Hot Work Controls and its Permit to work Form

11 min readHot work operations such as welding, cutting, soldering, and any activities that involve using open flames or excessive heat can cause multiple health and safety hazards. These activities also carry the threat of industrial fires that could be disastrous for your staff, your business premises as well as projects under construction.

Carrying out hot work activities safely is an important part of fire safety in the workplace, but to do so, you need to identify hot work hazards and control measures that will effectively reduce risks and keep workers safe.

In this article, we’ll explore the types of hot work hazards and the control measures you can use to help keep your staff and workplace safety during dangerous activities.

Hot Work Hazards to Consider in Your Risk Assessments

Working with high levels of heat and open flames is dangerous, but you need to identify the exact hazards created by hot work activities in order to conduct a thorough risk assessment and implement effective control measures.

- Electrical Hazards — Most hot work involves using electrical equipment, so workers will face electrical hazards such as the risk of equipment short-circuiting, faulty wiring, and the risk of shocks, or even fatal electrocution.

- Exposure to Harmful UV or Infrared Light — Hot work activities such as welding can involve potentially dangerous UV or infrared light. If workers are exposed to these types of non-ionizing radiation, it can cause damage to their skin or eyes.

- Exposure to Dangerous Fumes — Hot work can produce dangerous fumes that pose major health risks for workers. Fumes can cause respiratory health conditions, burns, flu-like symptoms, and damage to the eyes.

- Flying Sparks Can Cause Fires or Combustion — When hot work activities like welding are carried out, sparks can fly and these sparks can cause fires or combustion if they come into contact with flammable materials, debris, or hazardous materials.

- Conducting Heat through Pipes — Heat can be conducted through metal materials like pipes and, when heat is transferred, it can come into contact with flammable, combustible, or otherwise hazardous materials.

- Skin Injuries through Contact with Hot Materials or Equipment — If workers touch the equipment, debris, or surfaces that are extremely hot — or come into contact with open flames or sparks — they may sustain skin injuries like heat burns, friction burns, or cuts.

The above are just some of the hot work hazards that might apply to your workplace. The particular hazards your workers face will depend on the people involved, the area where hot work activities are being carried out, and any hazards that are specific to your equipment and workplace. Before implementing control measures, you’ll need to make sure you’ve considered all possible risks.

Hot Work Control Measures and Requirements to keep your workplace safe

Once you’ve identified the hot work hazards in your workplace, you’ll need to plan and implement control measures to make your workplace a safer environment and protect workers from harm and ill-health.

Just like hazards, the control measures you implement should be unique to your business operations and work environment. We’ve compiled some of the hot work control measures you might want to consider:

Avoid Hot Work Where Possible

Hot work is, by its very nature, dangerous. You won’t ever be able to completely eliminate the risks involved in working with excessive heat. So, where possible, avoid hot work completely. Consider alternative processes and activities that could have a similar result. For example, rather than welding, can you join items together using mechanical methods such as nuts and bolts or screwed fittings?

Designated Hot Work Areas

Hot Work must only be performed in designated areas, proven by risk assessment to have fire hazards adequately controlled, wherever practical.

As a minimum, designated areas must:

- Not contain combustible or flammable material within 11 m (35 feet) of the work area

- Be free of combustible atmospheres

- Be provided with weld curtains or barriers, including fire blankets to prevent sparks, molten metal, and hot slag from causing fires or affecting persons working close to or directly below the area of hot works

- Have an adequate number and type of fire extinguishing systems available (e.g. fire extinguishers, sprinklers)

- Be clearly marked and identified (e.g. signs, floor markings)

Hot works performed in a designated area do not require a Hot Work Permit unless the work is being performed on equipment that may contain or may have contained a flammable gas or liquid.

Hot Works in non-Designated Areas

A Hot Work Permit is required for all hot works performed in any non-designated or temporary work area e.g. work in a welding bay in a fabrication shop does not require a hot work permit but weld repairs to pipework on a worksite do. See the Hot Work Permit form below.

Notes:

- Hot Work must not be performed on a metal partition, wall, ceiling, or roof having a combustible covering or on walls or partitions of combustible sandwich-type panel construction

- Cutting or welding on pipes or other metals in contact with combustible walls, partitions, ceilings, or roofs must not be undertaken if the work is close enough to cause ignition by conduction

Hot Work Permits are valid for one shift and one job only. If the activity carries over onto another shift or work party, another permit must be issued with the same degree of inspection and control as the preceding shift.

