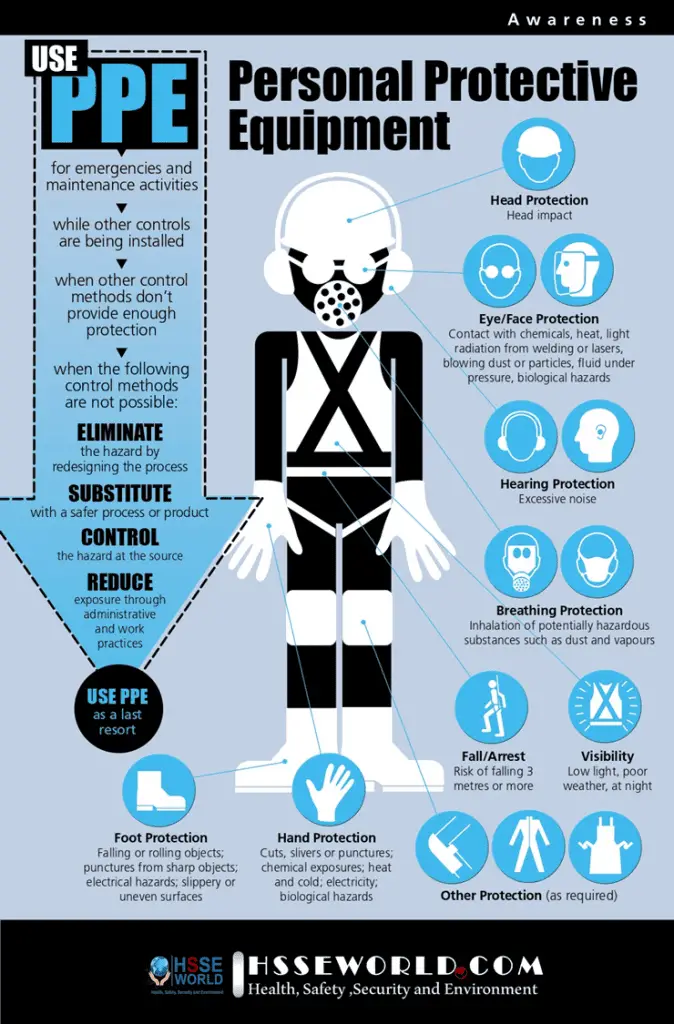

Photo of the day: Personal Protective Equipment last resort

13 min readHazards exist in every workplace so strategies to protect workers are essential. When possible, the priority should be the elimination and control of hazards at their source or along the path between the source and the worker.

Personal protective equipment (PPE) should be considered as the last level of protection when all other methods are not available or possible. PPE is only one element in a complete safety program that would use a variety of strategies to maintain a safe and healthy workplace, and does not reduce the hazard itself nor does it guarantee permanent or total protection.

Display this poster to promote awareness of PPE and when it should be considered and used to perform workplace tasks.

Personal protective equipment is to be used as a control measure as a last resort. It does not eliminate the hazard and will present the wearer with the maximum health risk if the equipment fails. Successful use of personal protective equipment relies on good user training, the availability of the correct equipment at all times, and good supervision and enforcement.

The most important limitations are that personal protective equipment:

- Only protects the person wearing the equipment, not others nearby

- Relies on people wearing the equipment at all times

- Must be used properly

- Must be replaced when it no longer offers the correct level of protection

The benefits of personal protective equipment:

- It gives immediate protection to allow a job to continue while engineering controls are put in place

- In an emergency, it can be the only practical way of effecting rescue or shutting down plant in hazardous atmospheres

- It can be used to carry out work in confined spaces where alternatives are impracticable, but it should never be used to allow people to work in dangerous atmospheres that are, for example, enriched with oxygen or potentially explosive

The ‘last resort’ rule applies in particular to respiratory protective equipment within the context of hazardous substances. The following are some working conditions where respiratory protective equipment may be necessary:

- During maintenance operations

- As a result of a new assessment, perhaps following the introduction of a new substance

- During emergency situations, such as fire or plant breakdown

- Where alternatives are not technically feasible

Types of PPE

There are several types of personal protective equipment such as footwear, hearing protectors, and hard hats that are not primarily concerned with protection from hazardous substances; those which are used for such protection include:

For all types of PPE, there are some basic standards that should be reached. The personal protective equipment should be fit well, be comfortable to wear and not interfere with other equipment being worn or present the user with additional hazards (e.g. impaired vision due to scratched eye goggles).

