Heavy equipment is a necessity on nearly every construction project. Unfortunately, they can be extremely dangerous when not used properly. Rollovers, struck-by accidents, and caught in or between accidents are common ways workers can be injured when working on or near heavy equipment.

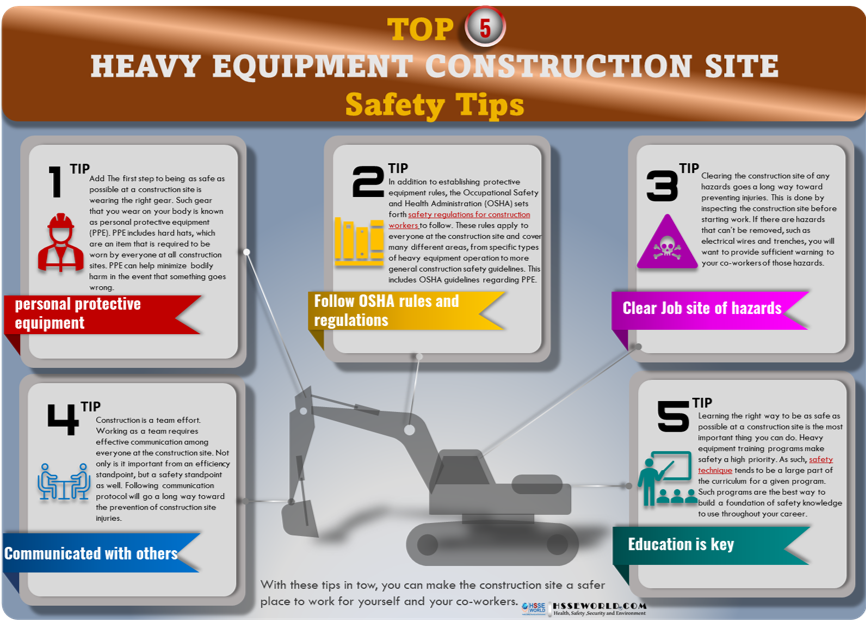

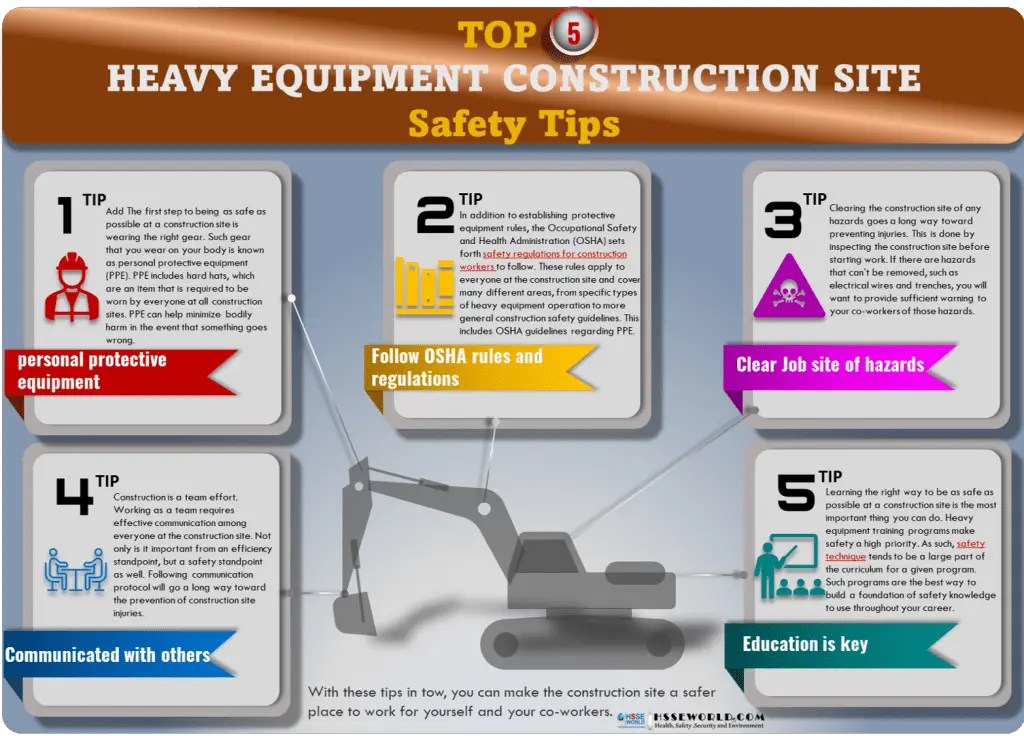

The Photo of today and infographic show the top 5 safety tips to follow when working with heavy equipment on the construction site to ensure you stay productive and maintain an accident-free Jobsite:

A construction site is a dangerous place to work. Between falling objects, heavy equipment malfunction, and multiple tasks being performed at once, there are many ways construction workers can get hurt. That’s why construction safety is important. Here are the top five construction site safety tips for heavy equipment operators and other construction workers to abide by.

- Wear personal protective equipment The first step to being as safe as possible at a construction site is wearing the right gear. Such gear that you wear on your body is known as personal protective equipment (PPE). PPE includes hard hats, which are an item that is required to be worn by everyone at all construction sites. PPE can help minimize bodily harm in the event that something goes wrong.

- Follow OSHA rules and regulations In addition to establishing protective equipment rules, the Occupational Safety and Health Administration (OSHA) sets forth safety regulations for construction workers to follow. These rules apply to everyone at the construction site and cover many different areas, from specific types of heavy equipment operation to more general construction safety guidelines. This includes OSHA guidelines regarding PPE.

OSHA regulations are updated from time to time to reflect best practices, so you will want to stay in the loop so as to be in compliance with the most current regulations. - Clear job site of hazards Clearing the construction site of any hazards goes a long way toward preventing injuries. This is done by inspecting the construction site before starting work. If there are hazards that can’t be removed, such as electrical wires and trenches, you will want to provide sufficient warning to your coworkers of those hazards.

It also includes being aware of any weather conditions that might make certain tasks or operating certain equipment dangerous. Your safety and the safety of others at the worksite are of the utmost importance.

