Hazard Identification Checklist

5 min readHazard identification is the process of detecting potential sources of harm or damage from doing a job task in a specific work area. Identifying workplace hazards is crucial to implement controls that will help ensure the safety of workers and other stakeholders. Hazard identification is part of a hazard assessment or evaluating risks associated with a hazard and taking action to remove it or reduce risks involved with it.

Every Manufacturing organization or Construction company believes that there is no task which is more important than workmen’s health and safety. In case of any job that represents a potential safety or health threat, every effort should be made to plan a better way to complete the task in a safer manner. Every procedure must be a safe procedure. Shortcuts in safe procedures by management and all the other associates should not be tolerated. If a worker observes any unsafe or unprotected exposure, which may pose a potential threat to their safety and health, he or she must inform the management immediately.

At any workplace, there are physical, chemical, biological, psychosocial, electrical, mechanical, and traffic hazards. Then there are common hazards in terms of falls from heights, falls into a depth, slips, trips, and falls; manual handling and exposure to hazardous substances. In addition to these, there are identifiable hazards like a body part striking against, being struck by, making harmful contact with an object, caught in, on, by or between objects, slip, trip or fall, abrasion from any object, reaction to any chemicals, strains from pushing, pulling, lifting, bending or twisting, etc.

At every workplace, it is required to spot hazards in all six directions like east, west, north, south, top, and bottom area.

Six Directional Hazard Identification Process is designed keeping the followings things in mind:

- What task are you about to perform?

- What tools and equipment will be used during the process?

- What mitigation or elimination steps will be taken into consideration to resolve each hazard as the task is executed?

Basically, six-directional hazards identification is a process to identify associated hazards of unsuitable or faulty materials, inadequately supported scaffold, any loose items, any kind of obstacles, liquid spills, the release of hazardous liquid or gas from pipelines, leakages from the defective components, inadequate or irregular platform area, the omission of handrails, toe boards, failure to secure loose components, faulty alterations without approval, unsecured ladder slip, misuse of tools and tackles, overloading of platforms, unsecured ladder slip, fire due to welding/gas cutting activities, falling object, falling of person, protruding nail or the sharp edge of any structure, being hit by exposed parts of structures, overhead electric lines, etc.

Implementation and monitoring of the safety management system ensure that all workmen are alert at the workplace, watching out for hazards and report them to the concerned supervisor. Six directional hazards identification process is used to fix hazards and make the workplace safe. Spotting the hazard in terms of unsafe conditions or unsafe acts in either construction or operation/maintenance activities is a process of identifying and accessing the RISK in the system.

A system of identifying six directional hazards and its analysis intends to provide safe working positions in the workplace area. This system eliminates fall exposures, fall-arrest equipment, and the use of barrels, boxes, loose tile blocks, or other unsuitable objects as a means to support work-on platforms. As part of any execution work at the time of receipt of the work permit, prior to its start, and as a part of safe work preparations, six-directional hazard identification is being carried out.

Method of Six Directional Hazard Identification and Analysis includes:

- Job safety management planning tool

- Planning safe execution of work

- Improving work efficiency and effectiveness

- Provision of information communication

- An accident prevention tool

- Identification of inherent hazards associated with a specific task or group of tasks

- Eliminating or mitigating hazards

- Stipulating controls, precautions, and safe-guards

- Defining potential hazards

- Creating a plan – ‘Safe System of Work’

