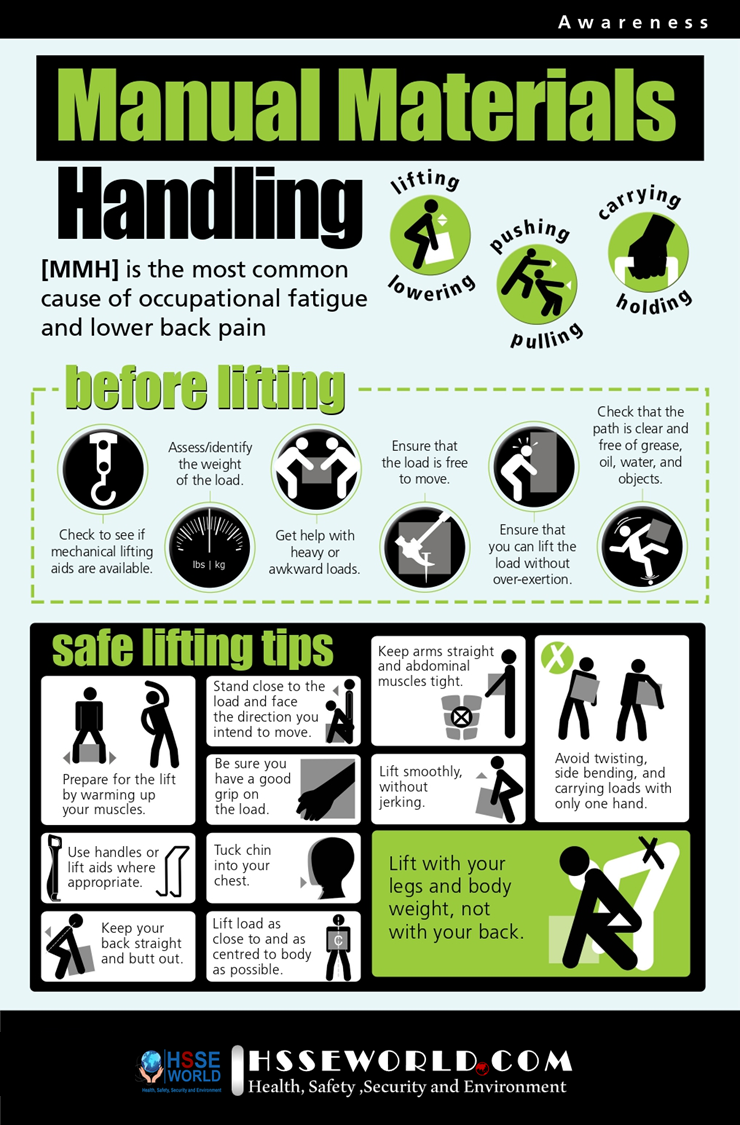

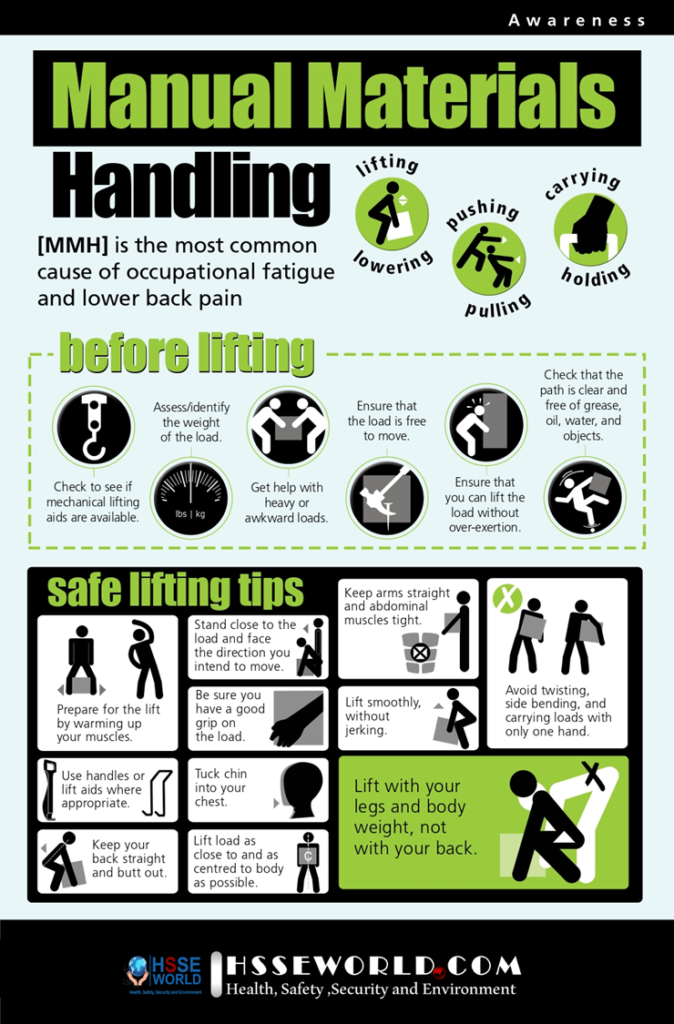

Manual material handling (MMH) is the most common cause of occupational fatigue and lower back pain. MMH includes any tasks that require a person to lift, lower, push, pull, hold or carry any object or material.

Manual materials handling (MMH) involves lifting, lowering, carrying, pushing, pulling or holding, and is the most common cause of occupational fatigue and low back pain.

About three of every four whose job includes MMH suffer pain due to back injury at some time. Each year several thousand workers are permanently disabled by back injuries, while many others are unable to return to their former jobs.

In the photo of the day and display this poster filled with practical tips to help remind workers of how to lift and handle materials properly and safely in the workplace.

What is manual materials handling?

Manual materials handling (MMH) means moving or handling things by lifting, lowering, pushing, pulling, carrying, holding, or restraining. MMH is also the most common cause of occupational fatigue, low back pain, and lower back injuries.

What makes manual materials handling hazardous?

MMH is always hazardous but the level of hazard depends on what you are handling, what the task is, and what the conditions are at the workplace or work site.

For example, the material or load that you are handling may be:

- Too heavy for the task that you are doing.

- Located too high or low for a safe lift.

- Too big or may have a shape that makes it hard to handle.

- Wet, slippery, or have sharp edges that make it hard to grasp.

- Unstable or can shift its center of gravity because it contains material that can flow (e.g., water, sand, a partially filled drum, or concrete in a wheelbarrow, or many objects within a container that are unbalanced or can shift).

- Too big to let you see where you are putting your feet.

The task can make MMH hazardous if a worker:

- Uses poor lifting techniques (lifting too fast, too often, or too long; lifting with back bent or while twisting or reaching too far; lifting while sitting or kneeling, etc.).

- Has to move material over long distances.

- Lifts or handles more than they can control safely.

- Do not take appropriate rest breaks; insufficient recovery time.

