A safety observation report (sometimes known as a “safety card”) collects information about the safety of working conditions observed by workers on site (For example, say you’re observing employees working at heights. You notice three employees forgot to test-check their safety harnesses before engaging in work. This would count as three unsafe actions. Alternatively, if you notice an employee has kept the walking area clear of debris, this would count as a safe condition).

Because everyone working on a job site can help ensure safety, especially in high-risk industries like construction, engineering, and manufacturing, the observation report template is a quick and easy way to empower workers to identify and report unsafe conditions or potential hazards. It also allows workers to highlight the work of other team members who are correctly following safety procedures. HSSE WORLD provides you with Safety Observation Report Template which can be downloaded easily and modified to fit your work.

What information goes into a safety observation report?

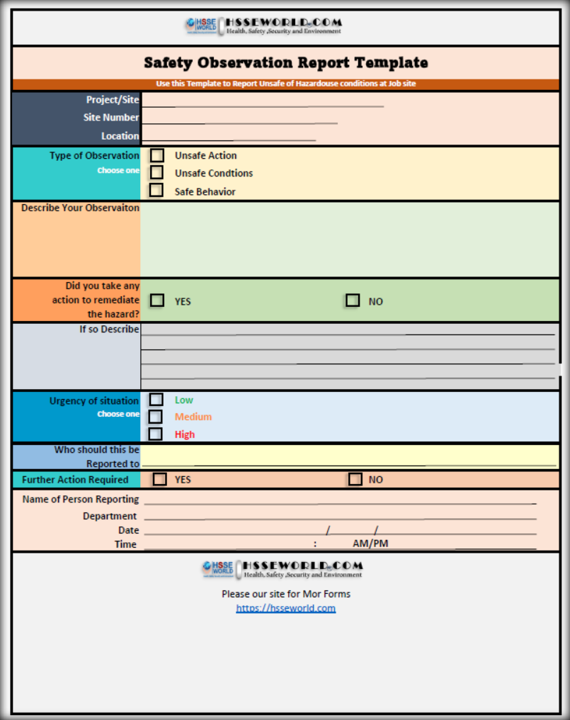

Following a brief description of the project and the job site, a safety observation report prompts the respondent to pick one of three types of observations to report, including unsafe actions performed by a team member (e.g. failure to wear hard-hat); unsafe conditions (e.g. slippery floor); or safe observations of procedures (e.g. identifying team member who is properly following safety protocols).

Respondents will then be asked to describe the observation in detail, including its urgency and what action, if any, was taken to remediate the hazard. Finally, the form flags who the observation should be reported to and whether further action is required, which helps remediate potential hazards.

Who uses a safety observation report, and why?

In risk-heavy industries like construction and manufacturing, unsafe workplace actions or conditions can become dangerous if ignored and unreported. The safety observation report is designed for workers on-site who, in the course of their everyday work, are best positioned to observe how and if safety conditions are followed, or not.

Engaging workers to use the observation report form improves hazard reporting, which helps ensure safety compliance and reduces workplace incidents and injuries. And by nurturing a company-wide culture of safety, you can strengthen your overall safety posture.

Safety managers are not required to fill out a safety observation report; rather, they should ensure that all workers have access to such a report and will likely be its primary recipient.

How to Encourage Observations at Work

Proper employee observations are the backbone of a successful Observation program. It is critical they are completed correctly and are a welcome part of the workplace.

You want to make sure your safety observations are done frequently. This will help employees accept them a regular occurrence as well as ensure you have enough data to make informed decisions.

Frequent observations are also a good way to communicate to employees they will not be punished for behaviors assessed to be high risk. While you want to eliminate these behaviors, punishing employees for their mistakes only encourages them to keep those behaviors hidden, rather than correct them.

Instead, you want to facilitate employee participation in reporting safety observations, both good and bad. Encouraging employee observations not only grows safety cultures in the workplace but also helps ensure the success of your Safety Observation Program program.

How to Make Effective Observation Reports

While encouraging employees to conduct observations is a key factor to a successful Safety observation Program as a behavior-based safety program ( BBS), it is not the only one.

Many behavior-based safety programs fail due to difficulty analyzing the data collected. This can either be caused by insufficient behavior-based safety reporting capabilities or dirty data.