- Communicate with others Construction is a team effort. Working as a team requires effective communication among everyone at the construction site. Not only is it important from an efficiency standpoint, but a safety standpoint as well. Following communication protocol will go a long way toward the prevention of construction site injuries.

- Education is key Learning the right way to be as safe as possible at a construction site is the most important thing you can do. Heavy equipment training programs make safety a high priority. As such, safety technique tends to be a large part of the curriculum for a given program. Such programs are the best way to build a foundation of safety knowledge to use throughout your career.

Safety education typically doesn’t stop for heavy equipment operators at the end of a training program. Completing continuous training in current construction safety techniques will help you do your part in making the construction site as safe as possible.

Other Tips to remember

Equipment Operator Training

Workers should be trained on the proper procedures to safely operate all pieces of equipment they will be working on. Training should be conducted as a combination of classroom and practical hands-on instruction. Topics that should be covered include safety, hazard identifications, safety features of the equipment, and safe maneuvering of the heavy equipment.

Workers should be trained on how to safely mount and dismount and the proper start-up procedure for each piece of equipment. They should have a clear understanding of lifting loads and load capacity for the equipment they will be working on. Retraining and refresher courses should be conducted as needed, especially if a worker is observed operating equipment unsafely or in a manner other than its intended purpose. Only trained workers should be allowed to operate equipment for any reason.

Be Aware of Your Surroundings

When operating heavy equipment, you need to be mindful of the area you are working in and any obstacles you may encounter. Overhead power lines should be de-energized, or if that’s not possible, establish barriers to avoid making contact with them. If digging, make sure that all underground utilities, such as sewer, water, gas, and electrical, have been identified and clearly marked to avoid damaging them and creating delays and more work.

Whenever possible, workers should be kept out of areas where heavy equipment is in operating. Operators should be aware of their swing radius, especially when working in tighter spaces, to avoid hitting other workers, bystanders, or other vehicles or equipment in the vicinity.

