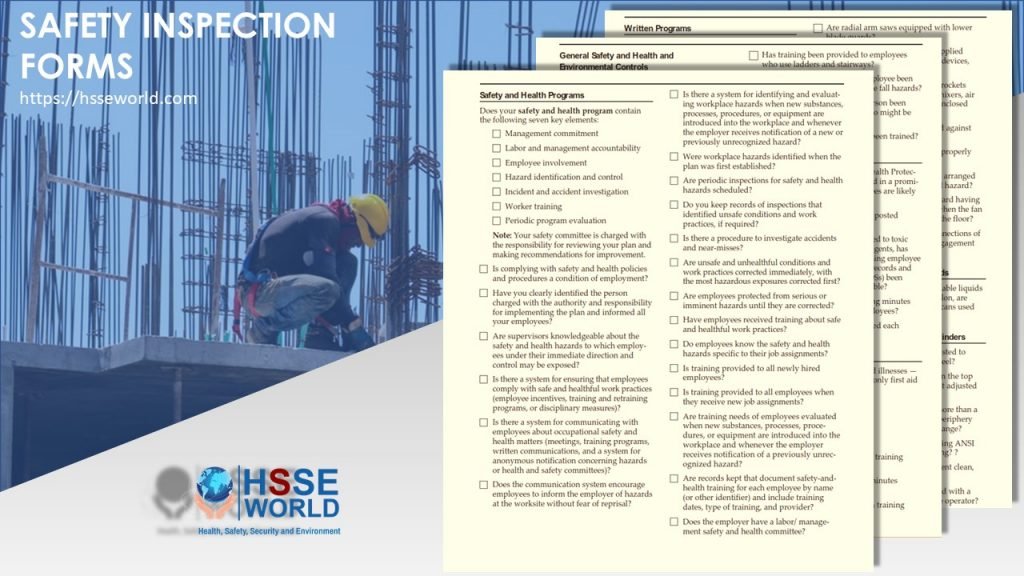

Workplace Safety Inspections Forms

4 min readA workplace inspection is a critical part of a comprehensive safety and health program in which the workplace is examined closely on a regular basis for the purpose of:

- identifying and recording potential and actual hazards associated with buildings, equipment, environment, processes, and practices

- identifying any hazards which require immediate attention, whether they are unsafe conditions or unsafe acts

- ensuring that existing hazard controls are functioning adequately; and where appropriate, recommending corrective action

Within any safety program, there may, in fact, be a variety of types of inspections, for example:

- spot inspections may be undertaken on a random basis as part of general safety responsibilities;

- pre-operation checks of special equipment or work processes are often necessary before work is carried out;

- critical parts inspections are regular planned inspections of those critical parts of a machine, piece of equipment, or system which have a high potential for serious accidents. They are often part of planned or preventive maintenance procedures, or hazard control programs;

- new equipment inspections are thorough inspections and checks before operations begin;

- regular planned inspections are done on a regular basis in a defined workplace and cover all conditions including work practices and procedures. Regular planned inspections are the subject of this publication. However, the principles which apply to this type of inspection can easily be adapted to other types of inspections.

The purpose and function of workplace inspections must be seen within the context of the whole safety and health program. It is not an isolated function, but relates to the major objectives of the program, namely:

- to identify hazards (unsafe conditions and unsafe acts)

- to set standards and related procedures

- to establish and determine effectiveness of controls

- to monitor the effectiveness of plans, programs, policies, and procedures

Effective inspections are used to assist and improve other elements of the safety program. Inspections are a critical component of safety and health programs. They help to identify possible corrective action for identified hazards and to monitor the effectiveness of controls.

