Scissor lift safety provides a safe and reliable platform for workers to perform job tasks when used according to the manufacturer’s instructions. When not used properly, scissor lifts can present a serious hazard to workers. Employers are responsible for keeping workers safe. Most construction or maintenance projects typically involve work that needs to be done off the ground, from repairs of structural ceiling damage to inventory work in a warehouse. Sometimes a simple ladder will do, but often workers need a safe and sturdy platform to complete their tasks. That’s why the scissor lift, which is a vertical rising platform on wheels, is known for being such a useful tool on just about any worksite.

In the Photo of today, and this article you be familiar with specific hazards present in workplaces where scissor lifts are used and controls employers must implement to prevent injuries or fatalities.

Also Read: Choosing a Low-Level Scissor Lift that Fits Your Project

While the scissor lift is undeniably one of the safest ways to work on projects at height, there are a lot of potential hazards associated with using it incorrectly. Over a one-year period, the Occupational Safety and Health Administration evaluated ten preventable fatalities and over 20 preventable injuries resulting from a scissor lift incident and found that most of these accidents fell into three categories: fall protection, stabilization, and positioning. By brushing up on a few basic rules and regulations, any worksite manager can rest easy knowing their crew is safe from preventable harm when using a scissor lift.

How to Safely Use a Scissor Lift

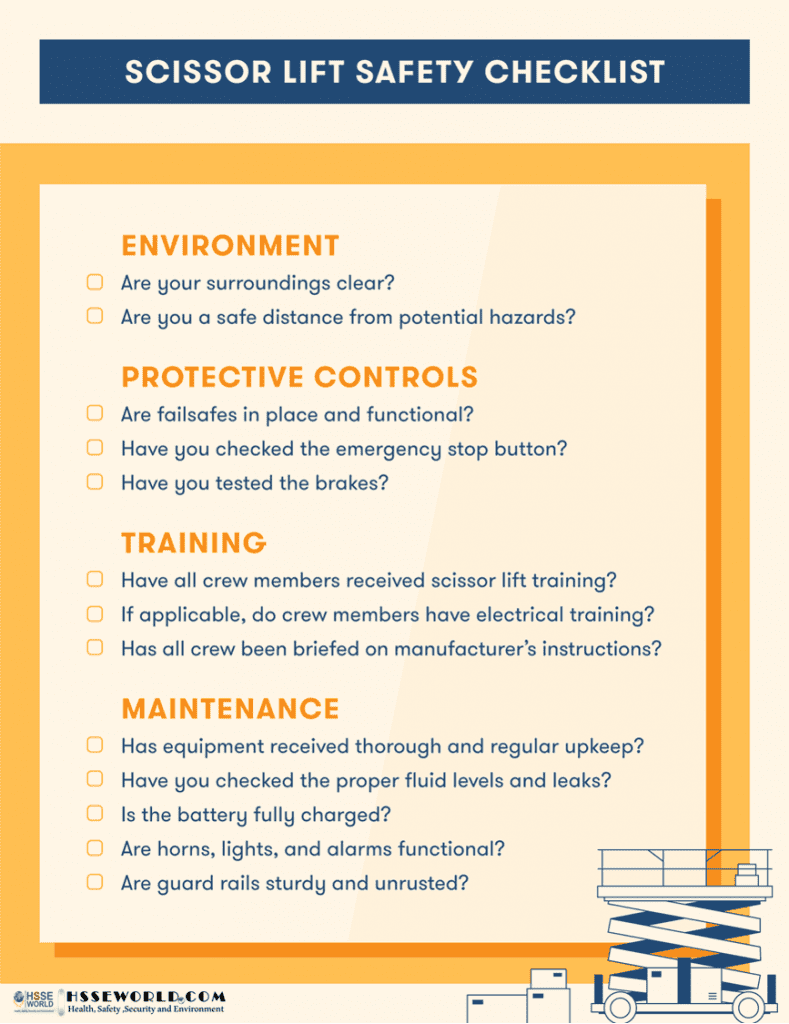

Most of the work involved in making sure you and your crew are safe while using a scissor lift happens long before anyone steps foot onto the equipment. Scissor lift safety preparation falls into four key categories:

Environment

It’s impossible to operate a scissor lift safely unless the surrounding area is secure. Assess the worksite beforehand and identify all possible hazards, like nearby power lines or uneven ground. If the physical features of your worksite make it impossible to safely position or stabilize your scissor lift, you may need to work with the site manager to make adjustments.

Protective Controls

Like all heavy machinery, a scissor lift comes equipped with an emergency stop button that will shut down all functions immediately in case of an emergency. However, it’s important to regularly test this and any other emergency controls to make sure all systems are functioning correctly and will operate properly in an emergency.

