Mobile Cranes: Basic Terms You Should Know

12 min readCranes vary in all shapes and sizes. From tower cranes that are used to construct high-rise buildings to overhead cranes utilized in factories and manufacturing, and each one in-between, every piece of equipment has its own unique characteristics, features, lifting capacities, and transportation needs.

Even if you are new to cranes and construction, you’ve probably seen a mobile crane in action or at least driven past one on the highway as it’s being transported to a Jobsite.

In this article, we’re going to talk about mobile cranes, breaking them down:

- Types of Mobile Cranes

- A Glossary of Mobile and Locomotive Crane Parts

- Governing Bodies and Standards

Types of Mobile Cranes

- Commercial Truck-Mounted

- Wheel-Mounted (Multiple Control Stations)

- Wheel-Mounted (Single Control Station)

- Rough Terrain

- All-Terrain

- Locomotive

- Carry Deck

Commercial Truck-Mounted Cranes

According to the American Society of Mechanical Engineers (ASME) B30.5 Mobile and Locomotive Cranes Standard, a Commercial Truck-Mounted Crane consist of a rotating superstructure, boom, operating machinery, and one or more operator’s stations mounted on the frame attached to a commercial truck chassis, usually retaining a payload hauling capability whose power source usually powers the crane. Its function is to lift, lower, and swing loads at various radii.

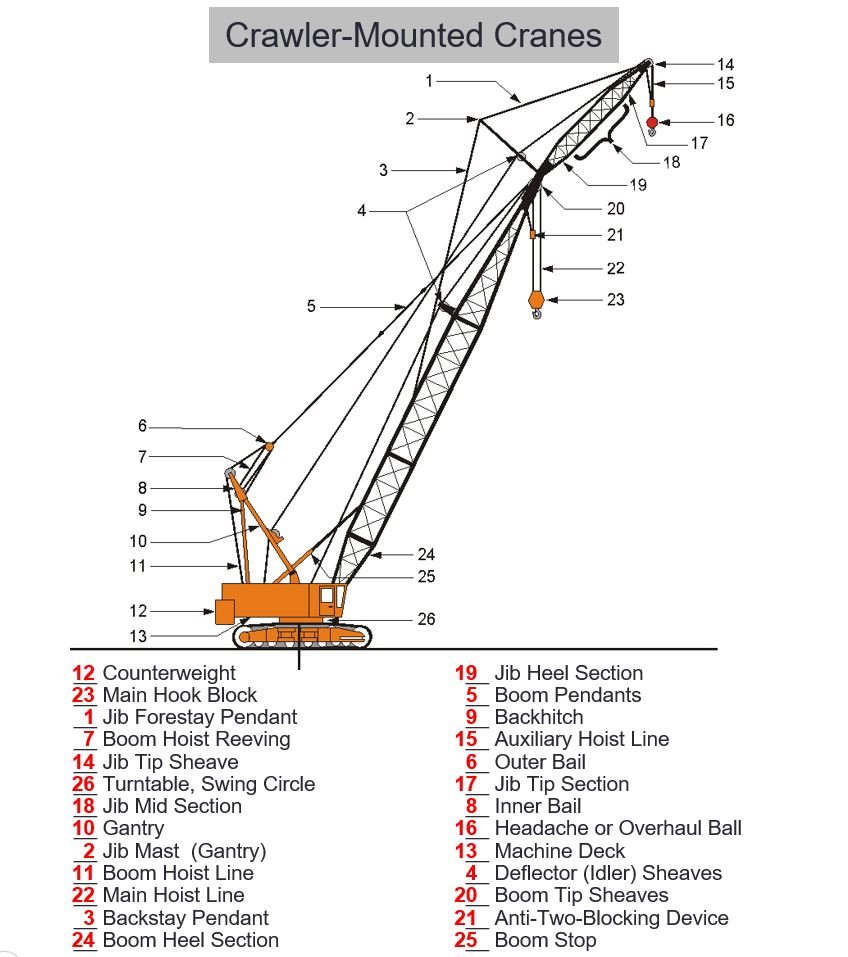

Crawler Cranes

Crawler cranes, also known as lattice cranes, boom lattice cranes, lattice crawlers, telescopic crawlers, etc. – are the largest of the mobile cranes. These are heavy-duty cranes that utilize “tank-like” treads to move throughout a construction site and can lift in excess of 2,500 tons.

