Scaffold Safety self Audit and checklist

16 min readThe purpose of this Scaffold checklist is two-fold: 1) to answer questions to help employers and employees understand the requirements to protect employees who use scaffolds, and 2) to provide employers with a self-audit tool to ensure their company complies with the Occupational Safety and Health Administration (OSHA) General Requirements for Scaffolds in Title 29 Code of Federal Regulations (CFR) 1926.451.

Scaffolding hazards continue to rank high on the list of OSHA’s most frequently cited standards in the construction industry. Each year, scaffold-related incidents account for a significant number of work-related injuries and deaths.

This Article is organized in a question-and-answer format followed by a checklist to highlight information that employers and employees need to know to prevent scaffold accidents. The subjects addressed to follow the basic organization of the standard and are followed by the regulatory text where that particular information can be located. An attached appendix is also included to provide an alphabetical list of definitions related to the scaffold standard for quick reference.

And provides an overview of the standard and OSHA’s rules outlined in Safety Standards for Scaffolds in the Construction Industry. It is not intended to supersede requirements in the standard or in the Occupational Safety and Health Act of 1970. For compliance with all of the standard’s requirements, refer to the regulatory text in 29 CFR 1926, Subpart L

General Requirements for Scaffolds Questions & Answers

OSHA defines a:

- competent person as “one who is capable of identifying existing and predictable hazards in the surrounding or working conditions which are unsanitary, hazardous, or dangerous to employees, and who has authorization to take prompt corrective measures to eliminate them,” [1926/32(f)]; and a

- the qualified person as “one who by possession of a recognized degree, certificate, or professional standing, or who by extensive knowledge, training, and experience has successfully demonstrated his/her ability to solve or resolve problems related to the subject matter, the work, or the project,” [1926.32(m)].

Also Read: Photo of the day: 10 Scaffold Safety Essentials

Capacity

Q. What are the capacity requirements for all scaffolds?

A. Each scaffold and scaffold component must support without failure its own weight and at least four times the maximum intended load applied or transmitted to it [29 CFR 1926.451(a) (1)]. A qualified person must design the scaffolds, which are loaded in accordance with that design [29 CFR 1926.451(a)(6)]. Scaffolds and scaffold components must not be loaded in excess of their intended loads or rated capacities, whichever is less [29 CFR 1926.451(f)(1)]. Load-carrying timber members should be a minimum of 1,500 pound-force/square inch construction grade lumber [29 CFR 1926 Subpart L Appendix A(1)(a)].maximum

Scaffold Platform Construction

Q. What are the requirements for constructing scaffold platforms?

A. Each platform must be planked and decked as fully as possible with the space between the platform and uprights not more than 1 inch (2.5 cm) wide. The space must not exceed 9½ inches (24.1 cm) when side brackets or odd-shaped structures result in a wider opening between the platform and the uprights [29 CFR 1926.451(b)(1)].

Q. What are the requirements for scaffold planking?

A. Scaffold planking must be able to support, without failure, its own weight and at least four times the intended load [29 CFR 1926.451(a)(1)]. Solid sawn wood, fabricated planks, and fabricated platforms may be used as scaffold planks following the recommendations by the manufacturer, a lumber grading association, or an inspection agency [29 CFR 1926 Subpart L Appendix A(1)(b) & (c)]. Tables showing maximum permissible spans rated load capacity, and nominal thickness are in 29 CFR 1926 Subpart L Appendix A(1)(b) & (c) of the standard.

Q. What is the maximum deflection of a platform?

A. The platform must not deflect more than 1/60 of the span when loaded [29 CFR 1926.451(f)(16)].

Q. What are the requirements for work on platforms cluttered with debris?

A. The standard prohibits work on platforms cluttered with debris [29 CFR 1926.451(f) (13)].

Q. How wide does the work area need to be on scaffolding?

A. Each scaffold platform and walkway must be at least 18 inches (46 cm) wide. Guardrails or personal fall arrest systems must be used [29 CFR 1926.451(b)(2)].

Q. Are guardrails required on all open sides of scaffolding?

A. The standard requires employers to protect each employee on a scaffold more than 10 feet (3.1 m) above a lower level from falling to that lower level [29 CFR 1926.451(g)(1)].