Contractors performing hot work must be advised on the location of flammable materials or hazardous conditions of which they might not be aware, the hot work permit process, and the fire watch requirements (if applicable); as part of their pre-job briefing at the site.

When hot work must be performed in a non-designated area, the employee (representing the work party performing the work) must first notify the Permit Issuer that a Hot Work Permit is required.

The work party must then prepare the work area in readiness for the issue of the Hot Work Permit and commencement of the work.

The employee and the Permit Issuer must walk down the work area together and complete the Hot Work Permit.

Where flammable/explosive gases may be present, the Permit Issuer must perform a combustible gas test before issuing the Hot Work Permit.

Only when the Permit Issuer is satisfied that any deficiencies have been rectified and all precautions implemented as specified on the permit, may the Hot Work Permit be issued and work commences.

Personnel performing the work are responsible for checking the Hot Work Permit to see if it is current and complete. Work must not begin if the permit is incomplete (e.g. missing signature or checks), conditions have changed or the permit has expired. If in doubt, they must STOP WORK and request clarification from their Supervisor.

The permit must remain accessible or posted within the job area until all work is completed.

Any area of hot work must be actively monitored for at least 60 minutes after completion of the hot works. Depending upon the task being performed and/or risk assessment, it may necessary to periodically re-visit the work area for up to two hours thereafter. Any such extended watches must be noted on the Hot Work Permit.

Note: This is an important consideration when scheduling hot work activities if the site is vacated at the end of the shift.

Watch Video: Preventing Fires During Hot Work Operations

Fire Watchers

Fire Watchers must not perform any other duties whilst involved in the fire watch. They must:

- Monitor the work area for fires throughout the full duration of the hot works for at least 60 minutes after completion of the work

- Have appropriate fire-extinguishing equipment readily available and be trained in its use

- Only try to extinguish fires when obviously within the capacity of the equipment available and their personal level of competency

- Familiarize themselves with facilities for sounding an alarm in the event of a fire

If the Fire Watcher observes a potential fire hazard or conditions change, they must tell the work party to STOP WORK and take corrective action.

The Fire Watcher must report the following to the Permit Issuer, as soon as possible and when safe to do so.

- Any potential fire Hazard / STOP WORK incident

- Any fire

- Use of a fire extinguisher

Read: Requirements of OSHA Fire Extinguisher Mounting Height, Placement & Signage

Welding and Cutting – General Requirements

No welding, cutting, or other hot work must be performed in the presence of explosive atmospheres (mixtures of flammable gases, vapors, liquids, or dust with air), or when explosive atmospheres may develop inside un-cleaned or improperly prepared tanks or equipment that have previously contained flammable materials, or when explosive atmospheres may develop with an accumulation of combustible dust.

All drums, barrels, tanks, or other containers must be thoroughly cleaned to remove all flammable materials or materials that may produce flammable or toxic vapors when subjected to heat. Any pipelines or connections to the drum or vessel must be disconnected or blanked. All hollow spaces, cavities or containers must be vented/purged to permit the escape of air or gases before preheating, cutting or welding.

Welding cables and oxy-fuel gas lines must be clear of passageways, stairways, and ladders when practical.

A fully charged A: B: C multi-purpose portable fire extinguisher, or other appropriate fire extinguishing equipment, must be available in the vicinity of the work area for immediate use before commencing hot works

All equipment used for Hot Work must be inspected before each use.

The task-specific risk assessment must consider the need for additional PPE for hot works, both for those performing the task and those observing e.g. fire watchers.

Mechanical ventilation must be used or air-supplied respirators worn when performing welding, cutting, or heating under the following conditions:

- In a confined space

- In any enclosed spaces involving materials that are based on, bearing, or coated with any of the following:

- Zinc

- Lead

- Cadmium

- Chromium

- Mercury

- Beryllium

- Iron

- Copper

- Tin

- Vanadium

- Nickel

- Selenium

- Manganese

- On stainless steel with inert-gas equipment

- Where the accumulation of air contaminants creates a hazard or in conditions that remove respirable air

Read: Creating safety in welding operations

Gas Welding and Cutting

At the beginning of each shift, users must inspect all cylinders, hoses, and torches, ensuring that:

- The regulator and pressure gauges are in good working condition

- That the non-return valves are correctly fitted

- Flashback protection is provided at both the gauge and torch end

- Hoses are correctly fitted and easily distinguishable from each other e.g. green or blue for oxygen, red (for acetylene) and there are no obvious signs of damage

Gas cylinders must be secured upright and kept away from molten metal and slag while in use.

