Photo of the day: Outline Safety observations

One of the most debated topics in the safety industry is the effectiveness of behavior-based safety (BBS) programs. The idea behind BBS programs is to improve workplace safety by correcting employee behavior through job safety observations. However, many skeptics claim these safety observations only play the blame game and don’t actually improve employee behavior.

While there are many pros and cons of behavior-based safety programs, oftentimes these programs fail because of poor implementation. This article will provide guidance on how to properly use safety observations that result in improvement.

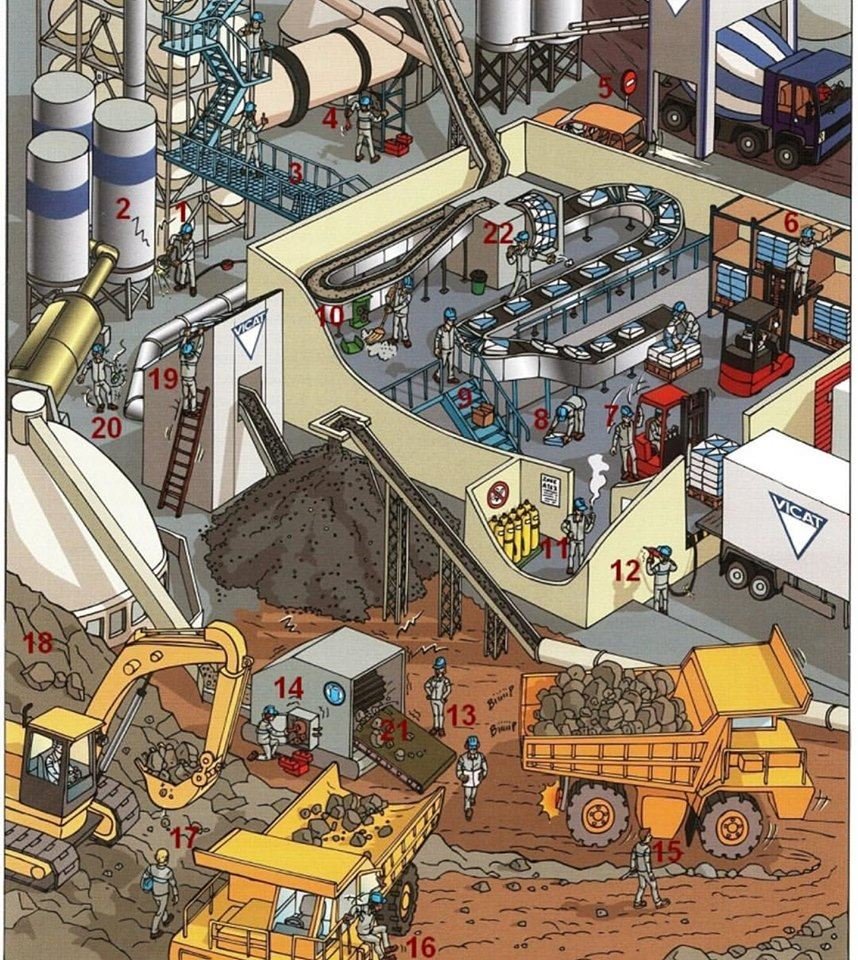

In the picture below try to find out all safety observations with a discussion about corrective Actions

What are Safety Observations?

Safety observations are counts of the number of safe and unsafe actions or conditions in a work area for a given time.

For example, say you’re observing employees working at heights. You notice three employees forgot to test-check their safety harness before engaging in work. This would count as three unsafe actions. Alternatively, if you notice an employee has kept the walking area clear of debris, this would count as a safe condition

Observations are often recorded by managers using checklists that have separate sections for each safety topic, such as different types of personal protective equipment. The goal is to identify what employees are doing correct in addition to any risky behavior, and use that data to apply corrections and improve safety.

Often times, this is the first pitfall of behavior-based safety programs, as EHS managers tend to focus on the negative. In order to create a safe work environment, you need to praise and reinforce safe behaviors as well as correct unsafe ones. When you only look at what workers are doing wrong, this can create a dissatisfied attitude toward work. Such negative feelings have been found to increase the risk of workplace injuries.

How to Encourage Safety Observations at Work

Proper employee observations are the backbone of a successful BBS program. It is critical they are completed correctly and are a welcome part of the workplace.

You want to make sure your safety observations are done frequently. This will help employees accept them a regular occurrence as well as ensure you have enough data to make informed decisions.

Frequent observations are also a good way to communicate to employees they will not be punished for at behaviors assessed to be high risk. While you want to eliminate these behaviors, punishing employees for their mistakes only encourages them to keep those behaviors hidden, rather than correct them.

Instead, you want to facilitate employee participation in reporting safety observations, both good and bad. Encouraging employee observations not only grows safety cultures in the workplace but also helps ensure the success of your BBS program.

However, the best way to encourage employees to report safety observations is to make it easy for them to do so. That’s why it’s recommended to invest in a behavior based safety software system to simplify the safety observation process.

The software ensures safety reports are filled out consistently, and capturing the required data while minimizing room for user error. Software that comes with a mobile app will give employees the option to perform observations at work with their mobile devices. Such EHS mobile apps will be able to work offline, without an internet connection, in case employees are out in the field. More importantly, using software to complete an observation report will be quicker than pen and paper, meaning they will be less intrusive during the workday.

How to Make Effective Safety Observation Reports

While encouraging employees to conduct observations is a key factor to a successful behavior based safety program, it is not the only one.

Many behavior based safety programs fails due to difficulty analyzing the data collected. This can either be caused by insufficient behavior based safety reporting capabilities, or dirty data.

