinder wheel being used, or

- Guard has been wedged back.

- Tag and/or remove defective tools from service.

Also Read: Photo of the day: Safe Lifting at work

Download the Infographic

Now you can download the Infographic ” Defective Tools” and post it at the workplace to communicate with everyone to be familiar with the Defective Tools Hazards and safe work practices to avoid Back Injuries

Also Read: First aid requirements at the construction site

Photo of the day: Defective Tools Safe Work Practice

Download more resources at SAFETY BAG

More photos:

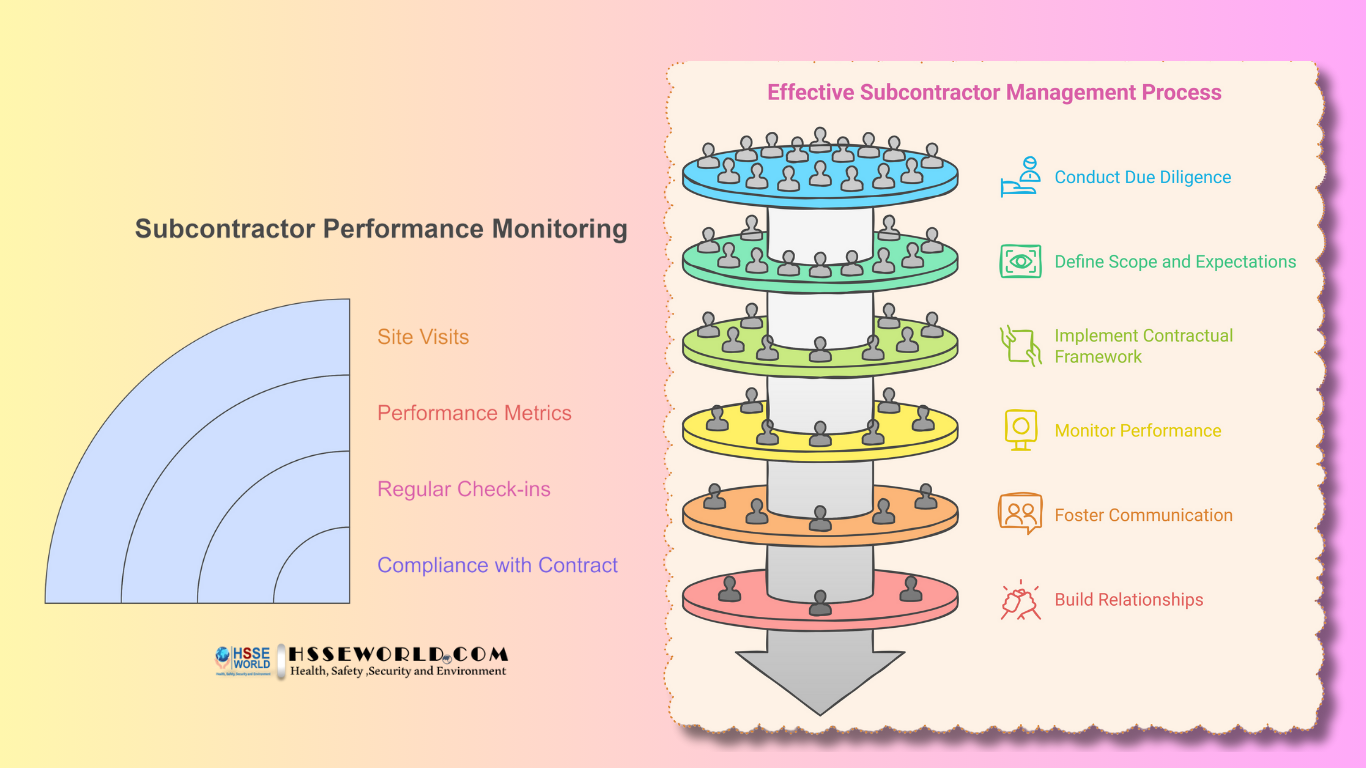

- What are the Best Practices for Managing Subcontractor Risk

- Photo of the day: 10 Essential Safety Tips for Driving in Hot Weather Conditions

- Photo of the day: best workplace safety tips

- Photo of the day: The Importance of Stop Work Authority in Maintaining Workplace Safety

- Photo of the day: Tomorrow’s Reward for Working Safely Today: Cultivating a Culture of Safety

