Mobile elevating work platforms (MEWPs) are useful but complex pieces of equipment that are often used for access in hazardous areas. People have been seriously injured and killed in accidents involving MEWPs.

The causes of these accidents have included:

- equipment failure

- not following the manufacturer’s recommendations

- inadequate training and supervision

- not fully assessing the hazards and risks of the job, site, and equipment.

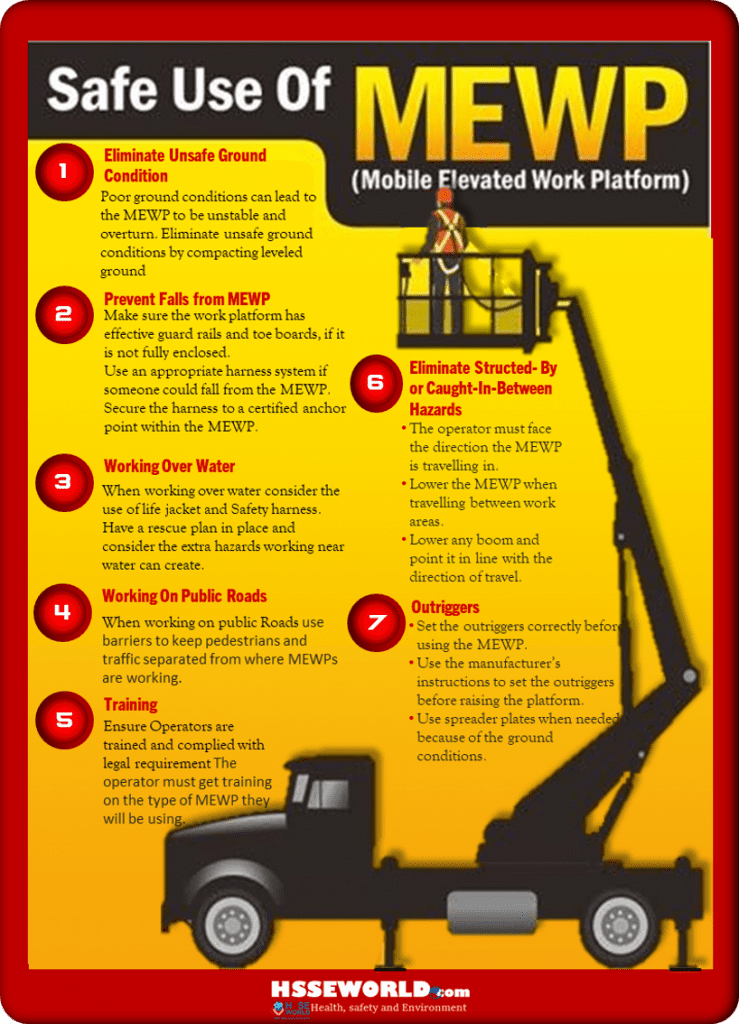

The photo of today outlines the safe work practices on how to use and maintain MEWPs safely

Also Watch: Video: Aerial Work Platform Safety: Safety Moment#35

identifying hazards and putting control measures in place makes using MEWPs in the workplace safer.

Duty holders must choose the best MEWP for the task, given the type of work and the work environment. The work needs to be properly planned and hazards managed at the worksite.

Operators must be trained and competent before using the MEWP and must follow the manufacturer’s operating instructions. Operators must also use safe working practices and use the MEWP within its limits.

MEWPs can seriously injure people in the following ways:

