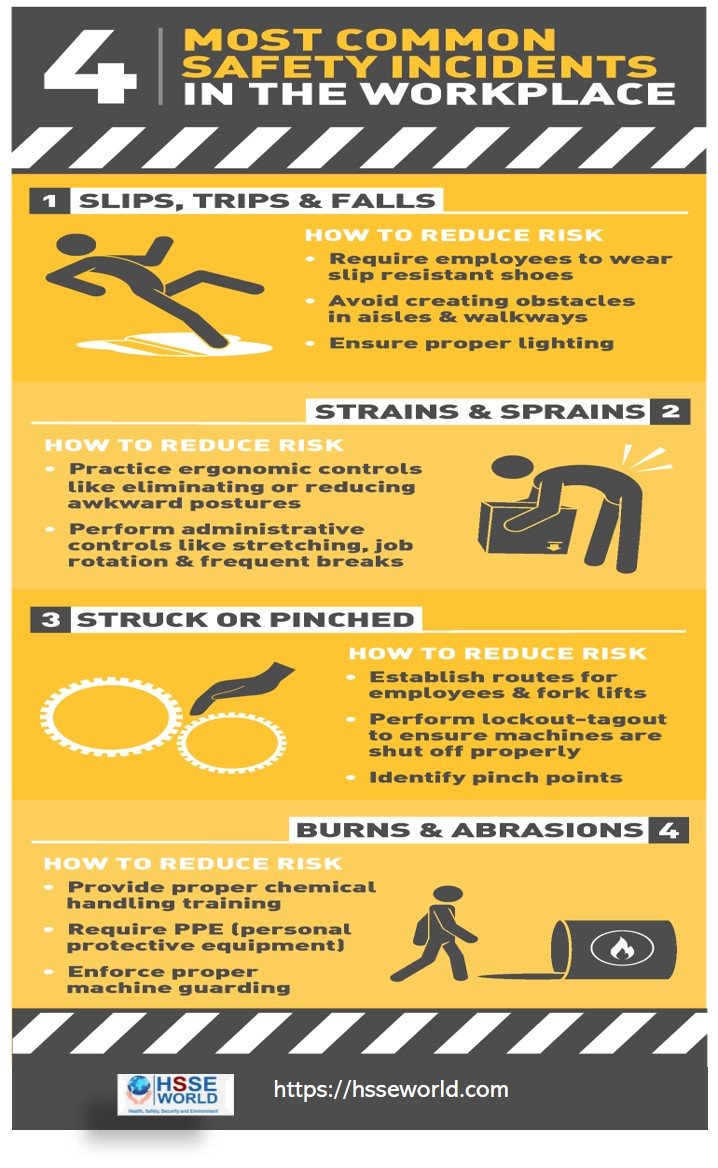

All kinds of injuries can occur in the workplace, which can cost both the employer and the employee valuable time and money.

Today, we’re going to take a look at the most common workplace injuries and offer some safety tips to help you prevent them from occurring.

1. Trips, Slips, And Falls

Slips, trips, and falls account for one-third of all personal injuries in the workplace, and they’re a top cause of all workers’ compensation claims. The types of injuries incurred include head, back, and neck injuries, broken bones, cuts, sprains, and pulled muscles.

The most common reasons for falls in the workplace are:

Slips: Occasional spills, wet or oily surfaces, weather hazards like icy steps or walkways, and loose rugs.

Trips: Poor lighting, clutter, wrinkled carpeting or mats, uncovered cables, and uneven walking surfaces.

There are 3 keys to preventing these types of workplace accidents: good housekeeping, quality walking surfaces, and proper footwear. Beyond that, employees should be encouraged to report areas where clutter, obstruction, spillage, or damage have occurred.

(learn more:E-books slips-trips-and-falls-advancing-your-safety-program).

2. Being Struck By Or Caught In Moving Machinery

Accidents can happen to anyone working with heavy machinery although they are more common in factories, with farm equipment, and construction equipment. Machinery that’s not properly guarded is a safety hazard. When body parts get caught in or struck by exposed moving parts or flying objects from machines without protective guards, the results are oftentimes disastrous. The long and horrifying list of machinery-related injuries includes crushed hands and arms, severed fingers, blindness, and even worse.