Training in the use of particular personal protective equipment is essential so that it is not only used correctly, but the user knows when to change an air filter or to change a type of glove. Supervision is essential, with disciplinary procedures invoked for non-compliance with personal protective equipment rules.

It is also essential that everyone who enters the proscribed area, particularly senior managers, wears the specified personal protective equipment.

RPE

Respiratory protective equipment can be subdivided into two categories: respirators (or face masks) that filter and clean the air, and breathing apparatus that supplies breathable air.

Respirators should not be worn in the air that is dangerous to health, including oxygen-deficient atmospheres. They are available in several different forms, but the common ones are:

- A filtering half mask – often called a disposable respirator it is made of filtering material. It covers the nose and mouth and removes respirable size dust particles. It is normally replaced after 8-10 hours of use. It offers protection against some vapors and gases.

- A half-mask respirator – made of rubber or plastic and covering the nose and mouth. Air is drawn through a replaceable filter cartridge. It can be used for vapors, gases, or dust but it is very important that the correct filter is used, as a dust filter will not filter vapors.

- A full-face respirator – similar to the half-mask type but covers the eyes with a visor.

- A powered respirator – a battery-operated fan delivering air through a filter to the face mask, hood, helmet, or visor.

(learn more about Respiratory protective equipment RPE guidelines/ ).

The breathing apparatus is used in one of three forms:

- Self-contained breathing apparatus – where the air is supplied from compressed air in a cylinder and forms a completely sealed system.

- Fresh air hose apparatus – fresh air is delivered through a hose to a sealed face mask from an uncontaminated source. The air may be delivered by the wearer, by natural breathing, or mechanically by a fan.

- Compressed air line apparatus – air is delivered through a hose from a compressed airline. This can be either continuous flow or on-demand. The air must be properly filtered to remove oil, excess water and other contaminants and the air pressure must be reduced. Special compressors are normally used.

The selection of appropriate respiratory protective equipment and correct filters for particularly hazardous substances is best done by a competent specialist person.

There are several important technical standards. RPE must be CE marked. Other standards include the minimum protection required (MPR) and the assigned protection factor (APR). The CE mark does not indicate that the equipment is suitable for a particular hazard. The following information will be needed before a selection of suitable RPE can be made:

- Details of the hazardous substance, in particular, whether it is gas, vapor or dust, or a combination of all three

- Presence of a beard or other facial hair which could prevent a good-leak free fit (a simple test to see whether the fit is right or not is to close off the air supply, breath in, and hold the breath; the respirator should collapse onto the face and it should then be possible check if there is a leak)

- The size and shape of the face of the wearer and physical fitness

- Compatibility with other personal protective equipment, such as ear defenders

- The nature of the work and agility and mobility required

Filters and masks should be replaced at the intervals recommended by the supplier or when taste or smell is detected by the wearer.

The performance of RPE with a tight-fitting face piece depends on good contact between the wearer’s skin and the face seal of the mask. However, research by the British Safety Industry Federation indicated that up to 50 percent of all respiratory protective equipment used does not offer the wearer the level of protection assumed, usually because it is not fitted correctly.

Many regulations state something like ‘Employers should ensure that the selected face piece is of the right size and can correctly fit each wearer. For a tight-fitting face piece, the initial selection should include fit testing to ensure the wearer has the correct device. Also, employers must ensure that whoever carries out the fit testing is competent to do so’.

Fit testing is needed when RPE is used as a control measure not when it is worn by choice for comfort. Fit testing should be repeated if the shape of the face of the wearer changes for any reason, such as weight loss or gain.

Re-testing is recommended to check that the face piece remains suitable and that the wearer is taking care to wear and remove the mask correctly. A two-year cycle has been suggested, and a one-year retest is suggested for work with asbestos.

Fit testing can be qualitative or quantitative. Qualitative testing involves a simple pass or fails based on whether the user can taste or smell a harmless aerosol or odor through respiratory protective equipment. Qualitative testing is only appropriate for disposable or half-face masks. A quantitative fit test may use a laboratory test chamber or a portable fit test device and produces a numerical ‘fit factor’ measure. The results of fit tests should be recorded. Fit test records must be made available to authorities on request, and to the employees who wear respiratory protective equipment. Respiratory protective equipment should be checked every time that it is used to make sure it has not been damaged and is being worn correctly.

All respiratory protective equipment should be examined at least once a month except for disposable respirators. A record of the inspection should be kept for at least five years. There should be a routine cleaning system in place and proper storage arrangements.

