What happened

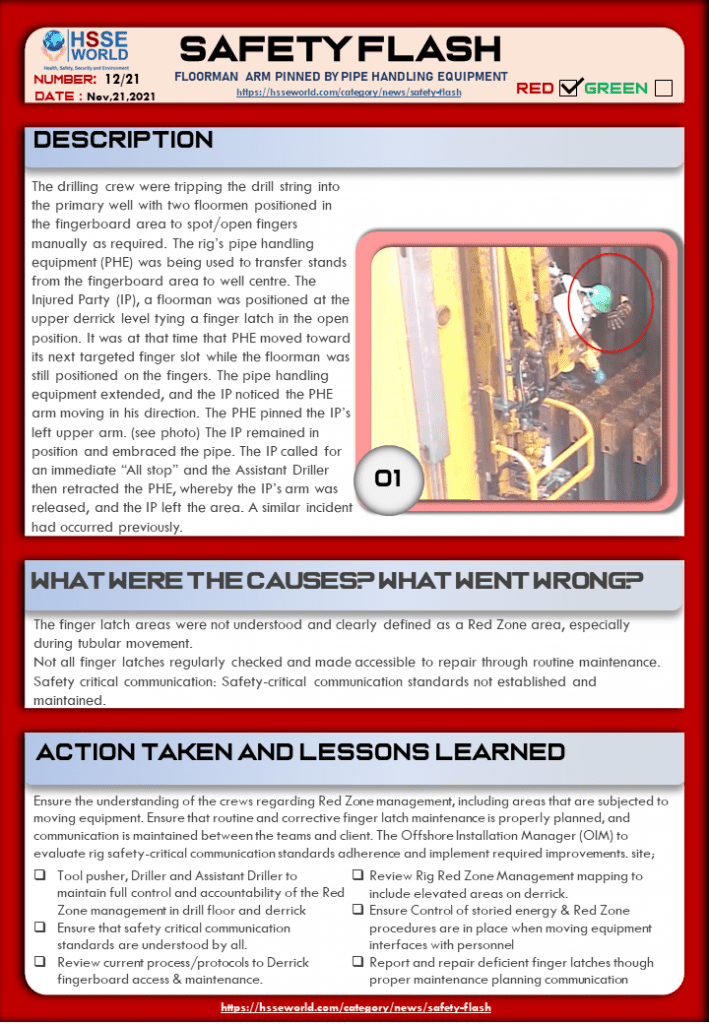

The drilling crew was tripping the drill string into the primary well with two floormen positioned in the fingerboard area to spot/open fingers manually as required. The rig’s pipe handling equipment (PHE) was being used to transfer stands from the fingerboard area to the well center. The Injured Party (IP), a floorman was positioned at the upper derrick level tying a finger latch in the open position. It was at that time that PHE moved toward its next targeted finger slot while the floorman was still positioned on the fingers. The pipe handling equipment extended, and the IP noticed the PHE arm moving in his direction. The PHE pinned the IP’s left upper arm. (see photo) The IP remained in position and embraced the pipe. The IP called for an immediate “All stop” and the Assistant Driller then retracted the PHE, whereby the IP’s arm was released, and the IP left the area. A similar incident had occurred previously.

What were the causes? Why did happen?

The finger latch areas were not understood and clearly defined as a Red Zone area, especially during tubular movement.

Not all finger latches are regularly checked and made accessible to repair through routine maintenance.

Safety-critical communication: Safety-critical communication standards are not established and maintained.

Corrective Actions Taken / Recommendations

Ensure the understanding of the crews regarding Red Zone management, including areas that are subjected to moving equipment. Ensure that routine and corrective finger latch maintenance is properly planned, and communication is maintained between the teams and client. The Offshore Installation Manager (OIM) to evaluate rig safety-critical communication standards adherence and implement required improvements. site;

- Tool pusher, Driller and Assistant Driller to maintain full control and accountability of the Red Zone management in drill floor and derrick

- Ensure that safety critical communication standards are understood by all.

- Review current process/protocols to Derrick fingerboard access & maintenance.

- Review Rig Red Zone Management mapping to include elevated areas on derrick.

- Ensure Control of storied energy & Red Zone procedures are in place when moving equipment interfaces with personnel

- Report and repair deficient finger latches though proper maintenance planning communication

You can download the Safety Flash by clicking download below

These flashes summarise key safety matters and incidents, allowing wider dissemination of lessons learned from them. The information below has been provided in good faith by members and should be reviewed individually by recipients, who will determine its relevance to their own operations. The effectiveness of the safety flash system depends on receiving reports from members in order to pass on the information and avoid repeat incidents.

Source and download

| Alert ID: | 20/12 |

| Published: | Nov 21 2021 |

| Download: | Safety flash (333 kB) |

Download the Safety Flash

Read More Safety Flash

- Safety Flash: Mobile concrete placing boom overturn incidents

- Safety Flash: Not Following Work permit and Isolation Procedure

- Safety Flash: Floorman arm pinned by Pipe Handling Equipment

- Safety Flash: Suspension Trauma

- Safety Flash: Fatality: explosive failure of corroded fire extinguisher

- Safety Flash: Crewman fell to his death through faulty grating

- Safety Flash: Fatal accident during cargo operations on Karina C

- Safety Flash: Overturning of the Lifeboat Kristin Faye

- Safety Flash: Short circuit on 440v AC bus bars-arc flash

- Safety Flash: Towing Fatality

- Safety Flash: Unsafe lifting operations

- Safety Flash: Electric Shock Resulting in Burn

- Safety Flash: LTI- Loss of Finger Tip and Nail

- Safety Flash: Explosion And Fire Onboard The chemical Tanker STOLT Greenland

- Safety Flash: Finger injury caused by incorrectly secured console cover

- Safety Flash: double Man overboard Resulting in one fatality

- Safety Flash: Alcohol-based hand sanitizer warning

- Safety Flash: Dump truck operator fatally electrocuted by high-voltage line

- Safety Flash: Laborer Dies After Footing Collapse – North Carolina

- Safety Flash: Reducing the risk of propane explosions in food trucks

- Safety Flash: Teen Roofer Electrocuted when Ladder Contacts High Voltage Power Line

- Safety Flash: Worker dies from carbon monoxide poisoning while using pressure washer

- Safety Flash: Explosion during welding operation

- A Bathtub Refinisher Dies from Methylene Chloride Exposure :Safety Flash

- Landscaper dies after auger entanglement:Safety Flash

- Worker dies after falling from scaffold

- Fatality Investigation: Orchard Worker Dies After Falling Off Tractor

- LTI: Fall from height leading to Multiple Fractures

- Operator dies when forklift falls off loading dock

- Worker struck, killed by outrigger

- Worker killed by platform

- Scaffolding Components

- Construction Worker Killed When Pipe Rolls Off a Trailer

- Near-Miss: Shackle Configuration

- Improper use of lifeline results in death of worker