In a time of rapid technological development, it is easy to forget that you have a very powerful portable computer with you all the time your brain

Unfortunately, just like a portable computer, your brain is fragile and its packaging is not strong enough to protect it from all shocks or impacts. So, you need to choose appropriate protection for your brain and head.

Head injury is still one of the most common causes of fatal injury in accidents. Choosing the right head protection, and then using it correctly, is not that difficult and will protect both your health and your wallet.

This Photo of the day and article gives an overview, including some of the aspects of head protection that are not so well known.

- Why is head protection important?

- Head protection standards

- Construction accidents

Why is head protection important?

Head protection in PPE terms is considered as protection against impact injury and some burn injuries. It generally protects the scalp area, and sometimes the jaw. The face is generally not included, except for some sports helmets. Eye and face protection, noise protection and respiratory protection are separate types of PPE. Protective clothing standards include protecting the head from chemical, biological, and radioactive hazards.

Head injuries

Head injuries can be very complicated – some are obvious when the accident happens but others appear hours or days after the accident. A head injury involves different kinds of damage to the skull and its contents. This may also include neck injuries. Different types of head injuries often happen in one accident.

Put very simply, the brain does not fill the skull – rather than being fixed firmly in place it “floats” inside the skull. Also, the brain and its blood vessels are soft and can be damaged by contact with the inside of the skull and by being compressed or twisted. Obviously, if the skull is broken then the brain can be damaged by direct contact – an open head injury. But the brain can also be damaged without direct contact if it hits the inside of the skull or is twisted on the top of the spinal cord – a closed head injury. For example, in a severe whiplash car accident, there can be damage to the brain from being shaken against the skull, as well as neck injuries.

Medical research has provided a lot of useful information on the types of head injuries occurring in accidents, and how these injuries are caused. However, because head injuries can be so complicated, the exact mechanisms that cause these injuries are still not clearly understood.

When there is an impact to the head, there are accelerations and rotations of both the head and the brain inside the head. Research studies have defined the impact forces and accelerations which cause some types of head injury. These data come from a combination of accident and casualty data, and tests on cadavers, animals, and volunteers. Because we are all different, our individual “head injury tolerances” are different. So, the forces and/or accelerations that are likely to cause head injuries are given as a range, and not as single values. As an example, the force to fracture the skull causing serious injury (and maybe death) is in the range of 600 to 20000 N, with the typical force for a healthy 25-year-old male likely to be around 3500 to 5000 N. Similarly, moderate or more severe concussion has been found to occur around 3000 N upward.

The general aims of head protection are then very simple:

- To reduce the level of the force/acceleration on the head to an “acceptable” level

- To prevent objects from cutting or penetrating the head

Clearly, the important question here is what is an “acceptable” level of injury? I will return to this later.

How does head protection reduce the level of the force/acceleration on the head?

There are two key mechanisms:

- Some of the energy of an impact is absorbed by the head protection which reduces the force/acceleration sustained by the head

- The duration of the impact is increased so that, for the same energy, the maximum force/acceleration on the head is lower

In simple terms, head protection will act like the crumple zone on your car. It absorbs some of the energy and spreads out the time of the impact. High-speed video of a hard hat during impact shows the helmet looking very like jelly – it wobbles and deforms, which absorbs energy. Of course, head protection must also be strong enough to protect the head from penetration. And, just like the crumple zone on your car, head protection should be replaced after an accident!

Regulations and sensible risk management

Head protection generally falls under the same regulations as other PPE – in the UK this is The PPE at Work Regulations 1992 2 and The PPE Regulations 2002 3. Some key points of these regulations are:

- Head protection should only be used after a risk assessment has been made

- Head protection should be selected, used, and maintained correctly

- Head protection should be CE marked (to show that it meets the essential safety requirements of the PPE Directive 89/686/EEC)

Correct selection, use, care, and maintenance are essential for you to get the best performance from your head protection. All head protection should come with full instructions, and the manufacturer or supplier can provide more information. You should always follow the manufacturer’s instructions.

There may be other specific national regulations that require head protection. In the UK the Construction (Head Protection) Regulations 1989 and Docks Regulations 1988 both require suitable safety helmets to be worn where there is a foreseeable risk of injury to the head.