Free download: Tool Box Talk: Aerial Lift Safety

Training

Though there’s no formal certification necessary to operate a scissor lift, OSHA standards dictate that employers must provide workers with training and necessary personal protective equipment before operating or performing work with it. As a manager, offering regular opportunities to brush up on basic training is a good way to ensure your entire crew remains safe on and around the scissor lift, like how to get on the platform using the three points of contact method.

Equipment Maintenance

No matter how cautious you are while operating a scissor lift, it’s impossible to create a safe work environment unless all of your equipment is properly and regularly maintained. If you own your scissor lift, make sure you follow the recommended upkeep schedule from the manufacturer. If you rent a scissor lift, do so from a reputable dealer, and be sure to ask about their equipment upkeep routine before signing a rental agreement.

Always test and inspect the scissor lift’s controls before every use, paying special attention to the emergency stop function. Though the whole unit should be inspected regularly, it’s especially important to test the guardrail and brakes often in order to prevent unexpected failure during a project.

Scissor Lift Stabilization for Safe Use

One of the greatest hazards and most frequent causes of preventable scissor lift accidents is poor stabilization. If the scissor lift isn’t properly secured, it can make the machine tip over, causing damage to the equipment and crew.

Here are a few rules to follow to ensure your scissor lift doesn’t tip over:

- Always work on firm, level surfaces.

- If your project is on rough terrain, make sure you use a scissor lift specifically made for use in that environment.

- Always lower the work platform completely before moving the equipment.

- Only work in appropriate weather—most outdoor-rated scissor lifts are only approved for use in wind speeds under 28 mph.

On rare occasions, scissor lifts can also collapse, injuring those on and around the equipment. To prevent this:

- Always check the failsafe functions on your machinery before use.

- Never exceed the weight limit listed in the manufacturer’s manual.

- Never use other equipment to raise the work platform.

How to Safely Position a Scissor Lift

Where and how you position your scissor lift for work can make a huge impact in preventing accidents. When scissor lifts are improperly positioned, crew members can be at risk of getting crushed or electrocuted, so it’s essential that workers are trained on how to avoid positioning accidents.

To prevent crushing incidents, use caution any time you have to move the scissor lift. Be sure to clear the surrounding area of people, and stay aware of moving vehicles and stationary objects that might be in the moving scissor lift’s path. If your worksite is crowded, assign someone to handle traffic control to prevent collisions.

When working on projects that involve or are located near a power source, be sure to maintain a careful distance to prevent electric damage. Always avoid direct contact with power lines, but also remember that electricity can arc from power lines to the equipment or to a worker, even if neither is directly touching the power source. The manufacturer’s manual will have a list of safe distances that vary according to the voltage of the source, so always check before you start on a project. Finally, if the project requires working with an electrical source, make sure workers have electrical training.

Fall Protection: Do I Need a Harness?

A harness is not required while using a scissor lift. According to OSHA, a properly designed and maintained guardrail system is enough to keep a worker safe while on the scissor lift. However, if the guardrail system is inadequate or the worker leaves the safety of the work platform, an additional fall protection device is required.

Scissor lifts must have guardrails installed around the perimeter of the work platform, and regular maintenance is essential to ensure they don’t rust or loosen. Workers should only stand on the work platform, never on the guardrails, and work should be kept close to the scissor lift to avoid having workers lean over the edge of the rails. Additionally, the scissor lift should always be lowered completely to allow workers onto the platform. Never climb up the scissor lift to access the work platform.

Scissor Lift Training: Do I Need a License?

There is no special license or certification for operating or working on a scissor lift. However, OSHA requires that employers provide training to workers before using a scissor lift. Site managers must go over standard procedures for scissor lift usage as well as how to handle materials on the scissor lift, other worksite hazards workers may encounter when working on a scissor lift, and how to report equipment defects or necessary maintenance. Employers must also include the manufacturer’s instructions for operating a scissor lift both vertically and while in transit.

Know Your Scissor Lift Inside and Out

Though there are plenty of safety measures that apply to all scissor lifts, the only way to make sure you’re taking the correct precautions to keep your crew safe around a scissor lift is to fully familiarize yourself with the particular make and model as well as the type of scissor lift that you’re using. Though certain warnings are applicable across the board, each piece of equipment has different weight limits, specifications, and hazard warnings. There should also be a legend in the manufacturer’s manual to help interpret the meaning of various warning decals on the scissor lift.