- Has a combination of handling tasks (e.g. lifting, carrying, and lowering).

- Wears clothing that restricts movement or reduces grip strength.

The conditions where you are working can also contribute to hazards of MMH and result in injuries, for example:

- Walking surfaces that are uneven, sloping, wet, icy, slippery, unsteady, etc.

- Differences in floor levels or walking surfaces.

- Poor housekeeping causes a slip, trip, and fall hazards.

- Inadequate lighting.

- Cold or very hot and humid working conditions.

- Strong wind or gusty conditions.

- Working at a high pace.

- Movement is restricted because of clothing or personal protective equipment.

- Space is small or posture is constrained or both.

As an employer, you must:

- Ensure that materials, machines, or equipment are stored and located so they do not create a hazard to an employee.

- Provide the necessary equipment to the employee for lifting and moving an object or material, and ensure the equipment is used by the employee.

- Instruct employees on the appropriate method of lifting and moving objects and materials, including how to use the equipment provided.

Handling Heavy Objects

Handling and moving heavy objects requires special precautions. As the employer, you must ensure employees handling heavy objects:

- Have and use chocks and ropes or other tackle to control the motion of the object.

- Have and use bars or sledges to change the direction of moving rollers.

- Do not stand on the downward side of an incline when moving heavy objects.

Key steps in preventing injuries from manual material handling include:

- Identifying high-risk manual handling tasks that involve heavy physical exertion, have a high score on the discomfort survey or have resulted in a musculoskeletal injury in the past.

- Assessing the tasks using the checklist. Consider the following risk factors:

- Forceful exertion (weight of objects, pushing/pulling force, carrying distance)

- Awkward posture (angle of body joints, workstation dimensions, working height)

- Repetitive motion (number of repetitions, duration, production rate)

- Identifying solutions to reduce or eliminate the risk factors.

- Regularly evaluating the tasks being performed, including investigating reported incidents due to manual handling and following up on employee concerns.

