Compressed Gases Safety Tips

5 min readMany welding and cutting operations require the use of compressed gases. When compressed gases are consumed in the welding process, such as oxygen-fuel gas welding, requirements for their handling, storage, and use are contained in Subpart J.

General requirements for the handling, storage, and use of compressed gases are contained in a number of OSHA regulations as well as in Compressed Gas Association Pamphlet P-1-1965. Certain welding and cutting operations require the use of compressed gases other than those consumed in the welding process. For example, gas metal arc welding utilizes compressed gases for shielding. Handling, storage, and use of compressed gases in situations such as these require compliance with all OSHA regulations, and the requirements contained in shall be in accordance with Compressed Gas Association Pamphlet P-1-1965.

Many hazards are involved in compressed gas handling, storage, and use. To understand these hazards, we must realize that compressed gases are stores of potential energy. It takes energy to compress and confine the gas. That energy is stored until purposely released to perform useful work or until accidental release by container failure or other causes.

Some compressed gases, for example, acetylene, have high flammability characteristics. Flammable compressed gases, therefore, have additional stored energy besides simple compression-release energy. Other compressed gases, such as nitrogen, have simple asphyxiating properties. Some compressed gases, such as oxygen, can augment or compound fire hazards.

Cylinder Inspection

Employers must determine that compressed gas cylinders under their control are in a safe condition to the extent that this can be determined by visual inspection. These inspections must be conducted as prescribed in the Hazardous Materials Regulations of the Department of Transportation (DOT) contained in 49 CFR Parts 171-179 and 14 CFR Part 103. Where these regulations are not applicable, these inspections shall be conducted in accordance with Compressed Gas Association (CGA) Pamphlets C-6 and C-8. According to DOT regulations:

“A cylinder that leaks bulge, has defective valves or safety devices, bears evidence of physical abuse, fire or heat damage, or detrimental rusting or corrosion, must not be used unless it is properly repaired and requalified as prescribed in these regulations.”

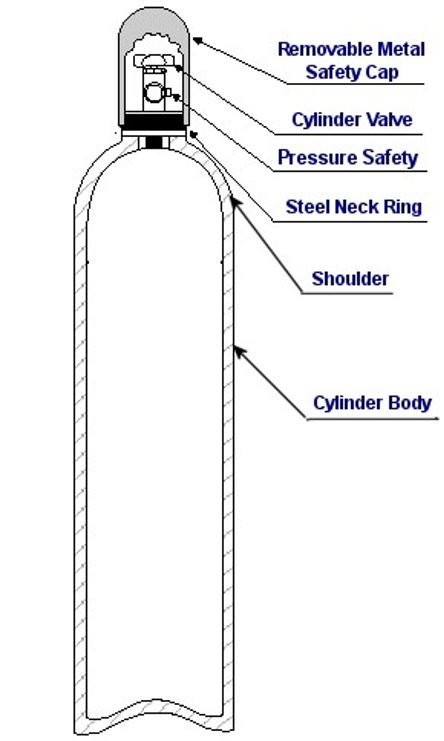

The term “cylinder” is defined as a pressure vessel designed for pressures higher than 40 psia (pounds per square inch absolute) and having a circular cross-section. It does not include a portable tank, multi-unit tank car tank, cargo tank, or tank car.

( Find out: Compressed- as cylinders access control inspection- hecklist).

