Fall hazards are the leading cause of construction worker deaths, accounting for almost half of all fatalities in construction each year. OSHA estimates that approximately 65 percent of construction workers perform some work on scaffolds each year. Without an understanding of the hazards of scaffolding, this could lead to dangerous situations for construction workers and operations across the country.

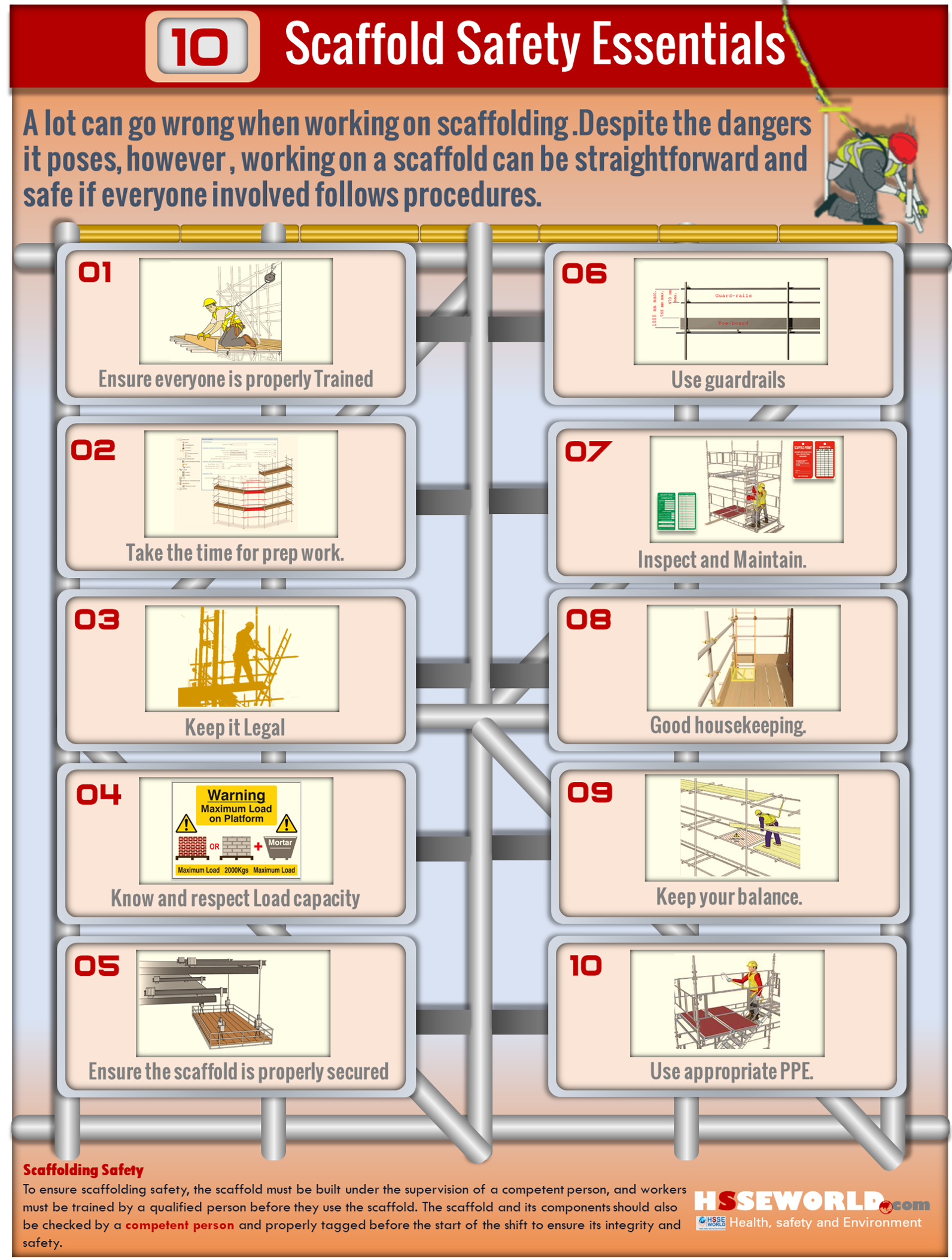

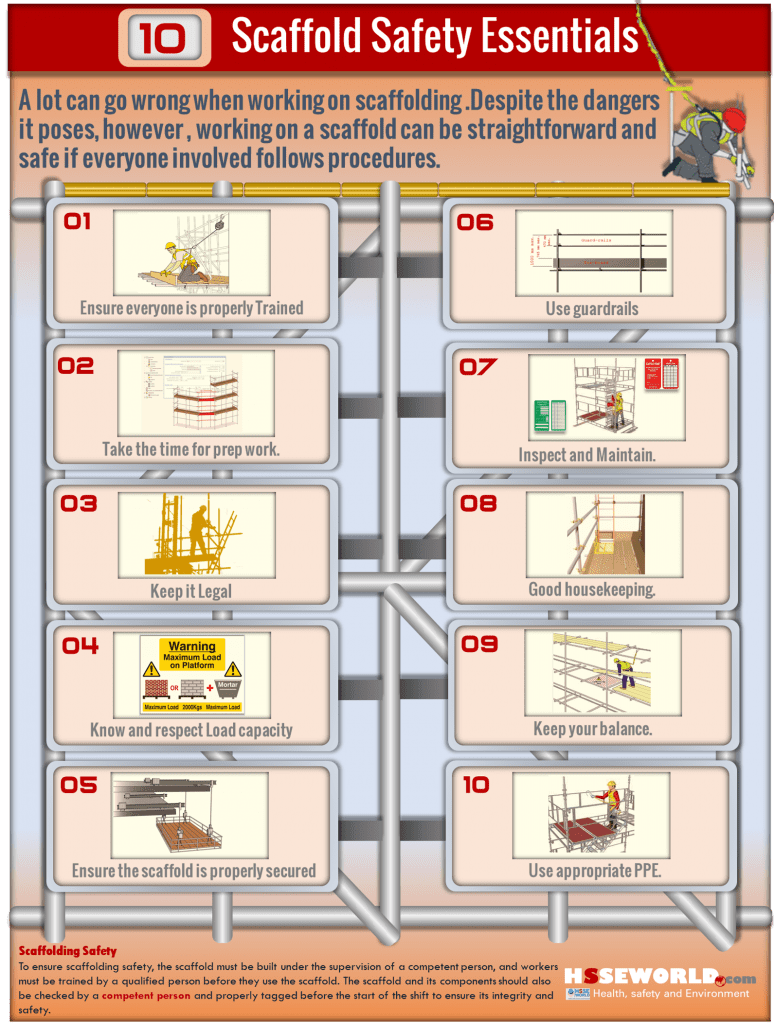

The key issue to safety when working on scaffolding boils down to whether or not the scaffold is safe to work on. Here are in the photo of today some guidelines to ensure complete safety.

before starting our safety tips we have some questions:

What is Scaffolding Safety?

Scaffolding safety is a set of preemptive actions in building, inspecting, using, and tagging scaffolds. To ensure scaffolding safety, the scaffold must be built under the supervision of a competent person, and workers must be trained by a qualified person before they use the scaffold. The scaffold and its components should also be checked by a competent person and properly tagged before the start of the shift to ensure its integrity and safety.

Why is Scaffolding Safety Important?

Around 65% of the construction industry work on scaffolds and experience 4,500 injuries and 60 fatalities annually in the United States alone. Scaffolding safety is important because it can help prevent workplace incidents from recurring. With baseline scaffold requirements to keep workers safe such as better inspections, training, and controls, frontline teams can ensure scaffolding safety and be proactive about building a safety culture from the ground up.

OSHA Scaffolding Safety: Who is a Competent and Qualified Person?

According to OSHA, a competent person is “one who is capable of identifying existing and predictable hazards in the surroundings or working conditions, which are unsanitary, hazardous to employees, and who has the authorization to take prompt corrective measures to eliminate them.” This is typically someone who holds a scaffolding high-risk work license.

While a qualified person is one who “has successfully demonstrated his/her ability to solve or resolve problems related to the subject matter, the work, or the project.” A qualified person has the right background such as education or degree in designing safe scaffolding, for example, this could be someone from the scaffold manufacturer or trained scaffold engineer.

The Bureau of Labor Statistics cites that 72% of scaffold injuries were due to scaffold planking or support giving way, slips, or falling objects. With regular inspections performed by a competent person, adequate scaffold safety training provided by a qualified person, and compliance with local regulatory standards, these dangers can be controlled.

Working on raised scaffolding can be very serious or dangerous whenever the proper safety precautions are not sustained or maintained.

