Working at height is always dangerous which makes it extremely important to provide a safe way for workers to access their job location. Using scaffolds to access hard-to-reach areas is often necessary for many construction activities. For especially difficult areas the safest approach may be to use a suspended scaffold. According to OSHA, two-point adjustable suspension scaffolds, also known as swing-stage scaffolds, are perhaps the most common type of suspended scaffold. These types of scaffolds are usually hung by rope or cables connected to stirrups at each end of a platform and allow the workers to be raised and lowered to reach various work locations.

Most suspended scaffolds must meet basic OSHA regulatory requirements however, it is always important to follow the regulations for the specific type of suspended scaffold. In addition, workers must be trained and familiar with the precautions and manufacturer’s operating procedures for the specific model and brand of scaffolding systems they are using at their site. today we provide a suspended Scaffold checklist. This checklist provides a guideline to identify any potential hazards in the installation and/or defects of the equipment to ensure the suspended scaffold system is safe for use. Be aware that this checklist is not all-inclusive and that the manufacturer’s operating instructions and labels must be adhered to in conjunction with all the stated requirements on this list. Only trained workers should be allowed to operate a suspended scaffold.

What should you do when working on a suspended platform?

- Make sure that platform is installed and maintained according to job requirements, safety regulations, standards, and the manufacturer’s specifications.

- Inspect all equipment before erecting and before each shift.

- Use appropriate fall arrest systems (e.g., a separate safety harness attached to an independent lifeline) for each worker. Maintain lanyard attachment at the highest point possible. If fall arrest systems are necessary, workers must be appropriately trained before use.

- Make sure that suspended platform roof beams and attachments are secure.

- Make sure that the roof or parapet wall is structurally sound to support either outriggers or cornice hooks.

- Check for kinked or damaged ropes.

- Secure all ropes at the anchor end.

- Make sure that all safety equipment, stops, override switches and brakes function properly.

- Prevent contact between welding or grinding equipment and wire safety or suspension ropes.

- Secure hand tools to the platform.

- Make sure that the power source is secured and properly grounded.

- The secure platform when not in use.

- Make sure that guardrails and toe boards are in place.

- Extend suspension ropes completely to the ground or terminate with wire rope clips to prevent the stage from running off the end of the ropes.

- Test by raising the fully loaded platform a few feet off the ground before going aloft.

What should you not do?

- Do not exceed platform load capacity.

- Do not enter or leave the platform other than at ground level or at other safe access points.

- Do not allow electric cables or connections to lie in gutters or other areas where water can collect.

- Do not work near exposed electrical circuits or equipment.

- Do not join platforms unless they are designed for this purpose.

- Do not use the damaged or defective equipment.

- Do not alter, substitute or remove components of the platform.

- Do not use fall arrest systems (e.g., the lifeline) for raising or lowering tools or materials.

- Do not move the work platform unless all workers on it are protected by an appropriate fall arrest system.