Entering and Exiting Equipment

This one should go without saying, but based on the number of injuries workers suffer each year, but there is a right and a wrong way to mount and dismount from heavy equipment. When climbing onto equipment, always maintain three points of contact just like you do when climbing a ladder. Never carry anything with you as you enter or exit the cab. Never jump out of the cab or off the equipment to exit.

Never enter or exit equipment that is moving or in operation. Make sure you completely shut off the equipment, engage the parking brake and release any pressure from hydraulic controls. Make sure to take the keys with you to avoid any unauthorized use.

Inspect Equipment Before Use

Visually inspect heavy equipment before each use to ensure it’s in good operating condition. Check tires and tracks for any wear and damage. At the very least, you should check fluid levels such as engine oil and hydraulic fluid and oil levels before you start up the equipment for the first time each day. Check hydraulic hoses, buckets, booms, and other components for cracks and damage. Make sure all attachments are securely locked into place.

When you fire up the equipment, make sure the lights, gauges, horns, and backup alarms are all working properly. Make sure all arms, shovels, buckets, etc. fully extend in all directions. If the cab rotates, check to make sure it can do so in all directions. Never use equipment that isn’t working properly or appears damaged. Not only could you damage the machine further, but it could be a major safety issue if not fixed before use.

( learn how to keep-heavy-equipment-operations-on-track/)

Only Use Equipment as Intended

Each piece of equipment was designed to perform a specific task. Excavators aren’t cranes and wheel loaders weren’t made to carry workers in the bucket and used as an aerial lift. Pick the right piece of equipment for the task at hand and use it as the manufacturer intended.

Don’t overload or overwork equipment. Be mindful of the payload or lift capacity of the equipment. This may require getting a bigger piece of equipment if what you have isn’t enough to get the job done. If lifting material, make sure all riggings are properly secured. Don’t try to go too fast when operating equipment, especially on slopes.

Wear Your Seatbelt

Those seatbelts aren’t just a suggestion, they could save your life. In the event the equipment starts to tip or rollover, the seatbelt is probably going to keep you alive. If equipment starts to tip or rollover, you might instinctively be compelled to jump out of the cab. Unfortunately, that is the worst thing you could possibly do. The equipment could tip back the other way and fall on as you make your escape or you could get caught or flung out as it rolls over and seriously injured.

The rollover protection system installed on the equipment is intended to keep you safe in such an event. The seatbelt will keep you from getting jostled around and banged up or flung from the cab.

Keep the Area Clear

Ideally, you can cordon off the area with barriers to keep workers from accidentally getting in close proximity to operating equipment. If you are moving or operating equipment near workers use a spotter, using radio or hand signals to communicate, to keep your blind spots clear. This is especially important when backing up. Yes, the equipment will have backup alarms, but they often go unheeded on construction sites due to their prevalence.

( read how to avoid-line-of-fire)

Download Infographic

Top FIVE Heavy Equipment Construction Site Safety Tips

More Photos

- What are the Best Practices for Managing Subcontractor Risk

- Photo of the day: 10 Essential Safety Tips for Driving in Hot Weather Conditions

- Photo of the day: best workplace safety tips

- Photo of the day: The Importance of Stop Work Authority in Maintaining Workplace Safety

- Photo of the day: Tomorrow’s Reward for Working Safely Today: Cultivating a Culture of Safety

- Photo of the day: Preventing slips and trips at work

- Photo of the day: Learn the DRSABCD action Plan

- Working with Electricity Electrical Accidents Guide for Electrical Workers

- Photo of the day: Hearing Protection Device Selection

- Photo of the day: If An Earthquake Shakes You-Infographic free

- Fire Safety Posters Free Download

- Photo of the day: First Aid for Electrical Burns-Infographic free

- Infographic: First Aid for Cuts and Scrapes free download

- Photo of The day: Work Safe with Lasers-Laser Safety free

- Photo of the day: Working Safely with chemicals and chemical Management

- Photo of the day: Safe work practices when using MEWPs ( updated)