To ensure adequate protection, install guardrails along all open sides and ends before releasing the scaffold for use by employees, other than the erection and dismantling crews [29 CFR 1926.451(g)(4) (i)]. Guardrails are not required, however:

- when the front end of all platforms is less than 14 inches (36 cm) from the face of the work [29 CFR 1926.451(b)(3)];

- when outrigger scaffolds are 3 inches (8 cm) or less from the front edge [29 CFR 1926.451(b)(3)(i)]; and

- when employees are plastering and lathing 18 inches (46 cm) or less from the front edge [29 CFR 1926.451(b)(3) (ii)].

Q. What materials are unacceptable for guardrails?

A. Steel or plastic banding must not be used as a toprail or a midrail [29 CFR 1926.451(g)(4)(xiii)].

Criteria for Supported Scaffolds

Q. What are supported scaffolds?

A. Supported scaffolds are platforms supported by legs, outrigger beams, brackets, poles, frames, or similar rigid support [29 CFR 1926.450(b)]. The structural members poles, legs, posts, frames, and uprights must be plumbed and braced to prevent swaying and displacement [29 CFR 1926.451(c)(3)].

Q. Do employees working on supported scaffolds need to be trained?

A. All employees must be trained by a qualified person to recognize the hazards associated with the type of scaffold being used and how to control or minimize those hazards. The training must include fall hazards, falling object hazards, electrical hazards, proper use of the scaffold, and handling of materials [29 CFR 1926.454(a)].

Q. When do supported scaffolds need to be restrained from tipping?

A. Supported scaffolds with a height to base width ratio of more than 4:1 must be restrained by guying, tying, bracing, or an equivalent means [29 CFR 1926.451(c)(1)].

Q. How can one prevent supported scaffolding from tipping?

A. Either the manufacturers’ recommendation or the following placements must be used for guys, ties, and braces:

- Install guys, ties, or braces at the closest horizontal member to the 4:1 height and repeat vertically with the top restraint no further than the 4:1 height from the top.

- Vertically every 20 feet (6.1 m) or less for scaffolds less than 3 feet (0.91 m) wide or every 26 feet (7.9 m) or less for scaffolds more than 3 feet (0.91 m) wide.

- Horizontally at each end and at intervals not to exceed 30 feet (9.1 m) from one end [29 CFR 1926.451(c) (1)].

Q. What are the footing and foundation requirements for supported scaffolds?

A. Supported scaffolds’ poles, legs, posts, frames, and uprights must bear on base plates and mud sills, or other adequate firm foundation [29 CFR 1926.451(c)(2)(i) and 29 CFR 1926.451(c)(2)(ii)].

Q. May forklifts, front-end loaders, or similar equipment support platforms?

A. Forklifts can support platforms only when the entire platform is attached to the fork and the fork-lift does not move horizontally when workers are on the platform [29 CFR 1926.451(c)(2)(v)].

Front-end loaders and similar equipment can support scaffold platforms only when they have been specifically designed by the manufacturer for such use [29 CFR 1926.451(c)(2)(iv)].

Also see, OSHA Standard Interpretation and Compliance Letter: 09/30/1999Forklifts in construction: Elevating personnel and operator training.

Q. What materials can be used to increase the working level height of employees on supported scaffolds?

A. Stilts may be used on a large area scaffold. When a guardrail system is used, the guardrail height must be increased in height equal to the height of the stilts. The manufacturer must approve any alterations to the stilts [29 CFR 1926.452(y)].

NOTE: A large area scaffold consists of a pole, tube, and coupler systems, or a fabricated frame scaffold erected over substantially the entire work area [29 CFR 1926.450(b)].

Criteria for Suspended Scaffolds

Q. What are suspension scaffolds?

A. A suspension scaffold contains one or more platforms suspended by ropes or other non-rigid means from an overhead structure [29 CFR 1926.450(b)] such as the following scaffolds: single-point, multi-point, multi-level, two-point, adjustable, boatswain’s chair, catenary, chimney hoist, continuous run, elevator false car, go-devils, interior hung, masons’, and stone setters’.

Q. What are the requirements for suspension scaffolds?

A. Some of the requirements for all types of suspension scaffolds include:

- Employers must ensure that all employees are trained to recognize the hazards associated with the type of scaffold being used [29 CFR 1926.454(a)].