As for all sensible risk management, you need to assess the hazards and risks and take steps to reduce the risks until they are “as low as is reasonably practicable” (ALARP). Because head protection only protects the wearer and does not remove the hazard it is the last line of defense. Before choosing PPE you should try to remove the hazard or make the hazard less severe. For example:

- Try to avoid having walkways underneath work areas where something might be dropped

- Try to close off work areas above the ground so that nothing can drop from them

- Create exclusion areas where there is heavy lifting overhead Most importantly, remember that head protection does not offer 100% protection against all hazards – it only protects against defined hazards and only reduces injuries to an acceptable level.

Head protection standards

You may often see standards referred to, but do you know what they do?

Just like other PPE, most head protection is CE marked against the requirements of a harmonized CEN standard. Meeting the requirements of a harmonized standard means that the essential requirements of the PPE Directive (89/686/EEC) have also been met, and the CE mark will be accompanied by the relevant standard number. Standards also offer the advantages of:

- Setting a specification that manufacturers, regulators, and consumers can use

- Giving a defined minimum protection performance so that products can be easily compared

Head protection standards set performance requirements for the:

- Resistance to penetration (by a sharp object)

- Shock absorption during impact

- Retention on the head

- Markings and information for the user

- Specific requirements for each type of head protection

Comfort and wearability issues are not very well addressed in current standards. One of the major reasons for this is that it is very difficult to devise objective tests to measure such subjective factors. However, work continues to improve head protection standards’ ability to address comfort. For example, tests that would measure the ventilation of the head when wearing head protection are being researched, as this could be used as an indicator of likely thermal comfort for comparing head protection.

Standards test methods

As I said before, head injuries can be complicated, and the exact mechanisms that cause injuries are not understood. So, how do standards writers define test methods and performance requirements?

All tests are conducted with head protection mounted on an artificial test head.

Penetration tests are easy – a sharp object hitting the head protection with given energy must not touch the test head.

Shock absorption tests are more difficult. A blunt object hits the head protection (on a test head) with a given energy. Different shapes of the blunt object are used according to the likely hazard e.g. a kerbstone shape is used in some motorcycle helmet standards. For standards where a falling object is the main hazard, the object falls onto the head protection. For standards where the wearer falling over is the main hazard, the head protection plus test head falls on the object. Either way, a limit needs to be set on the force/acceleration transmitted to the test head when the helmet is worn: this limit is intended to correspond to an acceptable level of injury. Setting this limit which is difficult, and requires the standards writers to use existing medical knowledge and experience of how head protection performs in use. At the moment, limits on the linear force or acceleration transmitted to the test head are used for shock absorption performance.

What is an “acceptable” level of injury?

This depends on what the injury would be without head protection.

- If the injury without head protection is a bump on the head or a cut, then an acceptable injury is probably no more than a mild headache (e.g. the industrial bump cap)

- If the injury without head protection is a skull fracture and/or moderate brain injury, then acceptable injury is probably no more than a concussion and bruising (e.g. the industrial safety helmet)

- If the injury without head protection is a major skull fracture and/or serious brain injury which could be fatal, then an acceptable injury might be as high as minor fractures and mild brain injury (e.g. the motorcycle helmet)

Head protection standards have an introduction including words like “the protection given by a helmet depends on the circumstances of the accident and wearing a helmet cannot always prevent death or long-term disability.”

This emphasizes again that head protection does not offer 100% protection. And, for head protection just as for other PPE, increasing the level of protection means heavier and bulkier equipment which may make working difficult and introduce its own hazards such as thermal discomfort or musculoskeletal problems.

Why won’t head protection always protect me?

Let’s consider some likely accidents.

Construction accidents

A brick drops from the second floor and hits a worker wearing an industrial safety helmet. If the brick weighs 1 kg and drops 5 m before impact then it has an energy of roughly 50 J. The helmet standard uses a 50 J impact for shock absorption, so the helmet should protect the worker from no worse than a concussion and bruising – the intended acceptable injury. Replace the brick with a pallet of 50 bricks dropping from the same height. The impact energy is now about 2500 J.

This is well above the energy used to test for shock absorption, so the helmet is no longer in its tested performance zone. The helmet will reduce the severity of the impact and the level of injury, but by an uncertain amount. If a 2500 J impact lasts 0.1 s then the force is roughly 5000 N. Without a helmet this is enough to fracture the skull causing severe injury or death. Even with the helmet, this is likely to be a major injury, maybe still fatal.

