Photo of the day: Fall Protection Plans

10 min readFalls are the top workplace danger as recorded by insurance companies and government regulators. Fall protection plans are designed to ensure the safety of employees so as to prevent falls from heights at the workplace. A fall protection plan shows the reason why conventional fall protection cannot, or should not be used in some places. It is prepared, altered, approved, and implemented only by qualified persons. A copy of this plan should be kept ready and at hand at the job site.

In the photo of the day, complete guidance and Modal Template ( Free download ) on how to develop or enhance site-specific fall protection plans which usually included but are not limited to :

- Identifying hazards

- Methods to be used in prevention

- Engineering Controls – moving the task to ground level, using mechanical devices to reach an area or use remote-sensing equipment

- Use of guardrails – made from steel, wood, and wire rope at open-sided floors, excavations or pits and on leading edges of roofs or mezzanines

- Warning signs and lines – warnings and safe working boundary lines

- Personal fall protection systems – safety harness, body belts, retractable lanyards and ropes

- Correct procedures to be used including adequacy of attachment points

- Alternative methods and procedures

- Prompt and safe evacuation of an injured person and treatment in an emergency

General

This guidance is to Prevent Falls in Construction to provide companies with guidance on how to develop or enhance their site-specific fall protection plans. While OSHA only requires written fall protection plans for employees engaged in leading-edge work, precast concrete erection work, or residential construction work who can demonstrate that it is infeasible or it creates a greater hazard to use conventional fall protection equipment (See 1926.501(b)(2), (b)(12), and (b)(13)), We believe that developing and implementing a detailed fall protection plan is essential to protect all workers at risk for a fall. We encourage you to use any and all sections that are applicable to your Jobsite(s) as follows.

1- JOBSITE/BUILDING DETAILS

Use the following page to sketch and note the important details of the Jobsite. Be sure to consider:

• Type of Jobsite or building (e.g. two-story residential home, commercial high-rise, highway work)

• Type of work being done (e.g. framing, roofing, electrical, restoration)

• Prevention through Design measures already in place (e.g. permanent railings or permanent ladders)

• Relevant work surfaces & building materials (e.g. abrasive concrete edges, slippery floors)

• Estimated duration of job (should you consider longer-term solutions such as scaffolding vs. moveable lifts?)