- Photo of the day: Preventing slips and trips at work

- Photo of the day: Learn the DRSABCD action Plan

- Working with Electricity Electrical Accidents Guide for Electrical Workers

- Photo of the day: Hearing Protection Device Selection

- Photo of the day: If An Earthquake Shakes You-Infographic free

- Fire Safety Posters Free Download

- Photo of the day: First Aid for Electrical Burns-Infographic free

- Infographic: First Aid for Cuts and Scrapes free download

- Photo of The day: Work Safe with Lasers-Laser Safety free

- Photo of the day: Working Safely with chemicals and chemical Management

- Photo of the day: Safe work practices when using MEWPs ( updated)

- Photo of the day: Preventing Common Kitchen Hazards

- Photo of the day: Safe handling of Gas Cylinders and lecture bottles

- Photo of the day: Forklift Stability Triangle

- Photo of the day: Defective Tools Safe Work Practice

- Photo of the day: Lift With Your Legs Not With Your Back

- Photo of the day: First Aid for burns

- Photo of the day: The 7 Principles of HACCP

- Photo of the day: Working Safely with Suspended Loads

- Photo of the day: Heat Stroke First Aid and safety posters

- Photo of the day: Near-Miss Reporting and Posters

- Photo of the day: Ergonomic chair and office chair safety tips

- Photo of the day: Whole Body Vibration

- Photo of the day: Substation Safety Equipment

- Photo of the day: Bypassing Safety Controls Rules

- Photo of the day: Lightning Safety Tips

- Photo of the day: Overhead Power lines Clearance

- Photo of the day: Floor Marking

- Photo of the day: Types of Foot Protection

- Photo of the day: Types of Hand Protection

- Photo of the day: Lockout and Tagout Safety

- Photo of the day: Fall Protection Plans

- Photo of the day: Flood Safety Tips

- Photo of the day: Read All Labels Work safe

- Photo of the day: Run Project safely with Crane Hand Signals

- Photo of the day: Flagman and Traffic control

- Photo of the day: Managing Risks of Exposure to Solvents in the workplace

- Photo of the day: Scissor Lift Safety

- Photo of the day: HSE Bulletin Board

- Photo of the day: Arc-Fault Circuit Interrupters (AFCI)

- Photo of the day: Safe use of ladders and step ladders

- Photo of the day: Concrete Truck Driver Hand Signals

- Photo of the day: Extension Cord Safety Tips

- Photo of the day: Protect your Head

- Photo of the day: choosing the right Anchorage

- Photo of the day: Work-Related Asthma

- Photo of the day: Top FIVE Heavy Equipment Construction Site Safety Tips

- Photo of the day: sun safety in the workplace

- Photo of the day: Cannabis and Impairment in the Workplace

- Photo of the day: Position for safety and comfort-Safety Tips

- Photo of the day: Generator Safety

- Photo of the day: Controlling COVID-19 in the Workplace-Physical Barriers

- Photo of the day: Manual Material handling

- Photo of the day: Personal Protective Equipment last resort

- Photo of the day: WHMIS 2015 – Pictograms

- Photo of the day: Indoor Air Quality

- Photo of the day: Noise in the affected workplace

- Photo of the day: Fatigue at Work

- Photo of the day: Don’t be Driven to Distraction

- Photo of the day: working in heat and Humidex Rating

- How to use Plate Clamps Safely: Safety Moment#34

- Photo of the day: Sitting at work

- Photo of the day: 5 ways to reduce the risk of Slipping and Tripping

- Photo of the day: Preventing the spread of contagious illness

- Photo of the day: Incident Investigations

- Photo of the day: 10 Scaffold Safety Essentials

- Photo of the day: Effective Health and Safety Committees

- Photo of the day: New worker Orientation & Safety Orientation checklist

- Photo of the day: Workplace Inspection

- Photo of the day: musculoskeletal disorders

- Photo of the day: Emergency preparedness in the workplace

- Photo of the day: Mental health in the workplace

- Photo of the day: Trenching Safety Tips That Can Save a Life

- Photo of the day: Dangerous Goods Classes

- Photo of the day: Safety Equipment for Confined Spaces

- Photo of the day: Tips to reduce Heat stress in the workplace

- Photo of the day: hierarchy of controls

- Your steps to chemical safety

- H2S Gas and how to handle its Emergency

- Photo of the day: Importance of Mock drill and Fire Action Emergency Procedure

- Photo of the day: Choosing the Right Face Mask and the difference between a respirator and face mask

- Photo of the day: Confined space safety Precautions

- Breath Safely: The Proper Use of Respiratory Protection

- Photo of the day: Electric shock survival

- Photo of the day: Chemical Spill Emergency Response

- Photo of the day: Construction Site fire Safety

- Photo of the day: Confined Space rescue

- Photo of the day: Conveyors Safety Tips