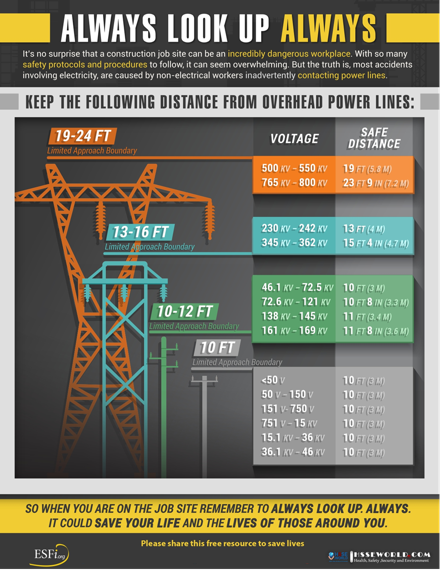

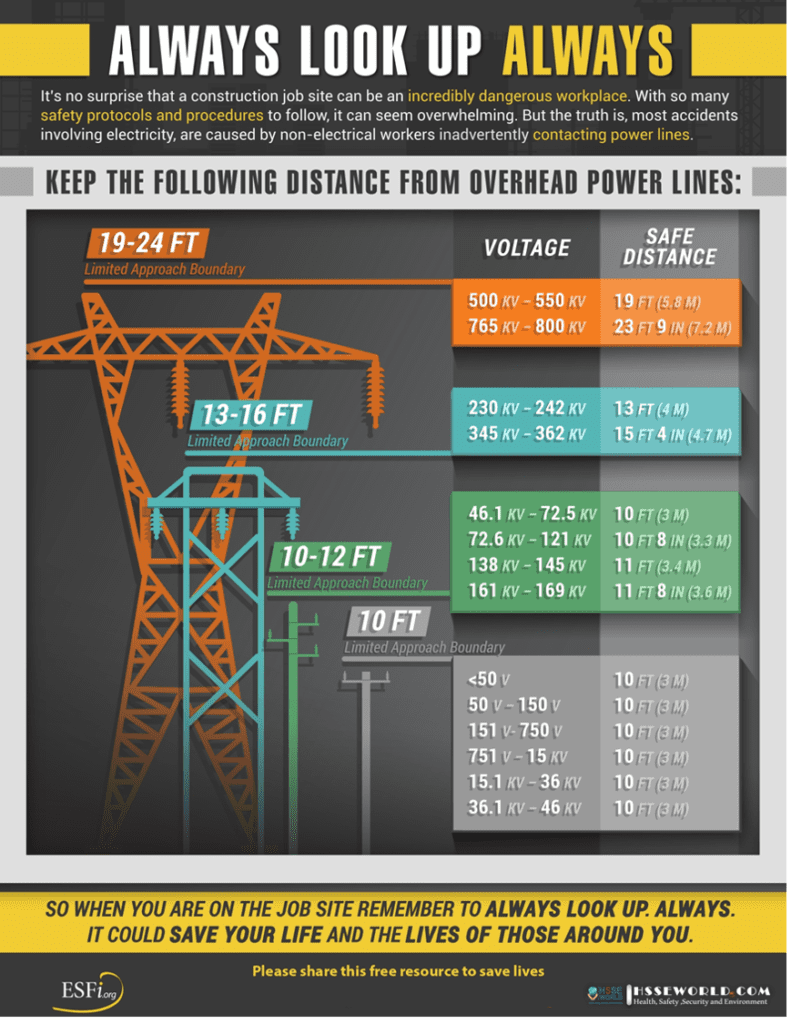

Overhead power lines cause 40% of all electrically related fatalities, in the workplace. A majority of these accidents occur with workers that have little to no electrical safety training. That’s why it’s important to always look up before doing any kind of work on a construction site. It could save your life.

If the equipment operator had raised the bed into the power line, both the line and the truck would be considered live and dangerous. If you see the equipment in contact with a power line, it’s not time to be a hero, you need to stay away and warn others to do the same.

You should stay at least 35 feet back. That’s about two dump truck lengths. If conditions are wet, you may need to move away even further.

The Photo of today outlines the clearance and safe distance from overhead Power lines So when you are on the job site remember to ALWAYS LOOKUP. ALWAYS. It could save your life and the lives of those around you.

Power Lines Safety

let’s have an example of the Assembly or disassembly of a crane near Overhead powerlines

Before assembly or disassembly of a crane, the employer must determine if it could come within 20 feet of a power line (up to 350 kV). If so, the employer must take one of the following actions:

- (a) Confirm with the power company that the line is de-energized and visibly grounded at the worksite.

