The removal of flooring or decking on elevated structures during construction works have a high potential of falling to workers and consequently, Death or undesired injuries, ( Read: crewman-fell-to-his-death-through-faulty-grating/ )and the most such incident of falling occurs due to the following reasons :

- The grating was not securely fastened and became loose during nearby activity (e.g. demolition of nearby equipment)

- Missing or ineffective safeguards – e.g. grating was not inspected after severe weather.

- The material used for gratings, supporting structure, or fixings did not meet standards/specifications.

- The replacement grating was not fitted correctly.

- Gratings, supporting structures, or fixings were in poor condition due to age, poor maintenance, or corrosion.

One tool of elimination of potential fall exposure due to the removal of flooring or decking on elevated structures through a thorough Risk Assessment

involving key project personnel and the utilization of a grating/flooring removal form

let’s first to know some general information and definitions :

- Opening: an uncovered hole measuring greater than 2 inches in its least dimension, or more than 3 bearing bars are missing

- Toe-Board: a safety barrier running vertically along the bottom edge to prevent items and people from falling.

- Guard-Rail: a safety barrier running along the sides of the walking surfaces to prevent objects and people from falling.

- Support Beam: The beam that the grating is supported by. This is the foundation of the walking-working surface.

- Floor Hole An opening in any floor, platform, or working surface that measures at least 25.4 mm (1”) but less than 304.8 mm (12”) at its smallest dimension and through which materials and tools (but not people) can fall.

- Flooring Any covering of floors, platforms, or working surface that when removed would create avoid such as a floor hole or opening, such as but not limited to platform grating, floor plates, roofing material, or decking material.

- Wall Opening An opening in a wall or partition having a height of at least 0.76 meters (30”) and a width of at least 457 mm (18”), through which a person might fall to a lower level.

Grating Installation/Re-installation

Grating Panels

- Grating panels are to be installed by laying them across the support beam and held in place with the appropriately designed clips. (Saddle clips and Grating clips are preferred)

- The panel-to-panel alignment needs to be accurate.

- The panels must overlap the support beam by at least one inch.

- The panel-to-panel edges must be the same height as the top of the support beam. There should be no uneven panels

- The panels should not slip, slide, or scoot after being secured

- The panels should not pop up or lift from the support beam after being secured

- All panels should be installed in a direction in accordance with the figure below

Toe Boards/Guards

- Toeboards and guards to be installed per standard

- Toeboards should not extend below the top surface of the grating.

Grating Clips

- The properly designed grating clips must be installed at each corner of each panel and with a minimum of 2 clips on each support beam.

- If the centerline of the clip fastener is on the edge or past the edge of the support steel, inspection should be completed to ensure adequate engagement of steel. For drilled type, the entire screw should be engaged within the steel. For clamp type, the majority of the throat should engage the steel.

- The clip should not move after installation or after any load is exerted on it.

Grating Removal

Before removing grating, the unit supervisor must approve and communicate the work to be done.

If removing or repairing any structural integrity, according to OSHA guideline 1910.22(d) (3), when any correction or repair involves the structural integrity of the walking-working surface, a qualified person performs or supervises the correction or repair. Any maintenance Supervisor is qualified. If structural integrity is being replaced, it must be an alike and kind replacement. If further modification is needed, the task needs to be escalated to the civil engineering group.