Crawler cranes can lift the heaviest loads and require the most on-site assembly out of all mobile cranes. Depending on the size of the crane and weight of loads it is intended to lift, the on-site assembly may include:

- Attaching the tracks

- Assembling the lattice boom

- Addition of counterweights

Crawler cranes do not require the use of outriggers as the treads provide adequate stability. Due to their extensive on-site assembly, massive size, and treads, crawler cranes are not road-legal.

Crawler cranes may utilize a lattice boom or a telescopic boom. Those that utilize a lattice boom can lift heavier capacities at higher heights and further distances than those that utilize a telescopic boom.

Wheel-Mounted Cranes (Multiple Control Stations)

ASME B30.5 Mobile and Locomotive Cranes Standard refer to Wheel-mounted (multiple control stations) cranes as those consisting of a rotating superstructure, operating machinery, and operator’s station and boom mounted on a crane carrier equipped with axles and rubber-tired wheels for travel, a power source, and heaving stations for driving and operating. Its function is to lift, lower, and swing loads at various radii.

Wheel-Mounted Cranes (Single Control Station)

Wheel-mounted single control station cranes are those consisting of a rotating superstructure, operating machinery, and operator’s station and boom mounted on a crane carrier equipped with axles and rubber-tired wheels for travel, a power source, and heaving stations for driving and operating. Its function is to lift, lower, and swing loads at various radii.

Rough Terrain Cranes

Rough terrain cranes, also known as “RT” cranes, are a type of mobile crane designed specifically for “off-roading” in challenging environments that may include mud, snow, etc.

Rough terrain cranes are mounted on four tires and use a telescoping boom for pick and carry operations up to 165 tons. Due to their compact frame, they are good for navigating through and lifting in confined areas. RT-cranes are often applicable in instances where a crawler crane could be applied, but a lesser load capacity or navigation through confined spaces is necessary.

Because RT-cranes are mounted on an undercarriage with tires, they are easily set up and transported from site to site but are not road legal. These cranes are operated from a cab, which swivels over the undercarriage in tandem with the boom’s movement. Their on-site assembly requirements include stabilizing the crane for hoisting with the use of outriggers.

All-Terrain Cranes

An all-terrain crane is a type of mobile truck crane that can travel both on the road (at high speeds on the highway) and on most off-road surfaces. Like a large truck, these cranes have anywhere from four to 18 tires depending on the size of the crane.

A telescopic boom mounted onto the bed of the truck is used to lift and move loads. All-terrain cranes can lift much more than a rough terrain crane can—at capacities up to 1,200 tons—but are less capable of navigating in extreme environments or in confined areas.

All-terrain cranes are operated from a cab that swivels over the truck bed in tandem with the boom’s movement. The crane requires some on-site assembly as it is stabilized by outriggers and balanced by counterweights.

Locomotive Cranes

Locomotive cranes consist of a rotating superstructure with a power plant, operating machinery, and boom, mounted on a base or car equipped for travel on a railroad track. It may be self-propelled or propelled by an outside source. Its function is to lift, lower, and swing loads at various radii.

Carry Deck Cranes

A carry deck crane consists of a rotating, telescopic boom mounted to a small, flat platform with four wheels. These cranes use outriggers and tend to lift loads at around 4-10 tons. As the name suggests, these cranes carry materials throughout a site by lifting and loading them onto the deck.

Glossary of Crane Parts

***Terms as defined in the ASME B30.5 Mobile and Locomotive Cranes Standard

Accessory-A secondary part or assembly of parts that contribute to the overall function and usefulness of a machine.

Angle Indicator (Boom)-An accessory that measures the angle of the boom to the horizontal.

Anti-Two Block Device-A device that when activated, disengages all crane functions whose movement can cause two-blocking.

Auxiliary Hoist-A secondary hoist rope system used either in conjunction with or independently of, the main hoist system.

Axis of Rotation-The vertical axis around which the crane superstructure rotates.

Axle-The shaft or spindle with which or about which a wheel rotates. On wheel-mounted cranes, it refers to a type of axle assembly including housings, gearing, differential, bearings, and mounting appurtenances.

Axle (bogie)-Two or more axles mounted in tandem in a frame so as to divide the load between the axles and permit vertical oscillation of the wheels.

Ballast-Weight used to supplement the weight of the machine in providing stability for lifting working loads (normally associated with locomotive cranes).

Base (Mounting)-The traveling base on which the rotating superstructure of a locomotive or crawler crane is mounted.

Boom (Crane)-A member hinged to the rotating superstructure and used for supporting the hoisting tackle.