This is why you should create exclusion areas where there is heavy lifting overhead – head protection is not designed to protect against very heavy falling objects.

Motorcycle accidents

Now consider a motorcycle accident where the rider is thrown off and hits a wall with their head so that their whole body weight is involved. This is the worst case for head impact and injury. At around just 6 mph, for an 80 kg rider, the energy is roughly 5000 J. The best motorcycle helmet uses a 150 J impact for shock absorption. So, again, the helmet is no longer in its tested performance zone and will reduce the level of injury by an uncertain amount. Even with the helmet, this is likely to be a major injury, maybe fatal.

These figures are NOT a reason for not wearing a helmet, they just illustrate how large the forces on the head can be in a “minor” accident.

Many accidents don’t involve the whole body weight, but only a proportion of it. Similarly, many impacts are not full-on but glancing. So, even at higher speeds or higher nominal impact energies, the helmet can be inside its performance zone, where its protection is known. And if the helmet is outside its performance zone it will still reduce the impact forces on the head. It is just that this reduction may not be big enough to prevent serious injury or death.

The different types of head protection

If you mention head protection most people will think of hard hats or motorcycle helmets. But there are many other types of head protection. Although head protection can be conveniently split into industrial (or workplace) and leisure categories, leisure head protection is often used in the workplace. The emergency services and the military have their own head protection standards but also use industrial and leisure head protection.

Industrial head protection

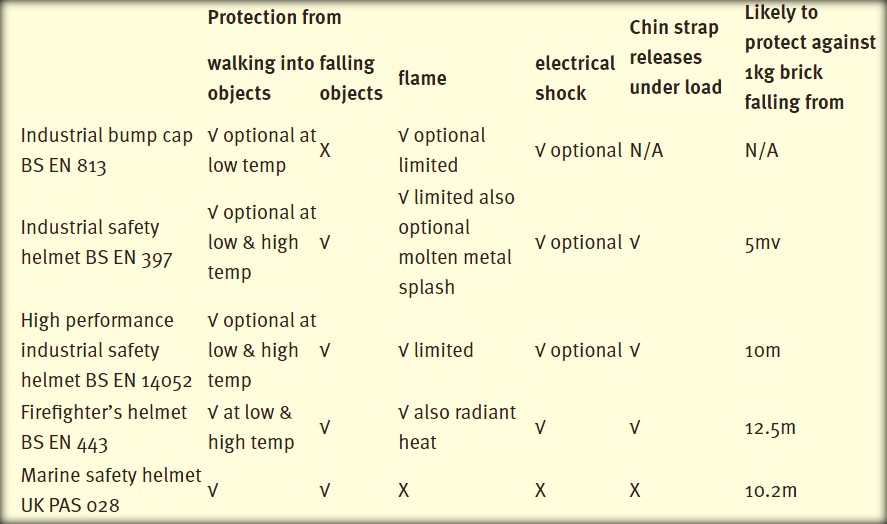

Table 1 summarizes the protection offered by the UK and European Standards.

Bump caps offer low protection and are not intended to protect against falling or moving objects. They are suitable where the risk is walking into objects e.g. in warehouses and garages. Bump caps are available in both safety helmet and baseball cap styles. The baseball cap style is popular because it looks more stylish and is often more comfortable. This is another important factor in selecting head protection – if the wearers like it and find it comfortable they will wear it.

Industrial safety helmets (the ubiquitous hard hat) offer medium protection against a range of hazards, with options for protection (e.g. electrical shock from brief contact with live wires, molten metal splash) that may be needed in some workplaces. They are suitable for a wide range of workplaces. Versions with reduced peaks are available to give better upward visibility. Some have ventilation holes to improve comfort – these holes must not affect the protection. Liners can be worn under the helmet in cold weather.

Safety helmets must be able to fit an adjustable chinstrap. A chinstrap is very useful for keeping the helmet on your head, especially when you are bending a lot. It is a very good idea to supply helmets with chinstraps. There are regular accidents where the injury is worse because the helmet had fallen off, or the wearer had got sick of the helmet falling off and had taken it off. The chinstrap is designed to release under a load. Although different products look very similar, they can feel different when worn because of different weights, the center of gravity, etc. Sweatbands can make a helmet feel more comfortable.