However, when the safety protocols & practices are correctly followed, working on these structures can be just as safe as any additional or other elevated construction technique or way. Let’s have a look at the ten scaffolding safety tips, and how they keep you safe while working.

Get the right training.

New safety regulations mandate that all workers who will be working on or near scaffolding be suitably trained and educated on how the scaffolds are invented and performed. This includes how to get on and off of the scaffolding safely, how to prevent falls and how to respond to emergency situations while on the scaffolding.

This type of training is necessary to keep not only yourself but everyone else on and below the scaffolding secure & safe at all times.

Be prepared

Always ensure that you are inspecting scaffolding thoroughly before using it. Check to make sure the base is secured, and that it is level and adjusted for any lean in the building & Make sure that every single guardrail and plank is installed or fitted safely and securely, and also look out for elevation changes, obstructions (such as wires), and weather conditions.

Ensure everyone is licensed

OSHA (Occupational Safety And Health Administration) has claimed that rogue employers are a significant risk when it comes to working on scaffolding. These employers are unlicensed to be working but do so.

Rather than go through the proper channels and become licensed, they throw together a pick-up truck, some workers, and uninspected building material. Not only does this put the workers in danger, but it also puts the future occupants of the building in danger as well.

Understanding load capacity

During the design stages of scaffolding, one of the leading mistakes that are made is failing to consider all of the different types of load that the material will be under during construction and setup.

To maximize the safety of everyone involved, do not attempt to overload the scaffolding with more workers than it is rated for to save time. Also, take care to ensure that equipment does not overload it and that nothing is pushing against any guardrails. ( Learn What are the types of scaffolds load ).

Secure the platform

Scaffolding is designed to be braced by or entirely attached to a building. If bracing isn’t adequately secured, scaffold movement may dislodge an end, which will reduce the stability of the scaffold. There are a few types of brace retention or locking systems on scaffolding.

These systems need to operate freely during assembly and dismantling, and also be able to secure or lock to prevent the brace from dislodging. You shouldn’t try and replace the proper parts supplied by the manufacturer with nails or other miscellaneous substitutions.

Take advantage of guardrails.

When taking the design of the scaffold into account, a construction company must assure that any scaffolding over 10 feet high has guardrails on the three sides facing apart from the building, at the very slightest.

The side facing the building is still the danger, so it is recommended to have them there as well. Guardrails should not be observed as a replacement for right fall protection gear, which should be worn at all times while on the scaffolding.

Inspect it

Scaffolding structures need to be constantly maintained and inspected to retain their structural integrity and safety. Someone knowledgeable about the construction of the scaffolds themselves needs to examine the structure to ensure that it is still functional and safe, making sure that boards are all still intact and that all of the components are still in good shape. Failure to keep these crucial components regularly maintained could lead to extremely hazardous conditions.( Download scaffold-register-and-inspection-checklist/)

Keep things organized

Scaffolding structures are notoriously cramped, so it is essential that tools are not left out and are put up neatly on the scaffolding itself. Keep all of the walkways free of obstructions and trash that might be able to cause a fall.

Balance yourself

Scaffolding must be perfectly level to minimize the risk that workers can fall off and be injured or killed. Still, stay alert when on a scaffold, and watch your balance at all times.

Use protection, or PPE

This can include things like head protection, fall prevention gear, and non-slip footwear. It is essential to wear these measures at all times to maximize your safety and the safety of all who are around you.

If these safety tips are followed, then you or your workers should have no problem operating on scaffolds to complete the job.

Download Infographic

10 Scaffold Safety Essentials

More Photos

- What are the Best Practices for Managing Subcontractor Risk

- Photo of the day: 10 Essential Safety Tips for Driving in Hot Weather Conditions

- Photo of the day: best workplace safety tips

- Photo of the day: The Importance of Stop Work Authority in Maintaining Workplace Safety

- Photo of the day: Tomorrow’s Reward for Working Safely Today: Cultivating a Culture of Safety

- Photo of the day: Preventing slips and trips at work

- Photo of the day: Learn the DRSABCD action Plan

- Working with Electricity Electrical Accidents Guide for Electrical Workers

- Photo of the day: Hearing Protection Device Selection

- Photo of the day: If An Earthquake Shakes You-Infographic free

- Fire Safety Posters Free Download

- Photo of the day: First Aid for Electrical Burns-Infographic free

- Infographic: First Aid for Cuts and Scrapes free download

- Photo of The day: Work Safe with Lasers-Laser Safety free

- Photo of the day: Working Safely with chemicals and chemical Management

- Photo of the day: Safe work practices when using MEWPs ( updated)