( Learn how to complete a respirator fit test)

Protecting the skin

Hand and skin protection is mainly provided by gloves (arm shields are also available). A wide range of safety gloves is available for protection from chemicals, sharp objects, rough working, and temperature extremes. Many health and safety catalogs give helpful guidance for the selection of gloves. For protection from chemicals, including paints and solvents, impervious gloves are recommended. These may be made of PVC, nitrile, or neoprene.

For sharp objects, such as trimming knives, a Kevlar-based glove is the most effective. Gloves should be regularly inspected for tears and holes since this will obviously allow skin contact to take place.

Another effective form of skin protection is the use of barrier creams and these come in two forms: pre-work and after-work. Pre-work creams are designed to provide a barrier between the hazardous substance and the skin. After-work creams are general-purpose moisteners that replace the natural skin oils removed either by solvents or by washing.

Eye protection

Eye protection comes in three forms: spectacles (safety glasses), goggles, and face visors. Eyes may be damaged by chemical and solvent splashes or vapors, flying particles, molten metals or plastics, non-ionizing radiation (arc welding and lasers), and dust.

Spectacles are suitable for low-risk hazards (low-speed particles such as machine swarf). Some protection against scratching of the lenses can be provided but this is the most common reason for replacement. Prescription lenses are also available for people who normally wear spectacles.

Goggles are best to protect the eyes from dust or solvent vapors because they fit tightly around the eyes. Visors offer protection to the face as well as the eyes and do not steam up so readily in hot and humid environments. For protection against very bright lights, special light filtering lenses are used (e.g. in arc welding). Maintenance and regular cleaning are essential for the efficient operation of eye protection.

When selecting eye protection, several factors need to be considered. These include the nature of the hazard (the severity of the hazard and its associated risk will determine the quality of protection required), comfort and user acceptability, compatibility with other personal protective equipment, training, and maintenance requirements and costs.

( learn more: Eye Protection 10 key facts ).

Protective clothing

Protective clothing includes aprons, boots, and headgear such as hard hats and bumps caps. Aprons are normally made of PVC and protect against spillages but can become uncomfortable to wear in hot environments. Other lighter fabrics are available for use in these circumstances.

Ensuring workers comply and correctly wear protective clothing can be expected to increase based on the comfort of the clothing system being worn. Being comfortable in their clothing allows workers to focus on the task at hand and helps promote safe workplace behavior. Discomfort from a clothing system may lead to premature worker fatigue and may increase the risk of accidents and personal injury.

Clothing system comfort is often influenced by a number of factors, such as:

- Environmental conditions such as temperature, precipitation, and wind

- Level of physical exertion required for the task at hand

- Age

- The physical condition of the individual

When choosing a clothing system, all of these factors must be considered, as well as the nature of the workers’ specific tasks. One must also consider the potential change in environmental conditions that can happen during a typical day. In the winter, for example, both indoors and out, it’s not uncommon for the days to start out very cold and reach a more pleasant working temperature by midday.

Safety footwear protects against falling objects, collision with hard or sharp objects, hot or molten materials, slippery surfaces, and chemical spills.

It has metal toecaps and comes in the form of shoes, ankle boots, or knee-length boots, and is made of a variety of materials depending on the particular hazard (e.g. thermally insulated against cold environments). It must be used with care near-live and unprotected against electricity. Specialist advice is needed for use with flammable liquids.

( learn more: safety footwear construction ).

The appropriate selection of safety footwear involves the matching of workplace hazards to the performance requirements of the footwear. The key issues are:

- The type of hazard e.g. physical, chemical or thermal

- type of environment e.g. indoor or outdoor

- The ergonomics of the job e.g. standing up or constant movement

- The footwear must have the correct grip for the environment, a hard-wearing sole unit, and possibly a good shock-absorbing capability.

Conclusion

It is important to note that appropriate PPE should be made available to work-related visitors and members of the public visiting workplaces where hazardous substances are being used. It is also important to stress that managers and supervisors must lead by example, particularly if there is a legal requirement to wear PPE equipment. Refusals by employees to wear mandatory PPE must lead to some form of disciplinary action.

