Employees must sometimes work in areas that have configurations that don’t allow for regular safety precautions. In these spaces, employees may be forced to work very close to hazards. Proper guarding may not exist to prevent falls and the air may be toxic or explosive. In addition, such an area may not have an easy way to exit should an emergency arise. These types of work areas are called confined spaces and learning how to safely work in these spaces is the purpose of this Article.

In the photo of today Follow these simple, common-sense rules and it’s extremely unlikely that your entry into a confined space will result in injury or death. But break them, and it’s only a matter of time before you get someone killed or injured. These general rules are the distilled wisdom of confined space operations, consolidated from many sources, and with the exception of the first rule, they are not in any particular order.

1. Monitor the atmosphere

Atmospheric monitoring is the first and most critical rule, as most fatalities in confined spaces are the result of atmospheric problems. Remember, your nose is not a gas detector — some hazards have characteristic odors and others do not. Even when you can detect the presence of a hazard, you cannot determine the extent of that hazard. Some materials may even deaden your sense of smell after short exposure, which can deceive you into thinking the problem has gone away, when in fact your ability to smell it is all that went away.

The only reliable method for accurate detection of atmospheric problems is instrument monitoring. Basic confined space atmospheric monitoring should routinely include oxygen concentration and flammable gases and vapors. OSHA regulations require the oxygen concentration to be between 19.5 and 23.5 percent and flammable vapors or gases to be below ten percent of the lower explosive limit (LEL).

But regulatory limits provide only minimal protection. Best practices dictate that any variation from normal (20.9 percent oxygen and 0 percent LEL) should be investigated and corrected prior to entering the space.

Toxic monitoring requires an evaluation of potential atmospheric contaminants before you even determine how the monitoring will be performed. Simply put, this means you must establish what you need to look for in order to determine what equipment to use. The following digital instruments are available for common toxic contaminants:

- Electrochemical sensors measure carbon monoxide, hydrogen sulfide, sulfur dioxide, ammonia, chlorine, and several other materials.

- Infrared sensors measure carbon dioxide and several other materials.

- Photoionization and flame ionization detectors will measure volatile organic compounds (VOCs) at the parts per million (ppm) level. This may be required if solvent vapors are present. These vapors will exceed the limits for inhalation long before they will be detected with most LEL meters.

- Colorimetric tubes can be used to determine if a toxic contaminant is present in situations where no digital instrument is available.

A thorough assessment of the atmospheric conditions in the space must be completed before entering the space and should be continued during the entire entry.

2. Eliminate or control hazards

All hazards identified during the hazard assessment must be eliminated or controlled prior to entering the space.

Elimination, the preferred method for dealing with hazards, means that a hazard has been handled in a way that cannot possibly have an impact on the operation. For example, a properly installed blank eliminates the hazard of material being introduced through a pipe.

Control implies that the measures in place contain a hazard. If these measures were to fail, the hazard could have an impact on the operation. Ventilation (see below) is an example of control, because if the ventilation setup quits, the atmospheric hazard may return.

3. Ventilate the space

Your approach to atmospheric problems should be to correct the condition prior to entry, and ventilation and related activities are the best options for correcting these problems.

Forced-air ventilation is generally the most effective approach for confined space entry operations. This technique dilutes and displaces the atmospheric contaminants in the space. Exhaust ventilation works best when a single-point source, such as welding, is the cause of the atmospheric contaminant.

Introduced air must be fresh. Use caution to avoid introducing hazards such as having the inlet of the ventilation setup too near the exhaust of a vehicle. Sufficient volume for the size of the space must be used. The length of the duct and the number of bends in the duct can significantly reduce airflow and must be considered.

(learn more:dangerous-gases-in-confined-spaces/)

4. Use proper personal protective equipment

Proper personal protective equipment (PPE) should be the last line of defense. Elimination and control of hazards should be done whenever possible. PPE is essential when the hazards present cannot be eliminated or controlled through other means. PPE that meets the specific hazard must be readily available to the work crew. And personnel must be trained and competent in the proper use of the equipment. It is equally important that supervisors insist on proper use.(Read more:combat-confined-space-hazards-with-the-right-PPE/)

5. Isolate the space

Isolation of the space should eliminate the opportunity for introducing additional hazards through external connections. This includes a lockout of all powered devices associated with space, such as electrical, pneumatic, hydraulic, and gaseous agent fire control systems. Piping isolation may be completed with blanks, by disconnecting piping, or with a double block-and-bleed arrangement. A single valve is not adequate isolation.