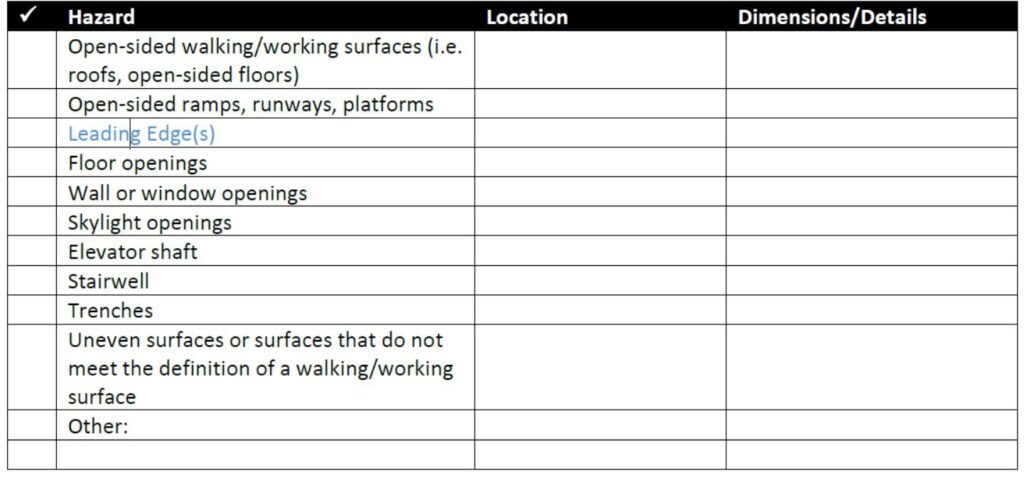

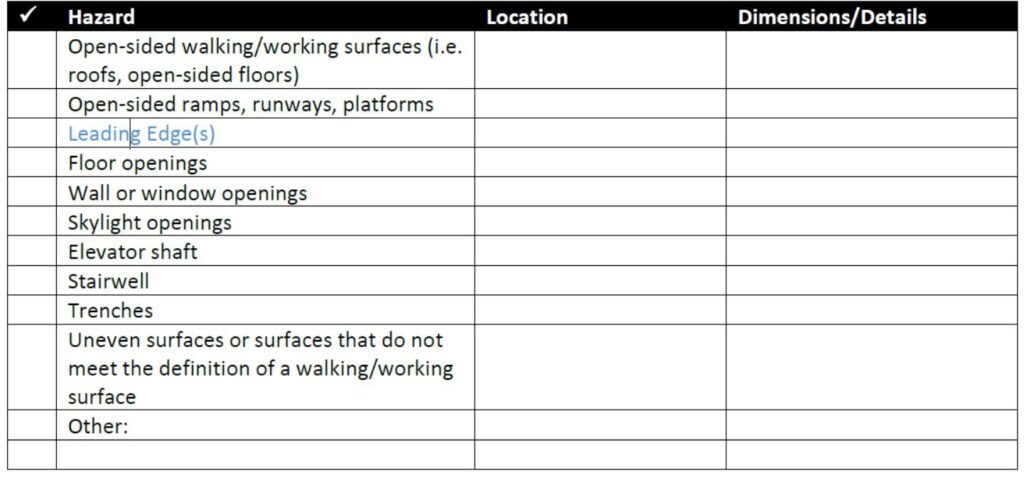

2- FALL HAZARDS IN THE WORK AREA

In the construction sector, OSHA requires fall protection for workers at heights of 6’ or more above the ground or a lower level, but slips, trips, and falls can occur at any height. In order to make this plan comprehensive and useful to everyone interested in providing a safer work environment for their employees, we have included these hazards as well.

Photo of the day: DO’S and DON’TS of Working At Heights

3- ACCESS EQUIPMENT BEING USED

This section provides space to identify the access equipment that will be used to allow workers to reach the heights necessary to conduct work (fall arrest, fall restraint, and fall protection equipment are covered in section 4). When selecting access equipment, it is important to use the right equipment for the work being performed. You may also want to consider how to access equipment that may be used for rescue in the event of a fall (see section 8). Add other equipment to the empty rows if necessary.

- Scaffolding

- Mast Climbing Scaffold(s)

- Aerial Lift(s)

- Scissor Lift(s)

- Boom Lift(s)

- Push Around Vertical/ Vehicle

- Extension Ladder(s)

- Step Ladder (s)

- Fixed Ladder (s)

- Other:

Limitations to Access Equipment:

Each type of equipment has different advantages and disadvantages. For example, while ladders may provide quick and easy access, there is a high rate of injury just from climbing up and down, and in some cases, a scaffold or lift may be safer. A competent person should carefully review all existing fall hazards and work activities, along with safe use requirements and product limitations, to ensure the best equipment is selected. List any possible limitations to the equipment you’ve selected and steps to address them below:

Assembly, Maintenance, Inspection, Disassembly Procedures:

Assembly and disassembly of all access equipment should be done according to manufacturers’ recommendations. Copies of the manufacturer’s specifications should be included in your plan for each type of equipment used. Pre-job checks should be conducted daily. Any defective equipment should be tagged and removed from use immediately. Manufacturer recommendations for maintenance and inspection should be followed. Use the following table to describe procedures for assembly, maintenance, inspection, and disassembly of access equipment to be used. Be sure to note the name of the qualified person responsible. ( Read: What is the difference between fall protection and fall prevention )

