The Safety task assessment ( STA) and Pre-Task Hazard Assessment ( PTHA) Is an efficient tool, which if utilized Correctly, will Identify the Hazards, and allow the team to communicate those measures to affected employees. This will effectively reduce or eliminate the hazards, thus further ensuring the health, safety, and wellness of employees.

STA/PTHA must be developed and made available for each job task performed at the workplace. This is intended to analyze the task at hand to analyze the best method to perform the task safely

how to use the form?

The STA/PHTA includes both routine and non-routine tasks and activities

- The sta/PTHA consists of a careful examination of the work area and works cope to determine what possible hazards for particular job tasks could cause harm to employees and the likelihood that the harm will actually occur. it must also identify the safety precautions necessary to eliminate the hazard, along with the personal protective equipment ( PPE) required to be worn when performing the task. specific regulatory requirements, best management practices, and what is reasonably practicable should also be taken into consideration during the review.

- STA/PTHA can be used with other documentation such as standard operating or work procedures as long as all elements of the STA/PTHA are included

- There may be regulatory requirements that must be met for these assessments. Ensure that you are referring to your local, state, and country-specific regulations before utilizing this document as an approved regulatory document.

- Employees who actually perform the job task being evaluated must be included in the assessment. These individuals know the work process, are adequately trained to perform the identified task, and are most familiar with and sensitive to the actual and potential hazards that might require precautionary measures.

- Routine tasks and non-routine task will be covered by task-specific STA/PTHA.

- Completed STA/PTHA shall be posted at the specific task area and will be integrated with field or fixed facility procedures.

STA/PTHA Process

The STA/PTHA process will include the following

- Visual observation of job task and location;

- Involvement of all employees performing the task, or those who may be impacted from the task;

- Job task/operation overview ( i.e describe what is done in each basic step ).

For any task-specific hazards that cannot be mitigated, a stop-work must be initiated, and supervisors shall be required to assess the task method.

A suitable and sufficient STA/PTHA is one that:

- Correctly and accurately identify each hazard relating to the task and any generated from its location ( EG; working above others )

- Takes into account the effectiveness of any existing control measures.

- Evaluate applicable local regulations and safety rules ( i.e. Confined space, Hot work, Grating removal )

- Will remain active for the duration of the task, but no longer than the shift

- provides sufficient information to develop appropriate control measures.

Hazard Identification

The following information should be evaluated to determine hazard:

- Nature of the tasks to be performed,

- Potential chemical hazards( e.g. inhalation, ingestion, and skin contact 0 and protection mechanism,

- potential physical hazards,

- Potential for ergonomic stressors( e.g. repetitive motion, lifting, awkward position) and protection mechanism,

- Operational references and work procedures ( e.g. equipment shut-down, lockout/Tagout procedures, manufactures instructions, SDS );

- Required special Personal protective equipment and its availability,

- Previous IH monitoring or prior assessments,

- Additional safety hazards such as falls, electrical, struck by, machine guarding, hand-eye-foot hazards as well as fire and explosion hazards.

Risk evaluation

For each hazard, consider the way in which the employee could be harmed, for each cause of harm, consider what existing precautions and control measures have already been taken to reduce harm.

the combination of these two factors mentioned above determines how well the risk is controlled and whether or not more needs to be done to reduce the risk.

While evaluating control measures, verify that all regulatory requirements have been addressed.

In controlling risks, apply the following principles, if possible, with the following priority:

- Prevent exposure by discontinuing the hazardous activity altogether,

- substitute the activity for a less hazardous one,

- Enclose the hazardous activity or separate the activity from the people by other means ( e.g. enclosure tent, machine guarding ),

- Reduce the numbers of people exposed to the hazard,

- Reduce the period of exposure ( i.e. rotational work assignment, heat, ergonomics, noise ), or

- provide personal protective equipment ( PPE).

As highlighted above the use of PPE should be considered the least acceptable method of controlling risks. All other methods of control should be evaluated first.