- Photo of the day: Preventing Common Kitchen Hazards

- Photo of the day: Safe handling of Gas Cylinders and lecture bottles

- Photo of the day: Forklift Stability Triangle

- Photo of the day: Defective Tools Safe Work Practice

- Photo of the day: Lift With Your Legs Not With Your Back

- Photo of the day: First Aid for burns

- Photo of the day: The 7 Principles of HACCP

- Photo of the day: Working Safely with Suspended Loads

- Photo of the day: Heat Stroke First Aid and safety posters

- Photo of the day: Near-Miss Reporting and Posters

- Photo of the day: Ergonomic chair and office chair safety tips

- Photo of the day: Whole Body Vibration

- Photo of the day: Substation Safety Equipment

- Photo of the day: Bypassing Safety Controls Rules

- Photo of the day: Lightning Safety Tips

- Photo of the day: Overhead Power lines Clearance

- Photo of the day: Floor Marking

- Photo of the day: Types of Foot Protection

- Photo of the day: Types of Hand Protection

- Photo of the day: Lockout and Tagout Safety

- Photo of the day: Fall Protection Plans

- Photo of the day: Flood Safety Tips

- Photo of the day: Read All Labels Work safe

- Photo of the day: Run Project safely with Crane Hand Signals

- Photo of the day: Flagman and Traffic control

- Photo of the day: Managing Risks of Exposure to Solvents in the workplace

- Photo of the day: Scissor Lift Safety

- Photo of the day: HSE Bulletin Board

- Photo of the day: Arc-Fault Circuit Interrupters (AFCI)

- Photo of the day: Safe use of ladders and step ladders

- Photo of the day: Concrete Truck Driver Hand Signals

- Photo of the day: Extension Cord Safety Tips

- Photo of the day: Protect your Head

- Photo of the day: choosing the right Anchorage

- Photo of the day: Work-Related Asthma

- Photo of the day: Top FIVE Heavy Equipment Construction Site Safety Tips

- Photo of the day: sun safety in the workplace

- Photo of the day: Cannabis and Impairment in the Workplace

- Photo of the day: Position for safety and comfort-Safety Tips

- Photo of the day: Generator Safety

- Photo of the day: Controlling COVID-19 in the Workplace-Physical Barriers

- Photo of the day: Manual Material handling

- Photo of the day: Personal Protective Equipment last resort

- Photo of the day: WHMIS 2015 – Pictograms

- Photo of the day: Indoor Air Quality

- Photo of the day: Noise in the affected workplace

- Photo of the day: Fatigue at Work

- Photo of the day: Don’t be Driven to Distraction

- Photo of the day: working in heat and Humidex Rating

- How to use Plate Clamps Safely: Safety Moment#34

- Photo of the day: Sitting at work

- Photo of the day: 5 ways to reduce the risk of Slipping and Tripping

- Photo of the day: Preventing the spread of contagious illness

- Photo of the day: Incident Investigations

- Photo of the day: 10 Scaffold Safety Essentials

- Photo of the day: Effective Health and Safety Committees

- Photo of the day: New worker Orientation & Safety Orientation checklist

- Photo of the day: Workplace Inspection

- Photo of the day: musculoskeletal disorders

- Photo of the day: Emergency preparedness in the workplace

- Photo of the day: Mental health in the workplace

- Photo of the day: Trenching Safety Tips That Can Save a Life

- Photo of the day: Dangerous Goods Classes

- Photo of the day: Safety Equipment for Confined Spaces

- Photo of the day: Tips to reduce Heat stress in the workplace

- Photo of the day: hierarchy of controls

- Your steps to chemical safety

- H2S Gas and how to handle its Emergency

- Photo of the day: Importance of Mock drill and Fire Action Emergency Procedure

- Photo of the day: Choosing the Right Face Mask and the difference between a respirator and face mask

- Photo of the day: Confined space safety Precautions

- Breath Safely: The Proper Use of Respiratory Protection

- Photo of the day: Electric shock survival

- Photo of the day: Chemical Spill Emergency Response

- Photo of the day: Construction Site fire Safety