Ensuring Workplace Safety: Comprehensive Guide to Overhead Crane Safety

7 min readIn today’s industrial landscape, overhead cranes are indispensable tools, used across various sectors to lift and transport heavy loads with precision and efficiency. However, the safety of crane operations is paramount, as any lapse can lead to severe accidents, injuries, or even fatalities. Ensuring the safety of overhead crane operations is paramount to protecting workers, preventing accidents, and maintaining smooth operational workflows. this article will present a comprehensive guide to Overhead crane safety.

Overhead Cranes Accident Hazard

Overhead cranes, often called bridge cranes, consist of parallel runways with a traveling bridge spanning the gap. These cranes are commonly used in manufacturing, construction, and logistics for moving heavy objects that standard lifting equipment cannot handle. Bridge cranes are also used in special occasions, such as foundry overhead cranes in steel mills and explosion-proof cranes in environments with dust and explosive gas, carry significant risks if an accident occurs. In steel mills, a malfunctioning foundry crane can lead to the uncontrolled release of molten metal, resulting in devastating fires, severe burns, fatalities, and substantial damage to equipment and infrastructure. In environments requiring explosion-proof cranes, a single spark from an accident can ignite explosive gas or dust, leading to catastrophic explosions that can cause extensive property damage, loss of life, and prolonged operational downtime. The repercussions of such incidents extend beyond immediate physical harm, impacting the entire operation’s safety, financial stability, and reputation.

Potential Hazards and Risks

Common Hazards Associated with Overhead Cranes

Despite their utility, overhead cranes pose several hazards that can lead to severe accidents if not properly managed. Some of the most common risks include:

- Overloading: Exceeding the crane’s maximum load capacity can lead to equipment failure.

- Mechanical Failures: Wear and tear or inadequate maintenance can cause malfunctions.

- Human Error: Inexperienced or improperly trained operators are prone to mistakes.

- Falling Loads: Improper securing of loads can result in them falling and causing injuries.

- Electrical Hazards: Cranes operating near power lines pose a risk of electrical shocks.

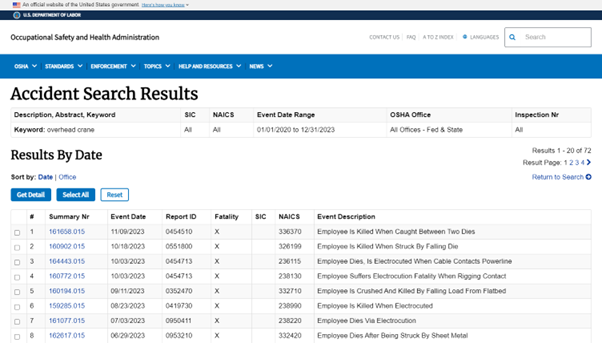

Statistics on Crane-Related Accidents

According to the Occupational Safety and Health Administration (OSHA), crane accidents result in numerous injuries and fatalities annually. For instance, in 2020-2023, over 70 overhead crane related injuries and fatalities were reported in the United States alone. These incidents often highlight the importance of adhering to safety protocols and ensuring thorough training for all personnel involved in crane operations.

Regulatory Standards and Compliance

Overview of Relevant Safety Regulations

Ensuring overhead crane safety begins with understanding and adhering to established safety standards and regulations. Key regulatory bodies like OSHA and the American National Standards Institute (ANSI) provide comprehensive guidelines for crane safety, including:

- OSHA Standards (29 CFR 1910.179): Outlines overhead and gantry cranes safety requirements.

- ANSI/ASME B30.2: Provides detailed safety standards for overhead and gantry cranes.

Importance of Compliance and Regular Audits

Compliance with these regulations is not only a legal requirement but also a crucial component of workplace safety. Regular audits and inspections help ensure that safety protocols are being followed and that the equipment is in good working condition. Failure to comply with these standards can result in hefty fines and, more importantly, endanger the lives of workers.

Pre-Operation Safety Measures

Conducting Thorough Risk Assessments

Before any crane operation, a thorough risk assessment should be conducted to identify potential hazards and implement measures to mitigate them. This includes evaluating the work environment, the load to be lifted, and the condition of the crane and its components.

Ensuring Proper Training and Certification

Operators must receive comprehensive training and certification to handle cranes safely. Training should cover operating procedures, safety protocols, emergency responses, and regular updates to keep up with new safety practices and technologies.

Pre-Operation Inspection Checklists

Implementing a pre-operation inspection checklist ensures that all aspects of the crane and the surrounding environment are checked for safety. Key items on the checklist include:

- Verifying the crane’s load capacity.

- Inspecting the hoist and trolley for any signs of damage.

- Ensuring all safety devices are functional.

- Checking for obstructions in the crane’s path.