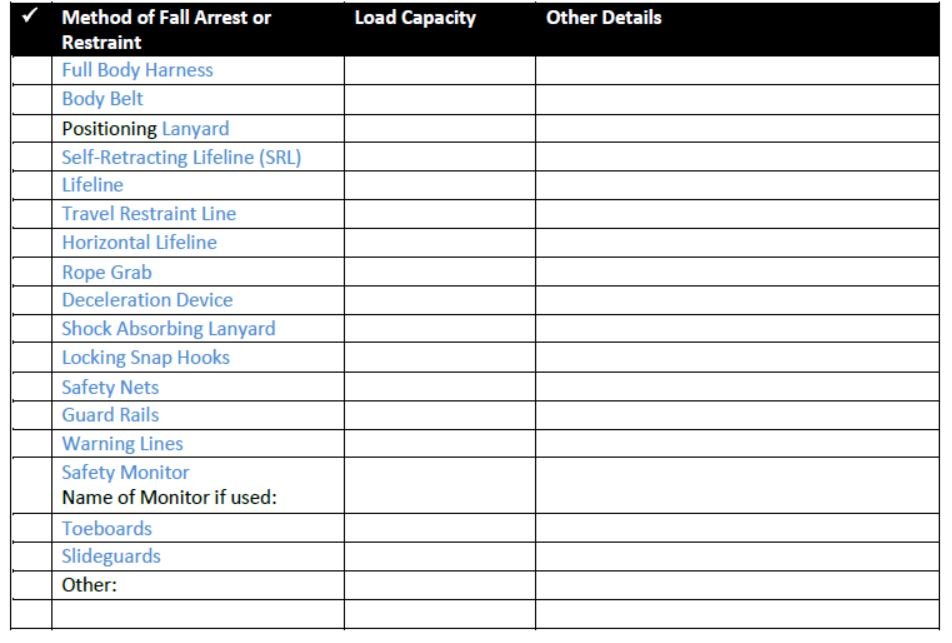

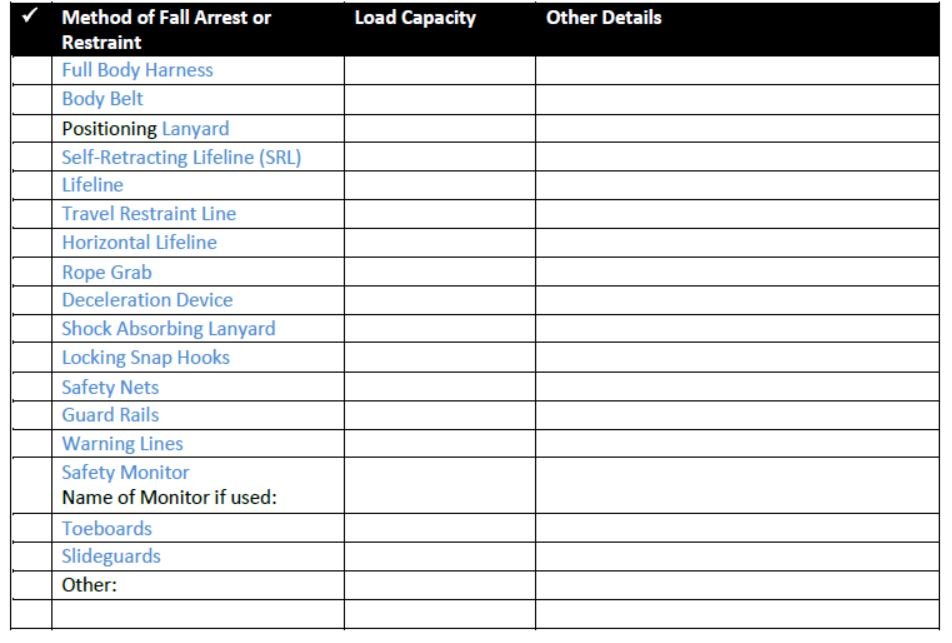

4- METHOD OF FALL ARREST OR FALL RESTRAINT

When selecting appropriate personal fall arrest or fall restraint systems, refer back to the sections above to consider factors such as building material, the height of work, and specific hazards such as leading edges. Fall arrest systems work by stopping a free fall after the fall occurs. Fall restraint systems work by preventing the fall from happening after a slip or trip. It is important not only to select the appropriate systems but to ensure that the category of equipment and materials used to construct each piece in the system are sufficient to mitigate the hazards. It is also important to consider the fall clearance distance needed – for both height and swing clearance (see infographic below; actual totals will be based on the characteristics of each worker and the equipment selected).

Check all that apply. Add other methods in blank rows if necessary. Write details such as manufacturer or location of anchorage points next to equipment when relevant.

