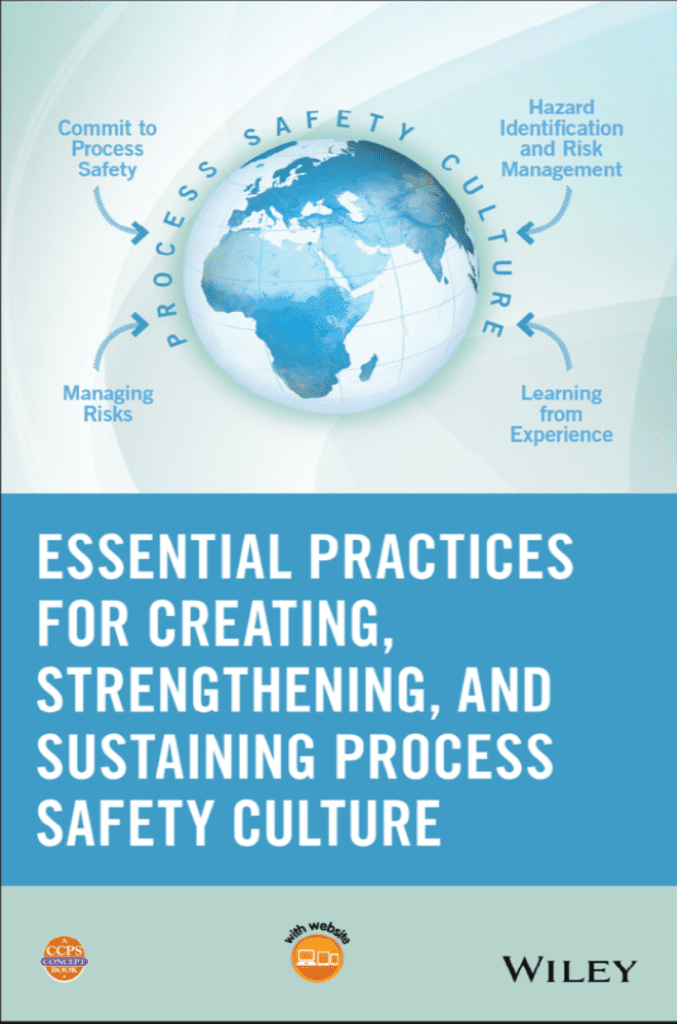

Essential Practices for Creating, Strengthening, and Sustaining Process Safety Culture by American Institute of Chemical Engineers (AIChE) and the Center for Chemical Process Safety (CCPS). This book offers several definitions of process safety culture. Even though there may be some disagreement about a report of process safety culture, when you visit a facility you very quickly get a sense of how strong a positive process safety culture is to the facility. You will know it when you see it. As you read this book you will learn many aspects of how to develop a sound process safety culture. From my experience, a strong process safety culture must start with leadership. ( Also Read: The Process and Benefits of Process Safety

This book offers several definitions of process safety culture. Even though there may be some disagreement about a definition of process safety culture, when you visit a facility you very quickly

get a sense of how important a positive process safety culture is to the facility. You will know it when you see it. From the first moment when you encounter a security guard or a receptionist to a tour of a control room, you can quickly gauge the culture. Are process safety metrics displayed around the plant? Are operators communicating with each other in a professional manner? Is the senior manager well versed in the hazards of the operation

As you read this book you will learn many aspects of how to develop a sound process safety culture. From my experience, a strong process safety culture must start with leadership. By leadership, I mean everyone in a leadership position from the chairman of the board to the supervisor on the shop floor. They must set an example. It starts with leadership being aware of the hazards in their processes and putting in place the organization and expertise to control those hazards. Just as important, the senior leadership must communicate his or her concerns about the need for an effective process safety program. These concerns should be an ongoing part of senior leadership’s communications with the organization. This is the way to ensure the establishment of a culture of process safety across the organization.

Also Read: E-Books: Is it Safe to Enter Confined Space?

Culture: When used alone in this book, the term culture specifically means process safety culture, and the two terms are used interchangeably. When used to refer to other types of corporate culture, the specific type of culture will be specified, e.g.

business culture.

Element Names: Process safety element names have been taken from CCPS Guidelines for Risk Based Process Safety. When alternative names are in common use, both the RBPS name and the common name are used, e.g., HIRA/PHA.

Operations: The full spectrum of tasks and activities involved in running a facility, including process operation, maintenance, engineering, construction, and purchasing.

Operator: An individual who runs the process from the control

room and/or the field. Process safety: A disciplined framework for managing the integrity of operating systems and processes handling hazardous substances by applying good design principles, engineering, and operating practices. It deals with the prevention and control of incidents that have the potential to release hazardous materials or energy. Such incidents can cause toxic effects, fire, or explosion and could ultimately result in serious injuries, property damage, lost production, and environmental impact.

Also Read: How to Develop a Safety Culture?

Process safety management system (PSMS) : A management system for implementing process safety. PSMSs include Risk Based on Process Safety (RBPS) as defined by CCPS, the many PSMSs developed by companies to suit their specific requirements, PSMSs specified by regulations, and others.

