The United Nations (UN) adopted the Globally Harmonized System of Classification and Labeling of Chemicals (GHS) in 2003. The GHS includes criteria for the classification of health, physical and environmental hazards, as well as specifying what information should be included on labels ( container Labels) and safety data sheets of hazardous chemicals.

Since that time, GHS has been and continues to be adopted and implemented transitionally around the globe.

The Hazard Communication Standard (HCS) describes chemical labels as information provided through a group of written, printed, or graphic appropriate elements concerning a hazardous chemical. These should be placed on the immediate container of a hazardous chemical. The Hazard Communication Standard also is now known as the Right to Understand Standard, requires chemical manufacturers, importers, or distributors to ensure that each container of hazardous chemicals is labeled, tagged, or marked. Employers also have a responsibility for labeling and ensuring employees are trained on hazardous chemicals. in the photo of today, you will be familiar with

- Chemical containers with GHSC Labels

- Immediate Use Container Labels

- GHS Labels for Primary Containers

- GHS Labels for Secondary Containers

- Workers Responsiablities in Container Labeling

Employer Labeling Responsiabilities

Employers are responsible for maintaining the labels on containers, including, but not limited to tanks, totes, and drums. This means that labels must be maintained on chemicals in a manner that continues to be legible and the pertinent information (such as the hazards and directions for use) does not get defaced or removed in any way. If the label is lost, damaged, or becomes illegible, it is the responsibility of the employer to relabel items immediately.

Additionally, if an employer is aware of newly-identified hazards that are not disclosed on a label, the employer must ensure that the workers are aware, through training, of the associated hazards.

( Know more about Hazard Communication )

OSHA Work Place Lables

OSHA has not changed the general requirements for workplace labeling, but it updated the requirements for labeling hazardous chemicals under its Hazard Communication Standard (HCS). Here are some of the key requirements to be aware of:

- All labels must have pictograms, a signal word, hazard and precautionary statements, the product identifier, and supplier identification.

- Workplace labels must be provided in English.

- Other languages should be added to the label if applicable or necessary.

Employers may use additional instructional symbols that are not included in OSHA’s HCS pictograms on the workplace labels. An example of an instructional pictogram is a person with goggles, denoting that goggles must be worn while handling the given chemical. Including both types of pictograms in the workplace, labels are acceptable.

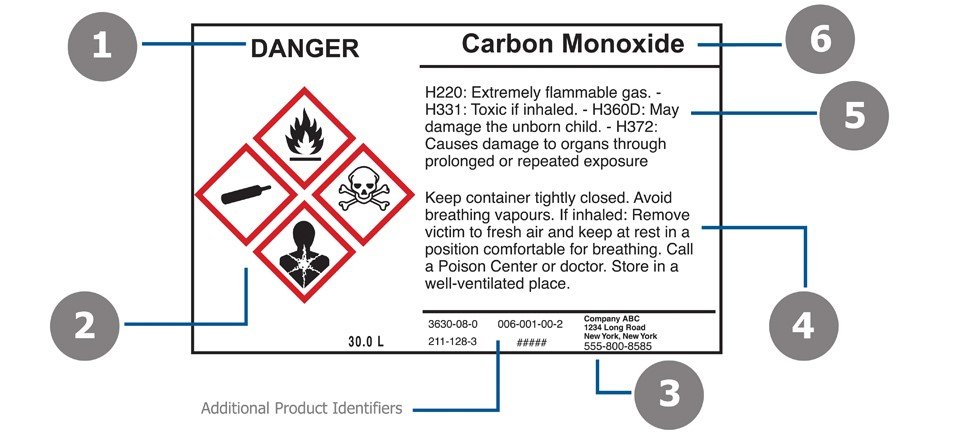

Labeling is the cornerstone of GHS compliance. With an emphasis on consistency and comprehension of chemical labels, it is important to know what goes into a GHS compliant label for primary and secondary containers. There are six key GHS label elements that you need to know.

- Signal WordThe signal word indicates hazard level. “Danger” is used for the most severe instances, while “Warning” is less severe.

- GHS Symbols (Hazard Pictograms)These pictograms are used to identify hazardous products and are commonly grouped by chemical / physical risk, health risk and environmental risk. View our GHS pictogram guide.

- Manufacturer InformationThis identifies the manufacturer’s company name, address and telephone number.

- Precautionary Statements / First AidThese are phrases that are tied to each hazard statement. They describe general preventive, response, storage or disposal precautions. These statements are found on the chemical’s Safety Data Sheet. Similar to Hazard Statements, Precautionary Statements can be identified by a P-Code (like P100).

- Hazard StatementsThese are phrases that describe the nature of hazardous products and the degree of hazard. Hazard statements are on the chemical’s Safety Data Sheet (SDS) and identified by an H-Code (like H100).

- Product Name or IdentifiersThis identifies the product or chemical name. Additional identifiers can be noted to the right of the Manufacturer’s information (#1).