- Minimizing risks the workforce will actually face

- Coordinating and controlling potential high-risk activities

- Communication of hazards and controls – to the people actually doing the work

- Avoiding injuries and or damage, interruptions to process/operation

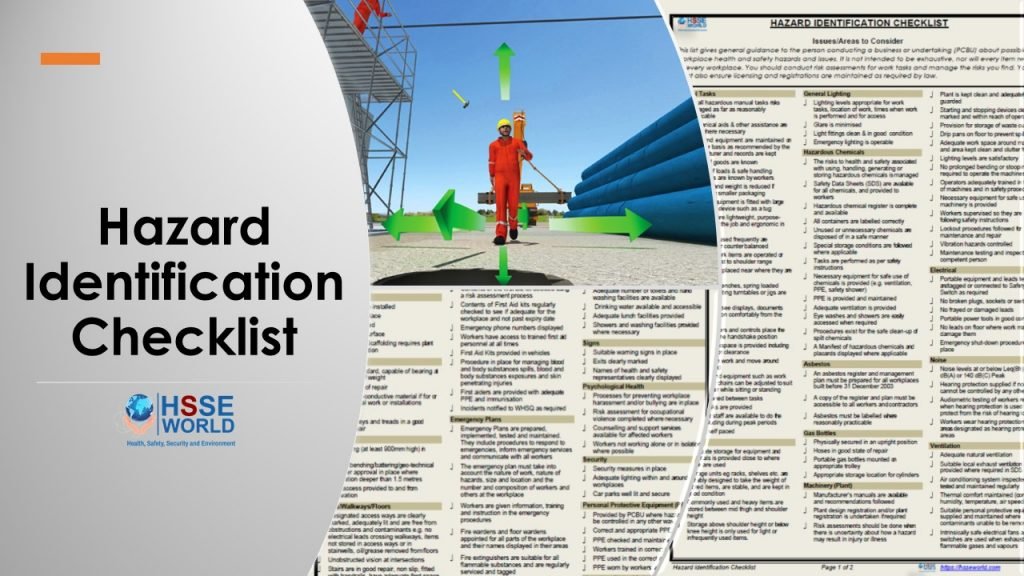

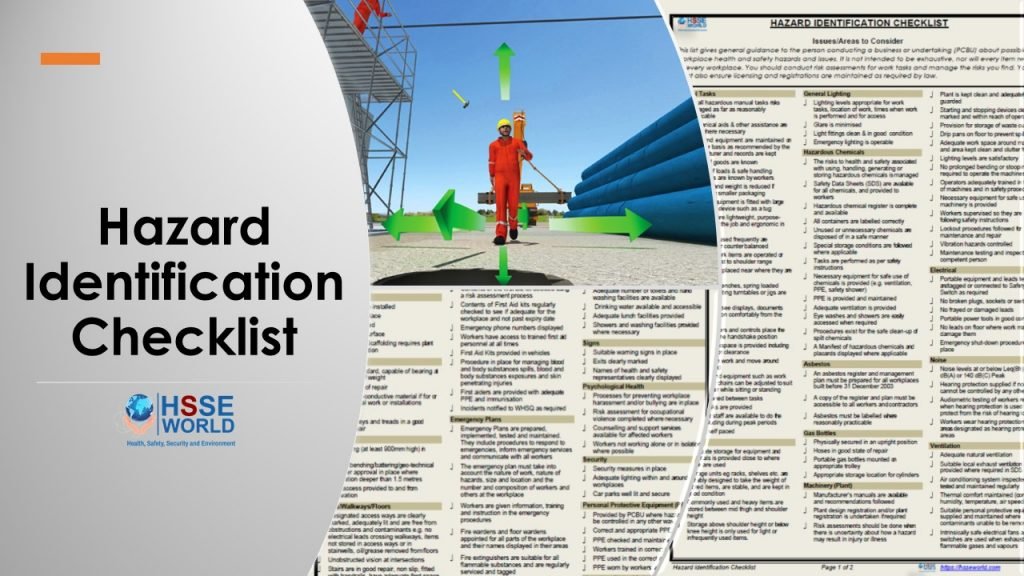

What is a Hazard Identification Checklist?

A hazard identification checklist, also known as a hazard assessment form, is a tool used by safety officers in performing hazard assessments. The main purpose of a hazard assessment is to identify potential health and safety hazards by examining conditions or practices in the workplace. Performing regular hazard assessments is critical for implementing adequate corrective measures that can help prevent injuries and illnesses.

Download the Checklist

Hazard Identification Checklist gives general guidance to the person conducting a business or undertaking (PCBU) about possible workplace health and safety hazards and issues. It is not intended to be exhaustive, nor will every item relate to every workplace. You should conduct risk assessments for work tasks and manage the risks you find. You must also ensure licensing and registrations are maintained as required by law.

More Forms

- Camp Inspection form

- Machines Access Control Inspection Checklists

- Lift Plan Form

- Slips,Trips and Falls checklist

- Emergency Drill Table Top meeting Form

- Emergency Drill After Action Review form

- Compressed Gas Cylinders Access Control Inspection Checklist

- Competent Person Designation form

- Contractor Weekly HSE Report Form

- Safety Inspection Form

- Incident Report Form

- Job Hazard Analysis form

- OSHA Inspection Checklist 8-Pages

- Process Safety Management (PSM) Compliance checklist

- Portable Ladder Self Inspection checklist

- Scaffold Register and Inspection Checklist

- CRANE INSPECTION REPORT

- Laboratory Inspection Checklist Form

- Electric Arc Welding and Cutting Checklist

- Crane Suspended Personnel Platform (MANBASKET) Permit

- Pressure Testing Checklist

- Hygiene and Sanitation Inspection Checklist

- Permit to Work (PTW ) AUDIT CHECKLIST

- Equipment Safe Operating Procedures- SOP 61 checklist

- Construction safety Inspection checklist

- Fall safety at construction checklist

- Contractor Pre-qualification Questionnaire Checklist

- Lifeline & Harness Inspection Guide checklist

- Templates: Management of Change NEW Modified Equipment Safety Checklist

- Lock Removal Form

- Workplace Safety Inspections Forms

- Safety Templates: COVID-19 Safety Plan

- Construction Site Traffic Management Plan (CSTMP) Guidance

- Fire Pump Daily Inspection Checklist

- Health Safety at Work Improvement Action Plan

- Work at Height Checklist

- Canteen Inspection Checklist

- Electrical Isolation Permit to Work forms and checklist

- Job Safety Analysis (JSA) Forms What’s Right and Wrong?

- Lifting Plan Audit Checklist

- ISO 45001:2018 READINESS CHECKLIST

- Workplace Housekeeping Checklist

- Hazard Identification Checklist

- Free Pre-Startup Safety Review Checklist (PSSR)

- Ladder Inspection Form

- Hazard Identification Plan (HIP) Template

- HIRA, HSE Hazards & Effects Management Process (HEMP) & Risk Register Template

- Temporary Construction Facilities (TCF) Inspection checklist

- Simultaneous Operation (SIMOPS) checklist

- Mobile Scaffold Inspection checklist

- Annual Internal Audit Form

- General Safety Guidelines and Employee Acknowledgment form

- E-Books: Fire Safety Logbook templates

- Electrical Inspection Checklists

- Grating-Decking-Floor- handrail-Removal Form

- Photo of the day: New worker Orientation & Safety Orientation checklist

- Suspended Scaffold Pre-Operation Inspection Checklist