- (b) Make sure no part gets within 20 feet of the power line.

- (c) Follow Table A, which has minimum clearance distances based on voltage.

Table A: Minimum Clearance Distances Based on Voltage

| Voltage | Limited Approach Boundary |

| < 50 V | 10 ft (3 m) |

| 50 V – 150 V | |

| 151 V – 750 V | |

| 751 V -15 kV | |

| 15.1 kV – 36 kV | |

| 36.1 kV – 46 kV | |

| 46.1 kV – 72.5 kV | 10 ft (3 m) |

| 72.6 kV – 121 kV | 10 ft 8 in (3.3 m) |

| 138 kV – 145 kV | 11 ft (3.4 m) |

| 161 kV – 169 kV | 11 ft 8 in (3.6 m) |

| 230 kV – 242 kV | 13 ft (4 m) |

| 345 kV – 362 kV | 15 ft 4 in (4.7 m) |

| 500 kV – 550 kV | 19 ft (5.8 m) |

| 765 kV – 800 kV | 23 ft 9 in (7.2 m) |

Learn more: High-Voltage Electrical Safety(Opens in a new browser tab)

Cranes cannot be assembled/disassembled below an energized power line or within the Table A clearances from a power line. If Table A is used, the owner/utility must provide the power line voltage to the employer within two days of a request.

Power lines must be assumed to be energized until they are confirmed to be de-energized and visibly grounded. Warnings about electrocution hazards must be posted conspicuously in the crane cab and outside the cab in view of the operator (except for overhead gantry and tower cranes).

The work zones must be demarcated 360 degrees around the equipment to prevent encroachments within 20 feet of a power line. If the line is not de-energized, a meeting must also be held with the crew before operations begin to review the location of the lines and procedures to prevent encroachment. Measures similar to those required during assembly/disassembly must be taken to prevent encroachment, but in this case, an insulating link between the load line and the load is also an option.

Operators and crew members must be trained:

- On the procedures to follow in the event of power line contact

- To presume that power lines are energized until confirmed and visibly grounded

- To presume that power lines are not insulated until otherwise confirmed by the owner or a qualified person

- On the limits of insulating links and other devices (e.g. proximity alarms)

- On proper grounding procedures and their limitations.

Spotters must also get applicable training.

What If the line is not De-Energized?

If the line is not de-energized, the employer must take the following actions:

- Conduct a meeting with the assembly/disassembly crew to review measures to prevent encroachment.

- Use only non-conductive tag lines.

- Use a dedicated spotter, a proximity alarm, a range control warning device, an automatic limit device, or an elevated warning line/barrier placed in view of the crane operator.

Exceptions to Table A? Follow these minimum Precaustions

If work must operate closer than the Table A values, then the following precautions must be taken at a minimum:

- The employer must show that Table A is infeasible and that it is infeasible to de-energize and ground or relocate the line.

- Safe distances must be determined by the owner/operator of the line or a registered professional engineer who is a qualified person.

- A planning meeting must be held and procedures developed must be implemented (if procedures are inadequate, work must be stopped and new procedures established or the line must be de-energized).

- Automatic re-energizing devices must be inoperative.

- A dedicated spotter must be assigned.

- An elevated warning line/barricade or an insulating link must be installed between the line and the load, except for work on electrical transmission/distribution lines covered by Subpart V (additional provisions take effect one to three years after the effective date).

- Non-conductive rigging must be used.

- A range-of-motion limiting device must be used.

- Non-conductive tag lines must be used.

- Barricades at least 10 feet from the equipment (where feasible) must be established.

- Equipment must be properly grounded.

- Workers must be kept from touching the line above the insulating link.

- Only essential personnel are allowed in the area.

- Insulating line hose or cover-up must be installed by the owner/operator unless unavailable.

- The owner and user must meet with the equipment operator and other workers to review procedures.

- One person must be identified who will implement the plan and can stop work if necessary.

- Documentation of these procedures must be immediately available on site.

- Safety devices and aids must comply with manufacturers’ specifications.

- All employees must be trained in power line safety per 1926.1408 (g).

Equipment Clearance Distances

Equipment traveling under or near a power line must:

(a) Have a lowered boom/mast and support system

(b) Obey minimum clearance distances set in Table T

(c) Reduce speeds to minimize breaching

(d) Use a dedicated spotter if closer than 20 feet

(e) Illuminate or identify the power lines at night

(f) Identify and use a safe path of travel.

