Mobile tower scaffolds are often used for painting and maintenance jobs both inside and outside buildings. They are light-duty scaffolds and their use should be restricted to light work. They have a working platform at the top which is accessible by a ladder fitted internally. They can be constructed using normal scaffolding tubes, but are mostly proprietary-made structures. The whole structure is usually mounted on wheels so it can be moved about.

Since tower scaffolds are inherently unstable they can only be built to a certain maximum height. This height depends upon the size of the base – the larger the base, the higher the tower can go, and to enlarge the base it is usual to use outriggers. The tower can also be made more stable by guying or by using ballast.

Main hazards associated with mobile tower scaffolds:

- Falls from the work platform.

- Objects falling from the platform.

- The collapse of the structure.

- Overturn (toppling) of the structure.

- Unintended movement of the wheels.

- Contact with live overheads.

Safety precautions for the safe use of mobile tower scaffolds include the following:

- The guardrail must be fitted to the work platform.

- The tower must not be overloaded.

- Wheels should be locked when the tower is in use.

- The tower must be sited on firm, level ground.

- People and materials should not remain on the tower when it is moved.

- Care should be taken to avoid overheads when the tower is moved.

- Outriggers should be used where necessary to ensure stability.

- People should not climb up the outside of the tower.

- The tower must be built by trained workers.

General Guidelines for the Safe Use of a Mobile Scaffold

- Post a sign indicating that only authorized staff are allowed to use a mobile scaffold.

- Mobile scaffold must be used only on a hard level surface and must not be located closer than 1 m to any slab edge, penetration, or other stepdown, unless a fixed fence, rail, or suitably high upturn is in place.

- Check for physical defects before every use, including the access ladder. (Refer to manufacturer’s manual if available).

- Ensure the scaffold is level.

- Ensure all sections are pinned or appropriately secured.

- Keep scaffold loads to a minimum (including tools and other equipment) and remove when the scaffold is not in use. DO NOT exceed the scaffold’s working load (refer to manufacturer’s manual).

- Heavy tools, equipment, and supplies must be hoisted up (rather than carried up by hand).

- Leave all castors locked or chocked against any possible movement. Castors shall comply with AS 1576.2 and shall be capable of being locked when work is being performed from the scaffold.

- Where the castors incorporate adjustable legs, the gradient of the surface shall not exceed 5 degrees, unless provision is made to take the load off the castors during the use of the scaffold.

- Where practicable, portable barriers and lights should be placed around the scaffold while in use.

- Ensure guardrails and toeboards are in place on all open sides.

- Never move the scaffold while someone is on it.