- All support devices must rest on surfaces capable of supporting at least four times the load imposed on them by the scaffold when operating at the rated load of the hoist, or at least one-and-a-half times the load imposed on them by the scaffold at the stall capacity of the hoist, whichever is greater [29 CFR 1926.451(d)(1)].

- A competent person must evaluate all direct connections prior to use to confirm that the supporting surfaces are able to support the imposed load [29 CFR 1926.451(d)(3)(i)].

- All suspension scaffolds must be tied or otherwise secured to prevent them from swaying, as determined by a competent person [29 CFR 1926.451(d)(18)].

- Guardrails, a personal fall-arrest system, or both must protect each employee more than 10 feet (3.1 m) above a lower level from falling [29 CFR 1926.451(g)].

- A competent person must inspect ropes for defects prior to each work shift and after every occurrence that could affect a rope’s integrity [29 CFR 1926.451(d)(10)].

- When scaffold platforms are more than 24 inches (61 cm) above or below a point of access, ladders, ramps, walkways, or similar surfaces must be used [29 CFR 1926.451(e) (1)].

- When using direct access, the surface must not be more than 24 inches (61 cm) above or 14 inches (36 cm) horizontally from the surface [29 CFR 1926.451(e)(8)].

- When lanyards are connected to horizontal lifelines or structural members on single-point or two-point adjustable scaffolds, the scaffold must have additional independent support lines equal in number and strength to the suspension lines and have automatic locking devices [29 CFR 1926.451(g) (3)(iii)].

- Emergency escape and rescue devices must not be used as working platforms unless designed to function as suspension scaffolds and emergency systems [29 CFR 1926.451(d)(19)].

Q. What are the specific requirements for counterweights?

A. Counterweights used to balance adjustable suspension scaffolds must be able to resist at least four times the tipping moment imposed by the scaffold operating at either the rated load of the hoist or one-and-a-half (minimum) times the tipping moment imposed by the scaffold operating at the stall load of the hoist, whichever is greater [29 CFR 1926.451(a)(2)]. Only those items specifically designed as counterweights must be used [29 CFR 1926.451(d)(3)(iii)].

Counterweights used for suspended scaffolds must be made of materials that cannot be easily dislocated. Flowable material, such as sand or water, cannot be used [29 CFR 1926.451(d)(3)(ii)].

Counterweights must be secured by mechanical means to the outrigger beams [29 CFR 1926.451(d)(3)(iv)].

Vertical lifelines must not be fastened to counterweights [29 CFR 1926.451(g)(3)(i)].

Q. Can sand, masonry units, or rolls of roofing felt be used for counterweights?

A. No. Such materials cannot be used as counterweights [29 CFR 1926.451(d)(3)(ii) and 29 CFR 1926.451(d)(3)(iii)].

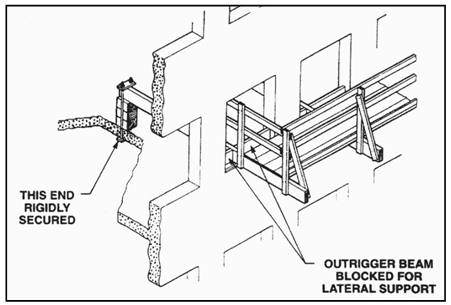

Q. Are there specific requirements for outrigger beams?

A. Outrigger beams (thrust out) are the structural members of suspension or outrigger scaffolds that provide support [29 CFR 1926.450(b)]. They must be placed perpendicular to their bearing support [29 CFR 1926.451(d)(3)(viii)].

Q. Where do tiebacks for outrigger beams, cornice hooks, roof hooks, roof irons, parapet clamps, or similar devices need to be secured?

A. Tiebacks must be secured to a structurally sound anchorage on the building or structure. Sound anchorages do not include standpipes, vents, other piping systems, or electrical conduit [29 CFR 1926.451(d)(3)(ix) and 29 CFR 1926.451(d)(5)].

Q. How do tiebacks need to be installed?

A. A single tieback must be installed perpendicular to the face of the building or structure. Two tiebacks installed at opposing angles are required when a perpendicular tieback cannot be installed [29 CFR 1926.451(d)(3)(x)].

Q. Are there requirements for suspension ropes?

A. The suspension ropes must be long enough to allow the scaffold to be lowered to the level below without the rope passing through the hoist, or the end of the rope configured to prevent the end from passing through the hoist [29 CFR 1926.451(d)(6)]. Also see, OSHA Standards and Interpretation Letter:

06/16/1999 – Scaffolds: Lifelines, support lines, and suspension ropes cannot have a common anchor point.