Dirty data arises when your observation reports are too complicated or unorganized. This is why effective safety observations are organized in a standard checklist format. The checklist ensures you’re recording consistently and focusing on identified topics. If you’re unsure where to start when creating a safety observation checklist, you can download our free template below

Use this safety observation report to document the safety conditions of a worksite.

The most effective safety observation reports count both conditions of the workplace, as well as actions by employees. This is because reactions to safe/unsafe conditions in the workplace is an extension of employee behavior.

If an employee casually walks past a spilled liquid, that is unsafe behavior, as ignoring the spill could lead to an injury. Part of the goal of altering employee behavior is to create a culture of safety. A culture where employees don’t ignore unsafe conditions but instead report safety hazards when they are discovered.

As such you should keep count of how many safe and unsafe conditions your employees create or ignore. Keeping this count separate from safe/unsafe actions allows you to better drill down where behavior needs to be corrected and apply a more effective solution.

Download

These Templates are not all-inclusive. You may wish to add to them or delete portions that do not apply to your workplace. Carefully consider each item as you come to it and then make your decision. Do not spend time with items that have no application to your workplace.

Safety Observation Report Template

More Forms

- Navigating the Risks: The Ultimate Guide to Safety When Working Near Water

- Downloadable Kitchen Safety Inspection Checklist for Restaurants

- Mastering LOTO: Protecting Workers with Energy Isolation and Isolation Confirmation Certificates

- Flammable and Combustible Storage Checklist Free Download

- Secure Your Lifts:Guidelines for Safe Lifting Operations Free Planning Tool

- Sample of Accident Prevention Program ( APP) Template for General Industry Free Download

- Free ISO 14001:2015 Environmental Management System Audit Checklist Download

- Guides for Walking and Working Surfaces Safety Program

- Workshop Safety Guideline and free Posters

- Free Ergonomics Checklist for General Industry

- Work Area Safety Checklist

- Machine Safety and 43-Equipment Inspection Checklists

- Scaffold Safety self Audit and checklist

- Hot Work Controls and its Permit to work Form

- Safety Observation Report Template

- Forklift Operator’s Daily Checklist and safety Tips

- Inspecting Fall Protection Equipment Forms

- Templates: HSE Incentives and rewards

- 35 Inspection forms for Rig Check

- Chemical Risk Assessment form

- 22-Safety Inspection Checklists

- Safety Task Assessment Form

- Suspended Scaffold Pre-Operation Inspection Checklist

- Photo of the day: New worker Orientation & Safety Orientation checklist

- Grating-Decking-Floor- handrail-Removal Form

- Electrical Inspection Checklists

- E-Books: Fire Safety Logbook templates

- General Safety Guidelines and Employee Acknowledgment form

- Annual Internal Audit Form

- Mobile Scaffold Inspection checklist

- Simultaneous Operation (SIMOPS) checklist

- Temporary Construction Facilities (TCF) Inspection checklist

- HIRA, HSE Hazards & Effects Management Process (HEMP) & Risk Register Template

- Hazard Identification Plan (HIP) Template

- Ladder Inspection Form

- Free Pre-Startup Safety Review Checklist (PSSR)

- Hazard Identification Checklist

- Workplace Housekeeping Checklist

- ISO 45001:2018 READINESS CHECKLIST

- Lifting Plan Audit Checklist

- Job Safety Analysis (JSA) Forms What’s Right and Wrong?

- Electrical Isolation Permit to Work forms and checklist

- Canteen Inspection Checklist

- Work at Height Checklist

- Health Safety at Work Improvement Action Plan

- Fire Pump Daily Inspection Checklist

- Construction Site Traffic Management Plan (CSTMP) Guidance

- Safety Templates: COVID-19 Safety Plan

- Workplace Safety Inspections Forms

- Lock Removal Form

- Templates: Management of Change NEW Modified Equipment Safety Checklist

- Lifeline & Harness Inspection Guide checklist

- Contractor Pre-qualification Questionnaire Checklist

- Fall safety at construction checklist

- Construction safety Inspection checklist

- Equipment Safe Operating Procedures- SOP 61 checklist

- Permit to Work (PTW ) AUDIT CHECKLIST