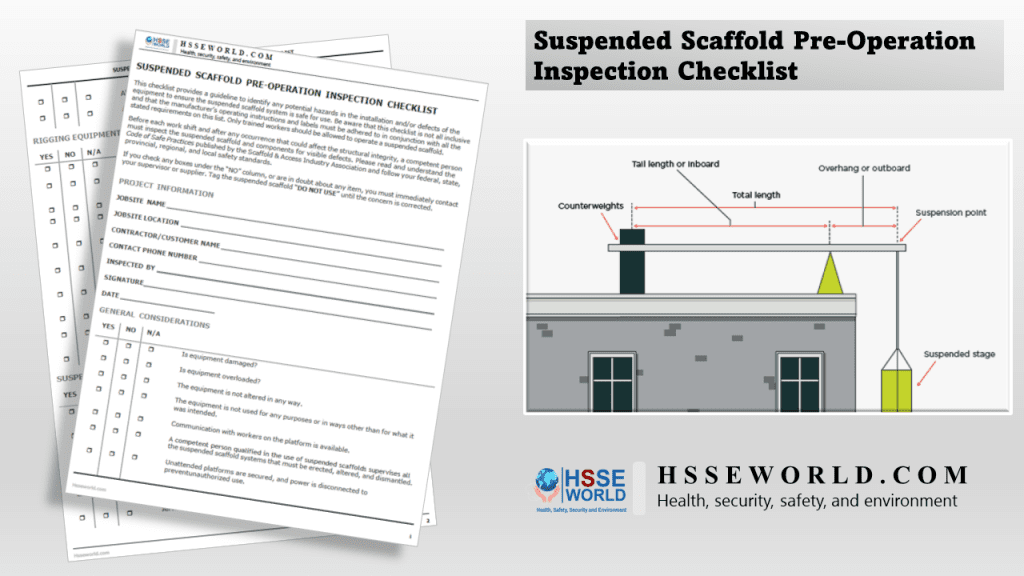

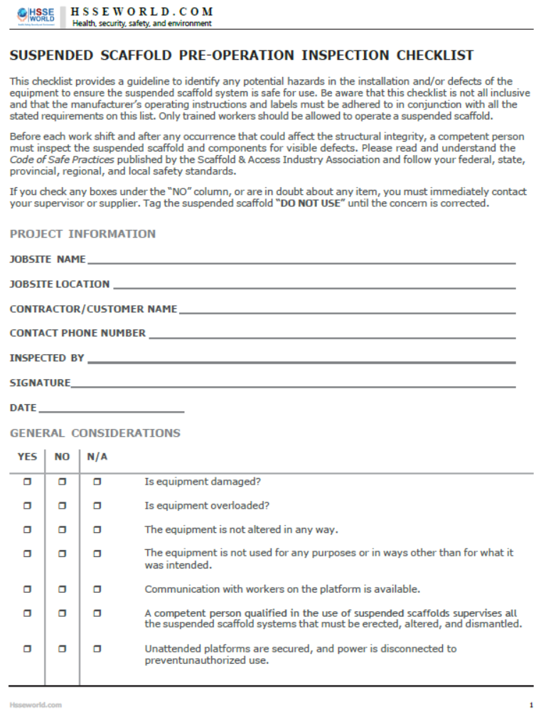

Snapshot of the form and checklist

*This checklist provides a guideline to identify any potential hazards in the installation and/or defects of the equipment to ensure the suspended scaffold system is safe for use. Be aware that this checklist is not all inclusive and that the manufacturer’s operating instructions and labels must be adhered to in conjunction with all the stated requirements on this list. Only trained workers should be allowed to operate a suspended scaffold.

Before each work shift and after any occurrence that could affect the structural integrity, a competent person must inspect the suspended scaffold and components for visible defects. Please read and understand the Code of Safe Practices published by the Scaffold & Access Industry Association and follow your federal, state, provincial, regional, and local safety standards.

If you check any boxes under the “NO” column or are in doubt about any item, you must immediately contact your supervisor or supplier. Tag the suspended scaffold “DO NOT USE” until the concern is corrected.

Now you can download the PDF and editable Checklist and use it to fit your purpose just click on download below

Download the Checklists

PDF: Suspended Scaffold Pre-Operation Inspection Checklist

DOC: Suspended Scaffold Pre-Operation Inspection Checklist

More Forms

- Navigating the Risks: The Ultimate Guide to Safety When Working Near Water

- Downloadable Kitchen Safety Inspection Checklist for Restaurants

- Mastering LOTO: Protecting Workers with Energy Isolation and Isolation Confirmation Certificates

- Flammable and Combustible Storage Checklist Free Download

- Secure Your Lifts:Guidelines for Safe Lifting Operations Free Planning Tool

- Sample of Accident Prevention Program ( APP) Template for General Industry Free Download

- Free ISO 14001:2015 Environmental Management System Audit Checklist Download

- Guides for Walking and Working Surfaces Safety Program

- Workshop Safety Guideline and free Posters

- Free Ergonomics Checklist for General Industry

- Work Area Safety Checklist

- Machine Safety and 43-Equipment Inspection Checklists

- Scaffold Safety self Audit and checklist

- Hot Work Controls and its Permit to work Form

- Safety Observation Report Template

- Forklift Operator’s Daily Checklist and safety Tips

- Inspecting Fall Protection Equipment Forms

- Templates: HSE Incentives and rewards

- 35 Inspection forms for Rig Check

- Chemical Risk Assessment form

- 22-Safety Inspection Checklists

- Safety Task Assessment Form

- Suspended Scaffold Pre-Operation Inspection Checklist

- Photo of the day: New worker Orientation & Safety Orientation checklist

- Grating-Decking-Floor- handrail-Removal Form

- Electrical Inspection Checklists

- E-Books: Fire Safety Logbook templates

- General Safety Guidelines and Employee Acknowledgment form

- Annual Internal Audit Form

- Mobile Scaffold Inspection checklist

- Simultaneous Operation (SIMOPS) checklist

- Temporary Construction Facilities (TCF) Inspection checklist

- HIRA, HSE Hazards & Effects Management Process (HEMP) & Risk Register Template

- Hazard Identification Plan (HIP) Template

- Ladder Inspection Form

- Free Pre-Startup Safety Review Checklist (PSSR)

- Hazard Identification Checklist

- Workplace Housekeeping Checklist

- ISO 45001:2018 READINESS CHECKLIST

- Lifting Plan Audit Checklist

- Job Safety Analysis (JSA) Forms What’s Right and Wrong?

- Electrical Isolation Permit to Work forms and checklist

- Canteen Inspection Checklist

- Work at Height Checklist

- Health Safety at Work Improvement Action Plan

- Fire Pump Daily Inspection Checklist

- Construction Site Traffic Management Plan (CSTMP) Guidance

- Safety Templates: COVID-19 Safety Plan

- Workplace Safety Inspections Forms

- Lock Removal Form

- Templates: Management of Change NEW Modified Equipment Safety Checklist

- Lifeline & Harness Inspection Guide checklist

- Contractor Pre-qualification Questionnaire Checklist

- Fall safety at construction checklist

- Construction safety Inspection checklist

- Equipment Safe Operating Procedures- SOP 61 checklist

- Permit to Work (PTW ) AUDIT CHECKLIST