The best way to prevent mechanical hazards is to remember that any machine part, function, or process that may cause injury MUST be safeguarded, and proper operator training, as well as protective clothing, must always be provided.

3. Vehicle-Related Accidents

Where there are vehicles of any kind, there’s the potential for accidents. These include being struck or run over by a moving vehicle, falling from a vehicle, being struck by objects falling from a vehicle, and getting crushed by or stuck under an overturned vehicle.

Avoiding these types of accidents begins with assessing who’s at risk, as well as where and when these accidents most commonly occur. Only then are prevention measures more easily established. Focus on workplace design, ensuring all layout routes always segregate pedestrians and vehicles and make any obstructions clearly visible. Directions, speed limit,s and priority signs are also helpful.

4. Fire And Explosions

Explosions and fires in the workplace are frequently caused by risk factors such as faulty gas lines, improperly stored combustible materials or open flames. The resulting injuries incurred include damage to the respiratory system, varying degrees of burns, and even potential disfigurement. Explosions and fires account for 3 percent of workplace injuries and have the highest casualty rate of all probable workplace accidents.

There are 4 types of injuries commonly associated with this type of accident:

Primary Blast: These occur due to the effects of pressure on body tissues, affecting the ears, lungs, and GI tract.

Secondary Blast: This occurs when flying objects strike nearby workers.

Tertiary Blast: High-energy explosions can lift someone off the ground.

Quaternary Blast: Everything else that happens as a result of an explosion, such as crush injuries, burns, and inhalation of toxic substances.

OSHA recommends following its hazard communication standards to help workers avoid these types of injuries. In addition, material safety data sheets for all chemicals should be kept on hand and employees should be required to wear personal protective equipment at all times.

5. Repetitive Stress and Overexertion Injuries

Musculoskeletal disorders are the most costly workplace injuries. Complaints of back pain alone cost employers more than 7 billion dollars annually and lead to more than 100 million lost workdays annually. These kinds of injuries contribute to loss of productivity and millions in annual health benefit payout costs.

The financial impact on the employer is one thing, but the long-term effects on workers can be severe and potentially debilitating and they account for nearly 33 percent of occupational injuries.

Repetitive Stress Injuries (RSIs) are the fasting growing category of workplace injury and comprise more than 100 different types of job-induced injuries, and they’re severe enough to inhibit simple activities with crippling and debilitating pain. They could even eventually permanently impair a worker’s ability to perform his or her job.

Causes for these types of injuries include:

Improper Lifting or Manually Lifting Heavy Objects: You’ve heard it a million times, lift with your knees, not your back. Especially objects weighing over 50lbs without the assistance of a co-worker or lifting device.

No Breaks: With repetitive work, short breaks should be required or the work may eventually result in wear and tear on the body.

Intensive Keying: Constant typing and clicking strain muscles and tendons.

The key to preventing these injuries is ergonomics! Ergonomics is the science of adjusting the job to fit the body’s needs and provides injury prevention solutions that are simple and relatively inexpensive. Workers assigned to tasks that require repetitive motion should be required to take frequent breaks to rest or stretch, and manual or mechanical lifting equipment should be provided for anything weighing over 50lbs.

The best way to protect your employees and help prevent injuries in your workplace is to take a holistic approach to workplace safety. This means ensuring your employees have the proper protective equipment, adequate training to perform their jobs, and making sure your facility is compliant with federal and environmental regulations.

Download the photo

More photos:

- What are the Best Practices for Managing Subcontractor Risk

- Photo of the day: 10 Essential Safety Tips for Driving in Hot Weather Conditions

- Photo of the day: best workplace safety tips

- Photo of the day: The Importance of Stop Work Authority in Maintaining Workplace Safety

- Photo of the day: Tomorrow’s Reward for Working Safely Today: Cultivating a Culture of Safety

- Photo of the day: Preventing slips and trips at work

- Photo of the day: Learn the DRSABCD action Plan

- Working with Electricity Electrical Accidents Guide for Electrical Workers

- Photo of the day: Hearing Protection Device Selection

- Photo of the day: If An Earthquake Shakes You-Infographic free

- Fire Safety Posters Free Download

- Photo of the day: First Aid for Electrical Burns-Infographic free

- Infographic: First Aid for Cuts and Scrapes free download

- Photo of The day: Work Safe with Lasers-Laser Safety free

- Photo of the day: Working Safely with chemicals and chemical Management

- Photo of the day: Safe work practices when using MEWPs ( updated)