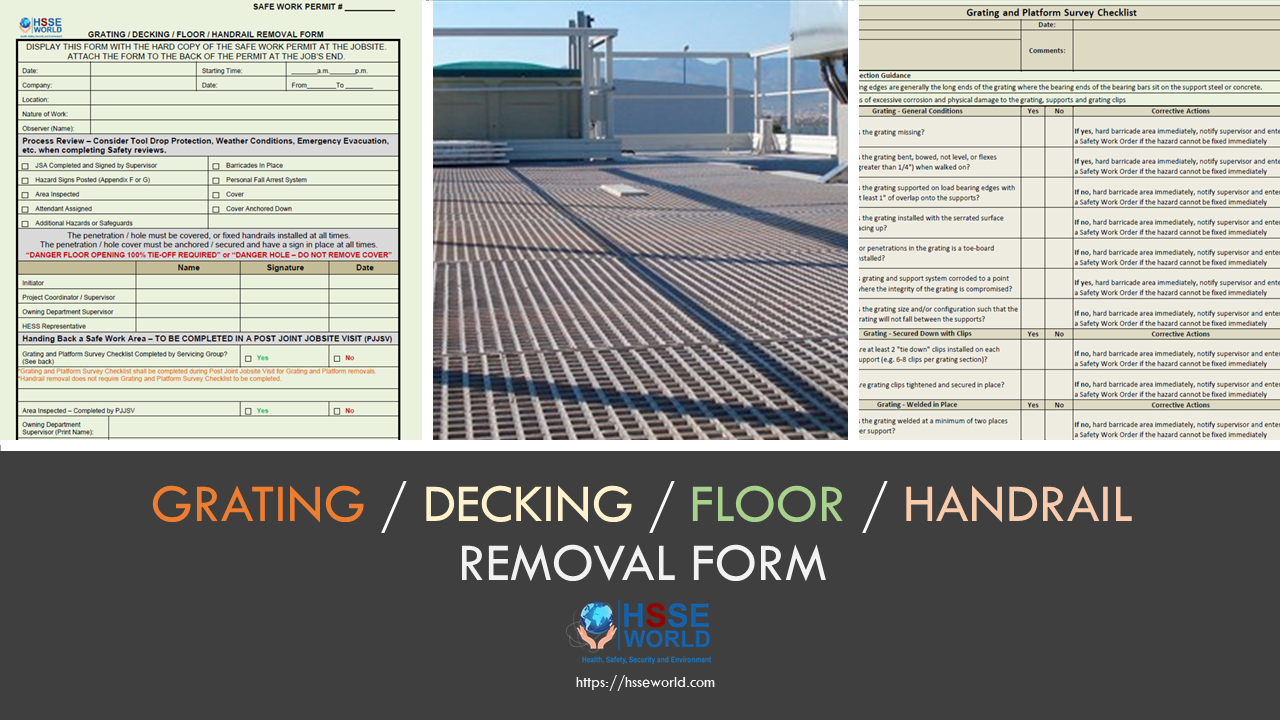

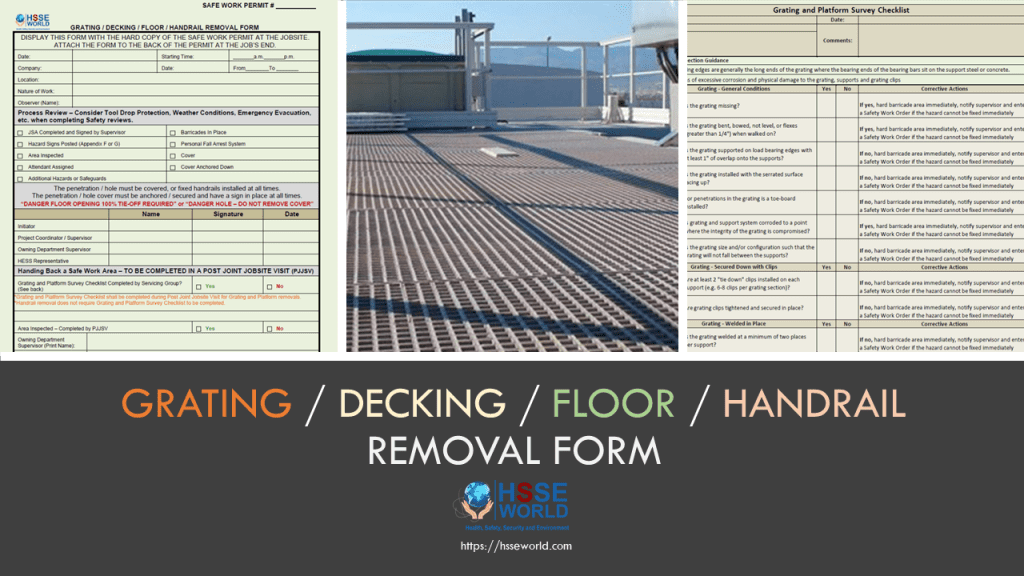

Once the removal is approved, the “Removal Form” (attached) must be completed and signed by the appropriate employees.

