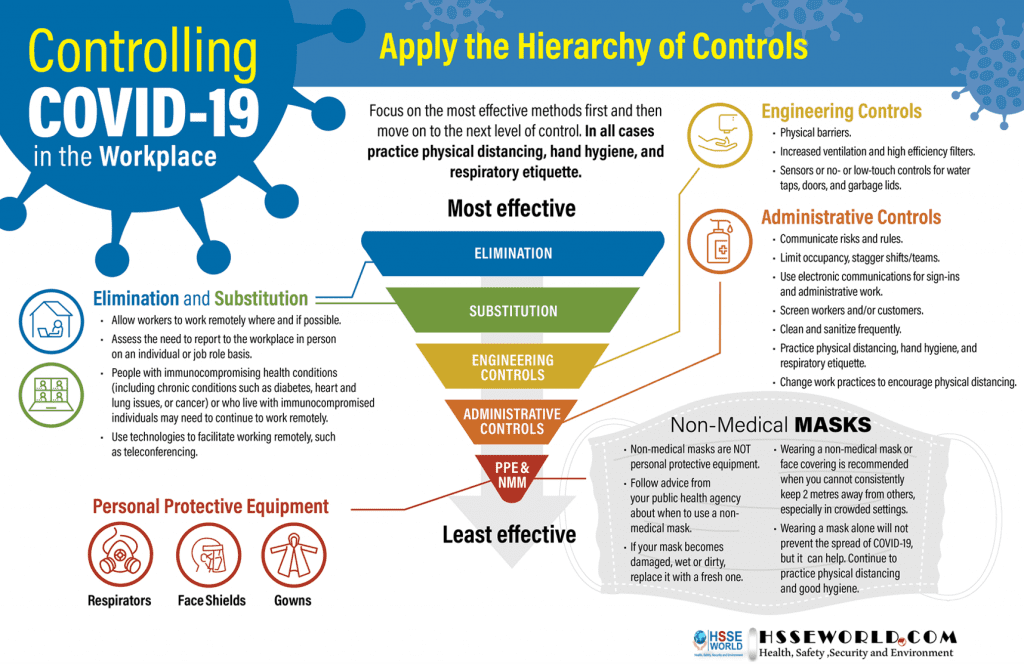

Selecting an appropriate method to control a hazard in the workplace is not always easy. When it comes to the transmission of viruses such as COVID-19, workplaces should consider establishing control measures that have the greatest impact. The main ways to control a hazard, from the most to the least effective, include elimination (and substitution), engineering controls, administrative controls, and personal protective equipment (PPE). In all cases, always practice physical distancing, hand hygiene, and respiratory etiquette.

The photo of today and infographic learn how the hierarchy of controls can be applied to COVID-19 in the workplace, including examples of controls for each level in addition to Physical Barriers as detailed control

Controlling COVID-19 in the Workplace

Apply the Hierarchy of Controls

Focus on the most effective methods first and then move on to the next level of control. In all cases practice physical distancing, hand hygiene, and respiratory etiquette.

Most effective -> Least effective

- Elimination

- Substitution

- Engineering Controls

- Administrative Controls

- PPE NMM

Elimination and Substitution

- Allow workers to work remotely where and if possible.

- Assess the need to report to the workplace in person on an individual or job role basis.

- People with immunocompromising health conditions (including chronic conditions such as diabetes, heart and lung issues, or cancer) or who live with immunocompromised individuals may need to continue to work remotely.

- Use technologies to facilitate working remotely, such as teleconferencing.

- Use technologies to facilitate working remotely, such as teleconferencing.

Engineering Controls

- Physical barriers

- Increased ventilation and high-efficiency filters

- Sensors or no- or low-touch controls for water taps, doors, and garbage lids

Administrative Controls

- Communicate risks and rules.

- Limit occupancy, stagger shifts/teams.

- Use electronic communications for sign-ins and administrative work.

- Screen workers and/or customers.

- Clean and sanitize frequently.

- Practice physical distancing, hand hygiene, and respiratory etiquette.

- Change work practices to encourage physical distancing.

Personal Protective Equipment

- Respirators

- Face shields

- Gowns

Non-Medical Masks (NMM)

- Non-medical masks are NOT personal protective equipment.

- Follow the advice from your public health agency about when to use a non-medical mask.

- Wearing a non-medical mask or face covering is recommended when you cannot consistently keep 2 meters away from others, especially in crowded settings.

- Wearing a mask alone will not prevent the spread of COVID-19, but it can help. Continue to practice physical distancing and good hygiene.

- If your mask becomes damaged, wet, or dirty, replace it with a fresh one.

( learn more:choosing-the-right-face-mask-and-the-difference-between-a-respirator-and-face-mask/ )

Physical Barriers

This section provides information regarding the use of physical barriers as a hazard control in the workplace

Consider the Risks

The risk of contracting COVID-19 increases in situations where people are working in closed spaces (with poor ventilation) and crowded places when with people from outside their immediate household. Risk is higher in settings where these factors overlap and/or involve activities such as close-range conversations, singing, shouting, or heavy breathing (e.g., during exertion).