The standard prohibits using repaired wire [29 CFR 1926.451(d)(7)].

Drum hoists must contain no less than four wraps of the rope at the lowest point [29 CFR 1926.451(d)(6)].

Employers must replace wire rope when the following conditions exist: kinks, six randomly broken wires in one rope lay or three broken wires in one strand in one lay, one-third of the original diameter of the outside wires is lost, heat damage, evidence that the secondary brake has engaged the rope, and any other physical damage that impairs the function and strength of the rope [29 CFR 1926.451(d) (10)].

Suspension ropes supporting adjustable suspension scaffolds must be a diameter large enough to provide sufficient surface area for the functioning of brake and hoist mechanisms [29 CFR 1926.451(f) (10)].

Suspension ropes must be shielded from heat-producing processes [29 CFR 1926.451(f)(11)].

Q. What are some of the requirements for power-operated suspension scaffold hoists?

A. Power-operated hoists used to raise or lower a suspended scaffold must be tested by a qualified testing laboratory [29 CFR 1926.451(d)(13)].

The stall load of any scaffold hoist must not exceed three times its rated load [29 CFR 1926.451(a)(5)].

The stall load is the load at which the prime-mover (motor or engine) of power-operated hoist stalls or the power to the prime-mover is automatically disconnected [29 CFR 1926.450(b)].

Gasoline power-operated hoists or equipment are not permitted [29 CFR 1926.451(d)(14)].

Drum hoists must contain no less than four wraps of suspension rope at the lowest point of scaffold travel [29 CFR 1926.451(d)(6)].

Gears and brakes must be enclosed [29 CFR 1926.451(d)(15)].

An automatic braking and locking device, in addition to the operating brake, must engage when a hoist makes an instantaneous change in momentum or an accelerated Overspeed [29 CFR 1926.451(d)(16)].

Q. What are some of the requirements for manually operated suspension scaffold hoists?

A. Manually operated hoists used to raise or lower a suspended scaffold must be tested and listed by a qualified testing laboratory [29 CFR 1926.451(d)(13)].

These hoists require a positive crank force to descend [29 CFR 1926.451(d)(17)].

Q. When can welding be done from a suspension scaffold?

A. Welding can be done from suspended scaffolds when:

- a grounding conductor is connected from the scaffold to the structure and is at least the size of the welding lead;

- the grounding conductor is not attached in series with the welding process or the workpiece;

- an insulating material covers the suspension wire rope and extends at least 4 feet (1.2 m) above the hoist;

- insulated protective covers cover the hoist;

- the tail line is guided, retained, or both so that it does not become grounded; and

- each suspension rope and any other independent lines are insulated from grounding [29 CFR 1926.451(f)(17)].

Q. What materials can be used to increase the working level height of employees on suspended scaffolds?

A. No materials or devices may be used to increase the working height on a suspension scaffold. This includes ladders, boxes, and barrels [29 CFR 1926.451(f)(14) and 29 CFR 1926.451(f) (15)].

Access Requirements

Q. What are the requirements for access to scaffolds?

A. Employers must provide access when the scaffold platforms are more than 2 feet (0.6 m) above or below a point of access [29 CFR 1926.451(e)(1)].

Direct access is acceptable when the scaffold is not more than 14 inches (36 cm) horizontally and not more than 24 inches (61 cm) vertically from the other surfaces [29 CFR 1926.451(e)(8)].

The standard prohibits the use of cross braces as a means of access [29 CFR 1926.451(e)(1)].

Q. What types of access can be used?

A. Several types of access are permitted:

- ladders, such as portable, hook-on, attachable, and stairway [29 CFR 1926.451(e)(2)];

- stair towers [29 CFR 1926.451(e)(4)];

- ramps and walkways [29 CFR 1926.451(e)(5)]; and

- integral prefabricated frames [29 CFR 1926.451(e)(6)].

Q. What are the access requirements for employees erecting and dismantling supported scaffolds?

A. Effective September 2, 1997, employees erecting and dismantling supported scaffolding must have a safe means of access provided when a competent person has determined the feasibility and analyzed the site conditions [29 CFR 1926.451(e)].

