Cranes are the most effective way to move heavy loads on a construction site, and proper use of crane hand signals is a vital part of safe operation. Ask any crane operator and they will tell you that one of the main factors for a successful project is coordination. a signal person is able to safely direct a crane operator to raise and lower the boom, hoist and lower the load, or move the load horizontally and, of course, to stop the crane in case of emergency.

Using crane hand signals while working in sync with your team on the ground is not only crucial for safety but can help your project run smoothly, on schedule, and keep the boss happy.

With absolute precision and accuracy needed for a job, being able to clearly communicate direction is critical but this is not always an easy task.

Construction sites can be exceptionally loud and busy, meaning verbal communication is at risk of being drowned out by roaring machinery.

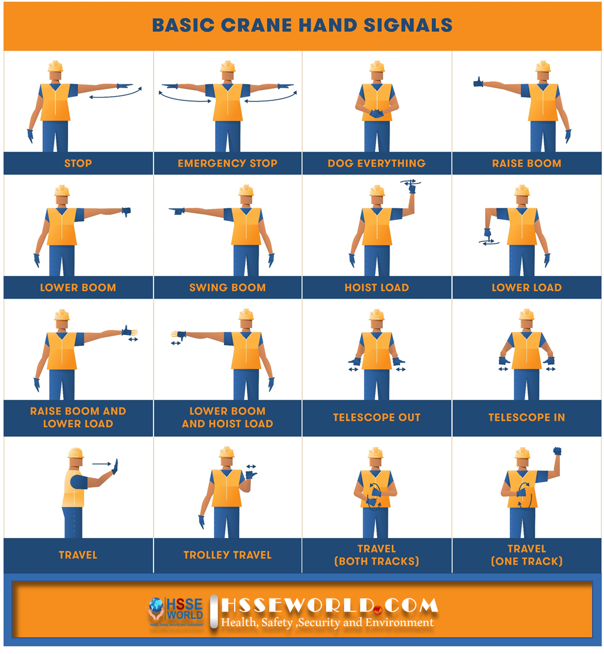

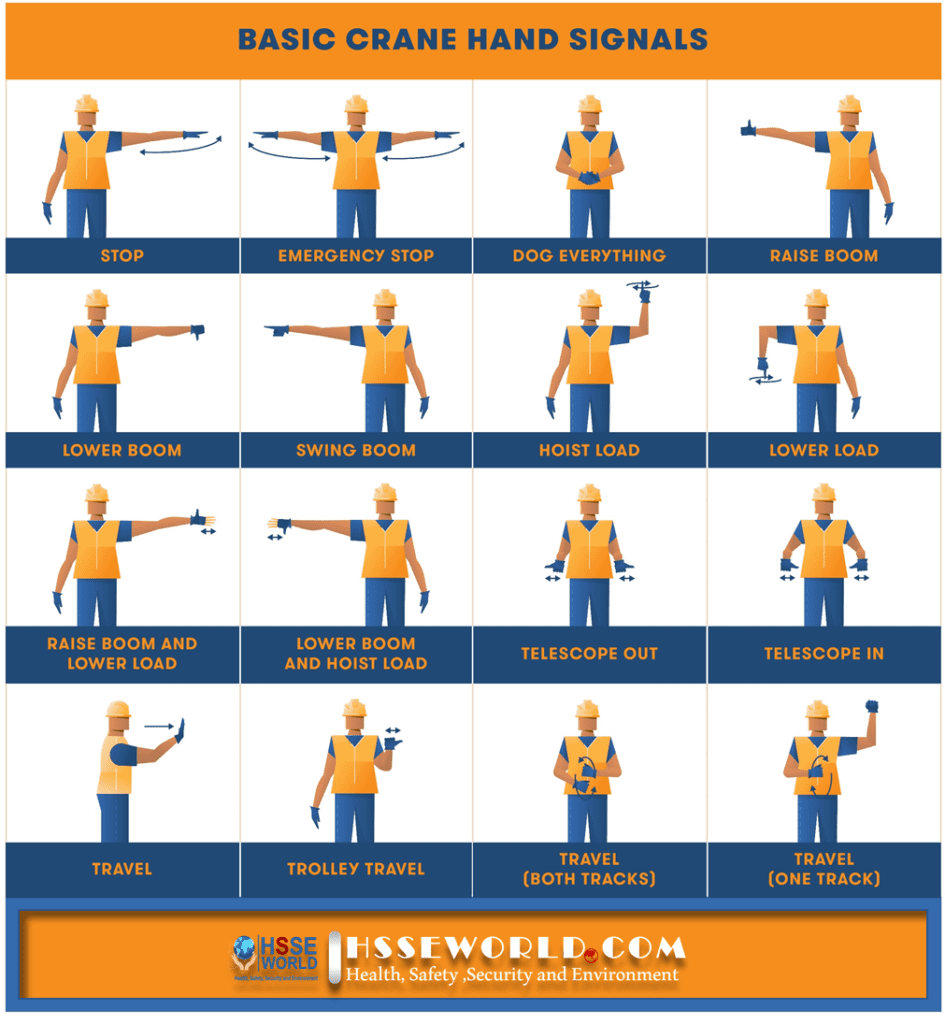

So how does an operator, with a load suspended in the air, follow instructions from their team? Using the simple but effective method of crane hand signals. In the Photo of today, you will be familiar with the basic and commonly used crane hand signals, including a few signals that are particular to telescopic, crawler, and tower cranes in addition you will learn The Role of a Crane Hand Signal Person