Grating removal must begin with a rigid barricade, cover, or guardrail that completely surrounds or covers the section of the grating being removed.

IF THERE IS GRATING BEING REMOVED JUST OUTSIDE OF A DOOR OR ANY ENTRY/EXIT, THE INSIDE OF THE DOOR MUST BE BARRICADED SO THAT EXITING THROUGH THE DOORIS NOT PERMITTED.

Grating removal and installation are to be completed without interruption.

If the decision is made to cover the opening, the cover must:

- Be able to tolerate at least twice the heaviest load that will possibly be exerted on the walkway

- Be secured properly

- Have an identification declaration to identify the opening hazard

If the decision is made to use a rigid barricade or guardrail, it must:

- Be installed using wood (2”x 4”), angle iron, or other material strong enough to withstand twice the possible load being exerted.

- Have a full top rail in between 39” and 42” above the grating

- Have a mid-rail installed at the midpoint of the top rail and the grating

- Have a toe board, except in the designated area to access the grating for removal

Grating Removal includes:

- Ensuring the surrounding grating panels will stay secure while removing the desired panel.

- Placing removed grating panels out of the way as to not cause any further unsafe hazards to any person

- Not stacking the grating up past the toe-board height or near the opening to ensure no grating can fall.

- Adding extra lighting if needed to properly see the work being done

- Communicating to other workers the job that is about to take place

- Wearing PPE and considering every person’s safety beforehand

- Securing all tools

- Never leaving an opening unguarded until the job is complete.

Grating Removal/Installation Steps:

- Fill out the Grating Removal Form ( download below ) and get appropriate approval signatures.

- Once approved, communicate the work to all area workers and supervisors.

- If the level of the grating is above 4’ off the ground, each worker must be tied off and wearing a safety harness.

- Before removing the desired grating panel, complete the task of creating a rigid barricade or placing a guard around the opening. All sides of the opening need to be barricaded except for the access point that will be chosen for grating removal. IF THERE IS GRATING BEING REMOVED JUST OUTSIDE OF A DOOR OR ANY ENTRY/EXIT, THE INSIDE OF THE DOOR MUST BE BARRICADED SO THAT EXITING THROUGH THE DOOR IS NOT PERMITTED.

- Remove the desired grating panel and place it in a location that is out of the way and will not cause any tripping hazards or any hazards for the people down below.

- Install the new grating panel into the correct position with the correct guidelines as stated in the installation procedure.

- Secure the panel with the correct clips and ensure that the clips are installed correctly and the panel is secure.

- Communicate that the job is complete and complete the “Grating/Guardrail removal Completion Form” (attached)

- Once the panel is secure and the form has been signed off by all parties, remove the opening guard rails around the replaced grating panel.

- Turn the completed removal form into operations supervision along with the safe work permit.

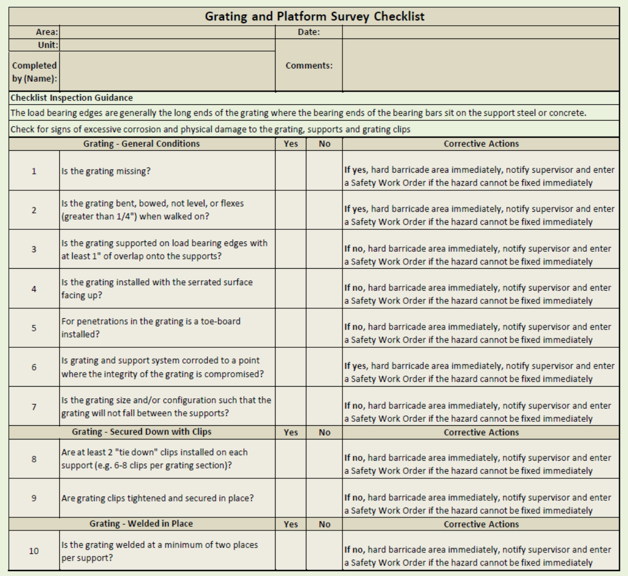

Snapshot of the form and checklist

*Grating and Platform Survey Checklist shall be completed during Post Joint Jobsite Visit for Grating and Platform removals.