Consider solutions such as:

- Changing the design of the job itself (work and rest schedules, job rotation, production rate).

- The object being handled (weight, size, shape, handle).

- The workstation (dimensions, layout, adjustability).

- Providing mechanical aid.

- Lifting, using employee teams.

- Employee education, such as:

- Understanding the principles of body mechanics

- Recognizing high-risk tasks

- Reporting symptoms and incidents early so that necessary action can be taken

- Performing warm-up stretches and exercises

Anyone solution may not eliminate all the risks of injury. Choose the solution that best applies to your situation and use it as a starting point to improve your work environment.

While the employer is ultimately responsible for all the provisions mentioned above, the supervisor has a vital role to play in the safety of their teams. As a supervisor, you must:

- Acquaint your employees with the hazards and control measures associated with their work

- Provide the information and instruction necessary to ensure their health and safety

- Enforce company safety rules, programs, codes of practice, and procedures.

(Tool box Talk about Manual-handling-of-loads-at-work/)

Safety Tips

Check out these safe lifting and handling tips

Think before you lift

Plan the lift. Where is the load going to be placed? Will help be needed with the load? Is there equipment you could use, such as a hoist, that could help with the lift?

Remove obstructions, such as discarded wrapping materials. For long lifts, such as from floor to shoulder height, consider resting the load midway on a table or bench to change your grip on it.

Keep the load close to the waist

Keep the load close to the waist for as long as possible while lifting to reduce the amount of pressure on the back.

Keep the heaviest side of the load next to the body. If closely approaching the load is not possible, try to slide it towards the body before trying to lift it.

Adopt a stable position

Your feet should be apart with 1 leg slightly forward to maintain balance (alongside the load, if it’s on the ground).

Be prepared to move your feet during the lift to maintain a stable posture. Wearing over-tight clothing or unsuitable footwear, such as high heels or flip flops, may make this difficult.

Ensure a good hold on the load

Where possible, hug the load close to the body. This should help you make a stronger and more solid lift than gripping the load tightly with the hands only.

Do not bend your back when lifting

A slight bending of the back, hips, and knees at the start of the lift is preferable to either fully flexing the back (stooping) or fully flexing the hips and knees – in other words, fully squatting.

Do not bend the back any further while lifting

This can happen if the legs begin to straighten before starting to raise the load.

Do not twist when you lift

Avoid twisting the back or leaning sideways, especially while the back is bent.

Keep your shoulders level and facing in the same direction as the hips. Turning by moving your feet is better than twisting and lifting at the same time.

Look ahead

Keep your head up when handling the load. Look ahead, not down at the load, once it has been held securely.

Move smoothly

Do not jerk or snatch the load as this can make it harder to keep control and increases the risk of injury.

Know your limits

Do not lift or handle more than you can easily manage. There’s a difference between what people can lift and what they can safely lift. If you’re in doubt, seek advice or get help.

Lower down, then adjust

Put the load down and then adjust. If you need to position the load precisely, put it down first, then slide it into the desired position.

( Learn more: Material-handling-hazards-and-controls/)

Download Infographic

Manual Material handling

More Photos

- What are the Best Practices for Managing Subcontractor Risk

- Photo of the day: 10 Essential Safety Tips for Driving in Hot Weather Conditions

- Photo of the day: best workplace safety tips

- Photo of the day: The Importance of Stop Work Authority in Maintaining Workplace Safety

- Photo of the day: Tomorrow’s Reward for Working Safely Today: Cultivating a Culture of Safety

- Photo of the day: Preventing slips and trips at work

- Photo of the day: Learn the DRSABCD action Plan

- Working with Electricity Electrical Accidents Guide for Electrical Workers

- Photo of the day: Hearing Protection Device Selection

- Photo of the day: If An Earthquake Shakes You-Infographic free

- Fire Safety Posters Free Download

- Photo of the day: First Aid for Electrical Burns-Infographic free

- Infographic: First Aid for Cuts and Scrapes free download

- Photo of The day: Work Safe with Lasers-Laser Safety free

- Photo of the day: Working Safely with chemicals and chemical Management

- Photo of the day: Safe work practices when using MEWPs ( updated)