Importantly, the Occupational Safety and Health Administration requires that anyone designated as a signal person must meet certain qualifications and be evaluated by a qualified individual. These regulations and a commitment to standardized signals have helped reshape the landscape of crane safety, with crane-related deaths falling to their lowest recorded level in 2017 according to the Bureau of Labor Statistics.

Crane hand signals provide a simple solution for the communication issues faced by crane operators.

Although radios can be used to relay messages across the site, there are some situations when an operator will need extra assistance.

Construction sites are loud. They produce a high level of noise from activities such as digging, piling, and drilling, therefore it can be difficult to convey instruction in an accurate and time-efficient way.

There are also times when an operator’s directional visibility is obstructed or the visibility of a load area is partially blocked, conducting a lift within these types of conditions can put the operator and the workers around them at serious risk of injury.

Although it is recommended to use crane hand signals during all lifts, it is in these situations when a signal person will definitely be called upon.

Easy to understand, crane hand signals help the operator avoid any potential hazards, completing actions in a safe and timely manner.( Critical Lifts )

The Role of a Crane Hand Signal Person

As the eyes and the ears of a dedicated area or crane, a crane hand signal person carries many responsibilities.

Before a person can direct the operation of a crane they must first undergo formal training and complete a qualification in crane signaling.

In training, a person will not only develop an understanding of standard crane hand signals but they will also be required to become familiar with many different types of cranes, how each crane functions and any hand signals specific to particular equipment.

The trainee signal person is required to grasp an understanding of the large library of signals without any memory prompts and show competence in recalling these during an examination by a third-party provider.

The crane hand signal person is also responsible for preventing injury and accidents to the best of their ability, this is done by following strict procedure during crane operation, for instance standing in clear view of the crane operator, ensuring the operating area is clear of people or hazardous objects and performing one signal at a time to avoid confusion.

Commonly Used Crane Hand Signals

The Occupational Safety and Health Administration (OSHA) standard method of signaling must be used when operating a crane unless non-standard crane hand signals are discussed during the pre-job meeting.

OSHA enforces standards and training requirements for safe working environments across multiple industries, including construction in the United States.

Stop signals

Stop signals are one the most important crane hand signals used on a construction site. When stop signals are used operation of the equipment must be halted.

- Emergency stop – A signal person will communicate an emergency stop by extending both arms horizontal of the body with palms faced down, from this position they will swing their arms back and forth.

- Stop – In order to pause or stop an action, the signal person will extend a single arm and face their palm down; they will then begin to swing the extended arm back and forth.

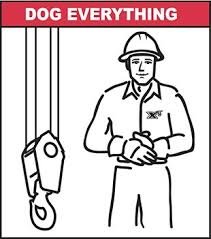

- Dog everything – This signal will stop all activity and is performed by clasping hands together and placing them at waist level.

Boom signals

Boom signals will inform the crane operator of which maneuver they should perform with the boom.

- Raise boom – To raise the boom, a signal person will extend an arm horizontally to the side of their body and signal thumbs up, with a closed fist.

- Lower boom – In order to lower the boom the signal person will extend an arm horizontally and signal thumbs down, with a closed fist.

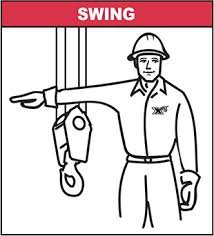

- Swing boom – To swing the boom, the signal person will extend an arm out horizontally, using their index finger to point in the direction the boom is to swing.

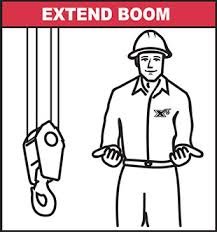

- Extend boom – To lengthen the boom, the signal person will place their hands at the front of their waist and point thumbs outwards with remaining fingers in a fist.

Load signals

Load signals will dictate what the operator should do with a load once it has been lifted by the crane.

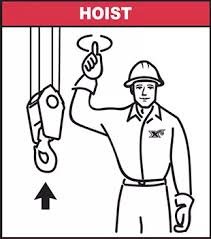

- Hoist load – In order to lift the load upwards the signal person will extend their arm vertically towards the ceiling/sky, point with their index finger and make small circles with their hand and index finger.

- Lower load – To lower the load downward, the signal person will extend their arm horizontally, pointing their index finger towards the ground, once in this position they will make a circle motion with their finger.

Speed signals

The signal person can also control the pace of any movement using speed signals.

- Move slowly – In order to slow the rate of an action, the signal person will a place their hand above the hand which is giving the action signal.

