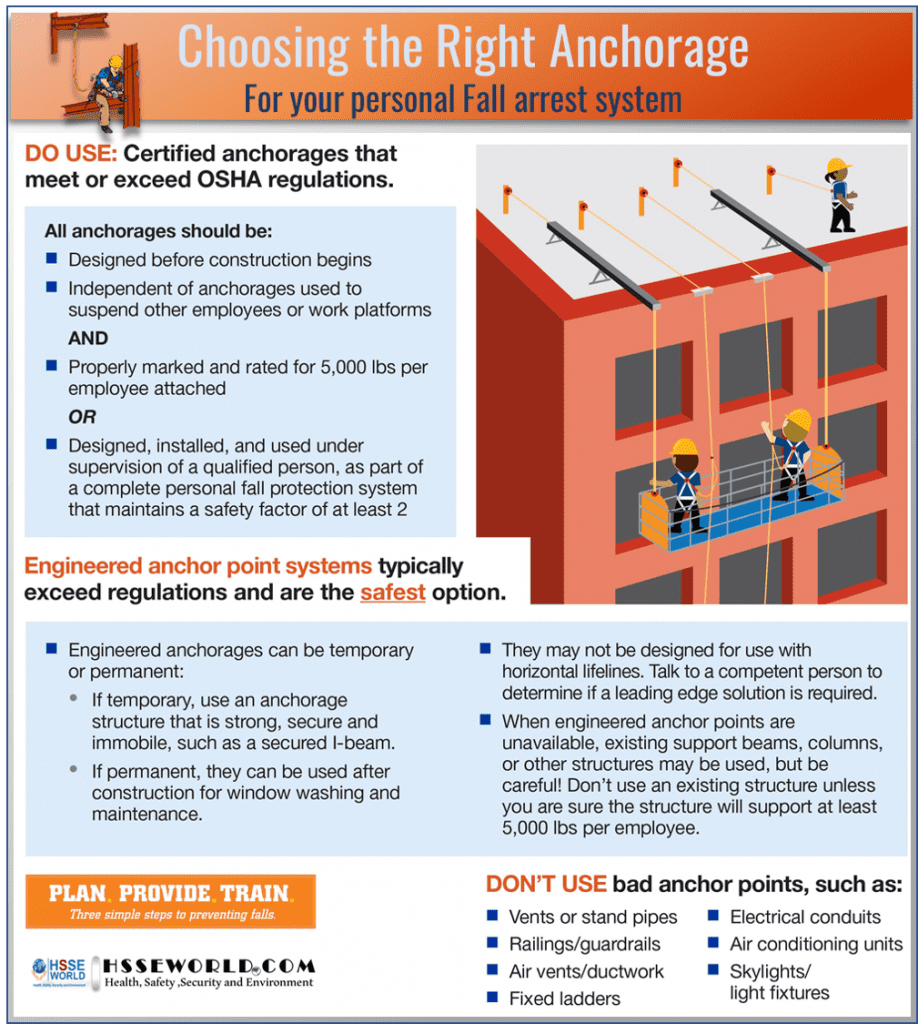

Why is choosing the right anchorage for a personal fall arrest system so important to your safety? Even with the latest in fall protection systems – including those utilizing foot-level tie-off rated energy absorbers – if the anchor fails, that state-of-the-art system won’t matter.

The photo of today and infographic will outline how to select the right anchorage for your personal fall arrest system in addition to how to use and what you shall not use an anchorage point

Anchors As Part of Your Fall Protection System

First, let’s establish an understanding of what comprises an anchorage system. There are two critical components – the anchorage and the anchorage connector. The anchorage is that structural element adjacent to the fall hazard upon which you will rely for the purpose of securing your personal fall arrest system. The anchorage connector is that element, component, or product which is affixed to the anchorage in order to establish a “tie-off point” to which you will attach your connecting device (lanyard, self-retracting device, and so on). The distinction between these two terms is critical, as they are commonly used interchangeably.

The first step in choosing the right anchorage for your fall arrest system begins with treating the anchorage as a vital component of that system, not as a separate component.

According to OSHA, employers must, to the degree possible, eliminate workplace hazards that could cause an employee to fall. This includes falling from overhead platforms, elevated workstations, or into holes in the floor and walls. In the event that these hazards cannot be eliminated, employees must have access to the right kind of anchorages and must also know how to identify them (for related reading, see The Hierarchy of Hazard Controls).

Fall protection was at the top of the list of OSHA violations. That’s why it’s important for employers to give serious attention to it. Anchorage plays a critical part in the outcome of most fall protection scenarios, as the elevation of the anchorage above the walking-working surface is a primary component of determining and managing available clearances (find out when your job takes you to the edge/).