- Confirming the area is clear of unauthorized personnel.

Read: Secure Your Lifts: Guidelines for Safe Lifting Operations Free Planning Tool

Operational Safety Protocols

Best Practices for Safe Crane Operation

Adhering to best practices during crane operation significantly reduces the risk of accidents. These include:

- Load Management: Ensuring loads are properly balanced and do not exceed the crane’s capacity.

- Clear Communication: Using standardized hand signals and communication methods to coordinate movements.

- Use of PPE: All personnel should wear appropriate personal protective equipment (PPE) such as helmets, gloves, and safety shoes.

- Emergency Preparedness: Having a clear emergency plan in place and ensuring all workers are familiar with it.

Read: Importance of Crane Load Chart

Importance of Clear Communication and Signaling

Effective communication is crucial in crane operations. Operators and ground personnel should use agreed-upon hand signals and communication devices to ensure coordinated and safe movements. Miscommunication can lead to serious accidents, especially in busy or noisy work environments.

Maintenance and Inspection

Importance of Regular Maintenance and Inspections

Regular maintenance and inspections are vital to ensure the safe and efficient operation of overhead cranes. Scheduled maintenance helps identify and rectify issues before they become serious problems. Inspections should include:

- Checking the condition of ropes and chains.

- Inspecting the crane’s electrical system.

- Verifying the functionality of safety devices.

- Ensuring the structural integrity of the crane.

Detailed Maintenance Schedules and Checklists

Developing a detailed maintenance schedule and checklist ensures that no aspect of the crane’s upkeep is overlooked. Maintenance should be performed by qualified technicians and should follow the manufacturer’s recommendations as well as regulatory requirements.

Read: CRANE INSPECTION REPORT

Emergency Procedures and Response Plans

Developing and Implementing Emergency Response Plans

An effective emergency response plan is essential for managing incidents involving overhead cranes. The plan should include:

- Procedures for immediate response to accidents.

- Evacuation routes and assembly points.

- Contact information for emergency services.

- Roles and responsibilities of personnel during an emergency.

Training Employees on Emergency Procedures

Regular training sessions should be conducted to ensure all employees are familiar with emergency procedures. Drills and simulations can help prepare workers for real-life scenarios, enabling them to respond quickly and effectively in an emergency.

learn how to implement Tower crane Rescue Plan

Choose a Well-known Overhead Crane Manufacturer

Selecting a reliable crane manufacturer is crucial to ensuring the safety, efficiency, and longevity of your crane operations. Renowned manufacturers such as Konecranes, Demag Crane, Weihua Group, Dfang Crane, GH Crane and so on.

When choosing a reliable crane manufacturer, it’s important to consider a range of factors from multiple dimensions to ensure you partner with a reputable and capable company. Key factors include the manufacturer’s factory area, which indicates production capacity and scale, and the number of employees, reflecting the company’s operational capabilities and expertise. Annual sales figures provide insight into the company’s market presence and financial stability. Additionally, the quality and modernity of production equipment are crucial for ensuring high manufacturing standards. Reviewing project cases can demonstrate the company’s experience and success in delivering similar projects. Together, these factors provide a comprehensive view of the manufacturer’s reliability and capability to meet your needs.

Take the Dafang Crane as an example:

Dafang Crane, a renowned manufacturer and supplier of high-quality overhead cranes and lifting solutions. Based in China, The plant covers a total area of 850,000 square meters and employs more than 2,600 people, brings in the equivalent of $1 billion in annual revenue. Committed to delivering innovative and reliable crane products to meet the diverse needs of our global clientele. Offer a comprehensive range of cranes, including but not limited to: overhead crane, gantry crane, jib crane, ladle crane, smart crane. Dafang Crane understand that each customer has specific needs, and they are dedicated to providing customized crane designs and services. Their team of experts works closely with clients to develop tailored solutions that enhance efficiency, safety, and productivity.

These companies leverage cutting-edge technology and high-grade materials to build cranes that withstand rigorous industrial demands while maintaining optimal performance. Additionally, reputable manufacturers provide extensive maintenance programs and customer support, ensuring that any issues are promptly addressed and the cranes continue to operate smoothly and safely. By choosing a trusted manufacturer, businesses can be confident in the reliability and longevity of their bridge cranes, leading to enhanced productivity and reduced operational risks.

Conclusion

Ensuring the safety of overhead crane operations is a multifaceted endeavor that requires diligent adherence to safety protocols, regular maintenance, and continuous training. By understanding the potential hazards, complying with regulatory standards, and implementing best practices, companies can significantly reduce the risk of accidents and create a safer work environment. Remember, a proactive approach to crane safety not only protects workers but also enhances operational efficiency and productivity.

have more safety resources at : https://safetybagresources.com/