6. Know the attendant’s role

An outside attendant must be present to monitor the safety of the entry operation, to help during an emergency, and to call for assistance from outside if that becomes necessary. The attendant’s role is primarily to help ensure that problems do not escalate to the point where rescue is needed. If an entrant does get injured or overcome, the attendant is to call for help and use external retrieval if available. This attendant must never enter the space during emergencies — multiple fatality incidents in confined spaces usually result from people attempting a rescue.

7. Be prepared for rescues

Any equipment required for rescue must be available to those who are designated to use it. External retrieval equipment that may be used by the attendant must be in place when appropriate. More advanced rescue equipment for entry-type rescues must be available to the designated rescue crew.

You must ensure that the rescue crew is properly equipped to handle rescue for the particular situation. For example, if the rescue crew for your facility has self-contained breathing apparatus (SCBA) and your spaces do not have large enough openings for the SCBA to pass through, the rescue crew will not be able to perform effectively. In this case, they should be equipped with airline breathing apparatus with escape cylinders.

(learn more:confined-space-rescue/)

8. Use good lighting

Lighting is important for two primary reasons: You cannot safely perform in environments where you cannot see adequately, and lighting failure can cause fear. Anyone who is uncomfortable inside a well-lit confined space may become afraid of the lighting fails, and fear can cause people to behave irrationally and injure themselves or others.

The entrant should always have at least one backup source of lighting, so if cord lights are used, the entrant should also carry a flashlight.

9. Plan for emergencies

You must assume you will have emergencies. While your efforts to prevent them need to be constant, odds are good that you will have to deal with at least a minor emergency if you engage in confined space entry over a long enough period.

Emergencies may not even have anything to do with the confined space, but if the entrant is in the space at the time of the emergency, prompt and effective action is required. If your entry crew is prepared for this emergency, it may be handled without a problem. If preparations are not adequate, the emergency may easily turn into a fatal incident.

(learn more:confined-space-safety-program-needs/)

10. Emphasize constant communication

Effective communications are critical to safe operation and are the string that ties all the other activities together. Communication must be maintained between entrants and the attendant. The attendant must also be able to contact the entry supervisor and call for emergency help.

None of these steps is complex or difficult, but they still provide the layout for a basic, safe approach to confined space entry. Be aware that the next time you read about a confined space fatality, at least one of these general rules was probably violated. And do your best to ensure that I won’t ever read about one of your entries.

(learn more:confined-spaces-communication-tools/)