Anchorage Characteristics

To select the right anchorage, there are a few helpful things to keep in mind. First, consider the purpose. You should also consider the materials used in the fall protection system, including the anchorage connector. Most importantly, keep in mind the structure to which the anchorage is attached.

According to the Infrastructure Health and Safety Association (IHSA), there are three basic types of anchor systems for fall protection:

- Designed Fixed Support – These are load-rated anchorage connectors permanently installed in the building structure. They’re designed specifically for fall protection purposes. They can be used to anchor fall arrest systems, work positioning systems, and travel-restraint systems. But, the installed support must comply with industry standards and regulations.

- Temporary Fixed Support – These anchorage connectors connect to the structure. An example would include nail-on anchors and beam clamps. These are temporary supports, and not designed as part of the building. So, they must meet strict guidelines for the amount of weight and stress they can handle.

- Existing Structural Features – These include equipment not intended as anchorage. A professional engineer or qualified person must verify that the equipment has adequate capacity to serve as an anchorage.

Requirements for Temporary Fixed Anchor Points

The weight support requirement for temporarily fixed anchor points varies. It depends on the type of fall protection system anchored to it.

The OSHA standard states:

Anchorages used for attachment of personal fall arrest equipment shall be…capable of supporting at least 5,000 pounds (22.2 kN) per employee attached, or shall be designed, installed, and used as follows: as part of a complete personal fall arrest system which maintains a safety factor of at least two” [29 CFR 1926.502(d)(15) and (d)(15)(i)]

According to the requirements of ANSI/ASSE Z359.2 and Z359.6, the following guidance applies:

- Fall Arrest Anchorage: 5,000 lbs or twice the expected impact load

- Fall Restraint Anchorage (Travel Restriction): 1,000 lbs or twice the expected impact load

- Work Positioning System: 3,000 lbs or twice the expected impact load

In all cases, a safety factor of at least two should be applied when determining the minimum load that an anchorage point must support. As a general rule, choose an anchor capable of supporting the weight of a small car (about 3,600 pounds) in the case of a certified anchorage approved by a qualified person or engineer.

You may choose an existing structural feature or equipment as an anchor point. If so, avoid corners or edges that could fray or cut the lines.

Regular Inspections

Inspect every part of your fall protection system daily before use, using the manufacturer’s instructions as a guide. This includes anchorages and anchorage Connectors. Employees should be trained on how to thoroughly inspect their fall protection equipment. Also, be sure to schedule regular inspections. Having a variety of inspectors take a careful look at the fall protection systems and anchorages is beneficial. It will give extra confidence to the employees who use them.

Sometimes, an inspection will reveal defects, inadequate maintenance, or unsafe conditions. If this is the case, remove the equipment from service immediately. Remove any equipment subjected to the forces of an arrested fall immediately as well. Only the manufacturer, or entities authorized in writing by the manufacturer, may make repairs to the product.

OSHA acknowledges that in some cases, anchorages are identified and anchorage connectors are installed right before use on the job site. When that happens, only competent persons should select the anchorage and install the anchorage connector.

Anchorages to Avoid

It can be difficult to find a sturdy and convenient anchorage. This may tempt you to use a makeshift anchorage so you can get on with the work. Never settle for these or allow anyone else to use them. It’s not worth the risk.

Never use these items as anchors:

- Vents

- Hatches

- Small pipes

- Scaffolding (unless approved by a qualified person)

- TV antennas

- Ladders (unless approved by a qualified person)

- Anything damaged by wear or weather

Making the Right Choice

Fall hazards are common at construction worksites, but fall-related injuries and fatalities are preventable. Choosing the right anchorage and anchorage connector is just one part of fall prevention. It’s important to focus on guardrails, restraint systems, and other fall prevention methods. This should never be to the exclusion of proper anchorage.

Knowing how to choose the right anchorage is an important part of an effective fall protection system. More importantly, it ensures that every employee will get home safely.

DO USE: Certified anchorages that meet or exceed OSHA regulations.