References to process safety culture core principles: Throughout the book, the names of the core principles of process safety culture are typeset in italics. Italics are also used when the context requires use of different syntax, including the negative forms, such as “They allowed deviance to be normalized, leading to…”

Should vs. must and shall: The term should be used throughout the book, refers to actions or guidance that are recommended or presented as options, but not mandatory. The pursuit of a process safety culture is very personal, and therefore a single approach cannot be mandated. The terms must and shall, commonly used in voluntary consensus standards and regulations, appear in this book only when quoting other sources. Quotes are offered only to provide perspective, and their use in this book does not mean that the authors consider the quoted text to be mandatory.

Also Read: NIOSH publishes fact sheet on fatigued driving in oil and gas industry

Contents The content of the Essential Practices for Creating, Strengthening, and Sustaining Process Safety Culture

- Introduction and Importance of Process Safety Culture

- Process SAFETY CULTURE Core Principles

- Leadership for Process Safety Culture

- Fundamentals of Process Safety

- Human Behavior and Process Safety Culture

- Risk Management-Related Element Grouping

- Process-Related Element Grouping

- Introduction to Process Safety for Undergraduates and Engineers

- Worker-Related Element Grouping

- Improving the Process Safety Culture of the Organization

- Sustainability of Process Safety Culture

- CDC NIOSH Pocket guide to chemical hazards

- Occupational Safety and Health Simplified for the Chemical Industry

- Other Safety & Process Safety Culture

Download Other safety Resources at https://safetybagresources.com/

Download the book

Essential Practices for Creating, Strengthening, and Sustaining Process Safety Culture

More Downloads

- E-Books: Healthcare Hazard Control & Safety Management

- E-Books: Safety, Health and Working Conditions Training Manual

- E-Books: Energy Efficiency in Water and Wastewater Facilities

- E-Books: Fire Service Features of Buildings and Fire Protection Systems

- E-Books: Evaluation of Fire Safety free download

- E-Books: PPE for Chemical, Biological, and Radiological Hazards free

- E-Books: Changing the Workplace Safety Culture free download

- E-Books: Site Emergency Planning Workbook

- E-Books: Load Restraint Guide

- E-Books: Essential Practices for Creating, Strengthening, and Sustaining Process Safety Culture

- E-Books: System Safety Engineering and Risk Assessment

- E-Books: Permit-Required Confined Spaces

- E-Books: Is it Safe to Enter Confined Space?

- E-Books: 5-Minute Workplace Safety Talks

- E-Books: Safety Culture and High-Risk Environments

- E-Books: Practical Guide to Industrial Safety

- E-Books: Slip, Trip, and Fall Prevention for Healthcare Workers

- E-Books: Health and Safety at Work Key Terms

- E-Books: Fundamentals of Process Safety Engineering

- E-Books: Gas Detection Hand Book

- E-Books: Occupational health and safety management systems ANSI-AIHA-z10-2012

- E-Books: Hot Work on Drums and Tanks

- E-Books: Human Fatigue Risk Management

- E-Books: Guidelines for the provision of facilities and general safety in the construction industry

- E-Books: Handbook of Training in Mine Rescue and Recovery Operations ( 2021)

- E-Books: Code of Practice for the Safe Use of Lifting Equipment – Edition 9 (Nov 2019)

- E-Books: Free Forklift Health and Safety Best Practices Guideline

- E-Books: Handbook of Hazardous Chemical Properties

- E-Books: Human Performance Improvement through Human Error Prevention

- E-Books: Principles Of Fire Risk Assessment In Buildings

- E-Books: Investigation of Occupational Accidents and Diseases

- E-Books: Radiation Protection and Safety in Industrial Radiography

- E-Books: Basic Guide to System Safety, Third Edition

- E-Books: Food Safety Management-A Practical Guide for the Food Industry

- E-Books: Safety identification: Escape and evacuation plan signs- ISO 23601

- E-Books: Safety at Work

- E-Books: The Safety-Critical Systems Handbook 4th edition

- E-Books: Fundamental principles of occupational health and safety

- E-Books: Fire Safety Risk assessment Guide – Sleeping Accommodation

- E-Books: Mental health at work series

- E-Books: Live Fire Training: Principles and Practice

- E-Books: Pre-Startup Safety Review Guide

- E-Books: Fire and Emergency Drill Manual and Building Inspection Guide

- E-Books: Health and Safety: Risk Management 5th edition

- E-Books: Fire Protection systems -Third edition 2021

- E-Books: Fire Safety Logbook templates

- E-Books: From Accidents to Zero

- E-Books: Electric Safety Practice and Standards

- Your steps to chemical safety

- E-Books: Ergonomics and Psychology Developments in Theory and Practice

- E-Books: HAZOPS Should BE fun-The Stream-Based HAZOP

- E-Books: Safety Health and Environmental Auditing

- E-Books: A Quick Guide to Health and Safety

- E-Books: Occupational Ergonomics A Practical Approach

- E-Books: Job Hazard Analysis A Guide for Voluntary Compliance and Beyond

- E-Books: Electrical Safety of Low Voltage Systems