( Know more about : hierarchy of controls )

STA/PTHA Implmentation

STA/PTHA shall be documented using STA/PTHA forms as discussed above,

Completed STA/PTHA shall be posted at a specific task area and will be integrated with filled or fixed facility Procedure

During the implementation of the STA/ PTHA, additional health, and safety issues may be documented that require immediate attention ( e.g missing guard ) or control measures ( e.g. ventilation ) outside the direct scope of the STA / PTHA.

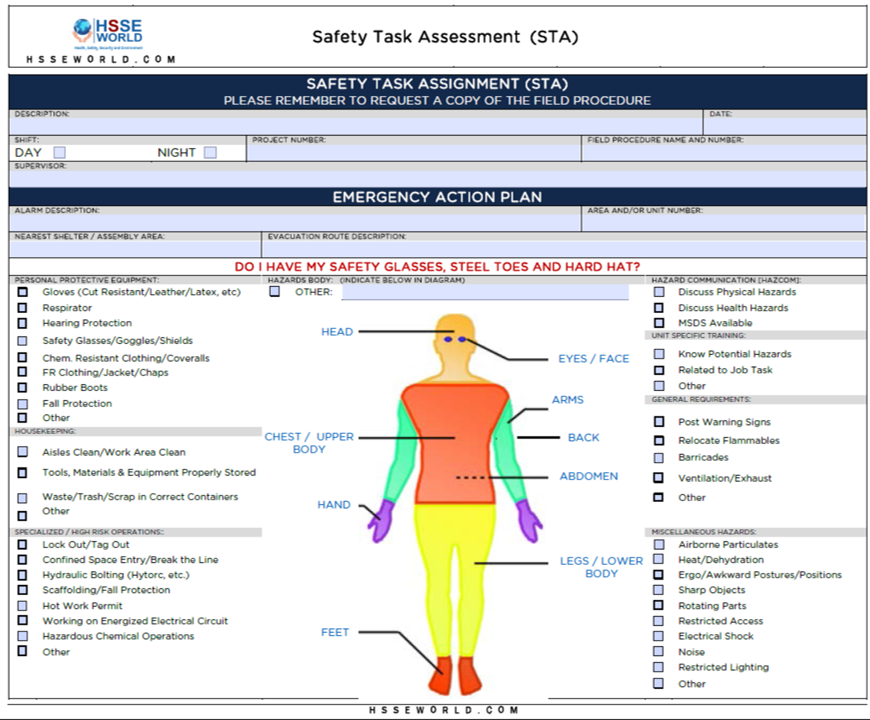

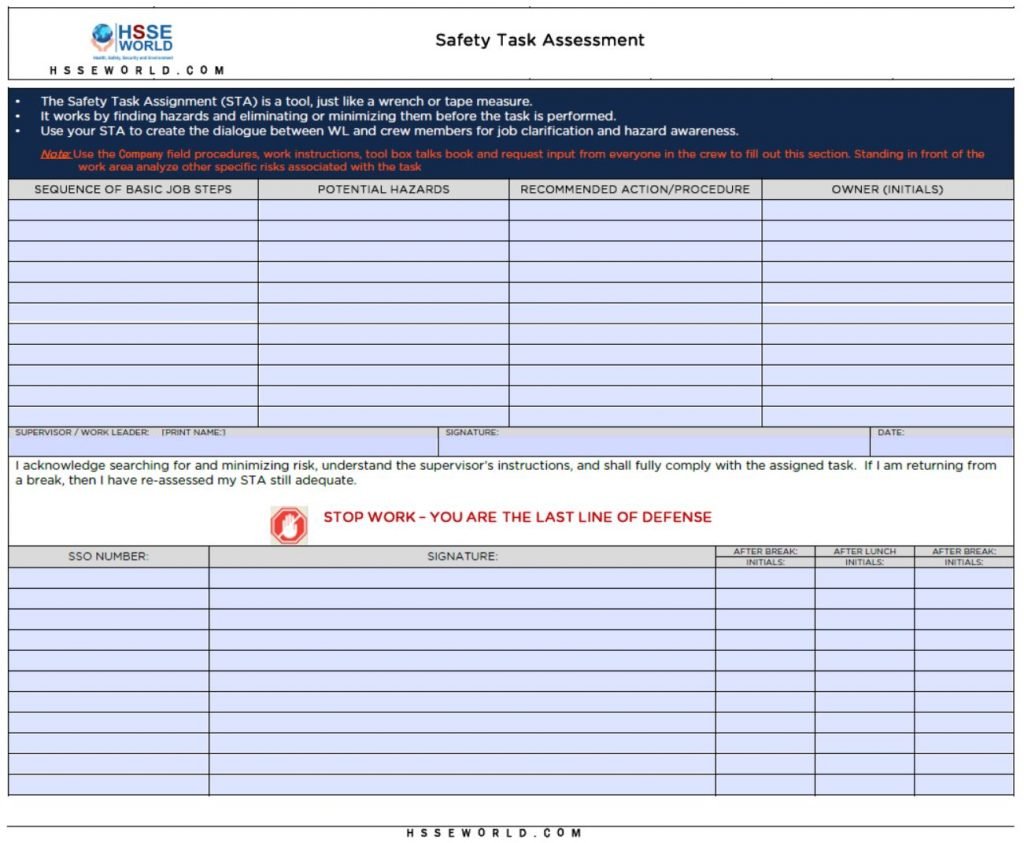

Snapshot of the forms

The Safety task assessment ( STA) and Pre-Task Hazard Assessment ( PTHA) Is an efficient tool, which if utilized Correctly, will Identify the Hazards, and allow the team to communicate those measures to affected employees. This will effectively reduce or eliminate the hazards, thus further ensuring the health, safety, and wellness of employees.

The Safety Task Assignment (STA) is a tool, just like a wrench or tape measure.

It works by finding hazards and eliminating or minimizing them before the task is performed.

Use your STA to create the dialogue between WL and crew members for job clarification and hazard awareness.

Completed STA/PTHA shall be posted at a specific task area and will be integrated with filled or fixed facility Procedure

Now you can download the PDF and editable Form and use it to fit your purpose just click on download below

Download the Checklists

Pre-TAsk hazard assessment/Safety Task Assessment Form

More Forms

- Navigating the Risks: The Ultimate Guide to Safety When Working Near Water

- Downloadable Kitchen Safety Inspection Checklist for Restaurants

- Mastering LOTO: Protecting Workers with Energy Isolation and Isolation Confirmation Certificates