Learn more: Working safely near overhead electric power lines

TABLE: T

Minimum clearance distances while traveling with no load

| Voltage (kV) | Minimum clearance distance (feet) |

| Up to 0.75 kV | 4 ft |

| >0.75 to 50 kV | 6 ft |

| >50 to 345 kV | 10 ft |

| >345 to 750 kV | 16 ft |

| >750 to 1,000 kV | 20 ft |

| > 1,000 kV | * |

| >1,000 | Determined by the utility/owner |

| *Established by the owner or registered professional engineer/qualified person. |

Download the photo

Now you can download the Infographic ” Overhead Power lines Clearance ” and post it at the workplace and communicate with everyone to be familiar with the safe Clearance during working under overhead power lines

Photo of the day: Overhead Powerline Clearance

More photos:

- What are the Best Practices for Managing Subcontractor Risk

- Photo of the day: 10 Essential Safety Tips for Driving in Hot Weather Conditions

- Photo of the day: best workplace safety tips

- Photo of the day: The Importance of Stop Work Authority in Maintaining Workplace Safety

- Photo of the day: Tomorrow’s Reward for Working Safely Today: Cultivating a Culture of Safety

- Photo of the day: Preventing slips and trips at work

- Photo of the day: Learn the DRSABCD action Plan

- Working with Electricity Electrical Accidents Guide for Electrical Workers

- Photo of the day: Hearing Protection Device Selection

- Photo of the day: If An Earthquake Shakes You-Infographic free

- Fire Safety Posters Free Download

- Photo of the day: First Aid for Electrical Burns-Infographic free

- Infographic: First Aid for Cuts and Scrapes free download

- Photo of The day: Work Safe with Lasers-Laser Safety free

- Photo of the day: Working Safely with chemicals and chemical Management

- Photo of the day: Safe work practices when using MEWPs ( updated)

- Photo of the day: Preventing Common Kitchen Hazards

- Photo of the day: Safe handling of Gas Cylinders and lecture bottles

- Photo of the day: Forklift Stability Triangle

- Photo of the day: Defective Tools Safe Work Practice

- Photo of the day: Lift With Your Legs Not With Your Back

- Photo of the day: First Aid for burns

- Photo of the day: The 7 Principles of HACCP

- Photo of the day: Working Safely with Suspended Loads

- Photo of the day: Heat Stroke First Aid and safety posters

- Photo of the day: Near-Miss Reporting and Posters

- Photo of the day: Ergonomic chair and office chair safety tips

- Photo of the day: Whole Body Vibration

- Photo of the day: Substation Safety Equipment

- Photo of the day: Bypassing Safety Controls Rules

- Photo of the day: Lightning Safety Tips

- Photo of the day: Overhead Power lines Clearance

- Photo of the day: Floor Marking

- Photo of the day: Types of Foot Protection

- Photo of the day: Types of Hand Protection

- Photo of the day: Lockout and Tagout Safety

- Photo of the day: Fall Protection Plans

- Photo of the day: Flood Safety Tips

- Photo of the day: Read All Labels Work safe

- Photo of the day: Run Project safely with Crane Hand Signals

- Photo of the day: Flagman and Traffic control

- Photo of the day: Managing Risks of Exposure to Solvents in the workplace

- Photo of the day: Scissor Lift Safety

- Photo of the day: HSE Bulletin Board

- Photo of the day: Arc-Fault Circuit Interrupters (AFCI)