Conclusion

Knowledge of crane hand signals helps to ensure the safe operation of cranes whether small carry deck cranes or large all-terrain cranes — which often weigh thousands of pounds and carry enormous loads. Using standardized hand signals helps maintain continuity between job sites and promotes safety across the entire construction industry.

Safety is the number one concern for crane operators, a person performing the crane hand signals stands at a vantage point that allows them to view the load area from a perspective that is not visible to the crane operator.

( Read more about Mobile Cranes: Basic Terms You Should Know )

Now you can download the Infographic of Crane Hand Signals and post at your workplace

Download the infographic

Crane Hand Signals

More Photos

- What are the Best Practices for Managing Subcontractor Risk

- Photo of the day: 10 Essential Safety Tips for Driving in Hot Weather Conditions

- Photo of the day: best workplace safety tips

- Photo of the day: The Importance of Stop Work Authority in Maintaining Workplace Safety

- Photo of the day: Tomorrow’s Reward for Working Safely Today: Cultivating a Culture of Safety

- Photo of the day: Preventing slips and trips at work

- Photo of the day: Learn the DRSABCD action Plan

- Working with Electricity Electrical Accidents Guide for Electrical Workers

- Photo of the day: Hearing Protection Device Selection

- Photo of the day: If An Earthquake Shakes You-Infographic free

- Fire Safety Posters Free Download

- Photo of the day: First Aid for Electrical Burns-Infographic free

- Infographic: First Aid for Cuts and Scrapes free download

- Photo of The day: Work Safe with Lasers-Laser Safety free

- Photo of the day: Working Safely with chemicals and chemical Management

- Photo of the day: Safe work practices when using MEWPs ( updated)

- Photo of the day: Preventing Common Kitchen Hazards

- Photo of the day: Safe handling of Gas Cylinders and lecture bottles

- Photo of the day: Forklift Stability Triangle

- Photo of the day: Defective Tools Safe Work Practice

- Photo of the day: Lift With Your Legs Not With Your Back

- Photo of the day: First Aid for burns

- Photo of the day: The 7 Principles of HACCP

- Photo of the day: Working Safely with Suspended Loads

- Photo of the day: Heat Stroke First Aid and safety posters

- Photo of the day: Near-Miss Reporting and Posters

- Photo of the day: Ergonomic chair and office chair safety tips

- Photo of the day: Whole Body Vibration

- Photo of the day: Substation Safety Equipment

- Photo of the day: Bypassing Safety Controls Rules

- Photo of the day: Lightning Safety Tips

- Photo of the day: Overhead Power lines Clearance

- Photo of the day: Floor Marking

- Photo of the day: Types of Foot Protection

- Photo of the day: Types of Hand Protection

- Photo of the day: Lockout and Tagout Safety

- Photo of the day: Fall Protection Plans

- Photo of the day: Flood Safety Tips

- Photo of the day: Read All Labels Work safe

- Photo of the day: Run Project safely with Crane Hand Signals

- Photo of the day: Flagman and Traffic control

- Photo of the day: Managing Risks of Exposure to Solvents in the workplace

- Photo of the day: Scissor Lift Safety

- Photo of the day: HSE Bulletin Board

- Photo of the day: Arc-Fault Circuit Interrupters (AFCI)

- Photo of the day: Safe use of ladders and step ladders

- Photo of the day: Concrete Truck Driver Hand Signals

- Photo of the day: Extension Cord Safety Tips

- Photo of the day: Protect your Head

- Photo of the day: choosing the right Anchorage

- Photo of the day: Work-Related Asthma

- Photo of the day: Top FIVE Heavy Equipment Construction Site Safety Tips

- Photo of the day: sun safety in the workplace

- Photo of the day: Cannabis and Impairment in the Workplace

- Photo of the day: Position for safety and comfort-Safety Tips

- Photo of the day: Generator Safety

- Photo of the day: Controlling COVID-19 in the Workplace-Physical Barriers

- Photo of the day: Manual Material handling

- Photo of the day: Personal Protective Equipment last resort

- Photo of the day: WHMIS 2015 – Pictograms

- Photo of the day: Indoor Air Quality

- Photo of the day: Noise in the affected workplace

- Photo of the day: Fatigue at Work

- Photo of the day: Don’t be Driven to Distraction

- Photo of the day: working in heat and Humidex Rating

- How to use Plate Clamps Safely: Safety Moment#34

- Photo of the day: Sitting at work

- Photo of the day: 5 ways to reduce the risk of Slipping and Tripping

- Photo of the day: Preventing the spread of contagious illness

- Photo of the day: Incident Investigations

- Photo of the day: 10 Scaffold Safety Essentials

- Photo of the day: Effective Health and Safety Committees

- Photo of the day: New worker Orientation & Safety Orientation checklist

- Photo of the day: Workplace Inspection

- Photo of the day: musculoskeletal disorders

- Photo of the day: Emergency preparedness in the workplace

- Photo of the day: Mental health in the workplace

- Photo of the day: Trenching Safety Tips That Can Save a Life