For moving material normally two types of equipment are used. Conveyors are used when the path is fixed and industrial trucks are used when the path is free.

Various types of conveyors and mono-rail systems are used in many industries to eliminate manual labor to expedite the movement of materials and also to facilitate the processing or assembling. Belt conveyors are widely used and they are of flat or trough type and can be horizontal or inclined. They are used for handling almost all the materials of the modern industry including coal, coke, grain, fertilizers, and building materials such as sand and gravel.

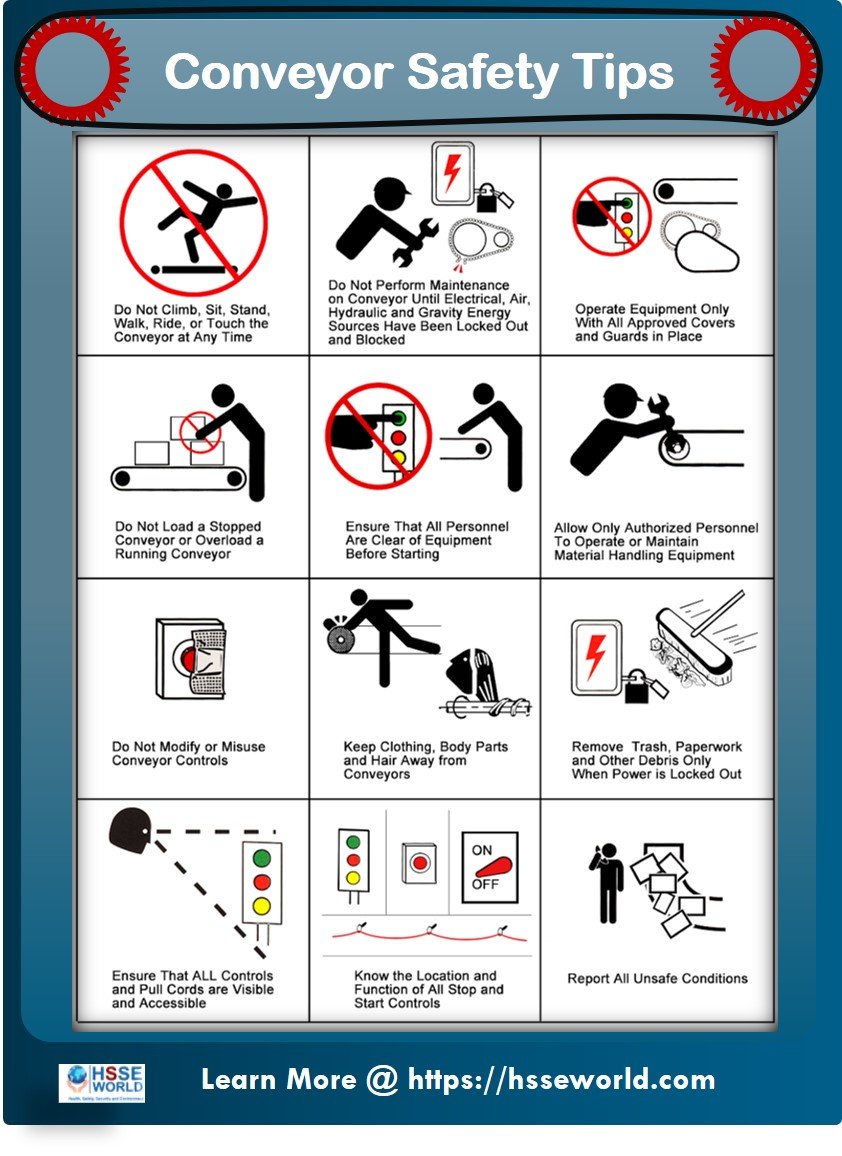

Important Safety measures in Conveyors

- Conveyors shall be so constructed and installed as to avoid hazardous points between moving and stationary parts or objects. Gears, sheaves, sprockets, and all moveable parts shall be securely guarded.

- Where workers have to cross over conveyors, regular crossing facilities affording safe passage and adequate lighting shall be provided. To cross underneath, at least 7 feet of headroom is required. Crossovers should be with bridges, stairs, and handrails.

- Conveyors shall be provided at loading and unloading stations and at other convenient places with devices (pull wire) for stopping the conveyor in an emergency. A pull wire at intervals of 8 m should be provided.

- When two or more conveyors are operated together, the controlling device shall be so designed that no conveyor can feed on to a stopped conveyor. This may be interlocked.

- Where conveyors extend to points not visible from the control station, they should be equipped with goings or signal lights to be used by the operations before starting the machinery so as to warn persons who might be in the position of danger.