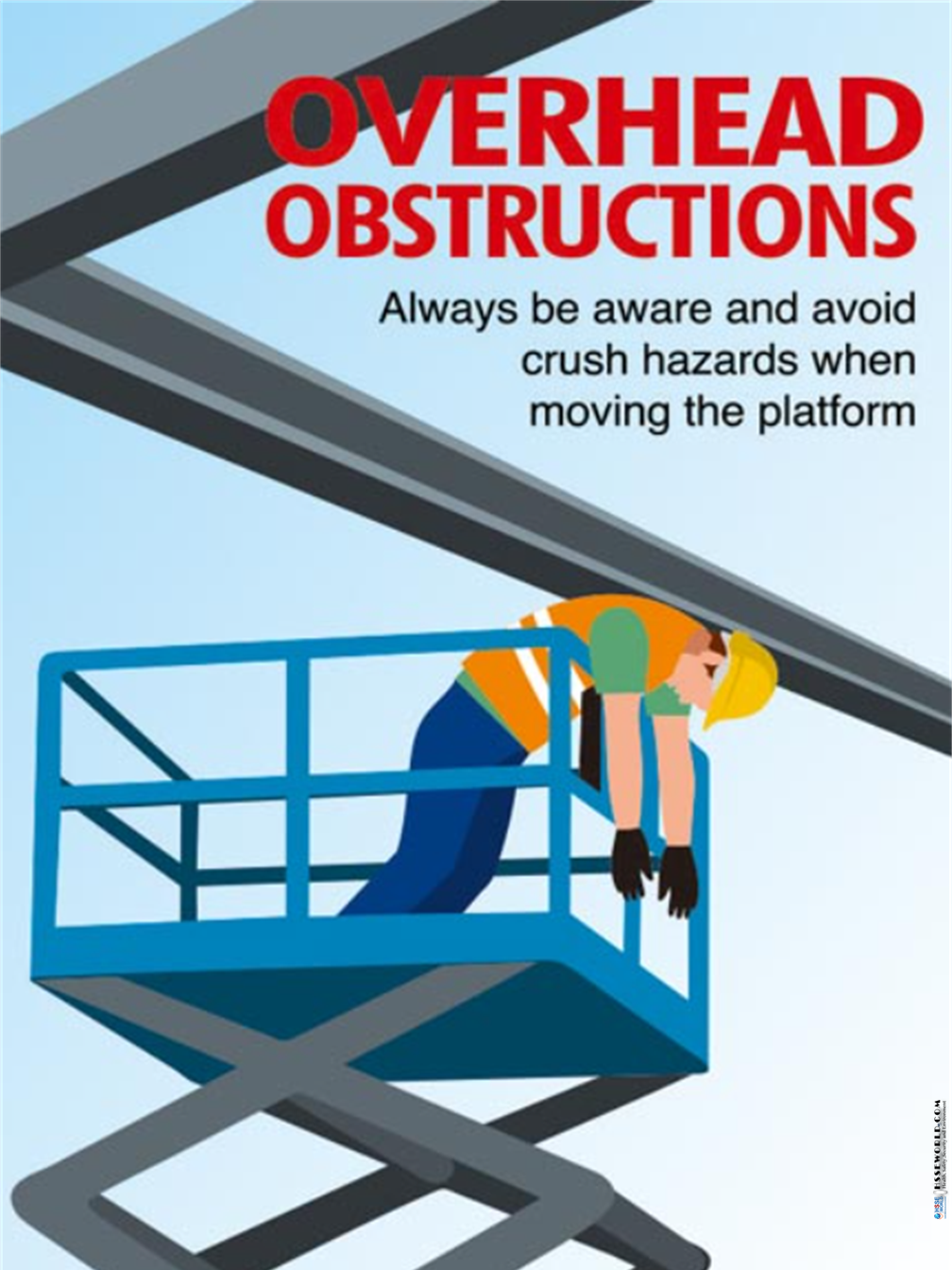

Entrapment – An operator can get trapped between the work platform and a fixed structure, such as when moving in tight overhead areas of steelwork. Operators can be trapped against the platform controls and, if this happens, they may not be able to stop the MEWP.

Overturning – On an uneven surface, the MEWP can overturn throwing the operator from the work platform.