6 Tips to Ensure GHS Compliance for Smaller, Down-Packed Chemical

Primary vs. Secondary Container Labels

GHS Labels for Primary Containers

Primary chemical containers are the bags, barrels, bottles, boxes, cans, cylinders, and drums that you receive from the manufacturer. These containers should be labeled following the GHS mandates per the GHS label example above and include all six labeling elements.

When a label is on a container directly from a supplier, this label cannot be removed, altered, or defaced. If it needs to be replaced, the new label must contain the same information as the original.

GHS Labels for Secondary Containers

Secondary containers are usually smaller than primary containers and could include spray bottles, jugs, or jars. These containers usually hold chemicals that are transferred from a primary container. GHS labels for secondary containers must comply with labeling requirements except when the following criteria are met:

- The material is used within the work shift of the individual who makes the transfer

- The worker who made the transfer is in the work area the entire time during use

- The container stays within the work area and in the possession of the worker who filled the container

For secondary containers that come with pre-printed labels, OSHA states that those labels will suffice if the container is used within the same shift and by the same worker. The worker also must retain possession of the container the entire time it is in use. Otherwise, employers should follow the labeling standards outlined above.

If an employer transfers hazardous chemicals from a labeled container to a portable secondary container that is only intended for immediate use by the employee who performs the transfer, no labels are required for the portable container. If the employee will not have direct control of the transferred chemical until it is exhausted, then the container must contain a label to warn other employees what the contents are. A labeled container is not a replacement for having the appropriate SDS available to the employee.

Used drink or food containers are not to be used for secondary containers since the chemical may react with the leftover residue, or employees may think what is on the label is what is in the container (i.e. sports drink) and could accidentally consume the liquid. Only use the containers provided by your employer and follow their labeling practices.

Note: OSHA has not changed the general requirements for secondary container labeling specifically. Employers have the option to create their own workplace labels by using all of the information provided by the manufacturer or using a combination of the label elements, specific to the hazards of the chemicals, from the above GHS label example.

Workers Responsiablities in Container Labeling

While the bulk of container labeling responsibilities falls upon the employer, employees do still have some responsibilities. These include:

- Employees must participate in training.

- Employees must report chemical containers with missing or damaged labeling to the employer.

- Employees should not use chemicals that are not labeled appropriately.

- Employees should not use chemicals that they have not received hazard communication training.

Conclusion

All containers of chemicals must be labeled. There are various types of labels that are used to inform people about chemicals and their hazards.

Adoption of the Globally Harmonized System for Classification and Labeling of Chemicals (GHS) by countries all over the globe has or will lead to new standardized label information to be used by chemical manufacturers and distributors.

More information on your country’s requirements and site labeling system will be provided in other chapters of this course and/or during site-level training.

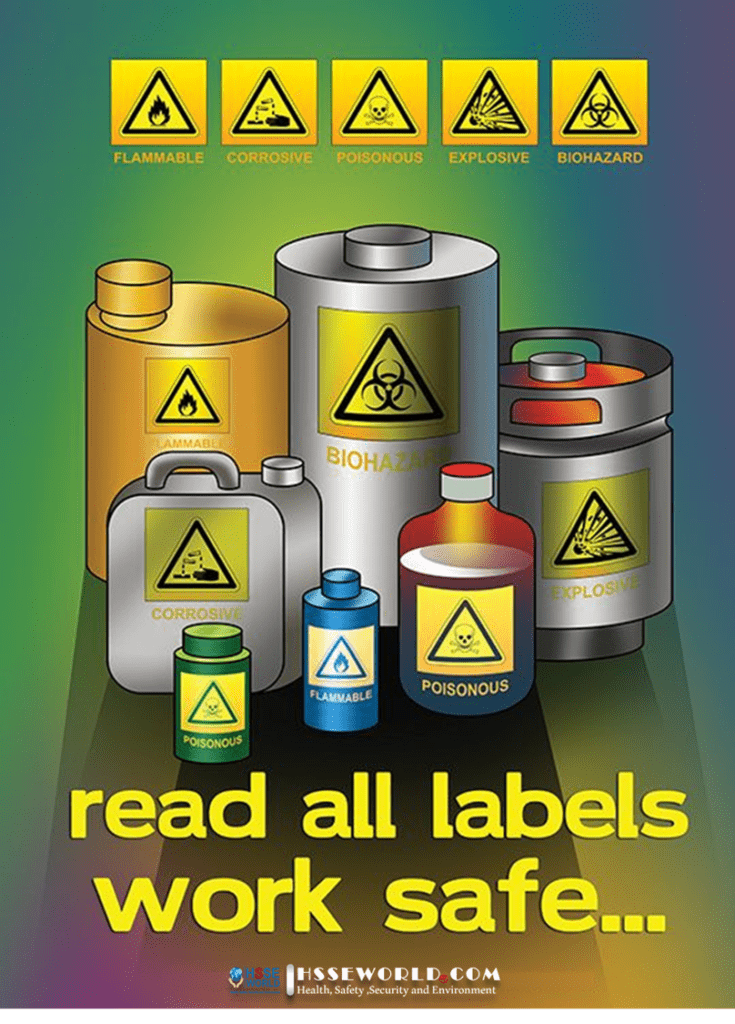

Now you can download the Infographic ” Read all labels work safe” and post it at the workplace to be communicated with workers