- Conveyors shall be provided with an automatic and continuous lubrication system or with lubricating facilities so arranged that oiling and greasing can be performed without the oiler coming into dangerous proximity of the moving parts.

- Workers should not ride on conveyors.

- For repair/maintenance work, power must be totally stopped and a danger-tag should be displayed. Belt cleaning by flammable solvent should be avoided.

- Tension pulley – nips and idler rollers should have the fixed guard on their complete length of movement.

- Moveable dead counterweights should also be similarly guarded.

- Static charge collectors should be provided close to the outrunning sections of the drive pulleys and idlers.

- Elevated conveyors should have a walkway with a toe board (10 cm) and handrail (1 m) all along the length. Flooring should be non-slip type, particularly on sloping walkways. A handrail should also be provided on the belt side. The stop cord must be within easy reach.

- Underpasses should have a firm ceiling. Guards should be provided below all conveyors passing over rodes, walkways, and work areas

- Conveyors running in tunnels, pits, etc. should be provided with sufficient lighting, ventilation, drainage, guards, escape ways, and maintenance clearance.

- If the hopper is used on the floor to feed the conveyor, the grill or guard should be provided to prevent failure of a person inside, Scrapper may be provided between the hopper bottom and the moving conveyor. They will restrict the excess flow of material and alert any person passing it.

- If two or more conveyors operate in series, it should be so interlocked that if one conveyor stops all conveyors feeding it are also stopped.

- In the case of reversing or running away possibility, anti-runaway and backstop devices should be provided so that the load cannot slide or fall in the event of mechanical or electrical failure.

- Overload stop devices like slip or fluid couplings and shear pins are desirable.

- The loading and discharge points of powdered material on conveyors should have an exhaust hood for dust removal.

- If the material is combustible, the dust concentration should be below LEL, electric fittings should be flameproof, the conveyor should be grounded and its parts bonded to prevent differences in electric potential. The container into or from which the material is conveyed should also be similarly grounded and its parts bonded.

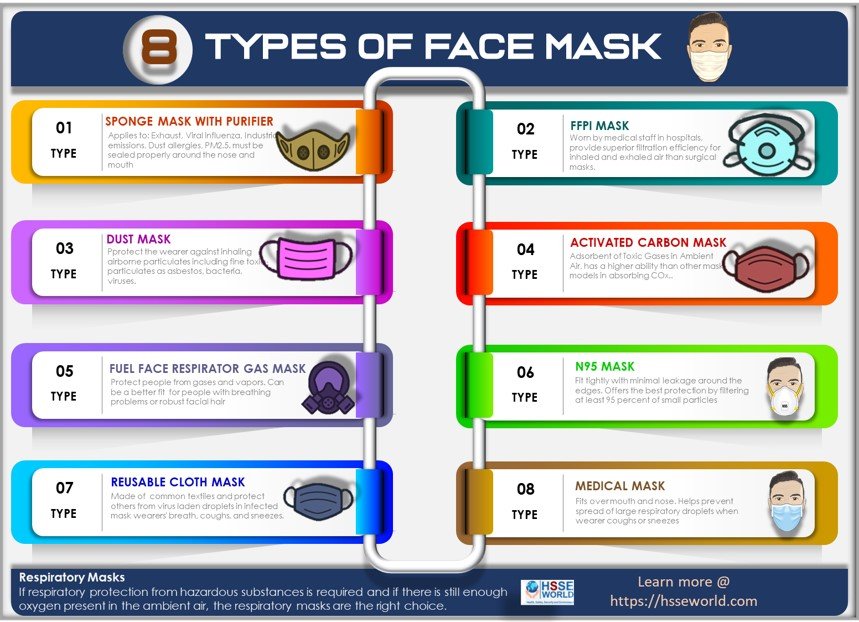

- PPE like Tight-fitting clothing, safety shoes, goggles in dusty areas, and respirators are useful equipment.

- Before starting maintenance or repair work, power should be locked in “off position” or lock-out tag-out should be used.

(Read more E-bookssafety-the-safety-professionals-expanded-guide-to-lockout-tagout/)

Download the Infographic

Photo of the day: Conveyors Safety Tips

More photos:

- What are the Best Practices for Managing Subcontractor Risk

- Photo of the day: 10 Essential Safety Tips for Driving in Hot Weather Conditions

- Photo of the day: best workplace safety tips

- Photo of the day: The Importance of Stop Work Authority in Maintaining Workplace Safety

- Photo of the day: Tomorrow’s Reward for Working Safely Today: Cultivating a Culture of Safety