All anchorages should be:

- Designed before construction begins

- Independent of anchorages used to suspend other employees or work platforms

AND

- Properly marked and rated for 5,000 lbs per employee attached

OR

- Designed, installed, and used under the supervision of a qualified person, as part of a complete personal fall protection system that maintains a safety factor of at least 2

DON’T USE bad anchor points, such as:

- Vents or standpipes

- Railings/guardrails

- Air vents/ductwork

- Fixed ladders

- Electrical conduits

- Air conditioning units

- Skylights/

- light fixtures

Download the infographic

Choosing the right Anchorage

More Photos

- What are the Best Practices for Managing Subcontractor Risk

- Photo of the day: 10 Essential Safety Tips for Driving in Hot Weather Conditions

- Photo of the day: best workplace safety tips

- Photo of the day: The Importance of Stop Work Authority in Maintaining Workplace Safety

- Photo of the day: Tomorrow’s Reward for Working Safely Today: Cultivating a Culture of Safety

- Photo of the day: Preventing slips and trips at work

- Photo of the day: Learn the DRSABCD action Plan

- Working with Electricity Electrical Accidents Guide for Electrical Workers

- Photo of the day: Hearing Protection Device Selection

- Photo of the day: If An Earthquake Shakes You-Infographic free

- Fire Safety Posters Free Download

- Photo of the day: First Aid for Electrical Burns-Infographic free

- Infographic: First Aid for Cuts and Scrapes free download

- Photo of The day: Work Safe with Lasers-Laser Safety free

- Photo of the day: Working Safely with chemicals and chemical Management

- Photo of the day: Safe work practices when using MEWPs ( updated)

- Photo of the day: Preventing Common Kitchen Hazards

- Photo of the day: Safe handling of Gas Cylinders and lecture bottles

- Photo of the day: Forklift Stability Triangle

- Photo of the day: Defective Tools Safe Work Practice

- Photo of the day: Lift With Your Legs Not With Your Back

- Photo of the day: First Aid for burns

- Photo of the day: The 7 Principles of HACCP

- Photo of the day: Working Safely with Suspended Loads

- Photo of the day: Heat Stroke First Aid and safety posters

- Photo of the day: Near-Miss Reporting and Posters

- Photo of the day: Ergonomic chair and office chair safety tips

- Photo of the day: Whole Body Vibration

- Photo of the day: Substation Safety Equipment

- Photo of the day: Bypassing Safety Controls Rules

- Photo of the day: Lightning Safety Tips

- Photo of the day: Overhead Power lines Clearance

- Photo of the day: Floor Marking

- Photo of the day: Types of Foot Protection

- Photo of the day: Types of Hand Protection

- Photo of the day: Lockout and Tagout Safety

- Photo of the day: Fall Protection Plans

- Photo of the day: Flood Safety Tips

- Photo of the day: Read All Labels Work safe

- Photo of the day: Run Project safely with Crane Hand Signals

- Photo of the day: Flagman and Traffic control

- Photo of the day: Managing Risks of Exposure to Solvents in the workplace

- Photo of the day: Scissor Lift Safety

- Photo of the day: HSE Bulletin Board

- Photo of the day: Arc-Fault Circuit Interrupters (AFCI)

- Photo of the day: Safe use of ladders and step ladders

- Photo of the day: Concrete Truck Driver Hand Signals

- Photo of the day: Extension Cord Safety Tips

- Photo of the day: Protect your Head

- Photo of the day: choosing the right Anchorage

- Photo of the day: Work-Related Asthma

- Photo of the day: Top FIVE Heavy Equipment Construction Site Safety Tips

- Photo of the day: sun safety in the workplace

- Photo of the day: Cannabis and Impairment in the Workplace

- Photo of the day: Position for safety and comfort-Safety Tips

- Photo of the day: Generator Safety

- Photo of the day: Controlling COVID-19 in the Workplace-Physical Barriers

- Photo of the day: Manual Material handling

- Photo of the day: Personal Protective Equipment last resort

- Photo of the day: WHMIS 2015 – Pictograms

- Photo of the day: Indoor Air Quality

- Photo of the day: Noise in the affected workplace

- Photo of the day: Fatigue at Work

- Photo of the day: Don’t be Driven to Distraction

- Photo of the day: working in heat and Humidex Rating

- How to use Plate Clamps Safely: Safety Moment#34

- Photo of the day: Sitting at work

- Photo of the day: 5 ways to reduce the risk of Slipping and Tripping

- Photo of the day: Preventing the spread of contagious illness

- Photo of the day: Incident Investigations

- Photo of the day: 10 Scaffold Safety Essentials

- Photo of the day: Effective Health and Safety Committees

- Photo of the day: New worker Orientation & Safety Orientation checklist

- Photo of the day: Workplace Inspection

- Photo of the day: musculoskeletal disorders

- Photo of the day: Emergency preparedness in the workplace

- Photo of the day: Mental health in the workplace

- Photo of the day: Trenching Safety Tips That Can Save a Life