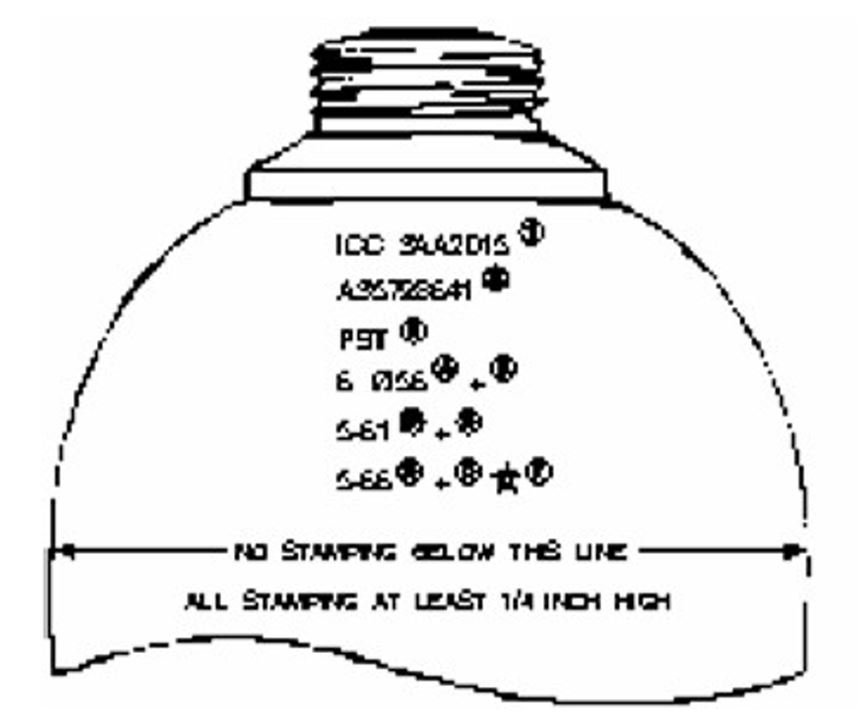

DOT requires basic information markings on all cylinders. Each required marking on a cylinder must be maintained so that it is legible. A summary of the DOT marking requirements is shown below.

- DOT or ICC marking may appear – new manufacture must-read “DOT.” 49 CFR 171.14. “3AA” indicates spec. in 49 CFR 178.37. “2015” is the marked service pressure.

- Serial number – no duplications permitted with any particular symbol-serial number combinations.

- Symbol of the manufacturer, user, or purchaser.

- “6 56” date of manufacture. Month and year “i ” disinterested inspector’s official mark.

- Plus mark (+) indicates cylinder maybe 10% overcharged per 49 CFR 173.302(c).

- Retest dates.

- 5 pointed star indicates a ten-year retest interval. See 49 CFR 173.34(e)(15).

Transporting, Moving, and Storing Compressed Gas Cylinders

- Valve protection caps shall be in place and secured.

- When cylinders are hoisted, they shall be secured on a cradle, sling board, or pallet. They shall not be hoisted or transported by means of magnets or choker slings.

- Cylinders shall be moved by tilting and rolling them on their bottom edges. They shall not be intentionally dropped, struck, or permitted to strike each other violently.

- When cylinders are transported by powered vehicles, they shall be secured in a vertical position.

- Valve protection caps shall not be used for lifting cylinders from one vertical position to another. Bars shall not be used under valves or valve protection caps to pry cylinders loose when frozen. Warm, not boiling, water shall be used to thaw cylinders lose.

- Unless cylinders are firmly secured on a special carrier intended for this purpose, regulators shall be removed and valve protection caps put in place before cylinders are moved.

- A suitable cylinder truck, chain, or another steadying device shall be used to keep cylinders from being knocked over while in use.

- When work is finished, when cylinders are empty, or when cylinders are moved at any time, the cylinder valve shall be closed

- Compressed gas cylinders shall be secured in an upright position at all times, if necessary, for short periods of time while cylinders are actually being hoisted or carried.

- Oxygen cylinders in storage shall be separated from fuel-gas cylinders or combustible materials (especially oil or grease), a minimum distance of 20 feet (6.1 m) or by a noncombustible barrier at least 5 feet (1.5 m) high having a fire-resistance rating of at least one-half hour.

- Inside of buildings, cylinders shall be stored in a well-protected, well-ventilated, dry location, at least 20 feet (6.1 m) from highly combustible materials such as oil or excelsior. cylinders should be stored in definitely assigned places away from elevators, stairs, or gangways. Assigned storage places shall be located where cylinders will not be knocked over or damaged by passing or falling objects, or subject to tampering.

- The in-plant handling, storage, and utilization of all compressed gases in cylinders, portable tanks, rail tank cars, or motor vehicle cargo tanks shall be in accordance with Compressed Gas Association Pamphlet P-1-1965.

Placing Cylinders

- Cylinders shall be kept far enough away from the actual welding or cutting operation so that sparks, hot slag, or flame will not reach them. When this is impractical, fire-resistant shields shall be provided.

- Cylinders shall be placed where they cannot become part of an electrical circuit. Electrodes shall not be struck against a cylinder to strike an arc.

- Fuel gas cylinders shall be placed with the valve end up whenever they are in use. They shall not be placed in a location where they would not be subject to open flame, hot metal, or other sources of artificial heat. Cylinders containing oxygen or acetylene or other fuel gas shall not be taken into confined spaces.

Treatment of Cylinders

- Cylinders, whether full or empty, shall not be used as rollers or supports.

- No person other than the gas supplier shall attempt to mix gases in a cylinder. No one except the owner of the cylinder or person authorized by him shall refill a cylinder. No one shall use a cylinder’s contents for purposes than those intended by the supplier. All cylinders used shall meet the Department of Transportation requirements published in 49 CFR Part 178, Subpart C, Specification for Cylinders.

- No damaged or defective cylinder shall be used.

(Learn More: E-books guidelines for gas-cylinders safety/).

1 thought on “Compressed Gases Safety Tips”