Use Requirements

Q. What types of scaffolds does the standard prohibit?

A. Shore and lean-to scaffolds are strictly prohibited [29 CFR 1926.451(f)(2)].

Also, employees are prohibited from working on scaffolds covered with snow, ice, or other slippery materials, except to remove these substances [29 CFR 1926.451(f)(8)].

Q. Are there required clearance distances between scaffolds and power lines?

A. Yes. The standard requires specific clearance distances. [Review the tables listed in 29 CFR 1926.451(f)(6)].

Fall Protection Requirements

Q. What are the fall protection requirements for all scaffolds?

A. Employers must provide fall protection for each employee on a scaffold more than 10 feet (3.1 m) above a lower level [29 CFR 1926.451(g)(1)].

A competent person must determine the feasibility and safety of providing fall protection for employees erecting or dismantling supported scaffolds [29 CFR 1926.451(g)(2)].

Q. What is fall protection?

A. Fall protection includes guardrail systems and personal fall arrest systems. A personal fall-arrest system is a system used to arrest an employee in a fall from a working level. Personal fall-arrest systems include harnesses and components of the harness such as D-rings, snap hooks, lifelines, and anchorage points. (More on guardrail systems appears later in this section.) NOTE: As of January 1, 1998, subpart M states that body belts are not acceptable as part of a personal fall arrest system [29 CFR 1926.502(d)]. The use of a body belt in a tethering system or in a restraint system is acceptable and is regulated [29 CFR 1926.502(e), 29 CFR 1926.453(b)(2)(v) and 29 CFR 1926.451(g)(3)].

Vertical or horizontal lifelines may be used [29 CFR 1926.451(g)(3)(iii) and 29 CFR 1926.451(g)(3)(iv)].

When working from an aerial lift, attach the fall-arrest system to the boom or basket [29 CFR 1926.453(b)(2)(v)].

Q. How will I know what kind of fall protection to provide for a specific- type of scaffold?

A. The following chart illustrates the type of fall protection required for specific scaffolds:

Q. When can personal fall-arrest systems be used when working on scaffolding and aerial lifts?

A. Personal fall arrest systems can be used on scaffolding when there are no guardrail systems [29 CFR 1926.451(g)(1)(vii)].

Use fall-arrest systems when working from the following types of scaffolding: boatswain’s chair, catenary, float, needle beam, ladder, and pump jack [29 CFR 1926.451(g)(1)(i)].

Use fall-arrest systems also when working from the boom/basket of an aerial lift [29 CFR 1926.453(b)(2)(v)].

Also Read: The Danger of Fall Arrest Systems: Suspension Trauma

Q. When are both fall-arrest and guardrail systems required?

A. Fall-arrest and guardrail systems must be used when working on single- and two-point adjustable suspension scaffolds and self-contained adjustable scaffolds that are supported by ropes [29 CFR 1926.451(g)(1)].

Falling Object Protection

Q. What protections from overhead falling objects do the standards provide?

A. To protect employees from falling hand tools, debris, and other small objects, install toeboards, screens, guardrail systems, debris nets, catch platforms, canopy structures, or barricades. In addition, employees must wear hard hats [29 CFR 1926.451(h)(1), 29 CFR 1926.451(h)(2), and 29 CFR 1926.451(h.(3)].