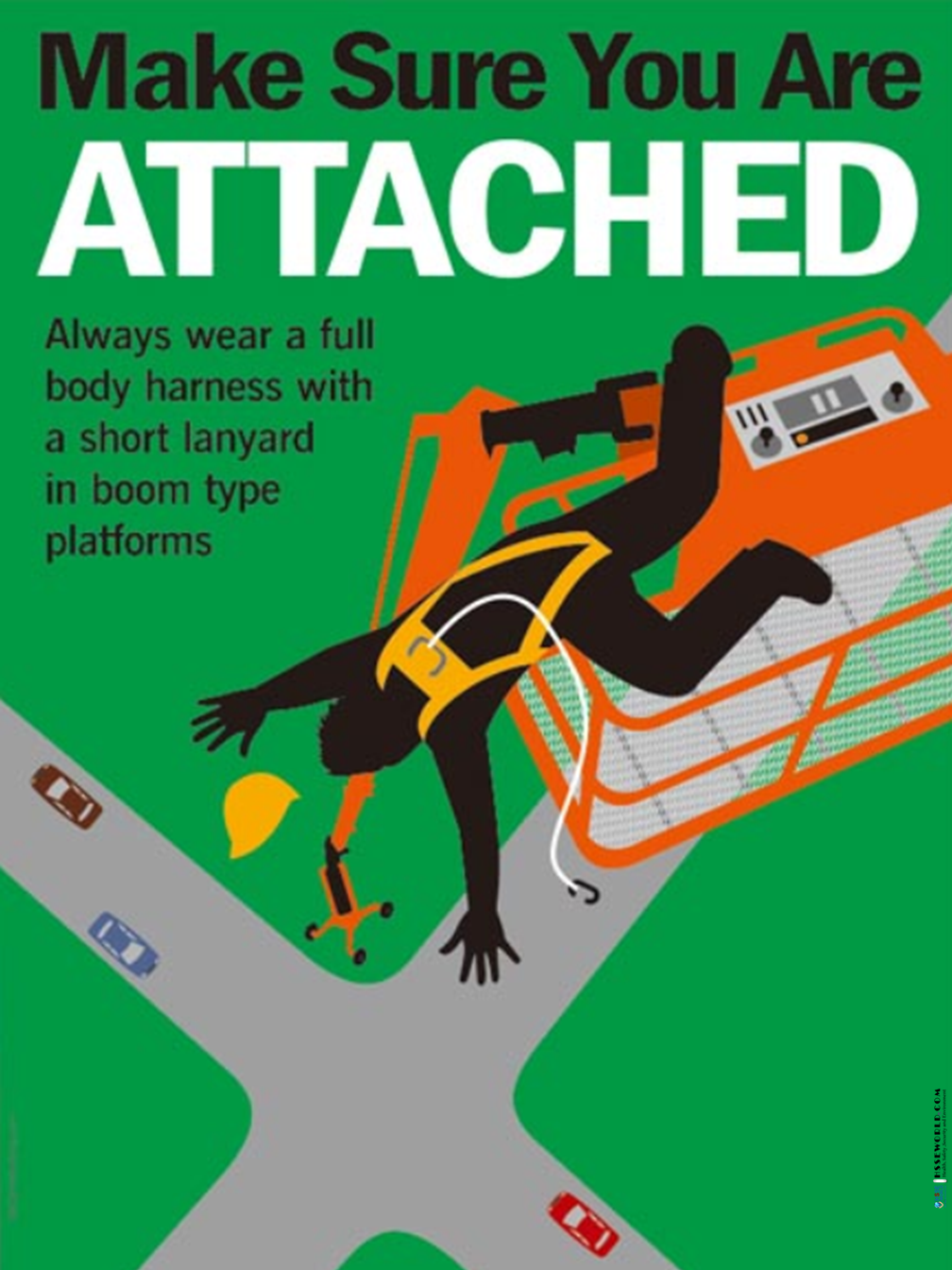

Falling – An operator can fall from the platform while working. They can even be catapulted out if, for example, the wheels go into a sinkhole.

Collision – The MEWP may hit pedestrians, or nearby vehicles or touch overhead power lines.

Also Read: Guide for Control Zones for Flat Roofing (Warning Line Systems)(Opens in a new browser tab)

Hazard management

Planning a safe way to do a job can help identify the hazards of any work using a MEWP. Planning safe work includes the hazard management process, which is:

- Identify the hazards.

- Assess the hazards – decide if the identified hazards are significant. Would they cause serious harm?

- Control the hazards – eliminate, isolate or minimize the hazard. This includes selecting the right MEWP for the task and workplace.

- Maintain the work plan or other safety documentation.

- Monitor the hazards and keep the work plan or task analysis updated

Identify hazards

Identify and assess all hazards for every job, site, or task.

These are some ways to identify hazards while working with a MEWP:

- Physical inspections – walk around the workplace using a checklist to identify and manage hazards.

- Task analysis – look at each task and identify the hazards involved.

- Process analysis – identify hazards at each stage of the project or piece of work.

- Review accident and incident investigations – identify hazards and see what caused any accidents using investigations of accidents on similar equipment or work.

See risk-assessment-a-practical-guide-to-assessing-operational-risks/).

Assess the hazard

Decide if the identified hazards are significant. How likely is it that someone could be harmed and, if they are harmed, how seriously could they be hurt? If someone could be seriously harmed, then it’s a significant hazard. All significant hazards need to be controlled to stop anyone from being seriously hurt. While significant hazards are a top priority, all hazards should have effective controls.