Boom Angle-The angle above or below horizontal of the longitudinal axis of the base boom section.

Boom Hoist Mechanism-Means for supporting the boom and controlling the boom angle.

Boom Point-The outer extremity of the crane boom, containing the hoist sheave assembly.

Boom Point Sheave Assembly-An assembly of sheaves and pin built as an integral part of the boom point.

Boom Stop-A device used to limit the angle of the boom at the highest recommended position.

Brake-A device used for slowing or stopping motion.

Cab-A housing that covers the rotating superstructure machinery or the operator’s or driver’s station.

Clutch-A means for engagement or disengagement of power.

Commercial Truck Vehicle-A commercial motor vehicle designed primarily for the transportation of property in connection with business and industry.

Counterweight-Weight used to supplement the weight of the machine in providing stability for lifting working loads.

Crane Carrier-The undercarriage of a wheel-mounted crane specifically designed for transporting the rotating crane superstructure. It may or may not provide its own travel mechanism. It is distinguished from a commercial truck vehicle in that it is not designed to transport personnel, materials, or equipment other than the crane-rotating superstructure.

Cross-Over Points-In multiple-layer spooling of rope on a drum, those points of rope contact where the rope crosses the preceding rope layer.

Designated Person-A personal selected or assigned by the employer or the employer’s representative as being competent to perform specific duties.

Drum-The cylindrical member around which a rope is wound for lifting and lowering the load or boom.

Dynamic (Loading)-Loads introduced into the machine or its components due to accelerating or decelerating forces.

Flange Point-A point of contact between rope and drum flange where the rope changes layers.

Gantry (A-Frame)-A structural frame, extending above the superstructure, to which the boom support ropes are reeved.

Hoist Mechanism-A hoist drum and rope reeving system used for lifting and lowering loads.

Jib-An extension attached to the boom point to provide added boom length for lifting specified loads. The jib may be in line with the boom or offset to various angles in the vertical plane of the boom.

Jib Backstop-A device that will restrain the jib from turning over backward.

Jobsite-Work area defined by the construction contract.

Load (Working)-The external load in pounds (kilograms) applied to the crane, including the weight of load-attaching equipment such as lower load block, shackles, and slings.

Load Block, Lower-The assembly of hook or shackle, swivel, sheaves, pins, and frame suspended by the hoisting ropes.

Load Block, Upper-The assembly of shackle, swivel, sheaves, pins, and frame suspended from the boom point.

Load Indicator-A device that measures the weight of the load.

Load Ratings-Crane ratings in pounds (kilograms) established by the manufacturer in accordance with Section 5-1.1 of the ASME B30.5 Mobile and Locomotive Cranes Standard.

Luffing Attachment-A front-end attachment for a mobile crane that uses an upper working boom or jib, which is capable of changing angle during operation and is mounted on top of a lower main boom. This is distinguished from a fixed jib where the operating angle cannot be changed during operation. Typically, the lower boom operating angle can also be changed.

Mast (Boom)-A-frame hinged at or near the boom hinge for use in connection with supporting a boom. The head of the mast is usually supported and raised or lowered by the boom hoist ropes.

Mast (Jib)-A-frame hinged at or near the boom point for use in connection with supporting a jib.

Normal Operating Conditions (Cab- or Station-Operated Cranes)-Conditions during which a crane is performing functions within the manufacturer’s operating recommendations. Under these conditions, the operator is at the operating control devices on the crane. No other persons, except those appointed, are to be on the crane.

Normal Operating Conditions (Ground- or Floor-Operated Cranes)-Conditions during which a crane is performing functions within the manufacturer’s operating recommendations. Under these conditions, the operator is at the operating control devices mounted to the crane but operated with the operator of the crane. No other persons, except those appointed, are to be on the crane.

Normal Operating Conditions (Remote-Operated Cranes)-Conditions during which a crane is performing functions within the manufacturer’s operating recommendations. Under these conditions, the operator is at the operating control devices that are not mounted to any part of the crane. No other persons, except those appointed, are to be on the crane.

Operational Aid-An accessory that provides information to facilitate the operation of a crane or that takes control of particular functions without the action of the operator when a limiting condition is sensed.

Examples of such devices include, but are not limited to, the following: anti-two-block device, rated capacity indicator, rated capacity (load) limiter, boom angle or radius indicator, lattice boom hoist disconnect device, boom length indicator, crane level indicator, drum rotation indicator, load indicator, and wind speed indicator.

Outriggers-Extendable or fixed members attached to the mounting base, which rest on supports at the outer ends used to support the crane.