- Flammable and Combustible Storage Checklist Free Download

- Secure Your Lifts:Guidelines for Safe Lifting Operations Free Planning Tool

- Sample of Accident Prevention Program ( APP) Template for General Industry Free Download

- Free ISO 14001:2015 Environmental Management System Audit Checklist Download

- Guides for Walking and Working Surfaces Safety Program

- Workshop Safety Guideline and free Posters

- Free Ergonomics Checklist for General Industry

- Work Area Safety Checklist

- Machine Safety and 43-Equipment Inspection Checklists

- Scaffold Safety self Audit and checklist

- Hot Work Controls and its Permit to work Form

- Safety Observation Report Template

- Forklift Operator’s Daily Checklist and safety Tips

- Inspecting Fall Protection Equipment Forms

- Templates: HSE Incentives and rewards

- 35 Inspection forms for Rig Check

- Chemical Risk Assessment form

- 22-Safety Inspection Checklists

- Safety Task Assessment Form

- Suspended Scaffold Pre-Operation Inspection Checklist

- Photo of the day: New worker Orientation & Safety Orientation checklist

- Grating-Decking-Floor- handrail-Removal Form

- Electrical Inspection Checklists

- E-Books: Fire Safety Logbook templates

- General Safety Guidelines and Employee Acknowledgment form

- Annual Internal Audit Form

- Mobile Scaffold Inspection checklist

- Simultaneous Operation (SIMOPS) checklist

- Temporary Construction Facilities (TCF) Inspection checklist

- HIRA, HSE Hazards & Effects Management Process (HEMP) & Risk Register Template

- Hazard Identification Plan (HIP) Template

- Ladder Inspection Form

- Free Pre-Startup Safety Review Checklist (PSSR)

- Hazard Identification Checklist

- Workplace Housekeeping Checklist

- ISO 45001:2018 READINESS CHECKLIST

- Lifting Plan Audit Checklist

- Job Safety Analysis (JSA) Forms What’s Right and Wrong?