Hazard controls

First, try and eliminate the hazard but if that’s not possible, then isolate it, and as a last resort try to reduce the harm that could be caused by a hazard, by minimizing it. A combination of controls may need to be used.

Develop ways to control the hazards that use ‘group controls’ (such as edge protection) that protect more than one worker from a hazard. Group controls are better than ‘individual controls’, which protect only one person (such as a fall restraint).

In this section, some of the main hazards of using MEWPs are covered along with recommended control measures. MEWPs that comply with AS/NZS 1418.10 will have the safety features listed below.

CONFINED OVERHEAD WORKING

Operators should:

- be briefed on the risks of working in and around structures where they could be trapped or pinned between the platform and the structure

- be aware of their working environment at all times

- wear hard hats with a chin strap.

GROUND CONDITIONS

- Use the MEWP on firm and level ground where possible. Make sure the MEWP is rated for any slopes it may face. Problems – like trenches, manholes, and soft ground conditions, – can cause a MEWP to overturn.

- Do not use a MEWP on a slope beyond the limits of the inclinometer or manufacturer’s specifications.

- Make sure any temporary covers used to block holes are strong enough to take the whole weight of the MEWP, including the maximum rated capacity – that is the weight of the MEWP fully loaded with people, tools, and equipment.

- Be careful when reaching out from the platform, going too far can affect stability, especially when working on slopes.

OUTRIGGERS

- Set the outriggers correctly before using the MEWP.

- Use the manufacturer’s instructions to set the outriggers before raising the platform.

- Use spreader plates when needed because of the ground conditions. They should be made of a material that gives a good grip to both the spreader foot and the ground.

- When setting up a MEWP on-ramp using outriggers, extreme caution is required to prevent slipping down the ramp. Do not set up the outriggers’ footplates on a slope.

PREVENTING FALLS

- Make sure the work platform has effective guard rails and toe boards if it is not fully enclosed.

- Use an appropriate harness system if someone could fall from the MEWP. Secure the harness to a certified anchor point within the MEWP.

Also Read: Slips, Trips, and Falls Prevention

FALLING OBJECTS

- Isolate the area around the MEWP so that falling tools or objects do not strike people below.

- Anyone working nearby should wear a hard hat.

WEATHER

- Poor weather can make affect a platform’s stability and make it unsafe to use.

- Only use a MEWP within the manufacturer’s specified wind rating. The wind rating should be on the manufacturer’s serial plate.

- Bad weather and storms can also damage a MEWP. After severe weather, inspect the MEWP before using it again.

- Do not park or store the MEWP with the platform elevated.

HANDLING MATERIALS

- If the MEWP is being used to install materials, check the weight, dimensions, and distribution of the materials so it does not exceed the rated capacity of the MEWP.

- Do not use handrails to support loads.

- Make sure workers can handle any materials safely.

- Use extra lifting equipment to move materials to the work position, if needed.

WORKING NEAR OR OVER WATER

- When working over or near water, assess the hazards and risks to decide what personal protective equipment should be worn and what control measures should be in place. Personal protective equipment includes life jackets and harness systems.

- Have a rescue plan in place and take into account the extra hazards working near water can create.

NEARBY HAZARDS

- Check the area for nearby hazards, such as overhead power lines, traffic, or dangerous machinery.

TRAVELLING BETWEEN WORK AREAS

- The operator must face the direction the MEWP is traveling in.

- Lower the MEWP when traveling between work areas.

- Lower any boom and point it in line with the direction of travel.

WORKING NEAR OTHERS

- Use barriers to keep pedestrians and traffic separated from where MEWPs are working.

Electrical hazards

Any hazard assessment must identify:

- all overhead power lines near the workplace

- all trees, structures, and work positions that are within 4 meters of the power lines.

- trees can conduct electricity if they are too close to or touch live power lines. All safety plans must include these identified hazards and give details of how the hazards are controlled.

- treat all overhead power lines as being life, unless the power company that owns the power lines formally advises that the lines are safe.

Also Read: Working safely near overhead electric power lines

NO-GO ZONE – STAY 4 METRES AWAY FROM OVERHEAD POWER LINES

- Never work within 4 meters of any power line without first contacting the power company. Written consent is required from the power company before any work can be done within 4 meters of the power line. A copy of the consent must be on-site at all times.