Each workplace is unique. It is important for employers to assess the risks of COVID-19 for their specific workplace and implement appropriate hazard controls using the hierarchy of controls (i.e., elimination, substitution, engineering controls, administrative policies, and the use of personal protective equipment (PPE) and non-medical masks). Use multiple personal preventive practices at once (i.e., use a layered approach) to protect yourself and others from COVID-19.

Use

- A physical barrier is an example of engineering control. It separates people and helps to prevent the spread of respiratory droplets.

- Physical barriers may be used as a hazard control when it is not possible to maintain physical distancing and there is frequent contact with others (e.g., co-workers, customers).

- Examples of when physical barriers may be used in the workplace include retail point of sale, grocery or dining checkout, ticket sales, public transit driver protection, reception desks, bank teller counters, pharmacy pick up or drop off, manufacturing production lines, and office areas to separate workstations.

- Physical barriers should always be used in conjunction with other COVID-19 control measures (e.g., reduced occupancy, adequate ventilation, use of non-medical masks, etc.).

Materials

- Physical barriers may include curtains, counter-mounted, and freestanding plexiglass barriers, or floor-mounted freestanding prefabricated dividers. Walls are also a barrier and can be added to made of wood, steel, or glass.

- Barriers can be made from a variety of different materials. Materials such as plexiglass (acrylic) or polycarbonate plastics are frequently used. They are light and flexible materials that can be easily cleaned and disinfected.

- Use material that blocks the transmission of air. Avoid materials such as plants, porous fabrics, paper, etc.

- In many cases, transparent materials are preferred because they do not obstruct the view of the user on either side of the barrier and are necessary for situations such as driving. However, an opaque barrier may be preferred in some settings (e.g., office cubicles).

- When selecting a material type for your physical barrier, consider the following properties:

- Durability and impermeability

- Scratch and impact resistance

- Ease of cleaning and disinfecting

- Local Fire Code and Building Code requirements (e.g., use of flame-retardant and non-combustible materials)

- Workplace-specific hazards (e.g., radiation) that will determine the type of material required for the physical barrier

Dimensions

- Determine if the barrier will be used by people who are sitting or standing.

- The height of the barrier should consider the tallest user and should cover the breathing zones of both people on either side of the barrier.

- The breathing zone can be thought of as a bubble with a radius of 30 cm (12 inches) extending out in every direction from the mouth and nose. It should be 30 cm above the tallest person’s nose and 30 cm below the shortest person’s nose.

- Pass-throughs or openings for objects (e.g., documents, money, payment machines) should be as small as possible and not located in the breathing zone of either user.

- The width of the barrier needs to be wide enough to accommodate a person’s normal movement.

Installation

- Consult your facilities manager or building owner before installing barriers. The barriers may need to comply with applicable building and fire codes.

- Ensure that physical barriers do not interfere with the ventilation or fire protection systems in the room.

- Determine if any municipal-issued construction permits are required before installation.

- Ensure that installation meets accessibility requirements.

- Verify that the barrier is securely installed and cannot tip or fall.

- Physical barriers should never prevent escape in an emergency or impede movement.

- Verify that travel distance to exits and the exit path width is not restricted by physical barriers.

- Barriers mounted in vehicles must not interfere with the driver’s ability to see or move freely. They should not hinder access to controls, or block emergency exits from the vehicle.

Cleaning and Disinfecting

- Viruses can remain on objects for a few hours to days depending on the type of surface and environmental conditions.

- Clean and disinfect both sides of the barrier frequently throughout the day.

- To promote consistent disinfecting practices, create and provide a routine cleaning and disinfecting schedule.

- The frequency of cleaning and disinfecting will depend on the amount of time the barriers are used. For example, barriers used in front of cashiers or bank tellers may become contaminated more quickly if many people use that workstation.

- Use household or commercial disinfectants to destroy or inactivate the virus. The disinfectant used should have a drug identification number (DIN), meaning that it has been approved for use in Canada.

- Employees should be trained on the safe use of cleaning and disinfecting products. Always follow the manufacturer’s instructions when using, handling, or storing the product. Review the product’s label, and (if applicable) safety data sheet to determine what precautions to follow (e.g., use of personal protective equipment).

- For additional information, refer to t “Cleaning and Disinfecting”.

Communication

- Encourage employees to report any concerns with the physical barriers to their supervisor or employer. Employees can also report concerns to their health and safety committee or representative.

Evaluate Controls

- Regularly review the effectiveness of the physical barriers and make improvements as necessary.