- Electrical Isolation Permit to Work forms and checklist

- Canteen Inspection Checklist

- Work at Height Checklist

- Health Safety at Work Improvement Action Plan

- Fire Pump Daily Inspection Checklist

- Construction Site Traffic Management Plan (CSTMP) Guidance

- Safety Templates: COVID-19 Safety Plan

- Workplace Safety Inspections Forms

- Lock Removal Form

- Templates: Management of Change NEW Modified Equipment Safety Checklist

- Lifeline & Harness Inspection Guide checklist

- Contractor Pre-qualification Questionnaire Checklist

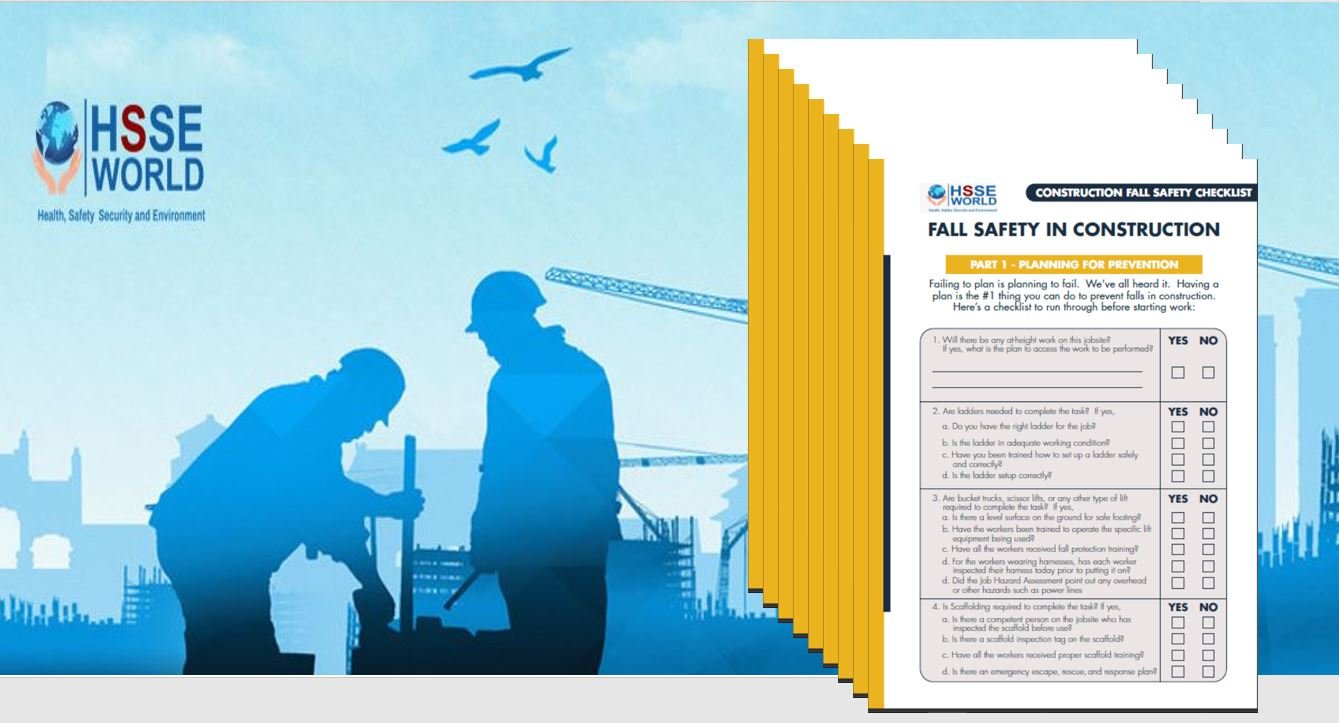

- Fall safety at construction checklist

- Construction safety Inspection checklist

- Equipment Safe Operating Procedures- SOP 61 checklist

- Permit to Work (PTW ) AUDIT CHECKLIST