EXCLUSION ZONE – 4 TO 6.4 METRES FROM POWER LINES

If any MEWP is likely to get closer than 6.4 meters to an overhead power line, make sure:

- operators, the MEWP including loads, attachments, tools, and equipment, and all work activity must stay at least 4 meters away from any overhead power lines. This is called the minimum approach distance (MAD)

- hazard controls are in place to make sure no one and nothing can enter the 4-meter no-go zone (MAD)

- the area between 6.4 and 4 meters from the overhead power line is separated from the workspace using cones or tape to show where the exclusion zone is

- the safety plan explains how the MEWP will be used so the operator can always see the power lines

- all operators of machines are briefed on limits to their movements and they must understand only specific operators can work in the exclusion zone (4–6.4 meters from a power line).

OPERATING WITHIN THE EXCLUSION ZONE

Anyone working in the exclusion zone must be competent to operate the specific type of MEWP used, be thoroughly briefed, and must understand the dangers of working near overhead power lines.

A competent safety observer must be present at all times to make sure everyone and everything (including the MEWP and tools) stay out of the 4-meter no-go zone (MAD).

The safety observer must be able to alert the MEWP operator immediately if they are about to enter the 4-meter no-go zone (MAD).

Operators working with MEWPs in the exclusion zone (4–6.4m) must obey any instructions given by the safety observer.

People working in the safety observer role must not do any other task at the same time. Operators must not use mobile phones or electronic equipment of any kind to avoid being distracted.

Operators must not wear clothing that could block their vision or movement in any way while working in the exclusion zone.

Everyone must treat power lines as live until the power company can formally advise that any line is safe.

Also Read: Photo of the day: Working Safely with Suspended Loads

EMERGENCY PROCEDURES

If a MEWP does touch overhead power lines, anyone in the MEWP should stay there and warn any others nearby to stay clear. If it is safe to do so, operate the controls to break contact.

If it is not safe to break contact:

- call for help, warning everyone to keep well clear of the machine

- stay put until the power company can de-energize the line and advise that it is safe to get off the MEWP.

If help is not immediately available, electrical contact cannot be broken and there is an urgent reason to get off the MEWP (such as a fire):

- switch off the motor and – where applicable – apply brakes > remove any loose clothing

- climb to a point on the MEWP where you can safely jump to the ground about 1 meter above the ground

- jump so that you are well clear of the platform before any part of you touches the ground

- fall away from the MEWP and not toward it

- do not touch the MEWP until the power company advises it is safe to do so.

Weather conditions and wind

All MEWPs (except those for indoor use) can work in wind, up to a maximum rating. The maximum wind rating must be clearly marked clearly either on the machine or the manufacturer’s serial plate. The MEWP must not be operated outside the maximum limits.

A traditional method of assessing wind speed is using the Beaufort wind scale. This scale relies on an operator looking at their environment to figure out wind speed. This can lead to the operator underestimating the wind speed and its hazards. Wind speed increases with height and may be 50% faster 20 meters above the ground.

An accurate way of measuring wind speed is by using an anemometer. This is a common tool used to assess weather conditions.

Building cladding, sheet materials, panels, and other such materials can act as sails and make a MEWP more likely to tip over, especially in gusty wind conditions. For the same reason, never attach signboards, banners, and the like to the platform, even if it is for a short time. Be aware that high buildings can funnel wind, which can cause high winds even when wind speed in open areas is low. This can even happen indoors in large warehouses, aircraft hangers, and high-rise buildings. Local wind speeds can be increased by things like aircraft slipstreams at airports and high-sided vehicles on motorways.

Snapshot of the infographic:

Download Infographic

Safe use of Mobile Elevated work platform ( MEWP)

More Photos

- What are the Best Practices for Managing Subcontractor Risk

- Photo of the day: 10 Essential Safety Tips for Driving in Hot Weather Conditions

- Photo of the day: best workplace safety tips

- Photo of the day: The Importance of Stop Work Authority in Maintaining Workplace Safety

- Photo of the day: Tomorrow’s Reward for Working Safely Today: Cultivating a Culture of Safety

- Photo of the day: Preventing slips and trips at work

- Photo of the day: Learn the DRSABCD action Plan

- Working with Electricity Electrical Accidents Guide for Electrical Workers

- Photo of the day: Hearing Protection Device Selection

- Photo of the day: If An Earthquake Shakes You-Infographic free

- Fire Safety Posters Free Download

- Photo of the day: First Aid for Electrical Burns-Infographic free

- Infographic: First Aid for Cuts and Scrapes free download

- Photo of The day: Work Safe with Lasers-Laser Safety free

- Photo of the day: Working Safely with chemicals and chemical Management

- Photo of the day: Safe work practices when using MEWPs ( updated)