Industrial safety helmets are often used with other PPE, where it is very important that there is full compatibility. If the PPE or head protection does not fit properly because of the other PPE then it will not offer its full protection. There are many options for helmet-mounted PPE e.g. ear defenders, visors, etc. which avoid compatibility problems.

The high-performance industrial safety helmet is similar to the industrial safety helmet but offers greater impact protection. The standard has none of the design restrictions of the industrial safety helmet (minimum helmet to head clearances etc). So, foam liners, etc could be used if the protection performance is achieved. This is a recent standard so there aren’t many products available yet.

The marine safety helmet uses a UK PAS, which is an agreed industry specification and not a full standard. It is a helmet specifically designed for users of small, fast craft such as lifeboat crews. The chinstrap is designed not to release.

There are other standards that include industrial head protection. Some PPE ensemble standards may include their own requirements for aspects of head protection, although they may also reference head protection standards.

There is also industrial PPE which uses the term “helmet” but is not strictly head protection.

“Welding helmets” generally face shields/visors with a hood over the head. They are intended to protect the eyes and face against welding radiation and spatter and may not offer head protection.

“Shotblasting helmets” are a form of hood intended to provide respiratory and abrasion protection. Protection against falling objects is optional (and uses test methods from BS EN 397).

There is no British or European Standard for “ATV helmets” (ATV – all-terrain vehicle or quad bike), “chainsaw helmets”, or “forestry helmets”. These are names for types of helmets that are CE approved either by technical file or by use of another Standard. Typically, ATV helmets are CE approved against some or all of BS EN 1384 (equestrian helmets). Chainsaw and forestry helmets are generally CE approved against some or all of BS EN 397 (industrial safety helmets). This means that there is no guarantee that different ATV helmets are directly comparable with other ATV helmets. Similarly, there is no guarantee that different chainsaw or forestry helmets are directly comparable with other chainsaw or forestry helmets. The manufacturer can supply details of how a helmet was CE approved.

Chinstraps – to release or not to release

Why do some chinstraps release when a given force is applied? The intention is to reduce the risk of strangulation. If a helmet became caught so that the wearer hung by the chinstrap with their feet off the ground, a chinstrap that does not release might strangle them.

But, it isn’t that simple. If a helmet is intended for accidents where there is more than one impact, then a releasing chinstrap might release the helmet early on and leave the head unprotected for later impacts.

So, the balance of strangulation versus multiple impact risks has been considered when deciding whether a standard will have a releasing chinstrap. This is why the helmets where multiple impacts is likely all have non-releasing chinstraps.

Head protection lifetime and replacement

This is the most frequent question that I am asked about head protection. The following comments apply to any helmet used as PPE, although they are written with the BS EN 397 industrial safety helmet in mind. I am not aware of any general legal or UK HSE requirements on specific replacement times. Some industries may have codes of practice or guidance which specify a given replacement time. Some workplaces/companies may have safety procedures that specify a given replacement time.

Replacement

A safety helmet should be replaced when or before its protective capacity has been significantly reduced. The manufacturer of the helmet is the source of guidance when deciding on a replacement policy. 3 years from manufacture is a widely accepted lifetime for helmets. This is a sensible “rule of thumb” lifetime, however, it is important that the user exercises some discretion. If the working or storage environment subjects the helmet to premature aging it may be advisable to reduce the replacement time. Hostile environments include exposure to UV (including sunlight) and exposure to chemical attacks (including vapor in the atmosphere). The manufacturer of the helmet will provide advice on environmental factors.

If the helmet suffers an impact, it uses up some of its protective capabilities and should be replaced, regardless of age. REPLACE THE WHOLE HELMET AND NOT JUST THE SHELL OR CRADLE. When a helmet has been exposed to regular small bangs and knocks, and is badly worn and scratched it should also be replaced. The best rule is “if in doubt, replace”.

Manufacture date

The date of manufacture will be found on the helmet as a permanent marking, as required by EN 397. It is usually given as a quarter and year and is often on the bottom of the peak. This marking can take different forms e.g. dials with arrows, dots for the quarter and a year, etc. Other head protection standards may also require manufacture date markings on the head protection.

In summary, there is a wide range of head protection suitable for almost all your needs. If you apply sensible risk management and an appreciation of the limitations of the protection offered by head protection then you can keep your head safe for its designed lifetime.

