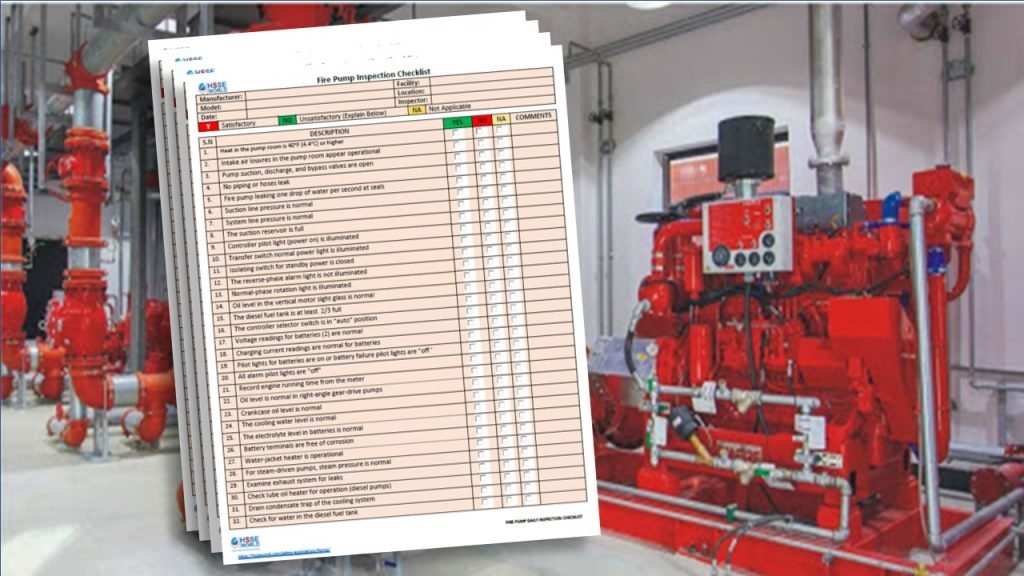

Fire Pump Daily Inspection Checklist

3 min readYour fire pump is the Heart of your fire protection System

A booster Pump Reinforces the public water supply when the public water main cannot provide the volume or pressure needed to supply an automatic sprinkler system.

A fire pump and tank with a self-contained water supply can be used either to supplement public water or as a source of water where no public supply is available

A pump Must not fail

If the water demand exceeds the capability of the public supply, or if no public water is available, the pump will need to start promptly in an emergency situation ( such as when sprinklers are activated ). So, it is essential to test your pump regularly and keep it maintained at all times. otherwise, a fire could cause severe property damage and shut down your operations.

A pump Needs constant Care

Establish a program of regular inspection, testing, and maintenance to ensure your fire pump performs its critical function during a fire.

weekly Fire Pump Test Form

Test all Fire pumps daily/weekly. using the checklist attached below and consider the following :

- Heat in the pump room is 40°F (4.4°C) or higher

- Intake air louvers in the pump room appear operational

- Pump suction, discharge, and bypass valves are open

- No piping or hoses leak

- Fire pump (FP) leaking one drop of water per second at seals

- Suction line pressure is normal

- System line pressure is normal

- The suction reservoir is full

- Controller pilot light (power on) is illuminated

- Transfer switch normal power light is illuminated

- Isolating switch for standby power is closed

- The reverse-phase alarm light is not illuminated

- Normal-phase rotation light is illuminated

- Oil level in the vertical motor sight glass is normal

- The diesel fuel tank is at least 2/3 full

- The controller selector switch is in “auto” position

- Voltage readings for batteries (2) are normal

- Charging current readings are normal for batteries

- The Pilot lights for batteries are on or battery failure pilot lights are “off ‘

- All alarm pilot lights are “off”

- Record engine running time from the meter

- Oil level is normal in right-angle gear-drive pumps

- Crankcase oil level is normal

- The cooling water level is normal

- The electrolyte level in batteries is normal

- Battery terminals are free of corrosion

- Water-jacket heater is operational

- For steam-driven pumps, steam pressure is normal

- Examine exhaust system for leaks

- Check lube oil heater for operation (diesel pumps)

- Drain condensate trap of the cooling system

- Check for water in the diesel fuel tank

Download the Form

More Forms

- Camp Inspection form

- Machines Access Control Inspection Checklists

- Lift Plan Form

- Slips,Trips and Falls checklist

- Emergency Drill Table Top meeting Form

- Emergency Drill After Action Review form

- Compressed Gas Cylinders Access Control Inspection Checklist

- Competent Person Designation form

- Contractor Weekly HSE Report Form

- Safety Inspection Form

- Incident Report Form

- Job Hazard Analysis form

- OSHA Inspection Checklist 8-Pages

- Process Safety Management (PSM) Compliance checklist

- Portable Ladder Self Inspection checklist

- Scaffold Register and Inspection Checklist

- CRANE INSPECTION REPORT

- Laboratory Inspection Checklist Form

- Electric Arc Welding and Cutting Checklist

- Crane Suspended Personnel Platform (MANBASKET) Permit

- Pressure Testing Checklist

- Hygiene and Sanitation Inspection Checklist

- Permit to Work (PTW ) AUDIT CHECKLIST

- Equipment Safe Operating Procedures- SOP 61 checklist

- Construction safety Inspection checklist

- Fall safety at construction checklist

- Contractor Pre-qualification Questionnaire Checklist

- Lifeline & Harness Inspection Guide checklist

- Templates: Management of Change NEW Modified Equipment Safety Checklist

- Lock Removal Form

- Workplace Safety Inspections Forms

- Safety Templates: COVID-19 Safety Plan

- Construction Site Traffic Management Plan (CSTMP) Guidance

- Fire Pump Daily Inspection Checklist

- Health Safety at Work Improvement Action Plan

- Work at Height Checklist

- Canteen Inspection Checklist

- Electrical Isolation Permit to Work forms and checklist

- Job Safety Analysis (JSA) Forms What’s Right and Wrong?

- Lifting Plan Audit Checklist

- ISO 45001:2018 READINESS CHECKLIST

- Workplace Housekeeping Checklist

- Hazard Identification Checklist

- Free Pre-Startup Safety Review Checklist (PSSR)

- Ladder Inspection Form

- Hazard Identification Plan (HIP) Template

- HIRA, HSE Hazards & Effects Management Process (HEMP) & Risk Register Template

- Temporary Construction Facilities (TCF) Inspection checklist

- Simultaneous Operation (SIMOPS) checklist

- Mobile Scaffold Inspection checklist

- Annual Internal Audit Form

- General Safety Guidelines and Employee Acknowledgment form

- E-Books: Fire Safety Logbook templates

- Electrical Inspection Checklists

- Grating-Decking-Floor- handrail-Removal Form

- Photo of the day: New worker Orientation & Safety Orientation checklist

- Suspended Scaffold Pre-Operation Inspection Checklist

1 thought on “Fire Pump Daily Inspection Checklist”