- Photo of the day: Safe use of ladders and step ladders

- Photo of the day: Concrete Truck Driver Hand Signals

- Photo of the day: Extension Cord Safety Tips

- Photo of the day: Protect your Head

- Photo of the day: choosing the right Anchorage

- Photo of the day: Work-Related Asthma

- Photo of the day: Top FIVE Heavy Equipment Construction Site Safety Tips

- Photo of the day: sun safety in the workplace

- Photo of the day: Cannabis and Impairment in the Workplace

- Photo of the day: Position for safety and comfort-Safety Tips

- Photo of the day: Generator Safety

- Photo of the day: Controlling COVID-19 in the Workplace-Physical Barriers

- Photo of the day: Manual Material handling

- Photo of the day: Personal Protective Equipment last resort

- Photo of the day: WHMIS 2015 – Pictograms

- Photo of the day: Indoor Air Quality

- Photo of the day: Noise in the affected workplace

- Photo of the day: Fatigue at Work

- Photo of the day: Don’t be Driven to Distraction

- Photo of the day: working in heat and Humidex Rating

- How to use Plate Clamps Safely: Safety Moment#34

- Photo of the day: Sitting at work

- Photo of the day: 5 ways to reduce the risk of Slipping and Tripping

- Photo of the day: Preventing the spread of contagious illness

- Photo of the day: Incident Investigations

- Photo of the day: 10 Scaffold Safety Essentials

- Photo of the day: Effective Health and Safety Committees

- Photo of the day: New worker Orientation & Safety Orientation checklist

- Photo of the day: Workplace Inspection

- Photo of the day: musculoskeletal disorders

- Photo of the day: Emergency preparedness in the workplace

- Photo of the day: Mental health in the workplace

- Photo of the day: Trenching Safety Tips That Can Save a Life

- Photo of the day: Dangerous Goods Classes

- Photo of the day: Safety Equipment for Confined Spaces

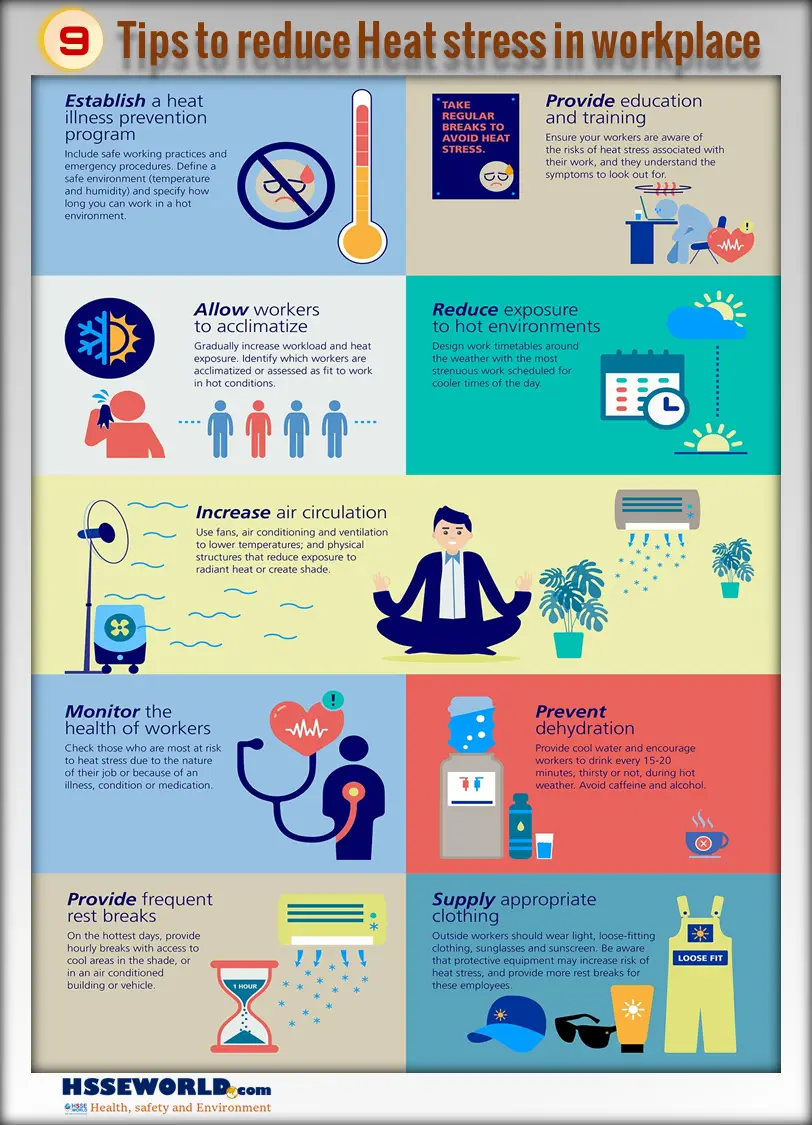

- Photo of the day: Tips to reduce Heat stress in the workplace

- Photo of the day: hierarchy of controls

- Your steps to chemical safety

- H2S Gas and how to handle its Emergency

- Photo of the day: Importance of Mock drill and Fire Action Emergency Procedure

- Photo of the day: Choosing the Right Face Mask and the difference between a respirator and face mask

- Photo of the day: Confined space safety Precautions

- Breath Safely: The Proper Use of Respiratory Protection

- Photo of the day: Electric shock survival

- Photo of the day: Chemical Spill Emergency Response

- Photo of the day: Construction Site fire Safety

- Photo of the day: Confined Space rescue

- Photo of the day: Conveyors Safety Tips