Download Infographic

Controlling COVID-19 in the Workplace

More Photos

- What are the Best Practices for Managing Subcontractor Risk

- Photo of the day: 10 Essential Safety Tips for Driving in Hot Weather Conditions

- Photo of the day: best workplace safety tips

- Photo of the day: The Importance of Stop Work Authority in Maintaining Workplace Safety

- Photo of the day: Tomorrow’s Reward for Working Safely Today: Cultivating a Culture of Safety

- Photo of the day: Preventing slips and trips at work

- Photo of the day: Learn the DRSABCD action Plan

- Working with Electricity Electrical Accidents Guide for Electrical Workers

- Photo of the day: Hearing Protection Device Selection

- Photo of the day: If An Earthquake Shakes You-Infographic free

- Fire Safety Posters Free Download

- Photo of the day: First Aid for Electrical Burns-Infographic free

- Infographic: First Aid for Cuts and Scrapes free download

- Photo of The day: Work Safe with Lasers-Laser Safety free

- Photo of the day: Working Safely with chemicals and chemical Management

- Photo of the day: Safe work practices when using MEWPs ( updated)

- Photo of the day: Preventing Common Kitchen Hazards

- Photo of the day: Safe handling of Gas Cylinders and lecture bottles

- Photo of the day: Forklift Stability Triangle

- Photo of the day: Defective Tools Safe Work Practice

- Photo of the day: Lift With Your Legs Not With Your Back

- Photo of the day: First Aid for burns

- Photo of the day: The 7 Principles of HACCP

- Photo of the day: Working Safely with Suspended Loads

- Photo of the day: Heat Stroke First Aid and safety posters

- Photo of the day: Near-Miss Reporting and Posters

- Photo of the day: Ergonomic chair and office chair safety tips

- Photo of the day: Whole Body Vibration

- Photo of the day: Substation Safety Equipment

- Photo of the day: Bypassing Safety Controls Rules

- Photo of the day: Lightning Safety Tips

- Photo of the day: Overhead Power lines Clearance

- Photo of the day: Floor Marking

- Photo of the day: Types of Foot Protection

- Photo of the day: Types of Hand Protection

- Photo of the day: Lockout and Tagout Safety

- Photo of the day: Fall Protection Plans

- Photo of the day: Flood Safety Tips

- Photo of the day: Read All Labels Work safe

- Photo of the day: Run Project safely with Crane Hand Signals

- Photo of the day: Flagman and Traffic control

- Photo of the day: Managing Risks of Exposure to Solvents in the workplace

- Photo of the day: Scissor Lift Safety

- Photo of the day: HSE Bulletin Board

- Photo of the day: Arc-Fault Circuit Interrupters (AFCI)

- Photo of the day: Safe use of ladders and step ladders

- Photo of the day: Concrete Truck Driver Hand Signals

- Photo of the day: Extension Cord Safety Tips

- Photo of the day: Protect your Head

- Photo of the day: choosing the right Anchorage

- Photo of the day: Work-Related Asthma

- Photo of the day: Top FIVE Heavy Equipment Construction Site Safety Tips

- Photo of the day: sun safety in the workplace

- Photo of the day: Cannabis and Impairment in the Workplace

- Photo of the day: Position for safety and comfort-Safety Tips

- Photo of the day: Generator Safety

- Photo of the day: Controlling COVID-19 in the Workplace-Physical Barriers

- Photo of the day: Manual Material handling

- Photo of the day: Personal Protective Equipment last resort

- Photo of the day: WHMIS 2015 – Pictograms

- Photo of the day: Indoor Air Quality

- Photo of the day: Noise in the affected workplace

- Photo of the day: Fatigue at Work

- Photo of the day: Don’t be Driven to Distraction

- Photo of the day: working in heat and Humidex Rating

- How to use Plate Clamps Safely: Safety Moment#34

- Photo of the day: Sitting at work

- Photo of the day: 5 ways to reduce the risk of Slipping and Tripping

- Photo of the day: Preventing the spread of contagious illness

- Photo of the day: Incident Investigations

- Photo of the day: 10 Scaffold Safety Essentials

- Photo of the day: Effective Health and Safety Committees

- Photo of the day: New worker Orientation & Safety Orientation checklist

- Photo of the day: Workplace Inspection

- Photo of the day: musculoskeletal disorders

- Photo of the day: Emergency preparedness in the workplace

- Photo of the day: Mental health in the workplace

- Photo of the day: Trenching Safety Tips That Can Save a Life

- Photo of the day: Dangerous Goods Classes

- Photo of the day: Safety Equipment for Confined Spaces

- Photo of the day: Tips to reduce Heat stress in the workplace

- Photo of the day: hierarchy of controls

- Your steps to chemical safety

- H2S Gas and how to handle its Emergency

- Photo of the day: Importance of Mock drill and Fire Action Emergency Procedure

- Photo of the day: Choosing the Right Face Mask and the difference between a respirator and face mask

- Photo of the day: Confined space safety Precautions

- Breath Safely: The Proper Use of Respiratory Protection

- Photo of the day: Electric shock survival

- Photo of the day: Chemical Spill Emergency Response

- Photo of the day: Construction Site fire Safety