Download Infographic

Personal Protective Equipment last resort

More Photos

- What are the Best Practices for Managing Subcontractor Risk

- Photo of the day: 10 Essential Safety Tips for Driving in Hot Weather Conditions

- Photo of the day: best workplace safety tips

- Photo of the day: The Importance of Stop Work Authority in Maintaining Workplace Safety

- Photo of the day: Tomorrow’s Reward for Working Safely Today: Cultivating a Culture of Safety

- Photo of the day: Preventing slips and trips at work

- Photo of the day: Learn the DRSABCD action Plan

- Working with Electricity Electrical Accidents Guide for Electrical Workers

- Photo of the day: Hearing Protection Device Selection

- Photo of the day: If An Earthquake Shakes You-Infographic free

- Fire Safety Posters Free Download

- Photo of the day: First Aid for Electrical Burns-Infographic free

- Infographic: First Aid for Cuts and Scrapes free download

- Photo of The day: Work Safe with Lasers-Laser Safety free

- Photo of the day: Working Safely with chemicals and chemical Management

- Photo of the day: Safe work practices when using MEWPs ( updated)

- Photo of the day: Preventing Common Kitchen Hazards

- Photo of the day: Safe handling of Gas Cylinders and lecture bottles

- Photo of the day: Forklift Stability Triangle

- Photo of the day: Defective Tools Safe Work Practice

- Photo of the day: Lift With Your Legs Not With Your Back

- Photo of the day: First Aid for burns

- Photo of the day: The 7 Principles of HACCP

- Photo of the day: Working Safely with Suspended Loads

- Photo of the day: Heat Stroke First Aid and safety posters

- Photo of the day: Near-Miss Reporting and Posters

- Photo of the day: Ergonomic chair and office chair safety tips

- Photo of the day: Whole Body Vibration

- Photo of the day: Substation Safety Equipment

- Photo of the day: Bypassing Safety Controls Rules

- Photo of the day: Lightning Safety Tips

- Photo of the day: Overhead Power lines Clearance

- Photo of the day: Floor Marking

- Photo of the day: Types of Foot Protection

- Photo of the day: Types of Hand Protection

- Photo of the day: Lockout and Tagout Safety

- Photo of the day: Fall Protection Plans

- Photo of the day: Flood Safety Tips

- Photo of the day: Read All Labels Work safe

- Photo of the day: Run Project safely with Crane Hand Signals

- Photo of the day: Flagman and Traffic control

- Photo of the day: Managing Risks of Exposure to Solvents in the workplace

- Photo of the day: Scissor Lift Safety

- Photo of the day: HSE Bulletin Board

- Photo of the day: Arc-Fault Circuit Interrupters (AFCI)

- Photo of the day: Safe use of ladders and step ladders

- Photo of the day: Concrete Truck Driver Hand Signals

- Photo of the day: Extension Cord Safety Tips

- Photo of the day: Protect your Head

- Photo of the day: choosing the right Anchorage

- Photo of the day: Work-Related Asthma

- Photo of the day: Top FIVE Heavy Equipment Construction Site Safety Tips

- Photo of the day: sun safety in the workplace

- Photo of the day: Cannabis and Impairment in the Workplace

- Photo of the day: Position for safety and comfort-Safety Tips

- Photo of the day: Generator Safety

- Photo of the day: Controlling COVID-19 in the Workplace-Physical Barriers

- Photo of the day: Manual Material handling

- Photo of the day: Personal Protective Equipment last resort

- Photo of the day: WHMIS 2015 – Pictograms

- Photo of the day: Indoor Air Quality

- Photo of the day: Noise in the affected workplace

- Photo of the day: Fatigue at Work

- Photo of the day: Don’t be Driven to Distraction

- Photo of the day: working in heat and Humidex Rating

- How to use Plate Clamps Safely: Safety Moment#34

- Photo of the day: Sitting at work

- Photo of the day: 5 ways to reduce the risk of Slipping and Tripping

- Photo of the day: Preventing the spread of contagious illness

- Photo of the day: Incident Investigations

- Photo of the day: 10 Scaffold Safety Essentials

- Photo of the day: Effective Health and Safety Committees

- Photo of the day: New worker Orientation & Safety Orientation checklist

- Photo of the day: Workplace Inspection

- Photo of the day: musculoskeletal disorders

- Photo of the day: Emergency preparedness in the workplace

- Photo of the day: Mental health in the workplace

- Photo of the day: Trenching Safety Tips That Can Save a Life

- Photo of the day: Dangerous Goods Classes

- Photo of the day: Safety Equipment for Confined Spaces

- Photo of the day: Tips to reduce Heat stress in the workplace

- Photo of the day: hierarchy of controls

- Your steps to chemical safety

- H2S Gas and how to handle its Emergency

- Photo of the day: Importance of Mock drill and Fire Action Emergency Procedure

- Photo of the day: Choosing the Right Face Mask and the difference between a respirator and face mask

- Photo of the day: Confined space safety Precautions

- Breath Safely: The Proper Use of Respiratory Protection

- Photo of the day: Electric shock survival

- Photo of the day: Chemical Spill Emergency Response

- Photo of the day: Construction Site fire Safety