- Photo of the day: Preventing Common Kitchen Hazards

- Photo of the day: Safe handling of Gas Cylinders and lecture bottles

- Photo of the day: Forklift Stability Triangle

- Photo of the day: Defective Tools Safe Work Practice

- Photo of the day: Lift With Your Legs Not With Your Back

- Photo of the day: First Aid for burns

- Photo of the day: The 7 Principles of HACCP

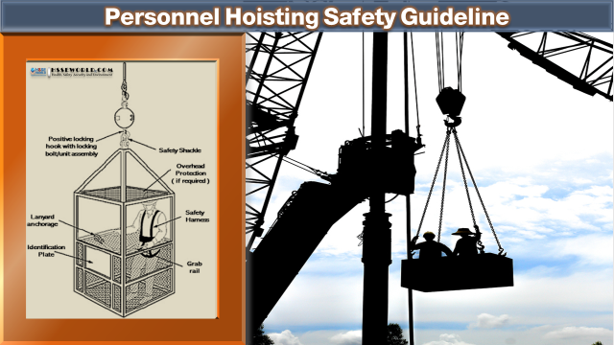

- Photo of the day: Working Safely with Suspended Loads

- Photo of the day: Heat Stroke First Aid and safety posters

- Photo of the day: Near-Miss Reporting and Posters

- Photo of the day: Ergonomic chair and office chair safety tips

- Photo of the day: Whole Body Vibration

- Photo of the day: Substation Safety Equipment

- Photo of the day: Bypassing Safety Controls Rules

- Photo of the day: Lightning Safety Tips

- Photo of the day: Overhead Power lines Clearance

- Photo of the day: Floor Marking

- Photo of the day: Types of Foot Protection

- Photo of the day: Types of Hand Protection

- Photo of the day: Lockout and Tagout Safety

- Photo of the day: Fall Protection Plans

- Photo of the day: Flood Safety Tips

- Photo of the day: Read All Labels Work safe

- Photo of the day: Run Project safely with Crane Hand Signals

- Photo of the day: Flagman and Traffic control

- Photo of the day: Managing Risks of Exposure to Solvents in the workplace

- Photo of the day: Scissor Lift Safety

- Photo of the day: HSE Bulletin Board

- Photo of the day: Arc-Fault Circuit Interrupters (AFCI)

- Photo of the day: Safe use of ladders and step ladders

- Photo of the day: Concrete Truck Driver Hand Signals

- Photo of the day: Extension Cord Safety Tips

- Photo of the day: Protect your Head

- Photo of the day: choosing the right Anchorage

- Photo of the day: Work-Related Asthma

- Photo of the day: Top FIVE Heavy Equipment Construction Site Safety Tips

- Photo of the day: sun safety in the workplace

- Photo of the day: Cannabis and Impairment in the Workplace

- Photo of the day: Position for safety and comfort-Safety Tips

- Photo of the day: Generator Safety

- Photo of the day: Controlling COVID-19 in the Workplace-Physical Barriers

- Photo of the day: Manual Material handling

- Photo of the day: Personal Protective Equipment last resort

- Photo of the day: WHMIS 2015 – Pictograms

- Photo of the day: Indoor Air Quality

- Photo of the day: Noise in the affected workplace

- Photo of the day: Fatigue at Work

- Photo of the day: Don’t be Driven to Distraction

- Photo of the day: working in heat and Humidex Rating

- How to use Plate Clamps Safely: Safety Moment#34

- Photo of the day: Sitting at work

- Photo of the day: 5 ways to reduce the risk of Slipping and Tripping

- Photo of the day: Preventing the spread of contagious illness

- Photo of the day: Incident Investigations

- Photo of the day: 10 Scaffold Safety Essentials

- Photo of the day: Effective Health and Safety Committees

- Photo of the day: New worker Orientation & Safety Orientation checklist

- Photo of the day: Workplace Inspection

- Photo of the day: musculoskeletal disorders

- Photo of the day: Emergency preparedness in the workplace

- Photo of the day: Mental health in the workplace

- Photo of the day: Trenching Safety Tips That Can Save a Life

- Photo of the day: Dangerous Goods Classes

- Photo of the day: Safety Equipment for Confined Spaces

- Photo of the day: Tips to reduce Heat stress in the workplace

- Photo of the day: hierarchy of controls

- Your steps to chemical safety

- H2S Gas and how to handle its Emergency

- Photo of the day: Importance of Mock drill and Fire Action Emergency Procedure

- Photo of the day: Choosing the Right Face Mask and the difference between a respirator and face mask

- Photo of the day: Confined space safety Precautions

- Breath Safely: The Proper Use of Respiratory Protection

- Photo of the day: Electric shock survival

- Photo of the day: Chemical Spill Emergency Response

- Photo of the day: Construction Site fire Safety