Pawl (Dog)-A device for positively holding a member against motion in one or more directions.

Payload-The load or loads being transported by the commercial truck chassis from place to place.

Pendant-A rope or strand of a specified length with fixed end connections.

Power-Controlled Lowering-A system or device in the power train, other than the load hoist brake, that can control the lowering rate of speed of the load hoist mechanism.

Qualified Person-A person who, by possession of a recognized degree in an applicable field or certificate of professional standing, or who, by extensive knowledge, training, and experience, has successfully demonstrated the ability to solve or resolve problems relating to the subject matter and work.

Rail Clamp-A tong-like metal device mounted on a locomotive crane car, which can be connected to the track.

Rated Capacity Indicator-A device that automatically monitors radius, load weight, and load rating, and warns the crane operator of an overload condition.

Rated Capacity (Load) Limiter-A device that automatically monitors radius, load weight, and load rating and prevents movements of the crane, which would result in an overload condition.

Reeving-A rope system in which the rope travels around drums and sheaves.

Repetitive Pickup Point-When operating on a short cycle operation, the rope being used on a single layer and being spooled repetitively over a short portion of the drum.

Rope-Refers to wire rope unless otherwise specified.

Rotation-Resistant Rope-A wire rope consisting of an inner layer of strand laid in one direction covered by a layer of strand laid in the opposite direction. This has the effect of counteracting torque by reducing the tendency of the finished rope to rotate.

Running rope-A rope that travels around sheaves or drums.

Shall-The term used to indicate that the rule is mandatory and must be followed.

Should-The term used to indicate that the rule is a recommendation, the advisability of which depends on the facts in each situation.

Side Loading-A load applied to an angle to the vertical plane of the boom.

Stabilizer-Extendable or fixed members attached to the mounting base to increase the stability of the crane, but that may not have the capability of relieving all of the weight from wheels or tracks.

Standby Crane-A crane that is not in regular service but that is used occasionally or intermittently as required.

Standing (Guy) Rope-A supporting rope that maintains a constant distance between the points of attachment to the two components connected by the rope.

Structural Competence-The ability of the machine and its components to withstand the stresses imposed by applied loads.

Superstructure-The rotating upper frame structure of the machine and the operating machinery mounted thereon.

Swing-Rotation of the superstructure for movement of loads in a horizontal direction about the axis of rotation.

Swing Mechanism-The machinery involved in providing rotation of the superstructure.

Swivel-A load-carrying member with thrust bearings to permit rotation under load in a plane perpendicular to the direction of the load.

Swiveling-The rotation of the load attachment portion (hook or shackle) of a load block (lower) or hook assembly about its axis of suspension in relation to the load line(s).

Tackle-An assembly of ropes and sheaves arranged for lifting, lowering, or pulling.

Telescoping Boom-Consists of a base boom from which one or more boom sections are telescoped for additional length.

Transit-The moving or transporting of a crane from one Jobsite to another.

Travel-The function of the machine moving under its own power from one location to another on a Jobsite.

Two-Block Damage Prevention Feature-A system that will stall when two-blocking occurs without causing damage to the hoist rope or crane machinery components.

Two-Block Warning Feature-A warning device to alert the operator of an impending two-blocking condition.

Two-Blocking-The condition in which the lower load block or hook assembly comes in contact with the upper load block or boom point sheave assembly.

Wheel Base-The distance between centers of the front and rear axles. For a multiple-axle assembly, the axle center for wheel base measurement is taken as the midpoint of the assembly.

Whipline (Runner or Auxiliary)-A secondary rope system usually of lighter load capacity than that provided by the main rope system.

Winch Head-A power-driven spool for handling loads by means of friction between fiber or wire rope and the spool.

Governing Bodies and Standards

OSHA-The Occupational Safety and Health Administration, which publishes federal standards and general safety requirements for a wide range of industries. Their rules are enforced through fines and penalties.

ASME-The American Society of Mechanical Engineers. This organization publishes more detailed/current standards than OSHA. Often referenced by OSHA.

ANSI-The American National Standards Institutes. ANSI is a private organization that works within practically every industry to provide a general framework for fair standards development and quality conformity assessment systems.

Manufacturers Recommendations-Specific information on the use, care, inspection, and maintenance of the product developed by the actual manufacturer. Often referenced by OSHA.

Company Rules and Guidelines-Safety rules developed by your employer specific to their needs.

1 thought on “Mobile Cranes: Basic Terms You Should Know”