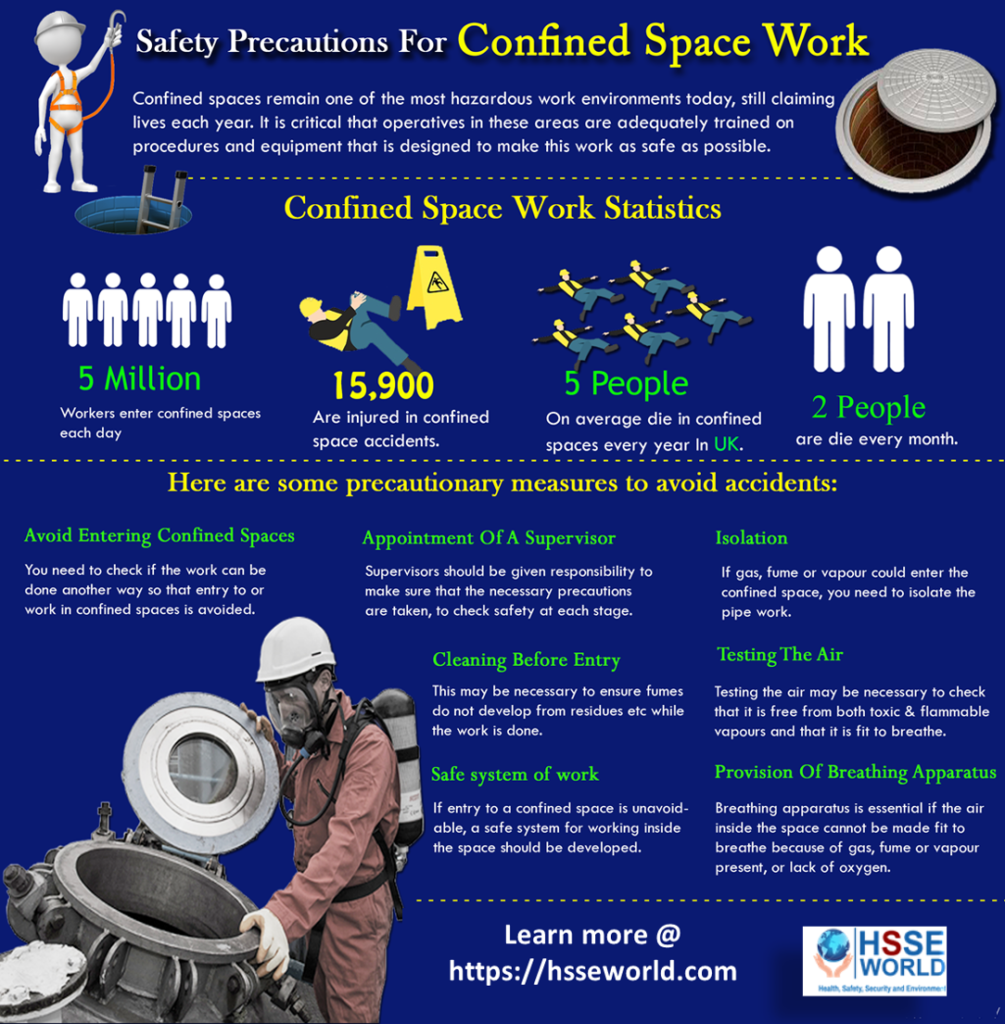

Download the Infographic

Photo of the day: Photo of the day: Confined Space Safety Precautions

More photos:

- What are the Best Practices for Managing Subcontractor Risk

- Photo of the day: 10 Essential Safety Tips for Driving in Hot Weather Conditions

- Photo of the day: best workplace safety tips

- Photo of the day: The Importance of Stop Work Authority in Maintaining Workplace Safety

- Photo of the day: Tomorrow’s Reward for Working Safely Today: Cultivating a Culture of Safety

- Photo of the day: Preventing slips and trips at work

- Photo of the day: Learn the DRSABCD action Plan

- Working with Electricity Electrical Accidents Guide for Electrical Workers

- Photo of the day: Hearing Protection Device Selection

- Photo of the day: If An Earthquake Shakes You-Infographic free

- Fire Safety Posters Free Download

- Photo of the day: First Aid for Electrical Burns-Infographic free

- Infographic: First Aid for Cuts and Scrapes free download

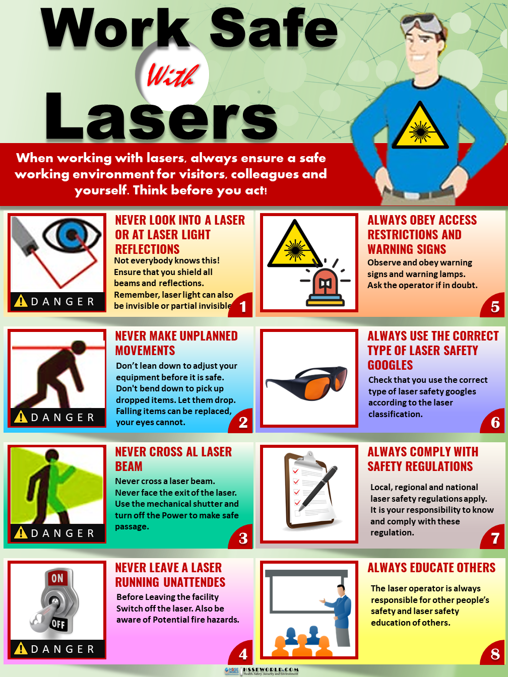

- Photo of The day: Work Safe with Lasers-Laser Safety free

- Photo of the day: Working Safely with chemicals and chemical Management

- Photo of the day: Safe work practices when using MEWPs ( updated)

