Safety Flash: Unsafe lifting operations

3 min readA member reports two incidences of unsafe lifting, which are worthy of note.

Incident 1 Unsafe Lifting Operations By sub-contractor

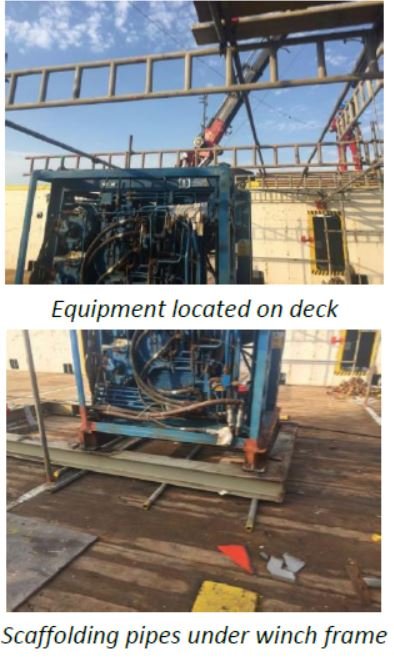

On a platform supply vessel (PSV) involved in demobilization operations alongside, the crane operator attempted to lift a winch frame located on the main deck while there was scaffolding structure still over the winch frame. In addition, the crew was still dismantling the scaffolding and so we’re in the line of fire. Upon observing this unsafe condition the job was immediately stopped by the vessel team.

What were the causes? What went wrong?

- Line of fire – there was scaffolding over the lifting area and the presence of personnel in the line of fire was not considered by the contractor;

- Incorrect lifting method – scaffolding pipes were placed under the winch platform with the purpose to roll it over with partial lifting, creating a risk of the winch sliding back off its platform as it was not welded on it;

- People were in a rush – the contractor’s lifting crew were in a hurry to complete the job on that day, as windy weather was forecast for the next day.

Actions are taken and lessons learned:

- SIMOPS! Take into account what else is happening around you. Avoid any conflicting activities during any lifting operations;

- All lifting operations should be properly planned and risk assessed.

Incident 2 Master Stopped Unsafe Lifting Operation

A client’s lifting crew attempted to load a metal structure to the vessel deck. The operation was stopped by the vessel Master. He questioned the certification of the lifting point and the lifting gear, as having no color code signs. As no certificates could be provided, the vessel Master refused cargo and took the matter up with company management and the client’s representatives.

Actions are taken and lessons learned:

- Crew to conduct vessel inspections to ensure valid color code applied to all lifting equipment and accessories, as per Safety management system;

- Reiterate the importance of checking lifting equipment condition before and after the task.

These flashes summarise key safety matters and incidents, allowing wider dissemination of lessons learned from them. The information below has been provided in good faith by members and should be reviewed individually by recipients, who will determine its relevance to their own operations. The effectiveness of the safety flash system depends on receiving reports from members in order to pass on the information and avoid repeat incidents.

Source and download

| Alert ID: | 28/20 |

| Published: | 28 September 2020 |

| Download: | Safety flash (333 kB) |

Read More Safety Flash

- Safety Flash: Mobile concrete placing boom overturn incidents

- Safety Flash: Not Following Work permit and Isolation Procedure

- Safety Flash: Floorman arm pinned by Pipe Handling Equipment

- Safety Flash: Suspension Trauma

- Safety Flash: Fatality: explosive failure of corroded fire extinguisher

- Safety Flash: Crewman fell to his death through faulty grating

- Safety Flash: Fatal accident during cargo operations on Karina C

- Safety Flash: Overturning of the Lifeboat Kristin Faye

- Safety Flash: Short circuit on 440v AC bus bars-arc flash

- Safety Flash: Towing Fatality

- Safety Flash: Unsafe lifting operations

- Safety Flash: Electric Shock Resulting in Burn

- Safety Flash: LTI- Loss of Finger Tip and Nail

- Safety Flash: Explosion And Fire Onboard The chemical Tanker STOLT Greenland

- Safety Flash: Finger injury caused by incorrectly secured console cover

- Safety Flash: double Man overboard Resulting in one fatality

- Safety Flash: Alcohol-based hand sanitizer warning

- Safety Flash: Dump truck operator fatally electrocuted by high-voltage line

- Safety Flash: Laborer Dies After Footing Collapse – North Carolina

- Safety Flash: Reducing the risk of propane explosions in food trucks

- Safety Flash: Teen Roofer Electrocuted when Ladder Contacts High Voltage Power Line

- Safety Flash: Worker dies from carbon monoxide poisoning while using pressure washer

- Safety Flash: Explosion during welding operation

- A Bathtub Refinisher Dies from Methylene Chloride Exposure :Safety Flash

- Landscaper dies after auger entanglement:Safety Flash

- Worker dies after falling from scaffold

- Fatality Investigation: Orchard Worker Dies After Falling Off Tractor

- LTI: Fall from height leading to Multiple Fractures

- Operator dies when forklift falls off loading dock

- Worker struck, killed by outrigger

- Worker killed by platform

- Scaffolding Components

- Construction Worker Killed When Pipe Rolls Off a Trailer

- Protecting workers from falls

- Near-Miss: Shackle Configuration

- Improper use of lifeline results in death of worker