Of course, the best way to be absolutely certain of your safety when using a scissor lift is to work with a professional. Opting to rent a scissor lift from a reputable dealer guarantees that your machinery is well-maintained, and inspected regularly, and gives you the opportunity to talk with an expert and ask any questions you may have about operating your rental. Renting can often be a smart financial decision, but it’s a good safety precaution, too.

also Read: Photo of the day: Lift With Your Legs Not With Your Back

Download the infographic

Scissor Lift Safety

For more safety Resources Please visit safetybagresources

Also Read: Lifting Plan Audit Checklist

More Photos

- What are the Best Practices for Managing Subcontractor Risk

- Photo of the day: 10 Essential Safety Tips for Driving in Hot Weather Conditions

- Photo of the day: best workplace safety tips

- Photo of the day: The Importance of Stop Work Authority in Maintaining Workplace Safety

- Photo of the day: Tomorrow’s Reward for Working Safely Today: Cultivating a Culture of Safety

- Photo of the day: Preventing slips and trips at work

- Photo of the day: Learn the DRSABCD action Plan

- Working with Electricity Electrical Accidents Guide for Electrical Workers

- Photo of the day: Hearing Protection Device Selection

- Photo of the day: If An Earthquake Shakes You-Infographic free

- Fire Safety Posters Free Download

- Photo of the day: First Aid for Electrical Burns-Infographic free

- Infographic: First Aid for Cuts and Scrapes free download

- Photo of The day: Work Safe with Lasers-Laser Safety free

- Photo of the day: Working Safely with chemicals and chemical Management

- Photo of the day: Safe work practices when using MEWPs ( updated)

- Photo of the day: Preventing Common Kitchen Hazards

- Photo of the day: Safe handling of Gas Cylinders and lecture bottles

- Photo of the day: Forklift Stability Triangle

- Photo of the day: Defective Tools Safe Work Practice

- Photo of the day: Lift With Your Legs Not With Your Back

- Photo of the day: First Aid for burns

- Photo of the day: The 7 Principles of HACCP

- Photo of the day: Working Safely with Suspended Loads

- Photo of the day: Heat Stroke First Aid and safety posters

- Photo of the day: Near-Miss Reporting and Posters

- Photo of the day: Ergonomic chair and office chair safety tips

- Photo of the day: Whole Body Vibration

- Photo of the day: Substation Safety Equipment

- Photo of the day: Bypassing Safety Controls Rules

- Photo of the day: Lightning Safety Tips

- Photo of the day: Overhead Power lines Clearance

- Photo of the day: Floor Marking

- Photo of the day: Types of Foot Protection

- Photo of the day: Types of Hand Protection

- Photo of the day: Lockout and Tagout Safety

- Photo of the day: Fall Protection Plans

- Photo of the day: Flood Safety Tips

- Photo of the day: Read All Labels Work safe

- Photo of the day: Run Project safely with Crane Hand Signals

- Photo of the day: Flagman and Traffic control

- Photo of the day: Managing Risks of Exposure to Solvents in the workplace

- Photo of the day: Scissor Lift Safety

- Photo of the day: HSE Bulletin Board

- Photo of the day: Arc-Fault Circuit Interrupters (AFCI)

- Photo of the day: Safe use of ladders and step ladders

- Photo of the day: Concrete Truck Driver Hand Signals

- Photo of the day: Extension Cord Safety Tips

- Photo of the day: Protect your Head

- Photo of the day: choosing the right Anchorage

- Photo of the day: Work-Related Asthma

- Photo of the day: Top FIVE Heavy Equipment Construction Site Safety Tips

- Photo of the day: sun safety in the workplace

- Photo of the day: Cannabis and Impairment in the Workplace

- Photo of the day: Position for safety and comfort-Safety Tips

- Photo of the day: Generator Safety

- Photo of the day: Controlling COVID-19 in the Workplace-Physical Barriers

- Photo of the day: Manual Material handling

- Photo of the day: Personal Protective Equipment last resort

- Photo of the day: WHMIS 2015 – Pictograms

- Photo of the day: Indoor Air Quality

- Photo of the day: Noise in the affected workplace

- Photo of the day: Fatigue at Work

- Photo of the day: Don’t be Driven to Distraction

- Photo of the day: working in heat and Humidex Rating

- How to use Plate Clamps Safely: Safety Moment#34

- Photo of the day: Sitting at work

- Photo of the day: 5 ways to reduce the risk of Slipping and Tripping

- Photo of the day: Preventing the spread of contagious illness

- Photo of the day: Incident Investigations

- Photo of the day: 10 Scaffold Safety Essentials

- Photo of the day: Effective Health and Safety Committees

- Photo of the day: New worker Orientation & Safety Orientation checklist

- Photo of the day: Workplace Inspection

- Photo of the day: musculoskeletal disorders

- Photo of the day: Emergency preparedness in the workplace

- Photo of the day: Mental health in the workplace

- Photo of the day: Trenching Safety Tips That Can Save a Life