*Handrail removal does not require the Grating and Platform Survey Checklist to be completed.

Now you can download the PDF and editable file and use it to fit your purpose just click on download below

Download the Checklists

PDF: Grating-Decking-Floor- handrail-Floor Removal Form & Grating and platform survey checklist

DOC: Grating-Decking-Floor- handrail-Floor Removal Form & Grating and platform survey checklist

More Forms

- Navigating the Risks: The Ultimate Guide to Safety When Working Near Water

- Downloadable Kitchen Safety Inspection Checklist for Restaurants

- Mastering LOTO: Protecting Workers with Energy Isolation and Isolation Confirmation Certificates

- Flammable and Combustible Storage Checklist Free Download

- Secure Your Lifts:Guidelines for Safe Lifting Operations Free Planning Tool

- Sample of Accident Prevention Program ( APP) Template for General Industry Free Download

- Free ISO 14001:2015 Environmental Management System Audit Checklist Download

- Guides for Walking and Working Surfaces Safety Program

- Workshop Safety Guideline and free Posters

- Free Ergonomics Checklist for General Industry

- Work Area Safety Checklist

- Machine Safety and 43-Equipment Inspection Checklists

- Scaffold Safety self Audit and checklist

- Hot Work Controls and its Permit to work Form

- Safety Observation Report Template

- Forklift Operator’s Daily Checklist and safety Tips

- Inspecting Fall Protection Equipment Forms

- Templates: HSE Incentives and rewards

- 35 Inspection forms for Rig Check

- Chemical Risk Assessment form

- 22-Safety Inspection Checklists

- Safety Task Assessment Form

- Suspended Scaffold Pre-Operation Inspection Checklist

- Photo of the day: New worker Orientation & Safety Orientation checklist

- Grating-Decking-Floor- handrail-Removal Form

- Electrical Inspection Checklists

- E-Books: Fire Safety Logbook templates

- General Safety Guidelines and Employee Acknowledgment form

- Annual Internal Audit Form

- Mobile Scaffold Inspection checklist

- Simultaneous Operation (SIMOPS) checklist

- Temporary Construction Facilities (TCF) Inspection checklist

- HIRA, HSE Hazards & Effects Management Process (HEMP) & Risk Register Template

- Hazard Identification Plan (HIP) Template

- Ladder Inspection Form

- Free Pre-Startup Safety Review Checklist (PSSR)

- Hazard Identification Checklist

- Workplace Housekeeping Checklist

- ISO 45001:2018 READINESS CHECKLIST

- Lifting Plan Audit Checklist

- Job Safety Analysis (JSA) Forms What’s Right and Wrong?

- Electrical Isolation Permit to Work forms and checklist

- Canteen Inspection Checklist

- Work at Height Checklist

- Health Safety at Work Improvement Action Plan

- Fire Pump Daily Inspection Checklist

- Construction Site Traffic Management Plan (CSTMP) Guidance

- Safety Templates: COVID-19 Safety Plan

- Workplace Safety Inspections Forms

- Lock Removal Form

- Templates: Management of Change NEW Modified Equipment Safety Checklist

- Lifeline & Harness Inspection Guide checklist

- Contractor Pre-qualification Questionnaire Checklist

- Fall safety at construction checklist

- Construction safety Inspection checklist

- Equipment Safe Operating Procedures- SOP 61 checklist

- Permit to Work (PTW ) AUDIT CHECKLIST