Also Read: Dropped Object Consequence Calculator

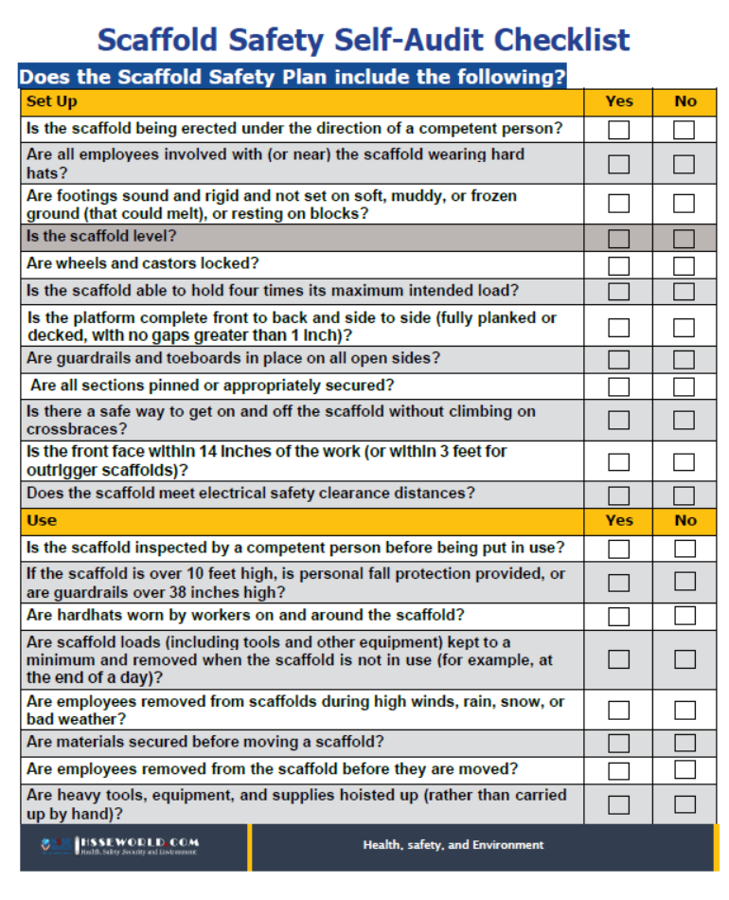

Scaffold Safety Self-Audit Checklist

Download the Checklists

Scaffold Safety self Audit and checklist

More Forms

- Downloadable Kitchen Safety Inspection Checklist for Restaurants

- Mastering LOTO: Protecting Workers with Energy Isolation and Isolation Confirmation Certificates

- Flammable and Combustible Storage Checklist Free Download

- Secure Your Lifts:Guidelines for Safe Lifting Operations Free Planning Tool

- Sample of Accident Prevention Program ( APP) Template for General Industry Free Download

- Free ISO 14001:2015 Environmental Management System Audit Checklist Download

- Guides for Walking and Working Surfaces Safety Program

- Workshop Safety Guideline and free Posters

- Free Ergonomics Checklist for General Industry

- Work Area Safety Checklist

- Machine Safety and 43-Equipment Inspection Checklists

- Scaffold Safety self Audit and checklist

- Hot Work Controls and its Permit to work Form

- Safety Observation Report Template

- Forklift Operator’s Daily Checklist and safety Tips

- Inspecting Fall Protection Equipment Forms

- Templates: HSE Incentives and rewards

- 35 Inspection forms for Rig Check

- Chemical Risk Assessment form

- 22-Safety Inspection Checklists

- Safety Task Assessment Form

- Suspended Scaffold Pre-Operation Inspection Checklist

- Photo of the day: New worker Orientation & Safety Orientation checklist

- Grating-Decking-Floor- handrail-Removal Form

- Electrical Inspection Checklists

- E-Books: Fire Safety Logbook templates

- General Safety Guidelines and Employee Acknowledgment form

- Annual Internal Audit Form

- Mobile Scaffold Inspection checklist

- Simultaneous Operation (SIMOPS) checklist

- Temporary Construction Facilities (TCF) Inspection checklist

- HIRA, HSE Hazards & Effects Management Process (HEMP) & Risk Register Template

- Hazard Identification Plan (HIP) Template

- Ladder Inspection Form

- Free Pre-Startup Safety Review Checklist (PSSR)

- Hazard Identification Checklist

- Workplace Housekeeping Checklist

- ISO 45001:2018 READINESS CHECKLIST

- Lifting Plan Audit Checklist

- Job Safety Analysis (JSA) Forms What’s Right and Wrong?

- Electrical Isolation Permit to Work forms and checklist

- Canteen Inspection Checklist

- Work at Height Checklist

- Health Safety at Work Improvement Action Plan

- Fire Pump Daily Inspection Checklist

- Construction Site Traffic Management Plan (CSTMP) Guidance

- Safety Templates: COVID-19 Safety Plan

- Workplace Safety Inspections Forms

- Lock Removal Form

- Templates: Management of Change NEW Modified Equipment Safety Checklist

- Lifeline & Harness Inspection Guide checklist

- Contractor Pre-qualification Questionnaire Checklist

- Fall safety at construction checklist

- Construction safety Inspection checklist

- Equipment Safe Operating Procedures- SOP 61 checklist

- Permit to Work (PTW ) AUDIT CHECKLIST

- Hygiene and Sanitation Inspection Checklist

1 thought on “Scaffold Safety self Audit and checklist”