Dirty data arises when your observation reports are too complicated or unorganized. This is why effective safety observations are organized in a standard checklist format. The checklist ensures you’re recording consistently and focusing on identified topics. If you’re unsure where to start when creating a safety observation checklist, you can download our free template below:

Download the photo

More photos:

- Photo of the day: Identify the Hazards

- Photo of the day: Hand safety Facts

- Photo of the day: What are the hazards

- Photo of the day: Outline Safety observations

- Photo of the day: Safety Leader

- Photo of the day: Unsafe Conditions

- Photo of the day: Why is PPE important?

- Photo of the day: DO’S and DON’TS of Working At Heights

- Photo of the day: 5 Tips to keep your Crew Healthy and safe at work

- Photo of the day: Tracking Near Miss Incidents

- Photo of the day: 10 Elements of Successful Behavior-Based Safety Program

- Photo of the day:5-Signs your Near-Miss Reporting is failing

- Photo of the day:7 Ineffective Safety Practices (And What To Do Instead)

- Photo of the day:5 keys for effective Self-Management in lone worker safety

- Photo of the day: FrontLine supervisors are the LINCHPINS of safety

- Photo of the day: Fostering Engagement at the front line

- Photo of the day: workplace Hazards

- Photo of the day: What is the line of fire

- Photo of the day: How to Avoid the Fatal Four

- Photo of the day: Fire Safety checklist for workplace

- Photo of the day: Most common safety incidents in the workplace

- Photo of the day: Fire Emergency

- Photo of the day: Ladder Safety Tips

- Photo of the day: 8 Basic steps to wear a safety harness

- Photo of the day: You can prevent workplace Falls

- Photo of the day: Top10 Injuries in office work

- Photo of the day: Overhead powerline safety

- Photo of the day: Eyes on the Road The challenges of safe driving

- Photo of the day: 5 Ways to Reinforce Commuting With Positive Reinforcement

- Photo of the day: Safe Lifting at work

- Photo of the day: 5 Essential outcomes of an effective leadership survey process

- Photo of the day: Conveyors Safety Tips

- Photo of the day: Confined Space rescue

- Photo of the day: Construction Site fire Safety

- Photo of the day: Chemical Spill Emergency Response

- Photo of the day: Electric shock survival

- Breath Safely: The Proper Use of Respiratory Protection

- Photo of the day: Confined space safety Precautions

- Photo of the day: Choosing the Right Face Mask and the difference between a respirator and face mask

- Photo of the day: Importance of Mock drill and Fire Action Emergency Procedure

- H2S Gas and how to handle its Emergency

- Your steps to chemical safety

- Photo of the day: hierarchy of controls

- Photo of the day: Tips to reduce Heat stress in the workplace

- Photo of the day: Safety Equipment for Confined Spaces

- Photo of the day: Dangerous Goods Classes

- Photo of the day: Trenching Safety Tips That Can Save a Life

- Photo of the day: Mental health in the workplace

- Photo of the day: Emergency preparedness in the workplace

- Photo of the day: musculoskeletal disorders

- Photo of the day: Workplace Inspection

- Photo of the day: New worker Orientation & Safety Orientation checklist

- Photo of the day: Effective Health and Safety Committees

- Photo of the day: 10 Scaffold Safety Essentials

- Photo of the day: Incident Investigations

- Photo of the day: Preventing the spread of contagious illness

- Photo of the day: 5 ways to reduce the risk of Slipping and Tripping

- Photo of the day: Sitting at work

- How to use Plate Clamps Safely: Safety Moment#34

- Photo of the day: working in heat and Humidex Rating

- Photo of the day: Don’t be Driven to Distraction

- Photo of the day: Fatigue at Work

- Photo of the day: Noise in the affected workplace

- Photo of the day: Indoor Air Quality

- Photo of the day: WHMIS 2015 – Pictograms

- Photo of the day: Personal Protective Equipment last resort

- Photo of the day: Manual Material handling

- Photo of the day: Controlling COVID-19 in the Workplace-Physical Barriers

- Photo of the day: Generator Safety

- Photo of the day: Position for safety and comfort-Safety Tips

- Photo of the day: Cannabis and Impairment in the Workplace

- Photo of the day: sun safety in the workplace

- Photo of the day: Top FIVE Heavy Equipment Construction Site Safety Tips

- Photo of the day: Work-Related Asthma

- Photo of the day: choosing the right Anchorage

- Photo of the day: Protect your Head

- Photo of the day: Extension Cord Safety Tips

- Photo of the day: Concrete Truck Driver Hand Signals

- Photo of the day: Safe use of ladders and step ladders

- Photo of the day: Arc-Fault Circuit Interrupters (AFCI)

- Photo of the day: HSE Bulletin Board

- Photo of the day: Scissor Lift Safety

- Photo of the day: Managing Risks of Exposure to Solvents in the workplace

- Photo of the day: Flagman and Traffic control

- Photo of the day: Run Project safely with Crane Hand Signals

- Photo of the day: Read All Labels Work safe

- Photo of the day: Flood Safety Tips

- Photo of the day: Fall Protection Plans

- Photo of the day: Lockout and Tagout Safety

- Photo of the day: Types of Hand Protection

- Photo of the day: Types of Foot Protection

- Photo of the day: Floor Marking

- Photo of the day: Overhead Power lines Clearance

blind spot at point 15 , shall have flag man

Unsafe acts and conditoins

Below some comments on the observations highlighted by numbers:

No.1: unauthorized cutting activity without considering live plant Safety precautions

No.2: presence of cracks on pressure vessel body

No.3: platform has opening without precautions nor cautions to suspend using until maintenance required is maintained

No.5: vehicle pass stop sign and enter unpermitted area