Limitations to Fall Arrest/Restraint Equipment:

Are there any potential limitations to the system(s) selected? For example, if the length of a lanyard constantly needs to be adjusted, you may determine that an SRL is the better choice. A competent person should carefully review all existing fall hazards and work activities, along with safe use requirements and product limitations, to ensure that the best fall protection system is selected. List any potential limitations and steps to address them

Assembly, Maintenance, Inspection, Disassembly Procedures:

Assembly and disassembly of all fall arrest/restraint equipment should be done according to manufacturers’ recommendations. Copies of the manufacturer’s specifications should be included in your plan for each type of equipment used. OSHA states that personal fall arrest systems shall be inspected prior to each use for wear, damage, and other deterioration. Any defective equipment or components should be tagged and removed from service immediately. Manufacturer recommendations for maintenance and inspection should be followed.

(Download: Lifeline & Harness Inspection Guide checklist )

Use the table to describe procedures for assembly, maintenance, inspection, and disassembly of fall protection systems to be used. Be sure to note the name of the qualified person responsible.

5-OTHER MITIGATION OF FALL HAZARDS

Depending on the fall hazards you checked in Section 2, additional safety measures may be needed. For example: installing substantial covers over skylights, posting signs alerting workers to floor openings or other dangers, or instituting good housekeeping measures to keep floors and work surfaces clean and clear of debris that could contribute to slips and trips. Describe additional fall hazard mitigation plans here and/or mark them on your drawing: _______________________________________________________________________________ __________________________________________________________________________________________________________________________________________________________________________

6- PROTECTION OF NEARBY WORKERS

Handling, Storage, & Securing of Tools and Material Steps should be taken to prevent tools and materials being used at heights from falling to lower levels. Toeboards or slideguards can be installed on roofs and scaffolding at a height that will prevent tools from sliding over the edge or down the slope. Lanyards may be used to avoid dropped tools. Describe plans for handling, storage and securing: ________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

Overhead Protection

Hardhats are required on all jobsites with the exception of those that have no exposure to overhead hazards. Warning signs should be posted to caution of overhead hazards whenever present. Conditions may warrant additional protection, such as the use of debris nets. Describe planned overhead protection: _____________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

7- RESCUE PLAN(S)

Even when all steps are taken to prevent them, falls can still occur. If a worker falls, you should call Emergency Contact Number immediately, but because time is sensitive when a worker is hanging in a harness susceptible to suspension trauma (see infographic below), it is crucial to be prepared by having a detailed rescue plan. OSHA mandates that an employer provide for prompt rescue of employees or ensure that employees are able to rescue themselves. If a worker is not injured after a fall, self-rescue through devices with descent capability may be the best option. However, because some rescue situations are more complicated and injuries preventing self-rescue do occur, it is important for employers to ensure the availability of trained rescue personnel and ladders, lifts, or other rescue equipment. Once the worker is moved to a safe area, a certified individual should perform normal first aid procedures. Even if you are able to rescue the worker and they don’t seem injured, they should be examined by a medical professional.

Phone Location: __________________________________________________________________

First Aid Location: ________________________________________________________________

Individual(s) Qualified to Provide First Aid: ____________________________________________

Rescue Equipment Provided: _______________________________________________________

Location of Rescue Equipment: _____________________________________________________

Authorized (Trained) Rescuer: _______________________________________________________

Methods to be used for the removal of injured worker(s): ________________________________ _____________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

Additional Information: ___________________________________________________________ _____________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

you may intrested to Read:

Who should be responsible for rescuing fallen workers?

Rescue Someone from a Confined Space

Photo of the day: Confined Space rescue

8- WORKER TRAINING & INSTRUCTION

All new employees should be trained on the proper use of equipment and fall protection devices before they begin work, and seasoned workers should be provided with regular refresher training. This fall protection plan should be part of the training/refreshers. It should be reviewed with all employees before work begins on the job site. Fall protection equipment use should be reviewed regularly at safety meetings. For Toolbox Talks, videos, and other training resources, visit HSE Training and Tool Box Talk

Modal of Fall Protection Plans Template ( DOWNLOAD )

In this template, you can remove the company Name and put your company name, and change it to fit your Jobsite requirement

Download the infographic

Fall Protection Plan Infographic

Read When Your Job Takes You to the Edge

More Photos

- What are the Best Practices for Managing Subcontractor Risk

- Photo of the day: 10 Essential Safety Tips for Driving in Hot Weather Conditions