- Photo of the day: Preventing Common Kitchen Hazards

- Photo of the day: Safe handling of Gas Cylinders and lecture bottles

- Photo of the day: Forklift Stability Triangle

- Photo of the day: Defective Tools Safe Work Practice

- Photo of the day: Lift With Your Legs Not With Your Back

- Photo of the day: First Aid for burns

- Photo of the day: The 7 Principles of HACCP

- Photo of the day: Working Safely with Suspended Loads

- Photo of the day: Heat Stroke First Aid and safety posters

- Photo of the day: Near-Miss Reporting and Posters

- Photo of the day: Ergonomic chair and office chair safety tips

- Photo of the day: Whole Body Vibration

- Photo of the day: Substation Safety Equipment

- Photo of the day: Bypassing Safety Controls Rules

- Photo of the day: Lightning Safety Tips

- Photo of the day: Overhead Power lines Clearance

- Photo of the day: Floor Marking

- Photo of the day: Types of Foot Protection

- Photo of the day: Types of Hand Protection

- Photo of the day: Lockout and Tagout Safety

- Photo of the day: Fall Protection Plans

- Photo of the day: Flood Safety Tips

- Photo of the day: Read All Labels Work safe

- Photo of the day: Run Project safely with Crane Hand Signals

- Photo of the day: Flagman and Traffic control

- Photo of the day: Managing Risks of Exposure to Solvents in the workplace

- Photo of the day: Scissor Lift Safety

- Photo of the day: HSE Bulletin Board

- Photo of the day: Arc-Fault Circuit Interrupters (AFCI)

- Photo of the day: Safe use of ladders and step ladders

- Photo of the day: Concrete Truck Driver Hand Signals

- Photo of the day: Extension Cord Safety Tips

- Photo of the day: Protect your Head

- Photo of the day: choosing the right Anchorage

- Photo of the day: Work-Related Asthma

- Photo of the day: Top FIVE Heavy Equipment Construction Site Safety Tips

- Photo of the day: sun safety in the workplace

- Photo of the day: Cannabis and Impairment in the Workplace

- Photo of the day: Position for safety and comfort-Safety Tips

- Photo of the day: Generator Safety

- Photo of the day: Controlling COVID-19 in the Workplace-Physical Barriers

- Photo of the day: Manual Material handling

- Photo of the day: Personal Protective Equipment last resort

- Photo of the day: WHMIS 2015 – Pictograms

- Photo of the day: Indoor Air Quality

- Photo of the day: Noise in the affected workplace

- Photo of the day: Fatigue at Work

- Photo of the day: Don’t be Driven to Distraction

- Photo of the day: working in heat and Humidex Rating

- How to use Plate Clamps Safely: Safety Moment#34

- Photo of the day: Sitting at work

- Photo of the day: 5 ways to reduce the risk of Slipping and Tripping

- Photo of the day: Preventing the spread of contagious illness

- Photo of the day: Incident Investigations

- Photo of the day: 10 Scaffold Safety Essentials

- Photo of the day: Effective Health and Safety Committees

- Photo of the day: New worker Orientation & Safety Orientation checklist

- Photo of the day: Workplace Inspection

- Photo of the day: musculoskeletal disorders

- Photo of the day: Emergency preparedness in the workplace

- Photo of the day: Mental health in the workplace

- Photo of the day: Trenching Safety Tips That Can Save a Life

- Photo of the day: Dangerous Goods Classes

- Photo of the day: Safety Equipment for Confined Spaces

- Photo of the day: Tips to reduce Heat stress in the workplace

- Photo of the day: hierarchy of controls

- Your steps to chemical safety

- H2S Gas and how to handle its Emergency

- Photo of the day: Importance of Mock drill and Fire Action Emergency Procedure

- Photo of the day: Choosing the Right Face Mask and the difference between a respirator and face mask

- Photo of the day: Confined space safety Precautions

- Breath Safely: The Proper Use of Respiratory Protection

- Photo of the day: Electric shock survival

- Photo of the day: Chemical Spill Emergency Response

- Photo of the day: Construction Site fire Safety