- Photo of the day: Preventing slips and trips at work

- Photo of the day: Learn the DRSABCD action Plan

- Working with Electricity Electrical Accidents Guide for Electrical Workers

- Photo of the day: Hearing Protection Device Selection

- Photo of the day: If An Earthquake Shakes You-Infographic free

- Fire Safety Posters Free Download

- Photo of the day: First Aid for Electrical Burns-Infographic free

- Infographic: First Aid for Cuts and Scrapes free download

- Photo of The day: Work Safe with Lasers-Laser Safety free

- Photo of the day: Working Safely with chemicals and chemical Management

- Photo of the day: Safe work practices when using MEWPs ( updated)

- Photo of the day: Preventing Common Kitchen Hazards

- Photo of the day: Safe handling of Gas Cylinders and lecture bottles

- Photo of the day: Forklift Stability Triangle

- Photo of the day: Defective Tools Safe Work Practice

- Photo of the day: Lift With Your Legs Not With Your Back

- Photo of the day: First Aid for burns

- Photo of the day: The 7 Principles of HACCP

- Photo of the day: Working Safely with Suspended Loads

- Photo of the day: Heat Stroke First Aid and safety posters

- Photo of the day: Near-Miss Reporting and Posters

- Photo of the day: Ergonomic chair and office chair safety tips

- Photo of the day: Whole Body Vibration

- Photo of the day: Substation Safety Equipment

- Photo of the day: Bypassing Safety Controls Rules

- Photo of the day: Lightning Safety Tips

- Photo of the day: Overhead Power lines Clearance

- Photo of the day: Floor Marking

- Photo of the day: Types of Foot Protection

- Photo of the day: Types of Hand Protection

- Photo of the day: Lockout and Tagout Safety

- Photo of the day: Fall Protection Plans

- Photo of the day: Flood Safety Tips

- Photo of the day: Read All Labels Work safe

- Photo of the day: Run Project safely with Crane Hand Signals

- Photo of the day: Flagman and Traffic control

- Photo of the day: Managing Risks of Exposure to Solvents in the workplace

- Photo of the day: Scissor Lift Safety

- Photo of the day: HSE Bulletin Board

- Photo of the day: Arc-Fault Circuit Interrupters (AFCI)

- Photo of the day: Safe use of ladders and step ladders

- Photo of the day: Concrete Truck Driver Hand Signals

- Photo of the day: Extension Cord Safety Tips

- Photo of the day: Protect your Head

- Photo of the day: choosing the right Anchorage

- Photo of the day: Work-Related Asthma

- Photo of the day: Top FIVE Heavy Equipment Construction Site Safety Tips

- Photo of the day: sun safety in the workplace

- Photo of the day: Cannabis and Impairment in the Workplace

- Photo of the day: Position for safety and comfort-Safety Tips

- Photo of the day: Generator Safety

- Photo of the day: Controlling COVID-19 in the Workplace-Physical Barriers

- Photo of the day: Manual Material handling

- Photo of the day: Personal Protective Equipment last resort

- Photo of the day: WHMIS 2015 – Pictograms

- Photo of the day: Indoor Air Quality

- Photo of the day: Noise in the affected workplace

- Photo of the day: Fatigue at Work

- Photo of the day: Don’t be Driven to Distraction

- Photo of the day: working in heat and Humidex Rating

- How to use Plate Clamps Safely: Safety Moment#34

- Photo of the day: Sitting at work

- Photo of the day: 5 ways to reduce the risk of Slipping and Tripping

- Photo of the day: Preventing the spread of contagious illness

- Photo of the day: Incident Investigations

- Photo of the day: 10 Scaffold Safety Essentials

- Photo of the day: Effective Health and Safety Committees

- Photo of the day: New worker Orientation & Safety Orientation checklist

- Photo of the day: Workplace Inspection

- Photo of the day: musculoskeletal disorders

- Photo of the day: Emergency preparedness in the workplace

- Photo of the day: Mental health in the workplace

- Photo of the day: Trenching Safety Tips That Can Save a Life

- Photo of the day: Dangerous Goods Classes

- Photo of the day: Safety Equipment for Confined Spaces

- Photo of the day: Tips to reduce Heat stress in the workplace

- Photo of the day: hierarchy of controls

- Your steps to chemical safety

- H2S Gas and how to handle its Emergency

- Photo of the day: Importance of Mock drill and Fire Action Emergency Procedure

- Photo of the day: Choosing the Right Face Mask and the difference between a respirator and face mask

- Photo of the day: Confined space safety Precautions

- Breath Safely: The Proper Use of Respiratory Protection

- Photo of the day: Electric shock survival

- Photo of the day: Chemical Spill Emergency Response

- Photo of the day: Construction Site fire Safety

- Photo of the day: Confined Space rescue

- Photo of the day: Conveyors Safety Tips