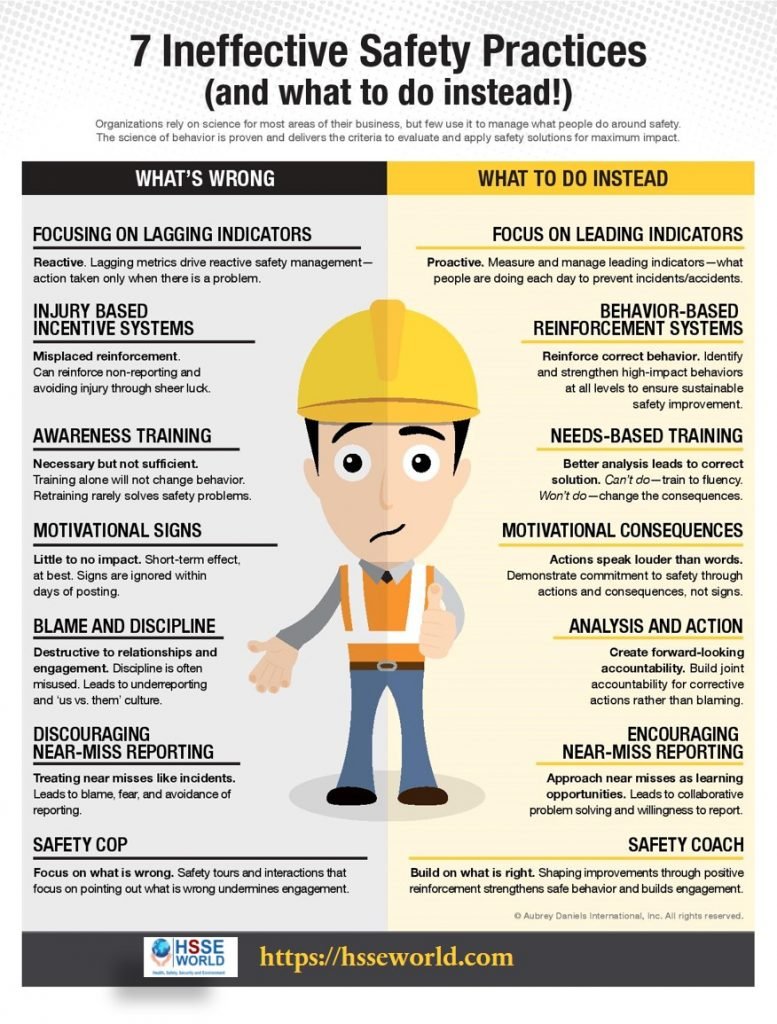

Sometimes, it’s good to be reminded of what works and what doesn’t work, whether you’re talking about food choices, sleep habits, or occupational safety. To give OSH professionals a visual reminder of effective safety practices,

below is an infographic that highlights seven safety practices, such as focusing on lagging indicators or discouraging near-miss reporting, that are generally ineffective and what companies might try instead, such as needs-based training and safety coaching.

There are so many aspects to creating and maintaining a safe working environment that sometimes it’s easy to get lost in it all. To truly succeed in creating a safe place of work, the key is to develop and implement an effective safety management system.

A safety management system combines all the different elements in your workplace that need attention to ensure you provide a safe working environment for everyone who enters it.

Safety management systems make health and safety an integral part of your business’s core operations. By designing, developing, and implementing an effective safety management system, you will have methods for managing reporting, responsibilities, planning, and resourcing to create a safer workplace.

Safety management systems have six elements:

- A safety plan

- Policies, procedures, and processes.

- Training and induction.

- Monitoring.

- Supervision.

- Reporting.

Remember, it is not enough to simply adopt a satisfactory safety management system. You must also actively implement that system in your workplace. To do this, you must ensure that:

- Workers comply with procedures and instructions;

- Workers are appropriately trained; and

- Workers are subject to ongoing supervision.

1. Safety plan

A safety plan is a strategic action plan that forms part of the business plan. It analyses the current and prospective risk for a company and charts how the risks will be eradicated and controlled over a calendar period (the safety plan must have a budget).

This plan will ensure that there is a governance structure within your company that ensures every worker clearly understands their safety obligations (and how to comply) and is accountable to carry out those obligations.

2. Policies, procedures, and processes

Policies, procedures, and processes include all safety paper infrastructures within your company. This paperwork will describe all safety behavior, expectations, record-keeping, incident reporting, and incident notification documentation.

3. Training and induction

Depending on the nature of your workplace (whether it is low-risk or high-risk), everyone who enters your workplace should receive training and induction on:

- The rules of your company;

- The rules of the site; and

- The rules of the location they are visiting.

The training content will depend on the level of risk the person is exposed to.

4. Monitoring

Your obligations to monitor your workplace depend on circumstances and need. Always consider the level of risk. The higher the risk, the more frequent and detailed the monitoring needs to be.

Other times when monitoring will be necessary include:

- To ensure that all risk has been covered by a new risk assessment that has been carried out due to a change in process, e.g. the installation of new workstations; and

- When an investigation takes place following an incident.

5. Supervision

The only way to ensure your workers are carrying out their safety obligations is to have adequate supervision.

The level of supervision required in your workplace will increase if the level of safety control put in place to reduce risk is low, i.e. the less effective the control measure used, the higher the level of supervision necessary.

