Safety Flash: Not Following Work permit and Isolation Procedure

3 min readWhat happened

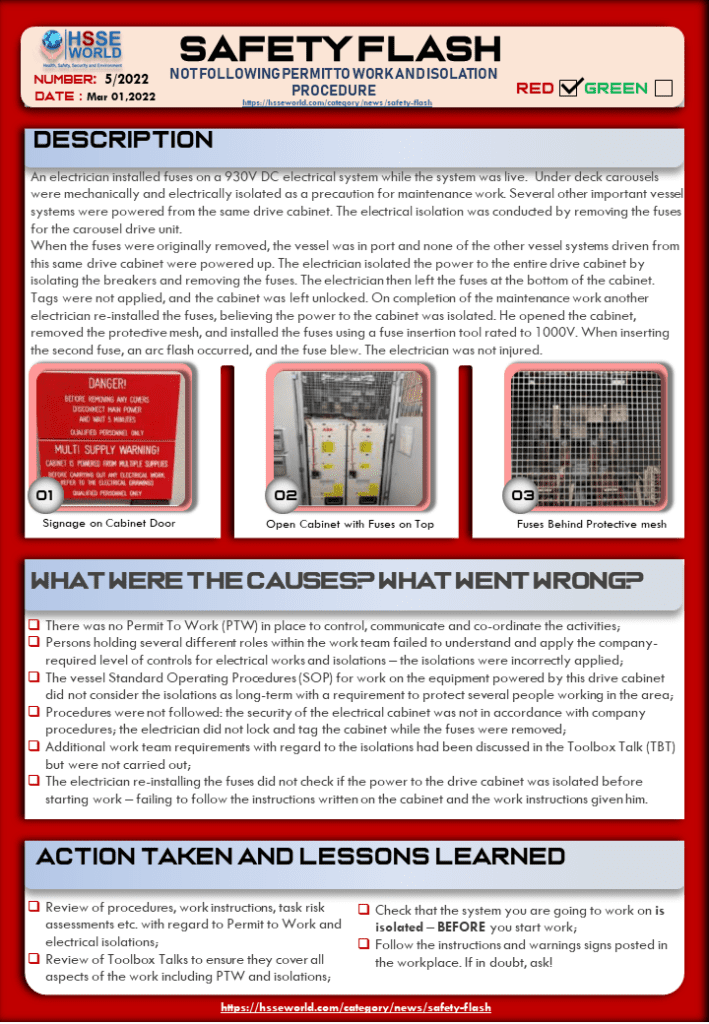

in this Safety Flash: An electrician installed fuses on a 930V DC electrical system while the system was live. Under deck, carousels were mechanically and electrically isolated as a precaution for maintenance work. Several other important vessel systems were powered from the same drive cabinet. The electrical isolation was conducted by removing the fuses for the carousel drive unit.

When the fuses were originally removed, the vessel was in port and none of the other vessel systems driven from this same drive cabinet were powered up. The electrician isolated the power to the entire drive cabinet by isolating the breakers and removing the fuses. The electrician then left the fuses at the bottom of the cabinet. Tags were not applied, and the cabinet was left unlocked. On completion of the maintenance work, another electrician re-installed the fuses, believing the power to the cabinet was isolated. He opened the cabinet, removed the protective mesh, and installed the fuses using a fuse insertion tool rated to 1000V. When inserting the second fuse, an arc flash occurred, and the fuse blew. The electrician was not injured.

What were the causes? Why did happen?

- There was no Permit To Work (PTW) in place to control, communicate and co-ordinate the activities;

- Persons holding several different roles within the work team failed to understand and apply the company-required level of controls for electrical works and isolations – the isolations were incorrectly applied;

- The vessel Standard Operating Procedures (SOP) for work on the equipment powered by this drive cabinet did not consider the isolations as long-term with a requirement to protect several people working in the area;

- Procedures were not followed: the security of the electrical cabinet was not in accordance with company procedures; the electrician did not lock and tag the cabinet while the fuses were removed;

- Additional work team requirements with regard to the isolations had been discussed in the Toolbox Talk (TBT) but were not carried out;

- The electrician re-installing the fuses did not check if the power to the drive cabinet was isolated before starting work – failing to follow the instructions written on the cabinet and the work instructions given him.

Read: Electrical Isolation Permit to Work forms and checklist

Actions

- Review of procedures, work instructions, task risk assessments etc. with regard to Permit to Work and electrical isolations;

- Review of Toolbox Talks to ensure they cover all aspects of the work including PTW and isolations;

- Check that the system you are going to work on is isolated – BEFORE you start work;

- Follow the instructions and warnings signs posted in the workplace. If in doubt, ask!

You may be interested to read:

- What procedure should we follow to reactivate equipment that has been locked out?

- E-Books: The safe isolation of plant and equipment

You can download the Safety Flash by clicking download below

This Safety flash summarises key safety matters and incidents, allowing wider dissemination of lessons learned from them. The information below has been provided in good faith by members and should be reviewed individually by recipients, who will determine its relevance to their own operations. The effectiveness of the safety flash system depends on receiving reports from members in order to pass on the information and avoid repeat incidents.

Source and download Safety Flash

| Alert ID: | 05/22 |

| Published: | Mar 01 2022 |

| Download: | Safety flash (333 kB) |

Download the Safety Flash

Read More Safety Flash

- Safety Flash: Mobile concrete placing boom overturn incidents

- Safety Flash: Not Following Work permit and Isolation Procedure

- Safety Flash: Floorman arm pinned by Pipe Handling Equipment

- Safety Flash: Suspension Trauma

- Safety Flash: Fatality: explosive failure of corroded fire extinguisher

- Safety Flash: Crewman fell to his death through faulty grating

- Safety Flash: Fatal accident during cargo operations on Karina C

- Safety Flash: Overturning of the Lifeboat Kristin Faye

- Safety Flash: Short circuit on 440v AC bus bars-arc flash

- Safety Flash: Towing Fatality

- Safety Flash: Unsafe lifting operations

- Safety Flash: Electric Shock Resulting in Burn

- Safety Flash: LTI- Loss of Finger Tip and Nail

- Safety Flash: Explosion And Fire Onboard The chemical Tanker STOLT Greenland

- Safety Flash: Finger injury caused by incorrectly secured console cover

- Safety Flash: double Man overboard Resulting in one fatality

- Safety Flash: Alcohol-based hand sanitizer warning

- Safety Flash: Dump truck operator fatally electrocuted by high-voltage line

- Safety Flash: Laborer Dies After Footing Collapse – North Carolina

- Safety Flash: Reducing the risk of propane explosions in food trucks

- Safety Flash: Teen Roofer Electrocuted when Ladder Contacts High Voltage Power Line

- Safety Flash: Worker dies from carbon monoxide poisoning while using pressure washer

- Safety Flash: Explosion during welding operation

- A Bathtub Refinisher Dies from Methylene Chloride Exposure :Safety Flash

- Landscaper dies after auger entanglement:Safety Flash

- Worker dies after falling from scaffold

- Fatality Investigation: Orchard Worker Dies After Falling Off Tractor

- LTI: Fall from height leading to Multiple Fractures

- Operator dies when forklift falls off loading dock

- Worker struck, killed by outrigger

- Worker killed by platform

- Scaffolding Components

- Construction Worker Killed When Pipe Rolls Off a Trailer

- Near-Miss: Shackle Configuration

- Improper use of lifeline results in death of worker