- Photo of the day: Preventing Common Kitchen Hazards

- Photo of the day: Safe handling of Gas Cylinders and lecture bottles

- Photo of the day: Forklift Stability Triangle

- Photo of the day: Defective Tools Safe Work Practice

- Photo of the day: Lift With Your Legs Not With Your Back

- Photo of the day: First Aid for burns

- Photo of the day: The 7 Principles of HACCP

- Photo of the day: Working Safely with Suspended Loads

- Photo of the day: Heat Stroke First Aid and safety posters

- Photo of the day: Near-Miss Reporting and Posters

- Photo of the day: Ergonomic chair and office chair safety tips

- Photo of the day: Whole Body Vibration

- Photo of the day: Substation Safety Equipment

- Photo of the day: Bypassing Safety Controls Rules

- Photo of the day: Lightning Safety Tips

- Photo of the day: Overhead Power lines Clearance

- Photo of the day: Floor Marking

- Photo of the day: Types of Foot Protection

- Photo of the day: Types of Hand Protection

- Photo of the day: Lockout and Tagout Safety

- Photo of the day: Fall Protection Plans

- Photo of the day: Flood Safety Tips

- Photo of the day: Read All Labels Work safe

- Photo of the day: Run Project safely with Crane Hand Signals

- Photo of the day: Flagman and Traffic control

- Photo of the day: Managing Risks of Exposure to Solvents in the workplace

- Photo of the day: Scissor Lift Safety

- Photo of the day: HSE Bulletin Board

- Photo of the day: Arc-Fault Circuit Interrupters (AFCI)

- Photo of the day: Safe use of ladders and step ladders

- Photo of the day: Concrete Truck Driver Hand Signals

- Photo of the day: Extension Cord Safety Tips

- Photo of the day: Protect your Head

- Photo of the day: choosing the right Anchorage

- Photo of the day: Work-Related Asthma

- Photo of the day: Top FIVE Heavy Equipment Construction Site Safety Tips

- Photo of the day: sun safety in the workplace

- Photo of the day: Cannabis and Impairment in the Workplace

- Photo of the day: Position for safety and comfort-Safety Tips

- Photo of the day: Generator Safety

- Photo of the day: Controlling COVID-19 in the Workplace-Physical Barriers

- Photo of the day: Manual Material handling

- Photo of the day: Personal Protective Equipment last resort

- Photo of the day: WHMIS 2015 – Pictograms

- Photo of the day: Indoor Air Quality

- Photo of the day: Noise in the affected workplace

- Photo of the day: Fatigue at Work

- Photo of the day: Don’t be Driven to Distraction

- Photo of the day: working in heat and Humidex Rating

- How to use Plate Clamps Safely: Safety Moment#34

- Photo of the day: Sitting at work

- Photo of the day: 5 ways to reduce the risk of Slipping and Tripping

- Photo of the day: Preventing the spread of contagious illness

- Photo of the day: Incident Investigations

- Photo of the day: 10 Scaffold Safety Essentials

- Photo of the day: Effective Health and Safety Committees

- Photo of the day: New worker Orientation & Safety Orientation checklist

- Photo of the day: Workplace Inspection

- Photo of the day: musculoskeletal disorders

- Photo of the day: Emergency preparedness in the workplace

- Photo of the day: Mental health in the workplace

- Photo of the day: Trenching Safety Tips That Can Save a Life

- Photo of the day: Dangerous Goods Classes

- Photo of the day: Safety Equipment for Confined Spaces

- Photo of the day: Tips to reduce Heat stress in the workplace

- Photo of the day: hierarchy of controls

- Your steps to chemical safety

- H2S Gas and how to handle its Emergency

- Photo of the day: Importance of Mock drill and Fire Action Emergency Procedure

- Photo of the day: Choosing the Right Face Mask and the difference between a respirator and face mask

- Photo of the day: Confined space safety Precautions

- Breath Safely: The Proper Use of Respiratory Protection

- Photo of the day: Electric shock survival

- Photo of the day: Chemical Spill Emergency Response

- Photo of the day: Construction Site fire Safety

- Photo of the day: Confined Space rescue

- Photo of the day: Conveyors Safety Tips