- Photo of the day: Preventing Common Kitchen Hazards

- Photo of the day: Safe handling of Gas Cylinders and lecture bottles

- Photo of the day: Forklift Stability Triangle

- Photo of the day: Defective Tools Safe Work Practice

- Photo of the day: Lift With Your Legs Not With Your Back

- Photo of the day: First Aid for burns

- Photo of the day: The 7 Principles of HACCP

- Photo of the day: Working Safely with Suspended Loads

- Photo of the day: Heat Stroke First Aid and safety posters

- Photo of the day: Near-Miss Reporting and Posters

- Photo of the day: Ergonomic chair and office chair safety tips

- Photo of the day: Whole Body Vibration

- Photo of the day: Substation Safety Equipment

- Photo of the day: Bypassing Safety Controls Rules

- Photo of the day: Lightning Safety Tips

- Photo of the day: Overhead Power lines Clearance

- Photo of the day: Floor Marking

- Photo of the day: Types of Foot Protection

- Photo of the day: Types of Hand Protection

- Photo of the day: Lockout and Tagout Safety

- Photo of the day: Fall Protection Plans

- Photo of the day: Flood Safety Tips

- Photo of the day: Read All Labels Work safe

- Photo of the day: Run Project safely with Crane Hand Signals

- Photo of the day: Flagman and Traffic control

- Photo of the day: Managing Risks of Exposure to Solvents in the workplace

- Photo of the day: Scissor Lift Safety

- Photo of the day: HSE Bulletin Board

- Photo of the day: Arc-Fault Circuit Interrupters (AFCI)

- Photo of the day: Safe use of ladders and step ladders

- Photo of the day: Concrete Truck Driver Hand Signals

- Photo of the day: Extension Cord Safety Tips

- Photo of the day: Protect your Head

- Photo of the day: choosing the right Anchorage

- Photo of the day: Work-Related Asthma

- Photo of the day: Top FIVE Heavy Equipment Construction Site Safety Tips

- Photo of the day: sun safety in the workplace

- Photo of the day: Cannabis and Impairment in the Workplace

- Photo of the day: Position for safety and comfort-Safety Tips

- Photo of the day: Generator Safety

- Photo of the day: Controlling COVID-19 in the Workplace-Physical Barriers

- Photo of the day: Manual Material handling

- Photo of the day: Personal Protective Equipment last resort

- Photo of the day: WHMIS 2015 – Pictograms

- Photo of the day: Indoor Air Quality

- Photo of the day: Noise in the affected workplace

- Photo of the day: Fatigue at Work

- Photo of the day: Don’t be Driven to Distraction

- Photo of the day: working in heat and Humidex Rating

- How to use Plate Clamps Safely: Safety Moment#34

- Photo of the day: Sitting at work

- Photo of the day: 5 ways to reduce the risk of Slipping and Tripping

- Photo of the day: Preventing the spread of contagious illness

- Photo of the day: Incident Investigations

- Photo of the day: 10 Scaffold Safety Essentials

- Photo of the day: Effective Health and Safety Committees

- Photo of the day: New worker Orientation & Safety Orientation checklist

- Photo of the day: Workplace Inspection

- Photo of the day: musculoskeletal disorders

- Photo of the day: Emergency preparedness in the workplace

- Photo of the day: Mental health in the workplace

- Photo of the day: Trenching Safety Tips That Can Save a Life

- Photo of the day: Dangerous Goods Classes

- Photo of the day: Safety Equipment for Confined Spaces

- Photo of the day: Tips to reduce Heat stress in the workplace

- Photo of the day: hierarchy of controls

- Your steps to chemical safety

- H2S Gas and how to handle its Emergency

- Photo of the day: Importance of Mock drill and Fire Action Emergency Procedure

- Photo of the day: Choosing the Right Face Mask and the difference between a respirator and face mask

- Photo of the day: Confined space safety Precautions

- Breath Safely: The Proper Use of Respiratory Protection

- Photo of the day: Electric shock survival

- Photo of the day: Chemical Spill Emergency Response

- Photo of the day: Construction Site fire Safety