- Secure materials before moving the mobile scaffold

- Remove the loads including tools after using the scaffold

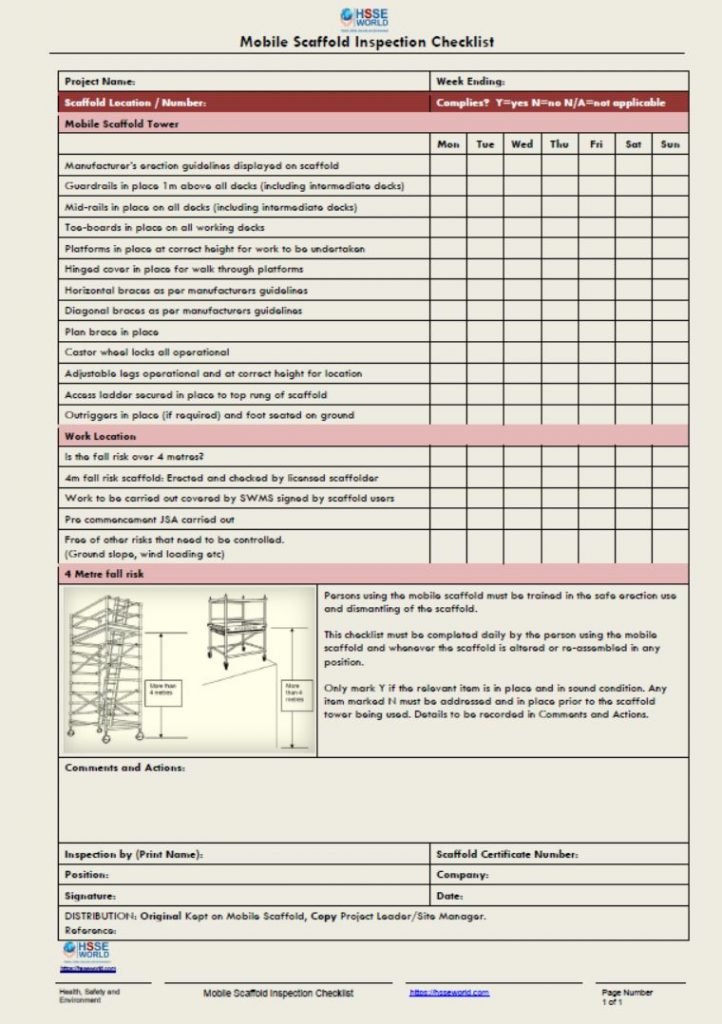

Download The checklist

Mobile Scaffold Inspection checklist could be used as a guideline during the Daily inspeciton of Mobile tower scaffold.The checklist are editable and could be modified to fit your purpose

Download Mobile Scaffold Inspection checklist Editable copy

Download PDF Checklist

More Forms

- Navigating the Risks: The Ultimate Guide to Safety When Working Near Water

- Downloadable Kitchen Safety Inspection Checklist for Restaurants

- Mastering LOTO: Protecting Workers with Energy Isolation and Isolation Confirmation Certificates

- Flammable and Combustible Storage Checklist Free Download

- Secure Your Lifts:Guidelines for Safe Lifting Operations Free Planning Tool

- Sample of Accident Prevention Program ( APP) Template for General Industry Free Download

- Free ISO 14001:2015 Environmental Management System Audit Checklist Download

- Guides for Walking and Working Surfaces Safety Program

- Workshop Safety Guideline and free Posters

- Free Ergonomics Checklist for General Industry

- Work Area Safety Checklist

- Machine Safety and 43-Equipment Inspection Checklists

- Scaffold Safety self Audit and checklist

- Hot Work Controls and its Permit to work Form

- Safety Observation Report Template

- Forklift Operator’s Daily Checklist and safety Tips

- Inspecting Fall Protection Equipment Forms

- Templates: HSE Incentives and rewards

- 35 Inspection forms for Rig Check

- Chemical Risk Assessment form

- 22-Safety Inspection Checklists

- Safety Task Assessment Form

- Suspended Scaffold Pre-Operation Inspection Checklist

- Photo of the day: New worker Orientation & Safety Orientation checklist

- Grating-Decking-Floor- handrail-Removal Form

- Electrical Inspection Checklists

- E-Books: Fire Safety Logbook templates

- General Safety Guidelines and Employee Acknowledgment form

- Annual Internal Audit Form

- Mobile Scaffold Inspection checklist

- Simultaneous Operation (SIMOPS) checklist

- Temporary Construction Facilities (TCF) Inspection checklist

- HIRA, HSE Hazards & Effects Management Process (HEMP) & Risk Register Template

- Hazard Identification Plan (HIP) Template

- Ladder Inspection Form

- Free Pre-Startup Safety Review Checklist (PSSR)

- Hazard Identification Checklist

- Workplace Housekeeping Checklist

- ISO 45001:2018 READINESS CHECKLIST

- Lifting Plan Audit Checklist

- Job Safety Analysis (JSA) Forms What’s Right and Wrong?

- Electrical Isolation Permit to Work forms and checklist

- Canteen Inspection Checklist

- Work at Height Checklist

- Health Safety at Work Improvement Action Plan

- Fire Pump Daily Inspection Checklist

- Construction Site Traffic Management Plan (CSTMP) Guidance

- Safety Templates: COVID-19 Safety Plan

- Workplace Safety Inspections Forms

- Lock Removal Form

- Templates: Management of Change NEW Modified Equipment Safety Checklist

- Lifeline & Harness Inspection Guide checklist

- Contractor Pre-qualification Questionnaire Checklist

- Fall safety at construction checklist

- Construction safety Inspection checklist

- Equipment Safe Operating Procedures- SOP 61 checklist

- Permit to Work (PTW ) AUDIT CHECKLIST