Spill Containment and Spill Prevention and Control Countermeasures

Download the infographic

Read All Labels work Safe

More Photos

- What are the Best Practices for Managing Subcontractor Risk

- Photo of the day: 10 Essential Safety Tips for Driving in Hot Weather Conditions

- Photo of the day: best workplace safety tips

- Photo of the day: The Importance of Stop Work Authority in Maintaining Workplace Safety

- Photo of the day: Tomorrow’s Reward for Working Safely Today: Cultivating a Culture of Safety

- Photo of the day: Preventing slips and trips at work

- Photo of the day: Learn the DRSABCD action Plan

- Working with Electricity Electrical Accidents Guide for Electrical Workers

- Photo of the day: Hearing Protection Device Selection

- Photo of the day: If An Earthquake Shakes You-Infographic free

- Fire Safety Posters Free Download

- Photo of the day: First Aid for Electrical Burns-Infographic free

- Infographic: First Aid for Cuts and Scrapes free download

- Photo of The day: Work Safe with Lasers-Laser Safety free

- Photo of the day: Working Safely with chemicals and chemical Management

- Photo of the day: Safe work practices when using MEWPs ( updated)

- Photo of the day: Preventing Common Kitchen Hazards

- Photo of the day: Safe handling of Gas Cylinders and lecture bottles

- Photo of the day: Forklift Stability Triangle

- Photo of the day: Defective Tools Safe Work Practice

- Photo of the day: Lift With Your Legs Not With Your Back

- Photo of the day: First Aid for burns

- Photo of the day: The 7 Principles of HACCP

- Photo of the day: Working Safely with Suspended Loads

- Photo of the day: Heat Stroke First Aid and safety posters

- Photo of the day: Near-Miss Reporting and Posters

- Photo of the day: Ergonomic chair and office chair safety tips

- Photo of the day: Whole Body Vibration

- Photo of the day: Substation Safety Equipment

- Photo of the day: Bypassing Safety Controls Rules

- Photo of the day: Lightning Safety Tips

- Photo of the day: Overhead Power lines Clearance

- Photo of the day: Floor Marking

- Photo of the day: Types of Foot Protection

- Photo of the day: Types of Hand Protection

- Photo of the day: Lockout and Tagout Safety

- Photo of the day: Fall Protection Plans

- Photo of the day: Flood Safety Tips

- Photo of the day: Read All Labels Work safe

- Photo of the day: Run Project safely with Crane Hand Signals

- Photo of the day: Flagman and Traffic control

- Photo of the day: Managing Risks of Exposure to Solvents in the workplace

- Photo of the day: Scissor Lift Safety

- Photo of the day: HSE Bulletin Board

- Photo of the day: Arc-Fault Circuit Interrupters (AFCI)

- Photo of the day: Safe use of ladders and step ladders

- Photo of the day: Concrete Truck Driver Hand Signals

- Photo of the day: Extension Cord Safety Tips

- Photo of the day: Protect your Head

- Photo of the day: choosing the right Anchorage

- Photo of the day: Work-Related Asthma

- Photo of the day: Top FIVE Heavy Equipment Construction Site Safety Tips

- Photo of the day: sun safety in the workplace

- Photo of the day: Cannabis and Impairment in the Workplace

- Photo of the day: Position for safety and comfort-Safety Tips

- Photo of the day: Generator Safety

- Photo of the day: Controlling COVID-19 in the Workplace-Physical Barriers

- Photo of the day: Manual Material handling

- Photo of the day: Personal Protective Equipment last resort

- Photo of the day: WHMIS 2015 – Pictograms

- Photo of the day: Indoor Air Quality

- Photo of the day: Noise in the affected workplace

- Photo of the day: Fatigue at Work

- Photo of the day: Don’t be Driven to Distraction

- Photo of the day: working in heat and Humidex Rating

- How to use Plate Clamps Safely: Safety Moment#34

- Photo of the day: Sitting at work

- Photo of the day: 5 ways to reduce the risk of Slipping and Tripping

- Photo of the day: Preventing the spread of contagious illness

- Photo of the day: Incident Investigations

- Photo of the day: 10 Scaffold Safety Essentials

- Photo of the day: Effective Health and Safety Committees

- Photo of the day: New worker Orientation & Safety Orientation checklist

- Photo of the day: Workplace Inspection

- Photo of the day: musculoskeletal disorders

- Photo of the day: Emergency preparedness in the workplace

- Photo of the day: Mental health in the workplace

- Photo of the day: Trenching Safety Tips That Can Save a Life