When not in use for hot work, cylinder caps must be secured in place and the main valves of these cylinders shut off.

Torches must be removed from confined spaces if left unattended for any length of time e.g. over lunch or overnight.

Compressed gas cylinders must be stored and used in accordance with the Compressed Gas procedure.

Arc Welding and Cutting

Installation, maintenance, and repair of welding equipment must only be performed by a Competent Person, as recommended by the manufacturer.

Wherever, practical, all work areas must be shielded with non-combustible or flameproof screens, to protect others in the area from the direct rays of the arc.

All arc welding and cutting cables must be insulated and capable of handling the maximum current requirements of the expected work.

Welding machine terminals must be effectively guarded to prevent inadvertent contact with energized terminals

The frames or cases of all arc welding and cutting machines (except engine-driven machines) are grounded/earthed.

Before leaving electrode holders unattended, the electrodes must be removed and placed in the holders and the power turned off.

Wires and connections must be periodically inspected; before moving or inspecting welding and cutting machines, the power must be turned off.

Portable welding machines must be thoroughly inspected and documented annually.

E-Books: Hot Work on Drums and Tanks

Training

The dangerous nature of hot work means it should only be carried out by those who have the skills, knowledge, experience, and training to complete tasks to a high standard while implementing control measures and monitoring health and safety standards.

If there are no workers within your organization with the necessary or desired level of competence, you may want to consider offering training to an individual or a group of employees. Alternatively, you could bring in an external contractor with the ability to complete hot work while effectively managing risks.

All employees who perform or assist with hot works must undertake the following training, , as a minimum:

- Welding, Cutting, and Brazing

- Portable Fire Extinguishers

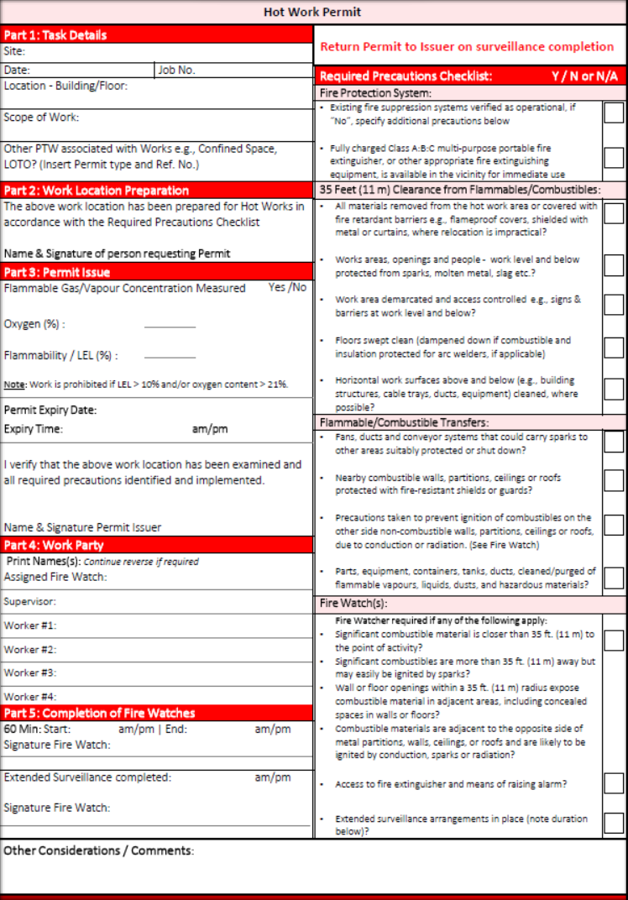

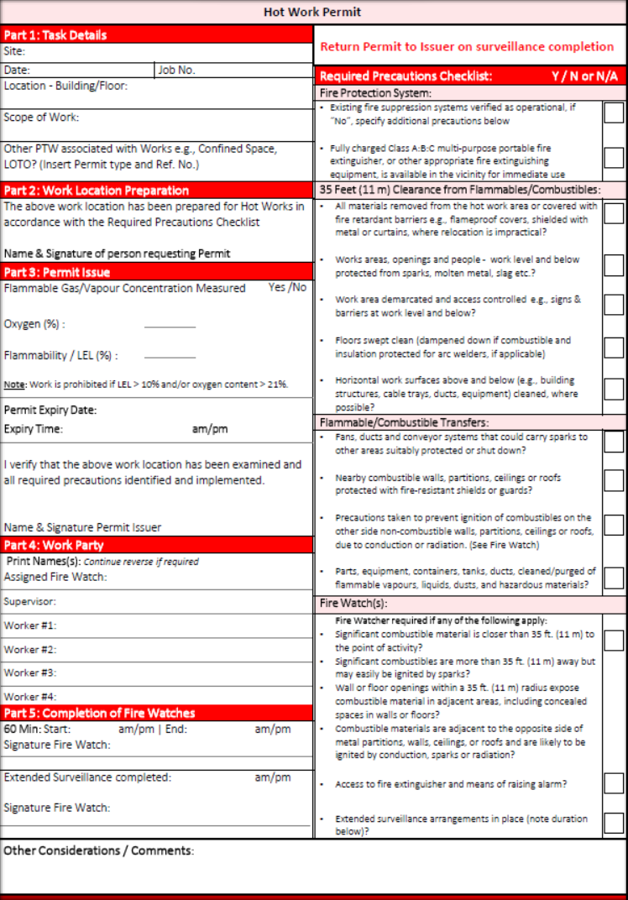

Hot work permit Form

Download the Hot work permit Form

This Form is not all-inclusive. You may wish to add to them or delete portions that do not apply to your workplace. Carefully consider each item as you come to it and then make your decision. Do not spend time with items that have no application to your workplace.

Hot Work Permit Form

Download: Templates: Hot Work ٍSafety Program

More Forms

- Downloadable Kitchen Safety Inspection Checklist for Restaurants

- Mastering LOTO: Protecting Workers with Energy Isolation and Isolation Confirmation Certificates

- Flammable and Combustible Storage Checklist Free Download

- Secure Your Lifts:Guidelines for Safe Lifting Operations Free Planning Tool

- Sample of Accident Prevention Program ( APP) Template for General Industry Free Download

- Free ISO 14001:2015 Environmental Management System Audit Checklist Download

- Guides for Walking and Working Surfaces Safety Program

- Workshop Safety Guideline and free Posters

- Free Ergonomics Checklist for General Industry

- Work Area Safety Checklist

- Machine Safety and 43-Equipment Inspection Checklists

- Scaffold Safety self Audit and checklist

- Hot Work Controls and its Permit to work Form

- Safety Observation Report Template

- Forklift Operator’s Daily Checklist and safety Tips

- Inspecting Fall Protection Equipment Forms

- Templates: HSE Incentives and rewards

- 35 Inspection forms for Rig Check

- Chemical Risk Assessment form

- 22-Safety Inspection Checklists

- Safety Task Assessment Form

- Suspended Scaffold Pre-Operation Inspection Checklist

- Photo of the day: New worker Orientation & Safety Orientation checklist

- Grating-Decking-Floor- handrail-Removal Form

- Electrical Inspection Checklists

- E-Books: Fire Safety Logbook templates

- General Safety Guidelines and Employee Acknowledgment form

- Annual Internal Audit Form

- Mobile Scaffold Inspection checklist

- Simultaneous Operation (SIMOPS) checklist

- Temporary Construction Facilities (TCF) Inspection checklist

- HIRA, HSE Hazards & Effects Management Process (HEMP) & Risk Register Template

- Hazard Identification Plan (HIP) Template

- Ladder Inspection Form

- Free Pre-Startup Safety Review Checklist (PSSR)

- Hazard Identification Checklist

- Workplace Housekeeping Checklist

- ISO 45001:2018 READINESS CHECKLIST

- Lifting Plan Audit Checklist

- Job Safety Analysis (JSA) Forms What’s Right and Wrong?

- Electrical Isolation Permit to Work forms and checklist

- Canteen Inspection Checklist

- Work at Height Checklist

- Health Safety at Work Improvement Action Plan

- Fire Pump Daily Inspection Checklist

- Construction Site Traffic Management Plan (CSTMP) Guidance

- Safety Templates: COVID-19 Safety Plan

- Workplace Safety Inspections Forms

- Lock Removal Form

- Templates: Management of Change NEW Modified Equipment Safety Checklist

- Lifeline & Harness Inspection Guide checklist

- Contractor Pre-qualification Questionnaire Checklist

- Fall safety at construction checklist

- Construction safety Inspection checklist

- Equipment Safe Operating Procedures- SOP 61 checklist

- Permit to Work (PTW ) AUDIT CHECKLIST

- Hygiene and Sanitation Inspection Checklist