Download the infographic

Protect your Head

More Photos

- What are the Best Practices for Managing Subcontractor Risk

- Photo of the day: 10 Essential Safety Tips for Driving in Hot Weather Conditions

- Photo of the day: best workplace safety tips

- Photo of the day: The Importance of Stop Work Authority in Maintaining Workplace Safety

- Photo of the day: Tomorrow’s Reward for Working Safely Today: Cultivating a Culture of Safety

- Photo of the day: Preventing slips and trips at work

- Photo of the day: Learn the DRSABCD action Plan

- Working with Electricity Electrical Accidents Guide for Electrical Workers

- Photo of the day: Hearing Protection Device Selection

- Photo of the day: If An Earthquake Shakes You-Infographic free

- Fire Safety Posters Free Download

- Photo of the day: First Aid for Electrical Burns-Infographic free

- Infographic: First Aid for Cuts and Scrapes free download

- Photo of The day: Work Safe with Lasers-Laser Safety free

- Photo of the day: Working Safely with chemicals and chemical Management

- Photo of the day: Safe work practices when using MEWPs ( updated)

- Photo of the day: Preventing Common Kitchen Hazards

- Photo of the day: Safe handling of Gas Cylinders and lecture bottles

- Photo of the day: Forklift Stability Triangle

- Photo of the day: Defective Tools Safe Work Practice

- Photo of the day: Lift With Your Legs Not With Your Back

- Photo of the day: First Aid for burns

- Photo of the day: The 7 Principles of HACCP

- Photo of the day: Working Safely with Suspended Loads

- Photo of the day: Heat Stroke First Aid and safety posters

- Photo of the day: Near-Miss Reporting and Posters

- Photo of the day: Ergonomic chair and office chair safety tips

- Photo of the day: Whole Body Vibration

- Photo of the day: Substation Safety Equipment

- Photo of the day: Bypassing Safety Controls Rules

- Photo of the day: Lightning Safety Tips

- Photo of the day: Overhead Power lines Clearance

- Photo of the day: Floor Marking

- Photo of the day: Types of Foot Protection

- Photo of the day: Types of Hand Protection

- Photo of the day: Lockout and Tagout Safety

- Photo of the day: Fall Protection Plans

- Photo of the day: Flood Safety Tips

- Photo of the day: Read All Labels Work safe

- Photo of the day: Run Project safely with Crane Hand Signals

- Photo of the day: Flagman and Traffic control

- Photo of the day: Managing Risks of Exposure to Solvents in the workplace

- Photo of the day: Scissor Lift Safety

- Photo of the day: HSE Bulletin Board

- Photo of the day: Arc-Fault Circuit Interrupters (AFCI)

- Photo of the day: Safe use of ladders and step ladders

- Photo of the day: Concrete Truck Driver Hand Signals

- Photo of the day: Extension Cord Safety Tips

- Photo of the day: Protect your Head

- Photo of the day: choosing the right Anchorage

- Photo of the day: Work-Related Asthma

- Photo of the day: Top FIVE Heavy Equipment Construction Site Safety Tips

- Photo of the day: sun safety in the workplace

- Photo of the day: Cannabis and Impairment in the Workplace

- Photo of the day: Position for safety and comfort-Safety Tips

- Photo of the day: Generator Safety

- Photo of the day: Controlling COVID-19 in the Workplace-Physical Barriers

- Photo of the day: Manual Material handling

- Photo of the day: Personal Protective Equipment last resort

- Photo of the day: WHMIS 2015 – Pictograms

- Photo of the day: Indoor Air Quality

- Photo of the day: Noise in the affected workplace

- Photo of the day: Fatigue at Work

- Photo of the day: Don’t be Driven to Distraction

- Photo of the day: working in heat and Humidex Rating

- How to use Plate Clamps Safely: Safety Moment#34

- Photo of the day: Sitting at work

- Photo of the day: 5 ways to reduce the risk of Slipping and Tripping

- Photo of the day: Preventing the spread of contagious illness

- Photo of the day: Incident Investigations

- Photo of the day: 10 Scaffold Safety Essentials

- Photo of the day: Effective Health and Safety Committees

- Photo of the day: New worker Orientation & Safety Orientation checklist

- Photo of the day: Workplace Inspection

- Photo of the day: musculoskeletal disorders

- Photo of the day: Emergency preparedness in the workplace

- Photo of the day: Mental health in the workplace

- Photo of the day: Trenching Safety Tips That Can Save a Life