6. Reporting

The governance structure of your company needs safety reporting at all levels, not just at the board level.

Your workers need to know what safety looks like – what’s going right and what’s going wrong. This can only occur when they receive safety feedback from you, e.g. how many hazards identification, the risk levels associated with those hazards and what control measures were implemented.

Download the photo

More photos:

- Photo of the day: Identify the Hazards

- Photo of the day: Hand safety Facts

- Photo of the day: What are the hazards

- Photo of the day: Outline Safety observations

- Photo of the day: Safety Leader

- Photo of the day: Unsafe Conditions

- Photo of the day: Why is PPE important?

- Photo of the day: DO’S and DON’TS of Working At Heights

- Photo of the day: 5 Tips to keep your Crew Healthy and safe at work

- Photo of the day: Tracking Near Miss Incidents

- Photo of the day: 10 Elements of Successful Behavior-Based Safety Program

- Photo of the day:5-Signs your Near-Miss Reporting is failing

- Photo of the day:7 Ineffective Safety Practices (And What To Do Instead)

- Photo of the day:5 keys for effective Self-Management in lone worker safety

- Photo of the day: FrontLine supervisors are the LINCHPINS of safety

- Photo of the day: Fostering Engagement at the front line

- Photo of the day: workplace Hazards

- Photo of the day: What is the line of fire

- Photo of the day: How to Avoid the Fatal Four

- Photo of the day: Fire Safety checklist for workplace

- Photo of the day: Most common safety incidents in the workplace

- Photo of the day: Fire Emergency

- Photo of the day: Ladder Safety Tips

- Photo of the day: 8 Basic steps to wear a safety harness

- Photo of the day: You can prevent workplace Falls

- Photo of the day: Top10 Injuries in office work

- Photo of the day: Overhead powerline safety

- Photo of the day: Eyes on the Road The challenges of safe driving

- Photo of the day: 5 Ways to Reinforce Commuting With Positive Reinforcement

- Photo of the day: Safe Lifting at work

- Photo of the day: 5 Essential outcomes of an effective leadership survey process

- Photo of the day: Conveyors Safety Tips

- Photo of the day: Confined Space rescue

- Photo of the day: Construction Site fire Safety

- Photo of the day: Chemical Spill Emergency Response

- Photo of the day: Electric shock survival

- Breath Safely: The Proper Use of Respiratory Protection

- Photo of the day: Confined space safety Precautions

- Photo of the day: Choosing the Right Face Mask and the difference between a respirator and face mask

- Photo of the day: Importance of Mock drill and Fire Action Emergency Procedure

- H2S Gas and how to handle its Emergency

- Your steps to chemical safety

- Photo of the day: hierarchy of controls

- Photo of the day: Tips to reduce Heat stress in the workplace

- Photo of the day: Safety Equipment for Confined Spaces

- Photo of the day: Dangerous Goods Classes

- Photo of the day: Trenching Safety Tips That Can Save a Life

- Photo of the day: Mental health in the workplace

- Photo of the day: Emergency preparedness in the workplace

- Photo of the day: musculoskeletal disorders

- Photo of the day: Workplace Inspection

- Photo of the day: New worker Orientation & Safety Orientation checklist

- Photo of the day: Effective Health and Safety Committees

- Photo of the day: 10 Scaffold Safety Essentials

- Photo of the day: Incident Investigations

- Photo of the day: Preventing the spread of contagious illness

- Photo of the day: 5 ways to reduce the risk of Slipping and Tripping

- Photo of the day: Sitting at work

- How to use Plate Clamps Safely: Safety Moment#34

- Photo of the day: working in heat and Humidex Rating

- Photo of the day: Don’t be Driven to Distraction

- Photo of the day: Fatigue at Work

- Photo of the day: Noise in the affected workplace

- Photo of the day: Indoor Air Quality

- Photo of the day: WHMIS 2015 – Pictograms

- Photo of the day: Personal Protective Equipment last resort

- Photo of the day: Manual Material handling

- Photo of the day: Controlling COVID-19 in the Workplace-Physical Barriers

- Photo of the day: Generator Safety

- Photo of the day: Position for safety and comfort-Safety Tips

- Photo of the day: Cannabis and Impairment in the Workplace

- Photo of the day: sun safety in the workplace

- Photo of the day: Top FIVE Heavy Equipment Construction Site Safety Tips

- Photo of the day: Work-Related Asthma

- Photo of the day: choosing the right Anchorage

- Photo of the day: Protect your Head

- Photo of the day: Extension Cord Safety Tips

- Photo of the day: Concrete Truck Driver Hand Signals

- Photo of the day: Safe use of ladders and step ladders

- Photo of the day: Arc-Fault Circuit Interrupters (AFCI)

- Photo of the day: HSE Bulletin Board

- Photo of the day: Scissor Lift Safety

- Photo of the day: Managing Risks of Exposure to Solvents in the workplace

- Photo of the day: Flagman and Traffic control

- Photo of the day: Run Project safely with Crane Hand Signals

- Photo of the day: Read All Labels Work safe

- Photo of the day: Flood Safety Tips

- Photo of the day: Fall Protection Plans

- Photo of the day: Lockout and Tagout Safety

- Photo of the day: Types of Hand Protection

- Photo of the day: Types of Foot Protection

- Photo of the day: Floor Marking

- Photo of the day: Overhead Power lines Clearance