Inspections should not be treated as isolated events. To be effective they must be conducted on a regular basis and be part of a systematic program aimed at accident prevention. The steps involved in establishing a sound workplace inspection system are:

- Planning

- Inspection

- Reporting

- Monitoring

Download the Form

here you can download the Checklist and use it for workplace Safety Inspections

More Forms

- Downloadable Kitchen Safety Inspection Checklist for Restaurants

- Mastering LOTO: Protecting Workers with Energy Isolation and Isolation Confirmation Certificates

- Flammable and Combustible Storage Checklist Free Download

- Secure Your Lifts:Guidelines for Safe Lifting Operations Free Planning Tool

- Sample of Accident Prevention Program ( APP) Template for General Industry Free Download

- Free ISO 14001:2015 Environmental Management System Audit Checklist Download

- Guides for Walking and Working Surfaces Safety Program

- Workshop Safety Guideline and free Posters

- Free Ergonomics Checklist for General Industry

- Work Area Safety Checklist

- Machine Safety and 43-Equipment Inspection Checklists

- Scaffold Safety self Audit and checklist

- Hot Work Controls and its Permit to work Form

- Safety Observation Report Template

- Forklift Operator’s Daily Checklist and safety Tips

- Inspecting Fall Protection Equipment Forms

- Templates: HSE Incentives and rewards

- 35 Inspection forms for Rig Check

- Chemical Risk Assessment form

- 22-Safety Inspection Checklists

- Safety Task Assessment Form

- Suspended Scaffold Pre-Operation Inspection Checklist

- Photo of the day: New worker Orientation & Safety Orientation checklist

- Grating-Decking-Floor- handrail-Removal Form

- Electrical Inspection Checklists

- E-Books: Fire Safety Logbook templates

- General Safety Guidelines and Employee Acknowledgment form

- Annual Internal Audit Form

- Mobile Scaffold Inspection checklist

- Simultaneous Operation (SIMOPS) checklist

- Temporary Construction Facilities (TCF) Inspection checklist

- HIRA, HSE Hazards & Effects Management Process (HEMP) & Risk Register Template

- Hazard Identification Plan (HIP) Template

- Ladder Inspection Form

- Free Pre-Startup Safety Review Checklist (PSSR)

- Hazard Identification Checklist

- Workplace Housekeeping Checklist

- ISO 45001:2018 READINESS CHECKLIST

- Lifting Plan Audit Checklist

- Job Safety Analysis (JSA) Forms What’s Right and Wrong?

- Electrical Isolation Permit to Work forms and checklist

- Canteen Inspection Checklist

- Work at Height Checklist

- Health Safety at Work Improvement Action Plan

- Fire Pump Daily Inspection Checklist

- Construction Site Traffic Management Plan (CSTMP) Guidance

- Safety Templates: COVID-19 Safety Plan

- Workplace Safety Inspections Forms

- Lock Removal Form

- Templates: Management of Change NEW Modified Equipment Safety Checklist

- Lifeline & Harness Inspection Guide checklist

- Contractor Pre-qualification Questionnaire Checklist

- Fall safety at construction checklist

- Construction safety Inspection checklist

- Equipment Safe Operating Procedures- SOP 61 checklist

- Permit to Work (PTW ) AUDIT CHECKLIST

- Hygiene and Sanitation Inspection Checklist

- Pressure Testing Checklist

- Crane Suspended Personnel Platform (MANBASKET) Permit

- Electric Arc Welding and Cutting Checklist

- Laboratory Inspection Checklist Form

- CRANE INSPECTION REPORT

- Scaffold Register and Inspection Checklist

- Portable Ladder Self Inspection checklist

- Process Safety Management (PSM) Compliance checklist

- OSHA Inspection Checklist 8-Pages

- Job Hazard Analysis form

- Incident Report Form

- Safety Inspection Form

- Contractor Weekly HSE Report Form

- Competent Person Designation form

- Compressed Gas Cylinders Access Control Inspection Checklist

- Emergency Drill After Action Review form

- Emergency Drill Table Top meeting Form

- Slips,Trips and Falls checklist

- Lift Plan Form

- Machines Access Control Inspection Checklists

- Camp Inspection form

2 thoughts on “Workplace Safety Inspections Forms”