- Photo of the day: Preventing Common Kitchen Hazards

- Photo of the day: Safe handling of Gas Cylinders and lecture bottles

- Photo of the day: Forklift Stability Triangle

- Photo of the day: Defective Tools Safe Work Practice

- Photo of the day: Lift With Your Legs Not With Your Back

- Photo of the day: First Aid for burns

- Photo of the day: The 7 Principles of HACCP

- Photo of the day: Working Safely with Suspended Loads

- Photo of the day: Heat Stroke First Aid and safety posters

- Photo of the day: Near-Miss Reporting and Posters

- Photo of the day: Ergonomic chair and office chair safety tips

- Photo of the day: Whole Body Vibration

- Photo of the day: Substation Safety Equipment

- Photo of the day: Bypassing Safety Controls Rules

- Photo of the day: Lightning Safety Tips

- Photo of the day: Overhead Power lines Clearance

- Photo of the day: Floor Marking

- Photo of the day: Types of Foot Protection

- Photo of the day: Types of Hand Protection

- Photo of the day: Lockout and Tagout Safety

- Photo of the day: Fall Protection Plans

- Photo of the day: Flood Safety Tips

- Photo of the day: Read All Labels Work safe

- Photo of the day: Run Project safely with Crane Hand Signals

- Photo of the day: Flagman and Traffic control

- Photo of the day: Managing Risks of Exposure to Solvents in the workplace

- Photo of the day: Scissor Lift Safety

- Photo of the day: HSE Bulletin Board

- Photo of the day: Arc-Fault Circuit Interrupters (AFCI)

- Photo of the day: Safe use of ladders and step ladders

- Photo of the day: Concrete Truck Driver Hand Signals

- Photo of the day: Extension Cord Safety Tips

- Photo of the day: Protect your Head

- Photo of the day: choosing the right Anchorage

- Photo of the day: Work-Related Asthma

- Photo of the day: Top FIVE Heavy Equipment Construction Site Safety Tips

- Photo of the day: sun safety in the workplace

- Photo of the day: Cannabis and Impairment in the Workplace

- Photo of the day: Position for safety and comfort-Safety Tips

- Photo of the day: Generator Safety

- Photo of the day: Controlling COVID-19 in the Workplace-Physical Barriers

- Photo of the day: Manual Material handling

- Photo of the day: Personal Protective Equipment last resort

- Photo of the day: WHMIS 2015 – Pictograms

- Photo of the day: Indoor Air Quality

- Photo of the day: Noise in the affected workplace

- Photo of the day: Fatigue at Work

- Photo of the day: Don’t be Driven to Distraction

- Photo of the day: working in heat and Humidex Rating

- How to use Plate Clamps Safely: Safety Moment#34

- Photo of the day: Sitting at work

- Photo of the day: 5 ways to reduce the risk of Slipping and Tripping

- Photo of the day: Preventing the spread of contagious illness

- Photo of the day: Incident Investigations

- Photo of the day: 10 Scaffold Safety Essentials

- Photo of the day: Effective Health and Safety Committees

- Photo of the day: New worker Orientation & Safety Orientation checklist

- Photo of the day: Workplace Inspection

- Photo of the day: musculoskeletal disorders

- Photo of the day: Emergency preparedness in the workplace

- Photo of the day: Mental health in the workplace

- Photo of the day: Trenching Safety Tips That Can Save a Life

- Photo of the day: Dangerous Goods Classes

- Photo of the day: Safety Equipment for Confined Spaces

- Photo of the day: Tips to reduce Heat stress in the workplace

- Photo of the day: hierarchy of controls

- Your steps to chemical safety

- H2S Gas and how to handle its Emergency

- Photo of the day: Importance of Mock drill and Fire Action Emergency Procedure

- Photo of the day: Choosing the Right Face Mask and the difference between a respirator and face mask

- Photo of the day: Confined space safety Precautions

- Breath Safely: The Proper Use of Respiratory Protection

- Photo of the day: Electric shock survival

- Photo of the day: Chemical Spill Emergency Response

- Photo of the day: Construction Site fire Safety

- Photo of the day: Confined Space rescue

- Photo of the day: Conveyors Safety Tips