- Photo of the day: best workplace safety tips

- Photo of the day: The Importance of Stop Work Authority in Maintaining Workplace Safety

- Photo of the day: Tomorrow’s Reward for Working Safely Today: Cultivating a Culture of Safety

- Photo of the day: Preventing slips and trips at work

- Photo of the day: Learn the DRSABCD action Plan

- Working with Electricity Electrical Accidents Guide for Electrical Workers

- Photo of the day: Hearing Protection Device Selection

- Photo of the day: If An Earthquake Shakes You-Infographic free

- Fire Safety Posters Free Download

- Photo of the day: First Aid for Electrical Burns-Infographic free

- Infographic: First Aid for Cuts and Scrapes free download

- Photo of The day: Work Safe with Lasers-Laser Safety free

- Photo of the day: Working Safely with chemicals and chemical Management

- Photo of the day: Safe work practices when using MEWPs ( updated)

- Photo of the day: Preventing Common Kitchen Hazards

- Photo of the day: Safe handling of Gas Cylinders and lecture bottles

- Photo of the day: Forklift Stability Triangle

- Photo of the day: Defective Tools Safe Work Practice

- Photo of the day: Lift With Your Legs Not With Your Back

- Photo of the day: First Aid for burns

- Photo of the day: The 7 Principles of HACCP

- Photo of the day: Working Safely with Suspended Loads

- Photo of the day: Heat Stroke First Aid and safety posters

- Photo of the day: Near-Miss Reporting and Posters

- Photo of the day: Ergonomic chair and office chair safety tips

- Photo of the day: Whole Body Vibration

- Photo of the day: Substation Safety Equipment

- Photo of the day: Bypassing Safety Controls Rules

- Photo of the day: Lightning Safety Tips

- Photo of the day: Overhead Power lines Clearance

- Photo of the day: Floor Marking

- Photo of the day: Types of Foot Protection

- Photo of the day: Types of Hand Protection

- Photo of the day: Lockout and Tagout Safety

- Photo of the day: Fall Protection Plans

- Photo of the day: Flood Safety Tips

- Photo of the day: Read All Labels Work safe

- Photo of the day: Run Project safely with Crane Hand Signals

- Photo of the day: Flagman and Traffic control

- Photo of the day: Managing Risks of Exposure to Solvents in the workplace

- Photo of the day: Scissor Lift Safety

- Photo of the day: HSE Bulletin Board

- Photo of the day: Arc-Fault Circuit Interrupters (AFCI)

- Photo of the day: Safe use of ladders and step ladders

- Photo of the day: Concrete Truck Driver Hand Signals

- Photo of the day: Extension Cord Safety Tips

- Photo of the day: Protect your Head

- Photo of the day: choosing the right Anchorage

- Photo of the day: Work-Related Asthma

- Photo of the day: Top FIVE Heavy Equipment Construction Site Safety Tips

- Photo of the day: sun safety in the workplace

- Photo of the day: Cannabis and Impairment in the Workplace

- Photo of the day: Position for safety and comfort-Safety Tips

- Photo of the day: Generator Safety

- Photo of the day: Controlling COVID-19 in the Workplace-Physical Barriers

- Photo of the day: Manual Material handling

- Photo of the day: Personal Protective Equipment last resort

- Photo of the day: WHMIS 2015 – Pictograms

- Photo of the day: Indoor Air Quality

- Photo of the day: Noise in the affected workplace

- Photo of the day: Fatigue at Work

- Photo of the day: Don’t be Driven to Distraction

- Photo of the day: working in heat and Humidex Rating

- How to use Plate Clamps Safely: Safety Moment#34

- Photo of the day: Sitting at work

- Photo of the day: 5 ways to reduce the risk of Slipping and Tripping

- Photo of the day: Preventing the spread of contagious illness

- Photo of the day: Incident Investigations

- Photo of the day: 10 Scaffold Safety Essentials

- Photo of the day: Effective Health and Safety Committees

- Photo of the day: New worker Orientation & Safety Orientation checklist

- Photo of the day: Workplace Inspection

- Photo of the day: musculoskeletal disorders

- Photo of the day: Emergency preparedness in the workplace

- Photo of the day: Mental health in the workplace

- Photo of the day: Trenching Safety Tips That Can Save a Life